Auto Crane AC30A User manual

AC30A

COMPRESSOR

OWNERS MANUAL

Rev. 03/15/2011

Serial No. __________________

Mailing Address:

P.O. Box 580697

Tulsa, OK 74158-0697

Physical Address:

4707 N. Mingo Rd.

Tulsa, OK 74117-5904 Phone (918) 836-0463

Manual No. AC30A Fax (918) 834-5979

Rev. 07/08/2008 http://www.autocrane.com

To: Fax:

From: Date:

Re: Pages:

Name: Phone:

Address:

City: State: Zip:

Contact:

Name:

Address:

City: State: Zip:

Contact:

VIN #

ONE REGISTRATION FORM PER UNIT (CRANE OR BODY)

Registration form must be mailed or faxed within 15 days of customer installation.

Mail to:

Warranty Department

Auto Crane Company

P.O. Box 581510

Tulsa, OK 74158-0697

Date Product Delivered: Date Processed:*

* For Auto Crane use only

Product Information:

(Required for Warranty Activation)

Model No.: Serial No.:

E-mail Address:

Distributor Information:

(Required for Warranty Activation)

Product Registration

E-mail Address:

(Required for Warranty Activation)

Auto Crane Warranty Registration

(918) 834-5979Warranty Department

End User Information:

Fax Transmission

Warranty Registration Rev. 050905

10/09

Rev Date Section(s)OrPage(s) Description of Change

09/02/03 Last page New 2-year warranty policy to replace 1-year warranty

policy

05/09/05 2nd Quarter New Revisions

11/28/05 3-1.0.0 Updated for new hydraulic motor

06/10/06 Updated for new machine design.

07/12/07 Bill of Materials Audit

08/13/07 Updated Drawing

11/28/11 Updated Drawing 200280-999

AC30A

OWNER’S MANUAL – REVISION RECORD

10/09

WARNINGS

READ THIS PAGE

WARNING! Federal law (49 cfr part 571) requires that the Final Stage Manufacturer of a vehicle

certify that the vehicle complies with all applicable federal regulations. Any modifications performed

on the vehicle prior to the final state are also considered intermediate stage manufacturing and must

be certified as to compliance. The installer of this crane and body is considered on of the

manufacturers of the vehicle. As such a manufacturer, the installer is responsible for compliance

with all applicable federal and state regulations, and is required to certify that the vehicle is in

compliance.

WARNING! It is the further responsibility of the installer to comply with the OSHA Truck Crane

Stability Requirements as specified by 29 CFR part 1910.180 (C) (1).

WARNING! NEVER OPERATE THE CRANE NEAR ELECTRICAL POWER LINES!

Death or serious injury will result from boom, line, or load contacting electric lines. Do not use crane

within 10 feet (3.05m) of electric power lines carrying up to 50,000 volts. One foot additional

clearance is required for every additional 30,000 volts or less. SEE DANGER DECAL (P/N 040529)

in this Owner's Manual.

WARNING! NEVER.........................................

i EXCEED load chart capacities (centerline of rotation to hoist hook).

i Un-reel last 5 wraps of cable from drum!

i Wrap cable around load!

i Attempt to lift or drag a load from the side! The boom can fail far below its rated capacity.

i Weld, modify, or use unauthorized components on any Auto Crane unit! This will void any

warranty or liability. Also failure of the crane may result.

i Place a chain link on the tip of the hook and try to lift a load!

i Use a sling bar or anything larger than the hook throat that could prevent the hook latch from

closing, thus negating the safety feature!

i Hold on any pendant Select Switch that will cause unsafe operating conditions!

WARNING! In using a hook with latch, ALWAYS make sure that the hook throat is closed before

lifting a load! Proper attention and common sense applied to the use of the hoist hook and various

slings will prevent possible damage to material being hoisted and may prevent injury to personnel.

WARNING! Failure to correctly plumb and wire crane can cause inadvertent operation and damage

to crane and/or personnel!

WARNING! Auto Crane Company remote controlled cranes are not designed or intended to be

used for any applications involving the lifting or moving of personnel.

WARNING! ALWAYS operate the crane in compliance with the load capacity chart. DO NOT USE

the overload shutdown device to determine maximum rated loads, if the crane is equipped with this

type of device.

