Auto Crane 600661 User manual

MODEL RS60AC

AIR COMPRESSOR

OPERATORS, MAINTENANCE

AND PARTS MANUAL

APPLIES TO SERIAL NUMBERS

600661 AND EARLIER

THIS MANUAL NO LONGER REPRESENTS

CURRENT PRODUCTION

P/N: 304173

4/7/2010 MCM

4

OPERATORS, MAINTENANCE, AND PARTS MANUAL

AUTO CRANE MODEL RS60AC

TABLE OFCONTENTS

Operation & Maintenance Section

Specifications ...................................................................................................................... 6

Safety .......................................................................................................................... 7 - 11

CompressorTerminology .................................................................................................. 12

Description of Components....................................................................................... 13 - 16

Inspection, Lubrication, and Maintenance ................................................................. 17 - 24

Troubleshooting ......................................................................................................... 25 - 27

Compressor Operation.............................................................................................. 28 - 29

Parts and Illustration Section.................................................................................... 30 - 38

Recommended Spare Parts............................................................................................... 39

ServiceQuestionnaire........................................................................................................ 40

Instructional Procedures For Installation ................................................................... 41 - 44

6

SPECIFICATIONS

GISP051@YREVILEDMFC5406

rosserpmoCotdeepStupnI MPR MPG

0051 @01 ISP0742

1591 @31 ISP0742

rosserpmoC-yticapaCdiulF )ciluardyhton( metsySsnollaG0.1 pmuSrosserpmoC57.

metsySrosserpmoC-stnenopmoC )snoisnemiDllarevO( wolebees

)yrd(thgieW .sbl003

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

SIZE DWG NO REV

SCALE SHEET OF

DRAWN

PATH

TIT L E

CHECKE D

MA TE RI A L

THIS D RAW IN G A ND AL L

INFORMATION THEREIN IS

THEP RO PERT Y OF AU T O-

CR ANE , IS CON-

FIDENTIAL AND MUSTNOT

BEMAD E PUB L IC OR

COPI ED . IT IS LO ANE D

SU BJE CT T O RETURNUPON

DE MA ND, IS N OT T O B E

US E D DI R ECT L Y O R IN -

DIR ECT L Y I N ANYWAYDE-

TRIMENTI AL TO TH E IN-

TER EST O F A UTO CRA NE.

DON O T SC ALE

TOL ERA N C ES

UNL E SS NOT ED

MAC HIN ED S URF ACE S

NOMINALDIM.

0. 00 0 TO 1. 00 0

.010

1. 00 1 TO 5. 00 0

.015

5. 001 T O 10.00 0

.020

10 .0 01 & OV ER

/

AUT O CR AN E

P.O. BOX 580697

TULSA, OK 74158-0697

G:\INVENTOR53\

Rev.Num. Rev. Date EN Num.Released For

RS60AC 45- 60 SCI 8G (RE V 6)