10/09

SPECIFICATIONS.............................................................................. 1-1.0.0

GENERAL DIMENSIONS................................................................... 1-2.0.0

INSTALLATION INSTRUCTIONS....................................................... 1-3.0.0

OPERATION....................................................................................... 1-4.0.0

SPARE PARTS LIST........................................................................... 1-6.0.0

HYDRAULIC INSTALLATION............................................................. 2-1.0.0

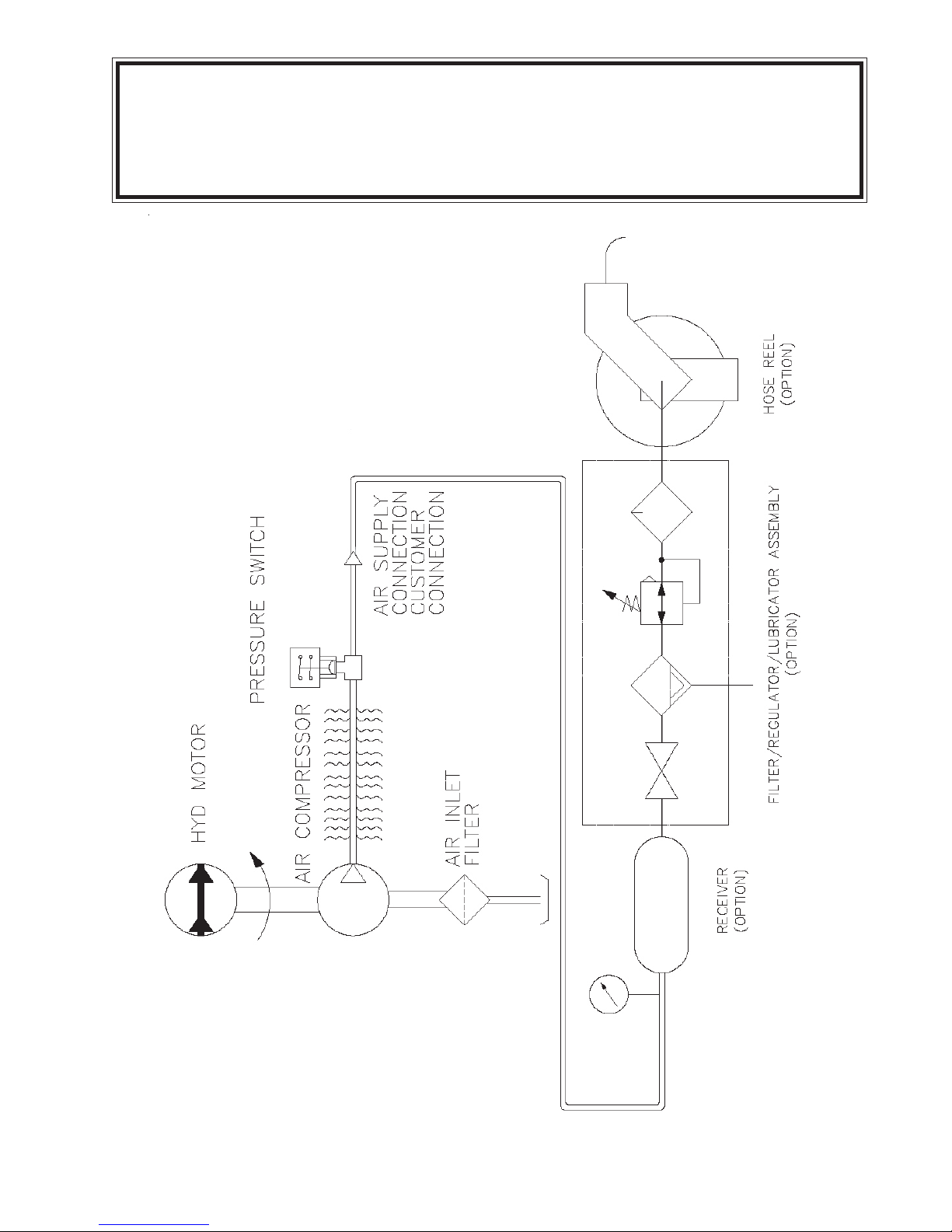

PNEUMATIC SCHEMATIC................................................................. 2-2.0.0

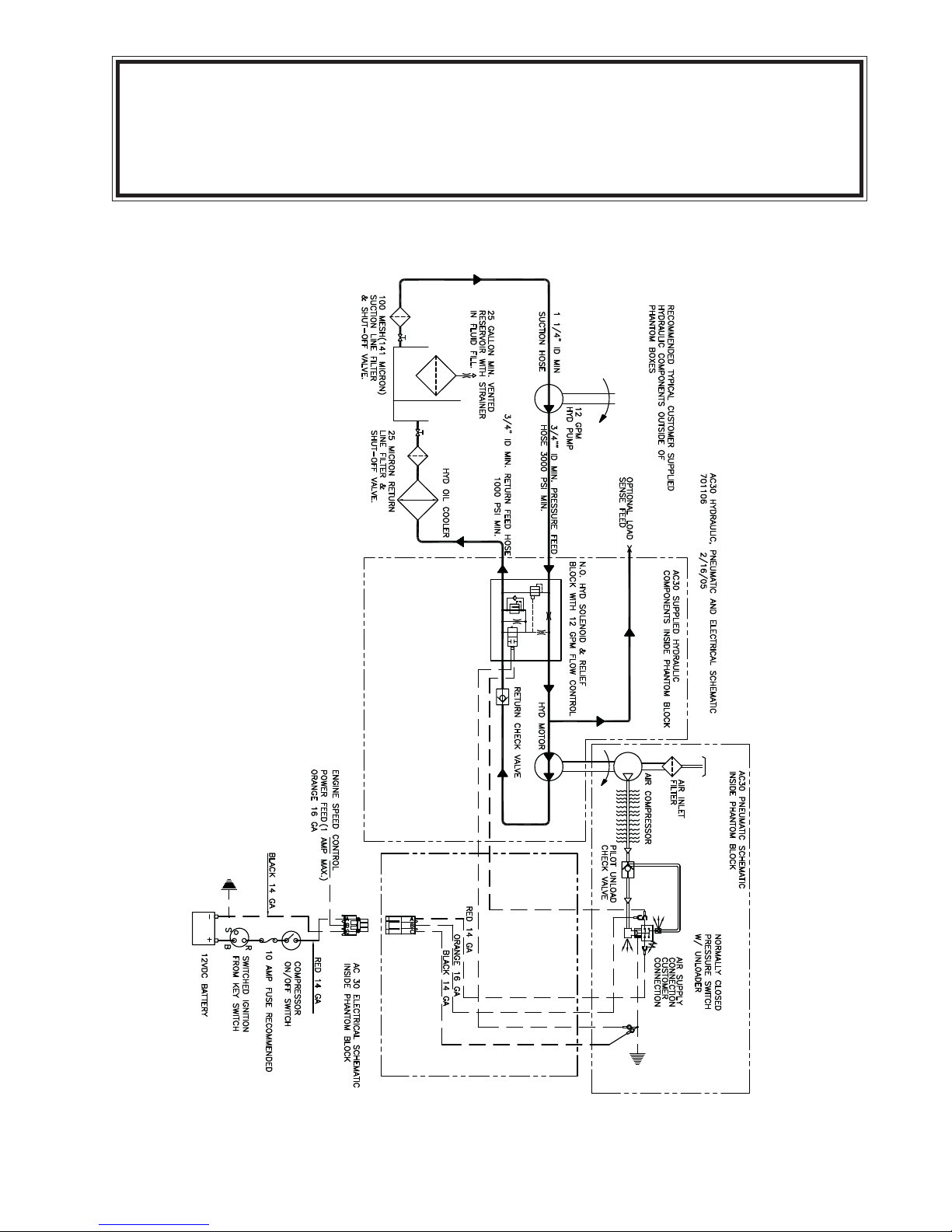

ELECTICAL SYSTEM......................................................................... 2-3.0.0

HYDRAULIC SCHEMATIC.................................................................. 2-4.0.0

GENERAL ASSEMBLY........................................................................ 3-1.0.0

MAINTENANCE.................................................................................. 4-1.0.0

TROUBLESHOOTING......................................................................... 4-2.0.0

RECEIVER TANK................................................................................ 5-1.0.0