20067-999

1 2

6

D

DC L 3/5/ 200 7

ND D 3/5 /200 7

G:/INV ENTOR10/

1=4

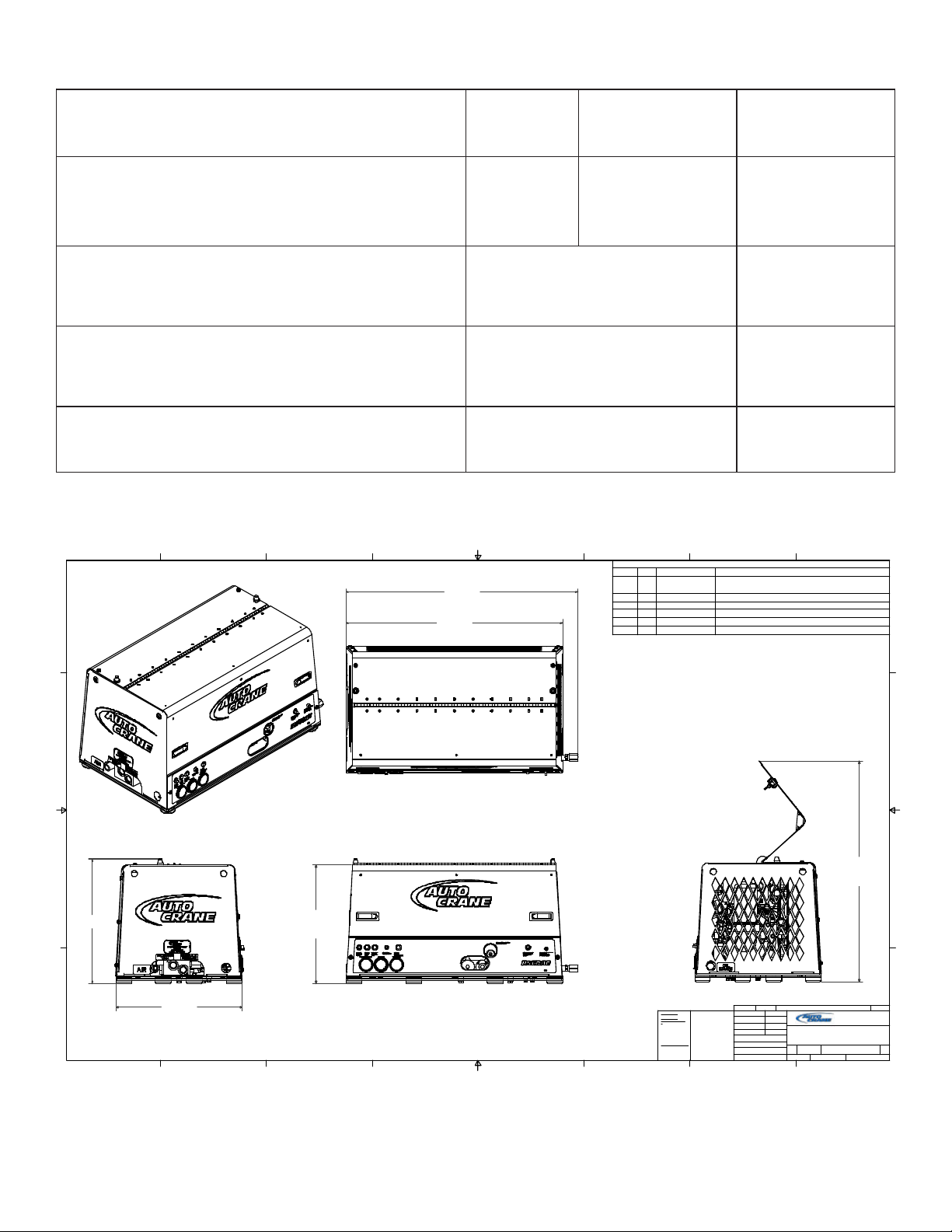

Parts List

ITEM QTY PART NUMBER DESCRIPTION

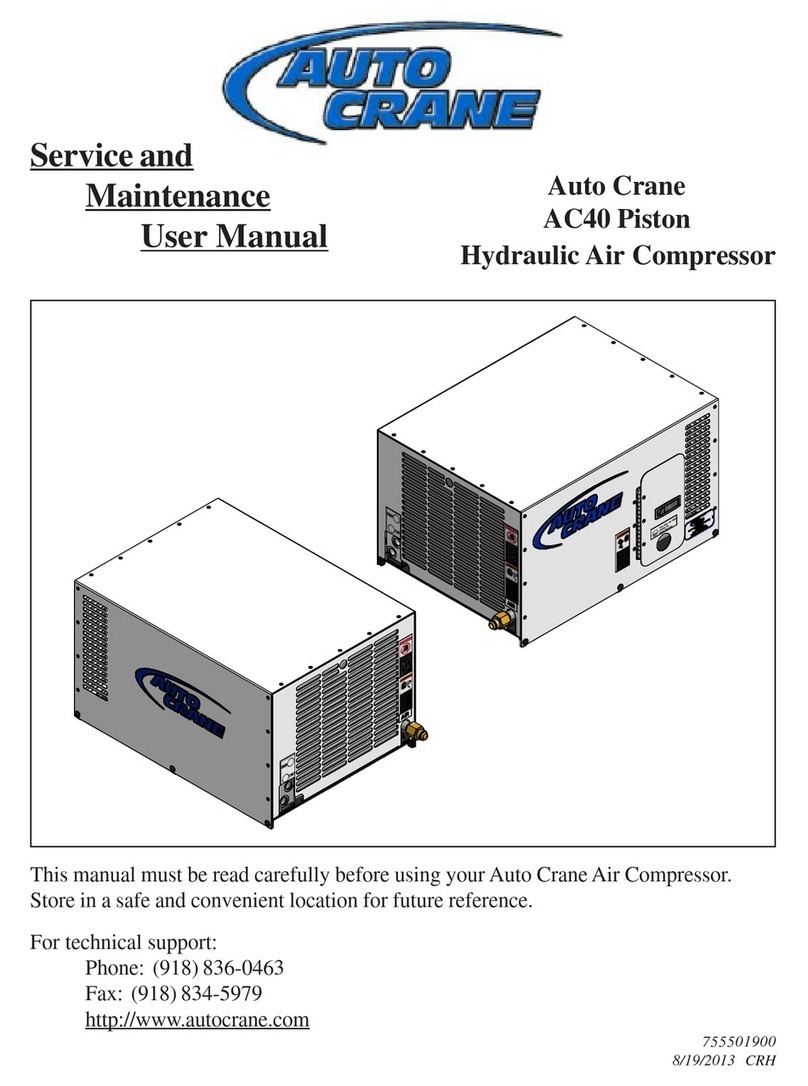

1 1 200338-999 COMPR & MTG SYS, RS60AC 45/60/150 SCI8G

(REV 3)

2 1 200339-999 OIL/AIR/ HYD CL NG SYS, RS60AC SCI8G (REV 1)

3 1 200201-999 CANOPY SYS, RS60AC 45/60/150 SCI8G (REV 1)

4 1 200202-999 ELEC SYS, RS60AC 45/60/150 SCI8G (REV 1)

NS 1 200237-AC OPT, SHIPPING MAT'LS AC

NS 1 60612 KIT, HOSE INFINITY

34 3/4 in

[883.0 mm]

3 7 1/ 8 i n

[944.2 mm]

1 9 1/ 8 in

[484.2 mm]

WITH DOOR

CLOSED

20 1/4 in

[514.4 mm]

20 in

[506.8 mm]

35 1/4 in

[895.9 mm]

WITH DOOR

OPEN

7

WARNING

AIR COMPRESSOR SAFETY PRECAUTIONS

Safety is basically common sense. While there are standard safety rules, each situation has its own

peculiarities that cannot always be covered by rules. Therefore with your experience and common

sense, you are in a position to ensure your safety. Lack of attention to safety can result in:

accidents, personal injury, reduction of efficiency and worst of all - Loss of Life. Watch for safety

hazards. Correct them promptly. Use the following safety precautions as a general guide to safe

operation:

Do not attempt to remove any compressor parts without first relieving the entire system of

pressure.

Do not attempt to service any part while machine is operating.

DANGER

Do not operate the compressor at pressure(s) or speed in excess of its rating as indicated in

“Compressor Specifications”.

Periodically check all safety devices for proper operation.

Do not play with compressed air. Pressurized air can cause serious injury to personnel.

Exercise cleanliness during maintenance and when making repairs by covering parts and exposed

openings.

SAFETY

ALLUNITSARE SHIPPEDWITHADETAILEDOPERATORSANDPARTS

MANUAL. THISMANUALCONTAINSVITALINFORMATIONFORTHESAFE

USEANDEFFICIENTOPERATIONOFTHIS UNIT. CAREFULLYREAD

THEOPERATORSMANUALBEFORE STARTINGTHE UNIT. FAILURE TO

ADHERE TO THE INSTRUCTIONS COULD RESULT IN SERIOUS BODILY

INJURYORPROPERTYDAMAGE.

CHECKTHECOMPRESSORSUMPOILLEVELONLYWHENTHECOMPRESSOR

ISNOTOPERATINGANDSYSTEMISCOMPLETELYRELIEVEDOFPRESSURE.

OPENSERVICEVALVETOENSURERELIEFOFSYSTEMAIRPRESSUREWHEN

PERFORMINGMAINTENANCEONCOMPRESSORAIR/OILSYSTEM. FAILURE

TOCOMPLYWITHTHISWARNINGMAYCAUSEDAMAGETOPROPERTY

AND SERIOUS BODILYHARM.

8

SAFETY

Do not install a shut-off valve between the compressor and compressor oil sump.

DANGER

Do not disconnect or bypass safety circuit system.

Do not install safety devices other than authorizedAUTO CRANE replacement devices.

Close all openings and replace all covers and guards before operating compressor unit.

Tools, rags, or loose parts must not be left on the compressor or drive parts.

Do not use flammable solvents for cleaning parts. This can cause the unit to ignite during operation.

Keep combustibles out of and away from the Compressor/Inlet and any associated enclosures.

The owner, lessor, or operator of the Compressor are hereby notified and forewarned that any

failure to observe these safety precautions may result in damage or injury.

AUTO CRANE expressly disclaims responsibility or liability for any injury or damage caused by

failure to observe these specified precautions or by failure to exercise that ordinary caution and

due care required when operating or handling the Compressor, even though not expressly specified

above.

DONOTUSEAUTOCRANECOMPRESSORSYSTEMSTOPROVIDEBREATHING

AIR. SUCH USAGE, WHETHER SUPPLIED IMMEDIATELY FROM THE

COMPRESSOR SOURCE, OR SUPPLIED TO BREATHING TANKS FOR

SUBSEQUENTUSE,CAN CAUSESERIOUS BODILYINJURY.