FILTER/REGULATOR/LUBRICATOR..................................................6-1.1.0

MISC....................................................................................................7-1.0.0

WARRANTY............................................................................................ LAST PAGE

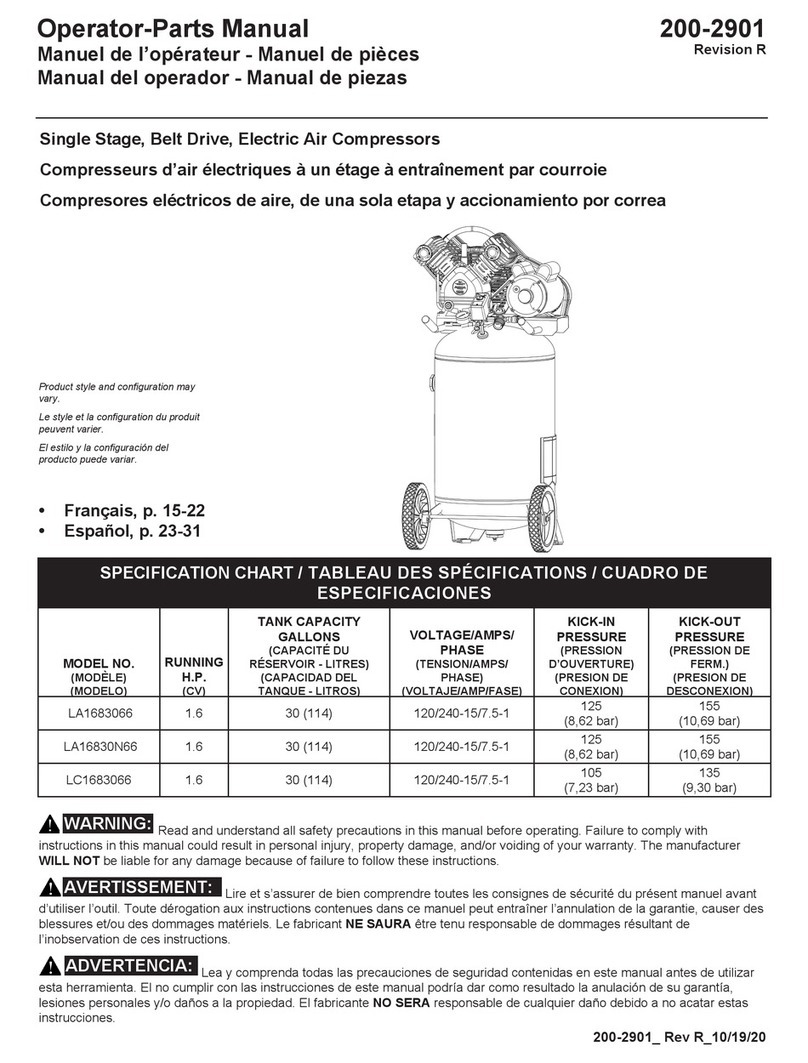

AC30A HYDRAULIC AIR COMPRESSOR

OWNER’S MANUAL

TABLE OF CONTENTS

10/09

Dimensions

Width: 25.0 in. (AT TOP)

20.0 in. (AT BASE)

Height: 24.5 in.

Length: 28.25 in.

Weight: 250 lbs. w/cage

Performance Data

28.8* cfm (Free Air Cubic Feet per Minute) @

100 psig air outlet pressure and 1800

rpm.

Piston Displacement: 48.5 cfm

*Reference Conditions:

Absolute Inlet Pressure: 14.5 psi

Relative Air Humidity:0 %

Air Inlet Temperature:68° F.

Hydraulic Requirements

Flow (Max): 12 gpm (45.4 l/min)

Pressure: 2500 psi (172 bar)

Fluid Type: Anti-Wear Hydraulic

Fluid viscosity: 150 SSU @ 100°F

Electrical System Requirements

Voltage: 12 Volts DC

Current: 2.5 Amps

Rotation

Bi-rotational Radial Fan Blade

Hose Connections

Pressure: -12 JIC MALE

Return: -12 JIC MALE

Technical Data

Maximum Air Pressure: 145 psig

Nominal RPM: 1800 rpm

Crankcase Oil Capacity: 1.5 qts

Approx. Oil Consumption: .025 oz/hr

Maximum Temperature (@ Outlet): 165°F

Noise Level: 84 dB(A)