AUTOCRANEDISCLAIMSANYANDALLLIABILITIESFORDAMAGEFORLOSS

DUE TO PERSONAL INJURIES, INCLUDING DEATH, AND/OR PROPERTY

DAMAGE INCLUDING CONSEQUENTIAL DAMAGES ARISING OUT OF ANY

AUTOCRANECOMPRESSORS USEDTOSUPPLYBREATHINGAIR.

9

SAFETY

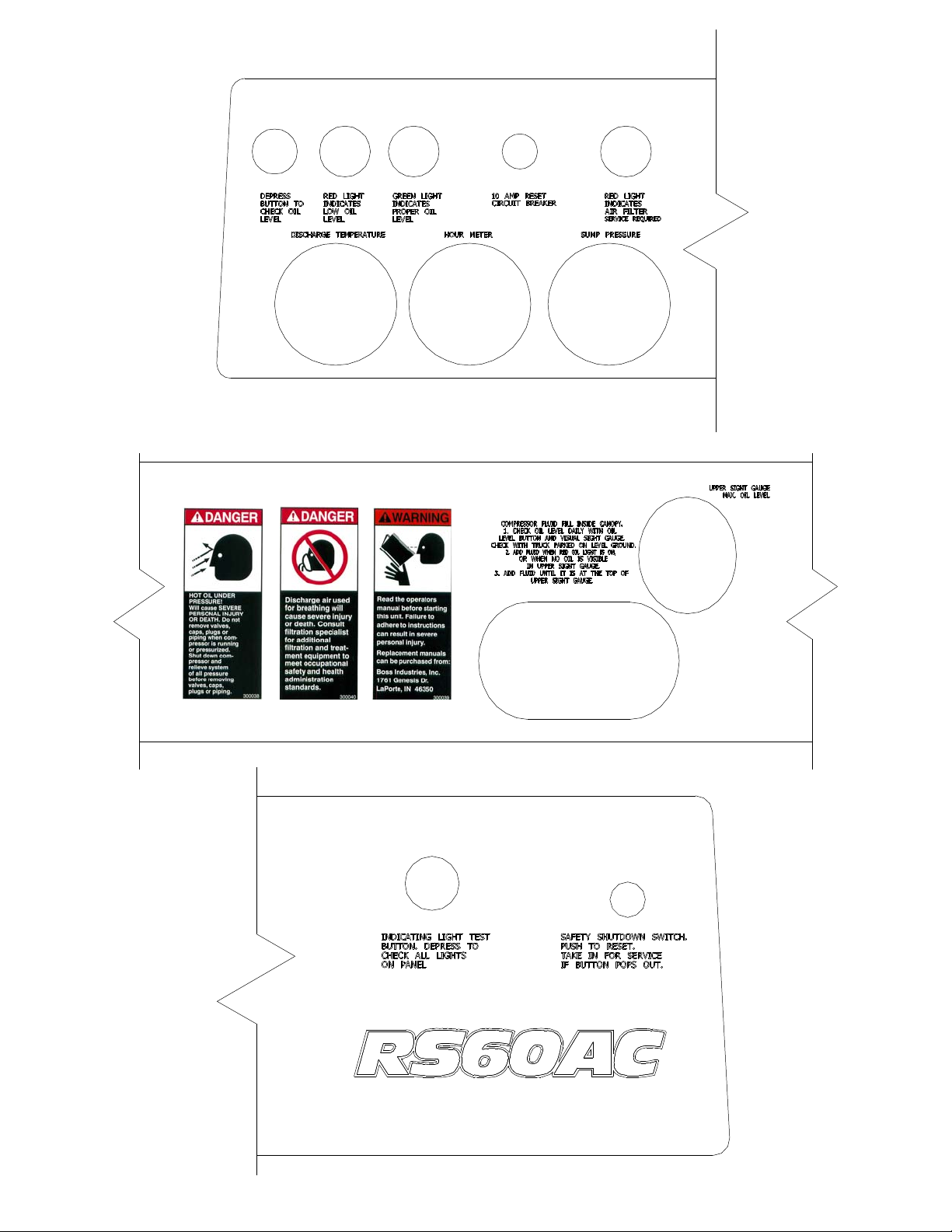

A compliment of warning decals is supplied with each unit. These decals must be affixed to the

comressor package in the locations noted in this manual. If for any reason a safety decal is

removed it is the owners responsibility to make sure it is replaced.

10

11

304174

12

COMPRESSOR TERMINOLOGY

AIR/OILCOALESCER- Performs second stage separation of oil from compressed air feeding

air tools. Sometimes referred to as the separator element.

CFM - Refers to the volume of compressed air being produced, expressed as cubic feet of air per

minute.

COMPRESSOR LUBRICANT - DEXRON IIIATF.

GPM- Refers to the amount of gallons per minute of hydraulic fluid flowing through the pump.

OILSUMP - The first stage of oil separation from compressed air. Also serves as reservoir area

for compressor lubricant and sometimes referred to as the receiver tank.

PSI - Refers to the operating pressure the system is set up at, expressed as pounds per square

inch.

SAFETYVALVE-Avalve located on the oil sump which opens in case of excessive pressure.

Sometimes referred to as the pop-off or pressure relief valve.

13

DESCRIPTION OF COMPONENTS

COMPRESSORASSEMBLY

TheAUTO CRANE hydraulic drive compressor assembly is a positive displacement, oil flooded,

rotary screw type unit employing one stage of compression to achieve the desired pressure.

Components include a housing (stator), two screws (rotors), bearings, and bearing supports.

Power from the hydraulic motor shaft is transferred to the male rotor through a drive coupling.

The female rotor is driven by the male rotor. There are five lobes on the male rotor while the

female rotor has six roots.

PRINCIPLES OF OPERATION

In operation, two helical grooved rotors mesh to compress air. Inlet air is trapped as the male

lobes roll down the female grooves, pushing trapped air along, compressing it until it reaches the

discharge port in the end of the stator and delivers smooth-flowing, pulse-free air to the receiver.

During the compression cycle, oil is injected into the compressor and serves these purposes:

1. Lubricates the rotating parts and bearings.

2. Serves as a cooling agent for the compressed air.

3. Seals the running clearances.

LUBRICATION SYSTEM

Oil from the compressor at discharge pressure, is directed into it’s integral housing, through the

thermal valve and filter, and then out of the integral housing to the oil cooling system, and then back

to the side of the compressor stator, where it is injected into the compressor. At the same time oil

is directed internally to the bearings and shaft seal of the compressor.

OIL SUMP

Compressed, oil-laden air enters the sump from the compressor. As the oil-laden air enters the

sump, most of the oil is separated from the air as it passes through a series of baffles and de-fusion

plates. The oil accumulates at the bottom of the sump for recirculation. However, some small

droplets of oil remain suspended in the air and are passed on to the Coalescer.

14

DESCRIPTION OF COMPONENTS

SAFETYVALVE

The pop safety valve is set at 200 PSI and is located at the top of the air/oil sump. This valve acts

as a backup to protect the system from excessive pressure that might result from a malfunction.

AIR/OIL COALESCER

The coalescer is self-contained within a spin-on housing. When air is demanded at the service line,

it passes through the coalescer which efficiently provides the final stage of oil separation.

OIL RETURN LINE

The oil that is removed by the coalescer accumulates and is returned through an internal oil return

line leading to the compressor.

MINIMUM PRESSUREVALVE

The minimum pressure valve is located at the outlet of the coalescer head and serves to maintain a

minimum discharge pressure of 75 PSIG in operation, which is required to assure adequate

compressor lubrication pressure.

OILFILTER

The compressor oil filter is a removable and cleanable screen built into the side of the compressor

housing. Screen replacement may be necessary after several cleanings.

COMPRESSOR OILAND HYDRAULIC OIL COOLING SYSTEMS

The compressor cooling system consists of a combination hydraulic cooler and compressor cooler

mounted on the common frame. Compressor oil temperature is controlled by a thermal valve

located down stream of the oil filter. The thermal valve maintains the compressor oil temperature

at 185ºF. Cool air is drawn through the vented end panel and across the combo cooler. The air is

heated by the coolers and the hot air exits out the back vented panel . Allow for adequate

clearance (12”) for the air to exit. Also, the package location should not be subjected to above

ambient air temperatures.

15

DESCRIPTION OF COMPONENTS

INSTRUMENTATION

TheAUTOCRANEhydraulic drive compressor unit incorporates agaugepanelthatmonitors

temperature,pressureand hours ofoperation.

HOURMETER

Thehourmeterrecordsthetotal number of operatinghours. Itservesasa guide in followingthe

recommendedinspectionandmaintenance schedule. The hourmeter willonlyrunwhenthereispressure

inthesystem.

COMPRESSORDISCHARGEAIR/OILTEMPERATURE SWICHGAUGE

Thisswichgaugeindicatescompressorair discharge temperature. The swichgauge ensuressafety

shutdownincaseofexcessiveoperatingtemperatures,preventingcompressordamage,bystopping

hydraulicflowtothecompressormotor.

ELECTRICALANDSAFETYSYSTEM

TheAUTO CRANE compressor’sstandardelectricalsystemconsists of:

-Gaugepanelwithatemperatureswichgauge,hourmeteranddischargepressureswichgauge.