1-1.0.0

GENERAL SPECIFICATIONS

AC30A HYD AIR COMPRESSOR

10/09

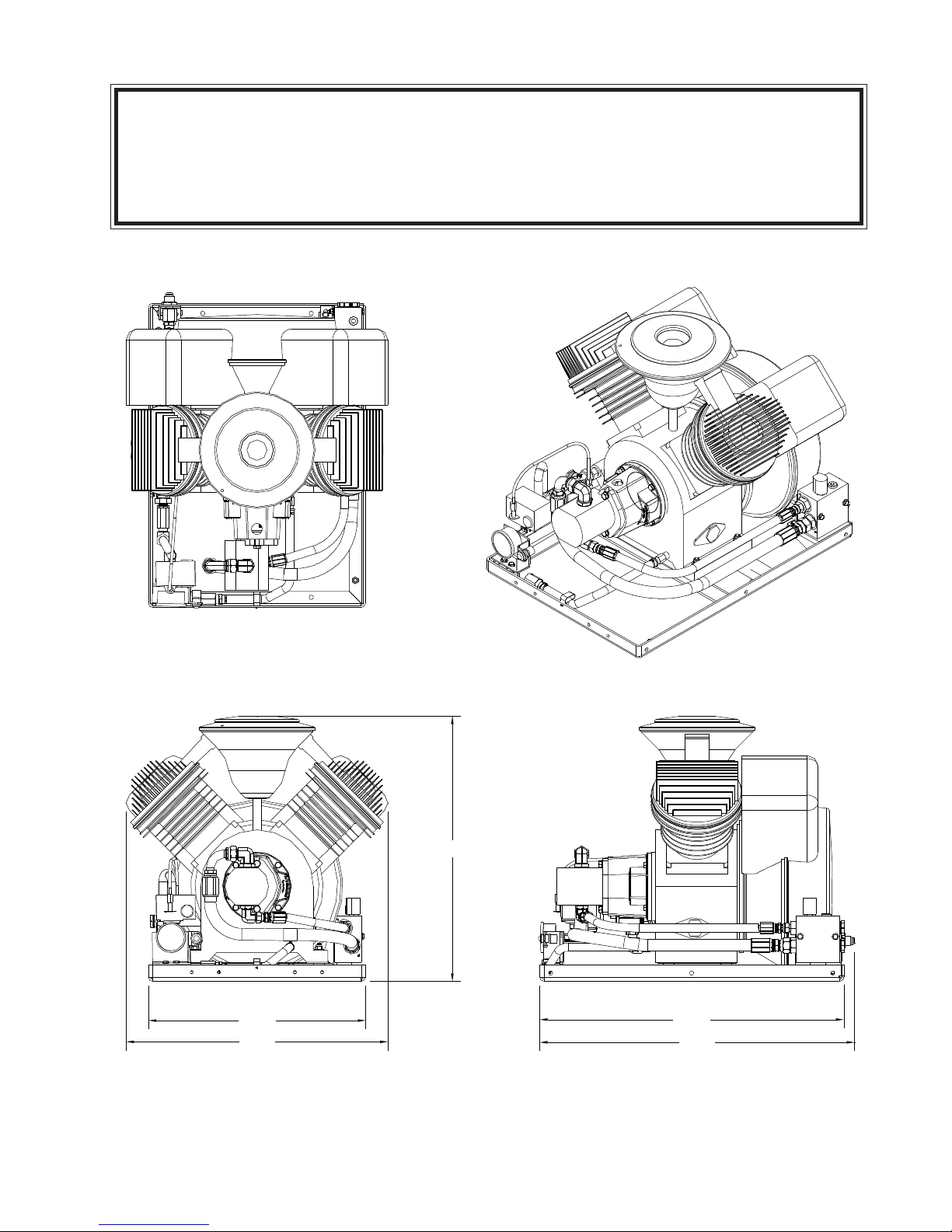

1-2.0.0

20.00

24.11

24.38

28.00

29.01

GENERAL DIMENSIONS AC30A

10/09

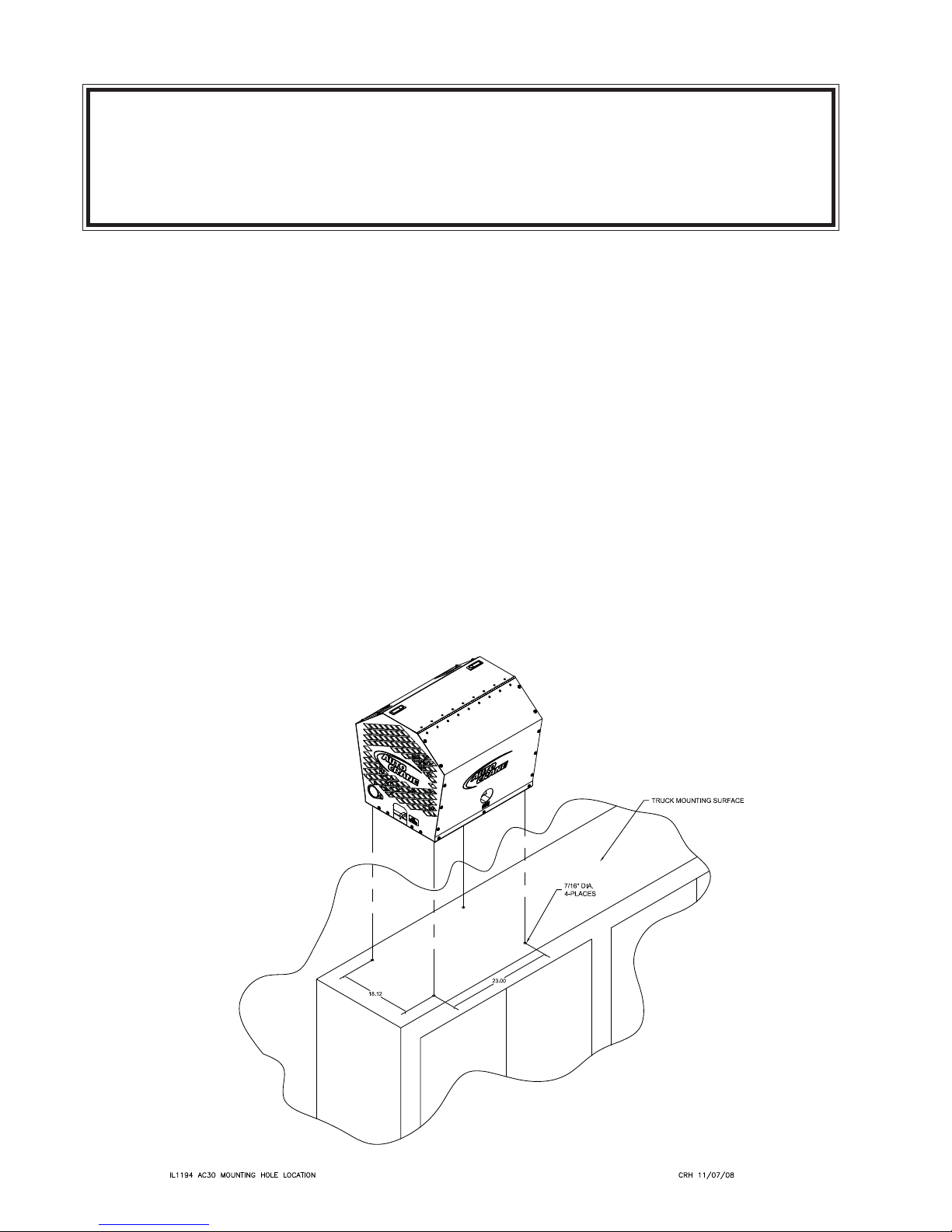

1Locate air pump in a well ventilated

area on truck body.

2Secure to truck body through

bottom side rails using four

(4) 3/8- 24 NF x 2¾ Grade 5 bolts.

Four (4) new 7/16 diameter holes

may be made in the side frame rail

to allow for obstruction problems.

3Remove plastic cap from “T” port in

the hydraulic valve block and install

return line to cooler or reservoir.

4Remove plastic cap from “P” port

in the hydraulic valve block and

install pressure line from hydraulic

pump.

5The mating electrical connector has

4 wires. Red, black and orange. Run

red power wire to a 10 amp fused

switched ignition source. The black

to a frame ground source. The

orange wire is optional and is a

power feed source from the

compressor when the compressor is

running only. This is a 10 amp max.

power feed.

6Attach air hose to the straight 5/8"

fitting (37 degree JIC male) on the

compressor discharge line.

7Follow initial start-up procedure.

1-3.0.0

AC30A

INSTALLATION INSTRUCTIONS

10/09

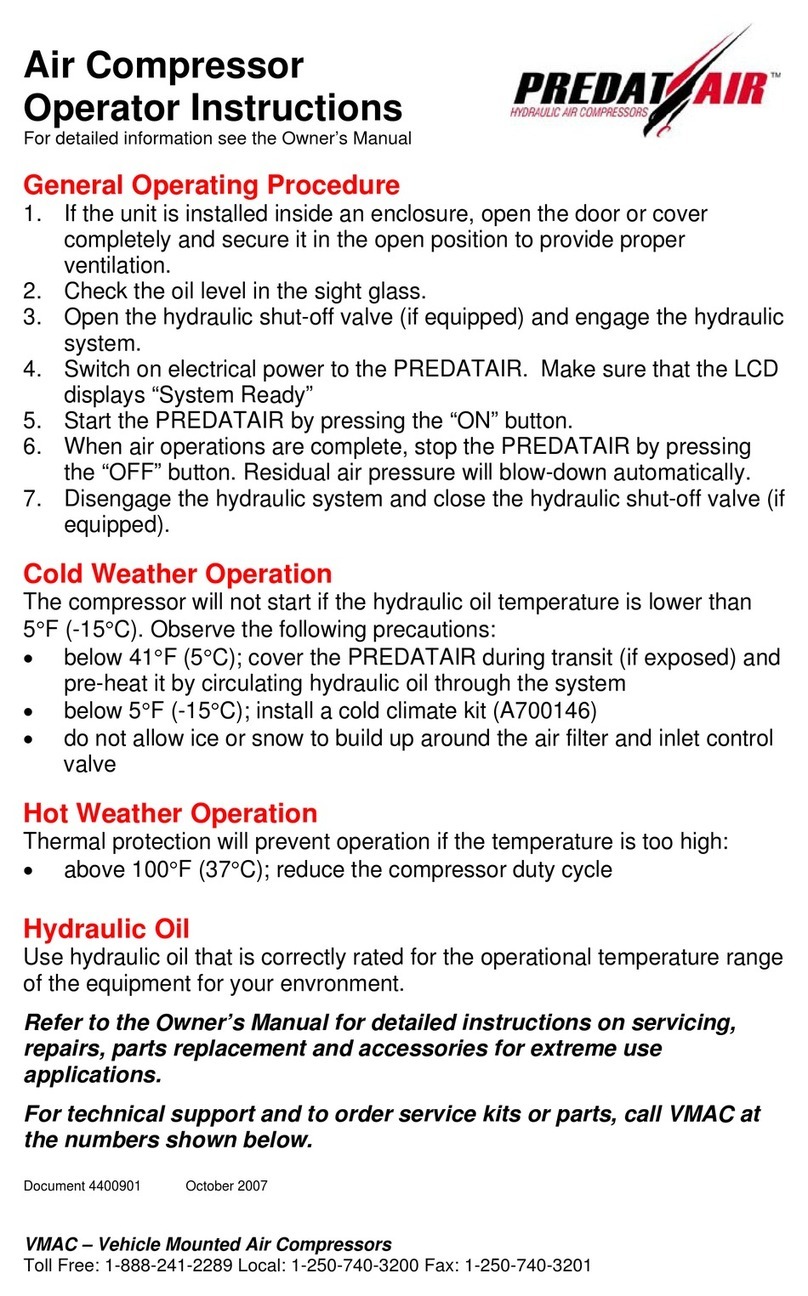

BASIC OPERATION

Air is drawn through the intake filter,

intake manifold and suction discs into

the cylinders. The air is compressed,

then discharged through the delivery

discs to the temperature reducer, where

the heat of the compressed air is partly

removed. From the temperature reducer

the compressed air is discharged

through the 5/8” JIC customer

connection points.

AUTO RUN MODE

When the demand for air is moderate, the

unit should be run in the auto mode.

This allows the compressor to produce

air until the pressure reaches the upper

limit of the pressure switch and stop. At

this point it shuts the compressor off.

When the tank pressure reduces to the

lower limit of the pressure switch the

unit will start up and continue producing

air.

CAUTION: When the hydraulic system

shuts down a shock wave is delivered to

the return line. Locate the hydraulic

coolers and filters a minimum of 10’

away.

The pressure switch is preset to

specified settings.

Pressure Switch:

Shutoff: 150 psig

Restart: 110 psig

1-4.0.0

OPERATION — AC30A

10/09

1Read the AC30A Owner’s Manual.

2Check all wiring for loose

connections.

3Check oil level in sight gauge. It

should be filled to the middle of the

sight glass. If not, fill to the proper

level. Fill with PAO synthetic

lubricant equivalent to Chevron-Gulf

GSL 838A or Summit SH-46. If

petroleum based crankcase oil is

required by operator, use an SAE

10W oil, API classification CD of SF,

Mil Spec MIL-L-2104C or MIL-L-46152.

CAUTION: Do not mix oil types.

4Check that pressure switch operates

at the pressure limits specified.

5Check the oil fill cap on top of

compressor (yellow knob) for

tightness.

6Check hydraulic fluid flow.

CAUTION: More than 12 GPM will

build excess heat in the system.

7Check all piping for leaks.

1-5.0.0

AC30A

INITIAL START-UP PROCEDURE

10/09

1-6.0.0

ITEM QTY PART NO. DESCRIPTION

1 3 750107000 AIR FILTER

2 5 750097000 OIL, CRANKCASE (QT BOTTLES OF PAO OIL)