-Compressorandhydraulicoilcoolerfanassemblyand relay.

-Compressoraftercooler/oilcoolerfanassemblywithrelay.

-N.O.hourmeterpressure switch.

-N.C.blowdown pressure switch.

-12VDCN.O.hydraulic solenoid andrelay.

-Switchrelayforcustomerequipmentinterfaceduringcompressor operation.

16

DESCRIPTION OF COMPONENTS

AUTOMATIC BLOW DOWN VALVE

There is one blow down valve in the compressor system. It is located at the intake valve and will

automatically bleed the sump to zero pressure when the compressor is disengaged. Blow down

time interval takes between 45 and 60 seconds.

CONTROL SYSTEM

The prime component of the compressor control system is the compressor inlet valve. The control

system is designed to match air supply to air demand and to prevent excessive discharge pressure

when compressor is at idle. Control of air delivery is accomplished by the inlet valve regulation

and modulation as directed by the discharge pressure regulator.

NORMALYOPEN REGULATOR SOLENOID

A closed Furnas air pressure switch will energize the normaly open regulator solenoid, thus closing

it. When the normaly open regulator solenoid is closed, air pressure will rise. When it is open air

pressure falls only in the compressor sump.

Note: See page 28 for description of Furnas switch.

NOTE: Most air tools operating pressure range is between 90 and 125 psi. Operating

above the tools recommended pressures will decrease the life of the tool. Higher

operating pressure can also over torque nut and bolts fatiguing the fastener and mating

parts. Strictly adhere to tool operating pressures and torque standards set forth by the

tool manufacturer and the specifications of the equipment that work is being performed

on.

INLETVALVE

The compressor inlet valve is a piston operated disc valve that regulates the inlet opening to control

capacity and serving as a check valve at shutdown.

17

INSPECTION, LUBRICATION, AND MAINTENANCE

Thissection contains instructions for performing the inspection,lubrication, and maintenance

procedures required to maintain the compressor in proper operating condition. The importance of

performing the maintenance described herein cannot be over emphasized.

The periodic maintenance procedures to be performed on the equipment covered by this manual

are listed below. It should be understood that the intervals between inspections specified are

maximum interval. More frequent inspections should be made if the unit is operating in a dusty

environment, in high ambient temperature, or in other unusual conditions. Aplanned program of

periodic inspection and maintenance will help avoided premature failure and costly repairs. Daily

visual inspections should become a routine.

The LUBRICATIONAND MAINTENANCE CHART lists serviceable items on this compressor

package. The items are listed according to their frequency of maintenance, followed by those

items which need only “As Required” maintenance.

The maintenance time intervals are expressed in hours. The hourmeter shows the

total number of hours your compressor has run. Use the hourmeter readings for determining your

maintenance schedules. Perform the maintenance at multiple intervals of the hours shown. For

example, when the hourmeter shows “100” on the dial, all items listed under “EVERY10 HOURS”

should be serviced for the tenth time, and all items under “EVERY 50 HOURS” should be

serviced for the second time, and so on.

DANGER

COMPRESSOR MUST BE SHUT DOWN AND COMPLETELY RELIEVED OF

PRESSUREPRIORTO CHECKINGFLUID LEVELS. OPEN SERVICEVALVETO

ENSURERELIEFOFSYSTEMAIRPRESSURE. FAILURETOCOMPLYWITHTHIS

WARNINGMAYCAUSEDAMAGETOPROPERTYANDSERIOUSBODILYHARM.

18

LUBRICATION AND MAINTENANCE CHART

NOTE: Compressor oil and filter is to be changed after the first 50 hours of operation. After this,

normal intervals are to be followed.

LAVRETNINOITCA

YLLACIDOIREP GNIRUD NOITAREPO

egnahcynaetoN.gnidaereguagllaevresbO.1 ehtenimreteddnagnidaerlamronehtmorf :ETON(.edamsriaperyrassecenevaH.esuac nehwgnidaereguaglausuehtsi"LAMRON" yadotyadanosnoitidnocralimistagnitarepo ).noitarepo

YLIAD

.levelliorosserpmocehtkcehC.1 rotacidniporderusserP.retlifriakcehC.2 .gnitareposirosserpmocelihw .skaelriadnaliorofkcehC.3 .sehctiwstiucricytefaskcehC.4

SRUOH52YREVE YLHTNOMRO .liorosserpmocmorfretawniarD.1

005YREVE 6ROSRUOH SHTNOM

neercsecalperdnaliorosserpmocegnahC.1 .egakaelroflaestfahsrosserpmockcehC.2 .spmalcdnasgnittif,gnipipretlifriakcehC.3 .stroppusrosserpmockcehC.4 retrohS(.tnemeleretlifriawenllatsnI.5 ytsudrednuyrassecenebyamlavretni ).snoitidnoc .evlavytefaspmuskcehC.6

0001YREVE 1ROSRUOH RAEY .tnemelegnicselaocegnahC.1

ROYLLACIDOIREP DERIUQERSA

.tnemeleretlifrianaelcdnatcepsnI.1 recselaocno-nipsecalperdnatcepsnI.2 .yrassecenfitnemele .snifrelooclionaelcdnatcepsnI.3

19

LUBRICANT RECOMMENDATIONS

WARNING

The following are general characteristics for a rotary screw lubricant. Due to the impossibility of

establishinglimits on all physical and chemical propertiesof lubricants which can affect their

performance in the compressor over a broad range of environmental influences, the responsibility

forrecommending and consistently furnishing a suitable heavyduty lubricant must rest with the

individual supplier if they choose not to use the recommendedAUTO CRANE rotary screw

lubricant. The lubricant supplier’s recommendation must, therefore, be based upon not only the

following general characteristics, but also upon his own knowledge of the suitability of the

recommended lubricant in helical screw type air compressors operating in the particular

environmentinvolved.

CAUTION

IT IS IMPORTANT THAT THE COMPRESSOR OIL BE OF A RECOMMENDED

TYPE AND THAT THIS OILAS WELL AS THE AIR FILTER, OIL FILTER, AND

COALESCERELEMENTSBEINSPECTEDAND REPLACEDASSTATED INTHIS

MANUAL.

THE COMBINATION OFACOALESCER ELEMENT LOADED WITH DIRTAND

OXIDIZEDOILPRODUCTSTOGETHERWITHINCREASEDAIRVELOCITYASA

RESULT OFTHISCLOGGEDCONDITION MAYPRODUCEACRITICALPOINT

WHILETHEMACHINEISINOPERATIONWHEREIGNITIONCANTAKEPLACE

ANDCOULD CAUSEAFIRE INTHEOILSUMP.

FAILURE TO COMPLY WITH THIS WARNING MAY CAUSE DAMAGE TO

PROPERTYAND SERIOUSBODILYHARM.

MIXING DIFFERENT TYPES OR BRANDS OF LUBRICANTS IS NOT

RECOMMENDED DUE TO THE POSSIBILITY OF A DILUTION OF THE

ADDITIVESORAREACTIONBETWEENADDITIVES OFDIFFERENTTYPES.

20

LUBRICANT RECOMMENDATIONS

LUBRICANT CHARACTERISTICS

1. Flashpoint 400°F minimum.

2. Pour point -40°F.

3. Contains rust and corrosion inhibitors.

4. Contains foam suppressors.

5. Containsoxidation stabilizer.

NOTE

NOTE

DUETOENVIRONMENTALFACTORSTHEUSEFULLIFEOFALL“EXTENDED

LIFE”LUBRICANTS MAYBESHORTERTHAN QUOTEDBYTHELUBRICANT

SUPPLIER. AUTOCRANE ENCOURAGESTHE USER TOCLOSELYMONITOR

THE LUBRICANT CONDITION AND TO PARTICIPATE IN AN OIL ANALYSIS

PROGRAMWITHTHESUPPLIER.

NO LUBRICANT, HOWEVER GOOD AND/OR EXPENSIVE, CAN REPLACE

PROPERMAINTENANCEANDATTENTION. SELECTAND USE ITWISELY.

21

MAINTENANCE

If some of the maintenance intervals in the schedule outlined in this manual seem to be rather short,

it should be considered that one hour’s operation of a compressor is equal to about 40 road miles

on an engine. Thus, eight hours operation is equal to 320 road miles, 250 hours is equal to 10,000

road miles, etc.

COMPRESSOR OILSUMPFILL, LEVEL,AND DRAIN

Before adding or changing compressor oil make sure that the compressor is completely relieved of

pressure. Oil is added at the fill cap on the side of the compressor body. Adrain valve/hose

assembly is provided at the bottom of the compressor body. The proper oil level, when unit is shut

down and has had time to settle between the top and the midpoint of the upper oil sightglass. The

truck must be level when checking the oil. DO NOT OVERFILL. The oil sump capacity is given

in“Compressor Specifications”. DANGER

AIR INTAKE FILTER

The air intake filter is a heavy-duty dry type high efficiency filter designed to protect the

compressor from dust and foreign objects. Optional two-stage available.

Optional filter is equipped with an evacuator cup for continuous dust ejection while operating and

when stopped.