3 1 302688-012 COIL, HYD VALVE SOLENOID/RELIEF

AC30A RECOMMENDED

SINGLE UNIT SPARE PARTS LIST

10/09

2-1.0.0

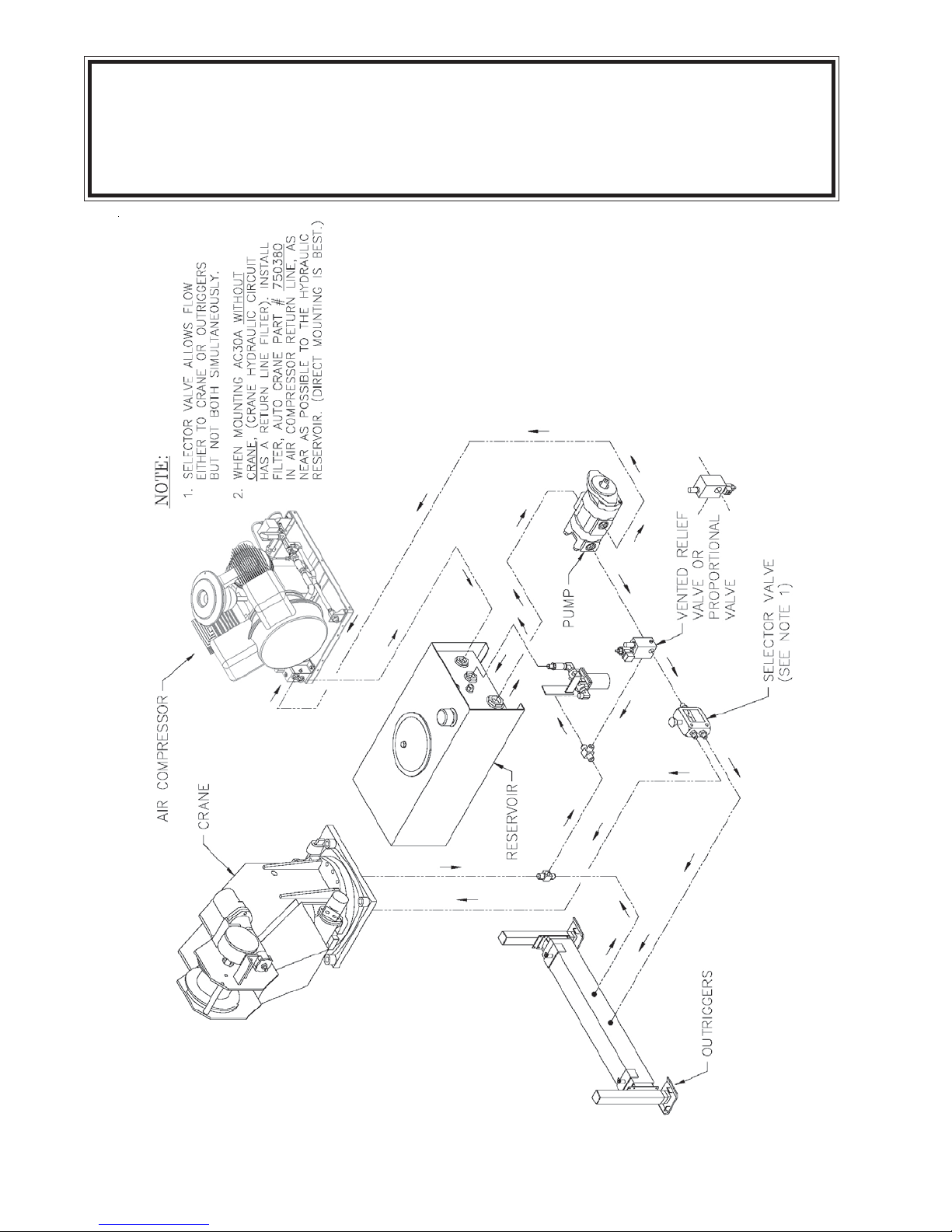

TYPICAL AC30A / CRANE

HYDRAULIC INSTALLATION

10/09

2-2.0.0

PNEUMATIC SYSTEM SCHEMATIC

10/09

2-3.0.0

AC30A ELECTRICAL SYSTEM

P/N: 200220-999

10/09

2-4.0.0

AIR/HYDRAULIC/ELECTRICAL

SCHEMATIC P/N: 701106

10/09

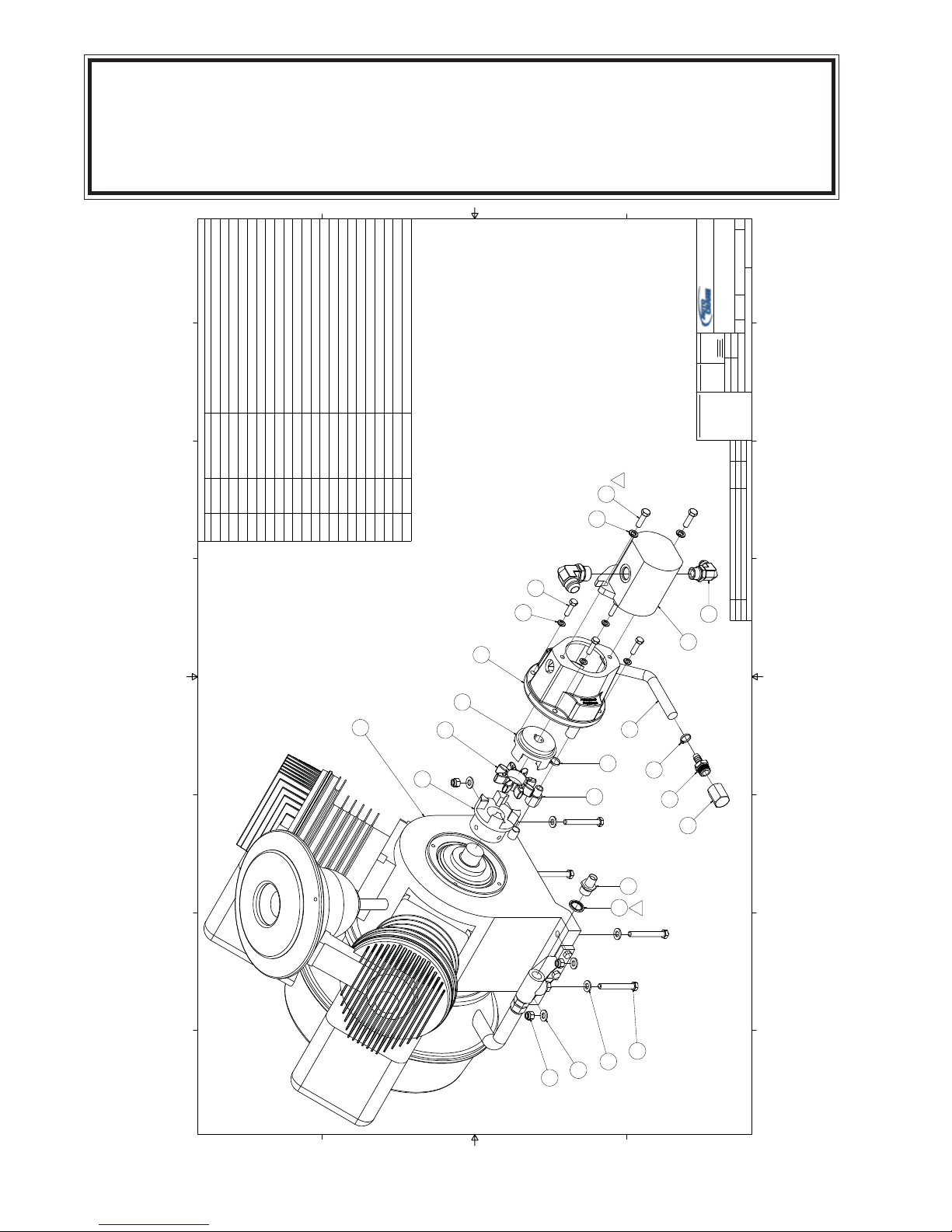

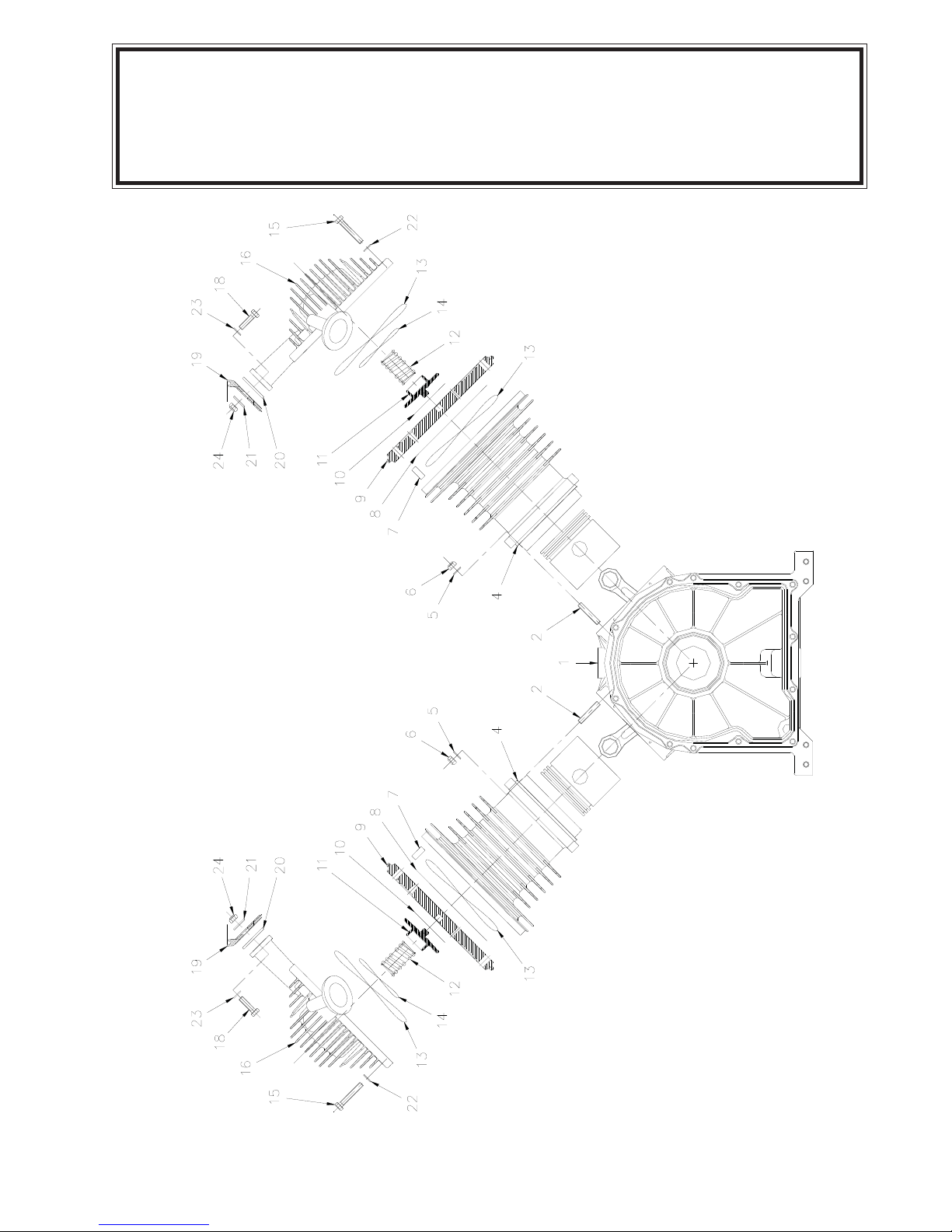

3-1.0.0

AC30A COMPR & PARTS SYS.

P/N: 200281-999

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

Parts List

DESCRIPTIONPART NUMBERQTYITEM

ELBOW, HYD 1/2 MJIC X -10 MSAE970408-08811

MOTOR, HYD 1.29 A 3/4-RD SP CCW HP30525812