Frequency of maintenance of the filter depends on dust conditions at the operating site. The filter

element must be serviced when clogged (maximum pressure drop for proper operation is 15”

of water). The filter is equipped with a pressure drop indicator, and the element should be

changed based on it’s reading first and then by the maintenance intervals outlined.

DO NOTATTEMPTTO DRAIN CONDENSATE, REMOVETHE OILLEVELFILL

PLUG, OR BREAKANYCONNECTIONINTHEAIROR OILSYSTEMWITHOUT

SHUTTINGOFFCOMPRESSORANDMANUALLYRELIEVINGPRESSUREFROM

THESUMP. FAILURETOCOMPLYWITHTHISWARNINGMAYCAUSEDAMAGE

TOPROPERTYANDSERIOUS BODILYHARM.

22

MAINTENANCE

AIR/OIL COALESCER

The air/oil coalescer employs an element permanently housed within a spin-on canister. This is a

single piece unit that requires replacement when it fails to remove the oil from the discharge air, or

pressure drop across it exceeds 15 PSI. Dirty oil clogs the element and increases the pressure

drop across it.

To replace element proceed as follows:

1. Shutdown compressor and wait for complete blow down (zero pressure).

2. Turn element counterclockwise for removal (viewing element from bottom).

3. Apply a film of fluid directly to seal on the new element.

4. Rotate element clockwise by hand until element contacts seal (viewing element from

bottom).

5. Rotate element approximately one more turn clockwise with band wrench near the top

ofelement.

6. Run system and check for leaks.

WARNING

COALERSCER OIL RETURN

This originates at the bottom of the air/oil coalescer and flows through a special recovery

pipe and venturi nozzle. If the coalerscer starts to fill with oil there is a good chance the

venturi or pipe has been plugged. Consult factory for cleaning instructions.

DO NOT SUBSTITUTE ELEMENT. USE ONLY A GENUINE AUTO CRANE

REPLACEMENT ELEMENT. THIS ELEMENT IS RATEDAT 200 PSI WORKING

PRESSURE. USEOFANYOTHERELEMENTMAYBEHAZARDOUSANDCOULD

IMPAIR THE PERFORMANCE AND RELIABILITY OF THE COMPRESSOR,

POSSIBLY VOIDING THE WARRANTY AND/OR RESULTING IN DAMAGE TO

PROPERTYAND SERIOUSBODILYHARM.

23

MAINTENANCE

OILFILTER

The compressor oil filter is a throwaway type cartridge. It is designed with a built-in bypass so that

if there is a large restriction, due to cold oil or clogged element, the compressor will still be

lubricated.

To replace filter proceed as follows:

1. Make sure system pressure is relieved.

2. Unscrew with 14mm allen wrench.

3. Remove oil filter from housing.

4. Replace the oil filter screen element.

5. Reinsertoil filter screen into housingand tighten with 14mm allen wrench.

6. Add oil (total system takes one gallon), re-tighten filler cap.

7. Check for leaks in operation.

WARNING

HYDRAULIC OILCOOLERAND COMPRESSOR OILCOOLER COMBINATION

The interior of the oil cooler should be cleaned when the pressure drop across it at full flow

exceeds 25 PSI. The following procedure has been recommended by the vendor who supplies the

cooler:

1. Remove cooler.

2. Circulate a suitable solvent to dissolve and remove varnish and sludge.

3. Flush generously with compressor lubricant (compressor oil cooler section only, use

hydraulic oil to flush the hydraulic cooler portion on the combo cooler).

4. Once the coolers are reinstalled, fill the compressor and hydraulic systems with the

proper fluids to their appropriate levels.

DO NOT SUBSTITUTE ELEMENT. USE ONLY A GENUINE AUTO CRANE

REPLACEMENT ELEMENT. USE OF ANY OTHER ELEMENT MAY BE

HAZARDOUSAND COULD IMPAIR THE PERFORMANCEAND RELIABILITY

OF THE COMPRESSOR, POSSIBLY VOIDING THE WARRANTY AND/OR

RESULTINGIN DAMAGETOPROPERTYANDSERIOUS BODILYHARM.

This manual suits for next models

1

Table of contents

Other Auto Crane Air Compressor manuals

Popular Air Compressor manuals by other brands

Craftsman

Craftsman 919.165180 owner's manual

Oshkosh Corporation

Oshkosh Corporation IMT CAS80R Installation, Operation, Maintenance & Parts Manual

Clarke

Clarke RANGER 24 Operation & maintenance instructions

Husky

Husky 41004 Operator's manual

Sullair

Sullair TS32 Series user manual

Vmac

Vmac H400005 Installation and owner's manual