WASHER, FLAT GR8 3/8938206-07183

NUT, NYLOC GR8 3/8-16925506-19844

HUB, DRIVE COUPLING R38(.750 DIA BORE).0005

30126615

SPIDER, DRIVE COUPLING R3830126716

WASHER, LOC 8MM

938808-20047

BOLT, HEX GR10.9 8MM X 30MM929208-300

4

8

COMPR, 35 PISTON AC30476019

ADAPTER, 1/2 BSPP X 1/2 NPT

302631110

BOLT, HEX GR8 3/8-16 X 3929806-300411

ADAPTER, HYD MTD TO AC30 COMPR

305767112

WASHER, LOC GR8 3/8937806-094213

BOLT, HEX GR8 3/8-16 X 1 1/4929806-125214

ADAPTER, 3/8 MBSPT X 3/8 FNPT

989206-038115

HOSE, .500 OIL DRAIN AC303026361.167 FT16

HUB, DRIVE COUPLING 35MMX10X8MM KEY

305434117

CLAMP, HOSE 3/4 WORM GEAR300033-075218

CAP, PIPE HEX 1/2 ZINC906030-020119

ELBOW, HYD 3/4 MJIC X -12 MSAE

970412-106120

CONNECTOR, 1/2 BARB X 1/2 MNPT974808-050121

SEAL, WASHER 1/2 MBSPP

308525122

SHEET

200281

11

OF

REV

2

COMPR & PARTS, AC30

AUTO CRANE

P.O. BOX 580697

TULSA, OK 74158-0697

N/A

PATH

MATERIAL

G:\Inventor Files\200k\200281.dwg

1/11/2006

NDD

DRAWN

CHECKED

1=2

D

DESCRIPTION

DWG NOSCALE

SIZE

UNMACHINEDSURFACES

FRACTIONAL

`

1/16

DECIMAL

`

.03

ANGULAR

`

1°

DO NOT SCALE

TOLERANCES

UNLESS NOTED

MACHINEDSURFACES

NOMINALDIM.

0.000 TO 1.000

`

.010

1.001 TO 5.000

`

.015

5.001 TO 10.000

`

.020

10.001& OVER

`

.025

THIS DRAWING AND ALL

INFORMATION THEREIN IS

THE PROPERTY OF

AUTOCRANE, IS

CONFIDENTIAL AND MUST

NOT BEMA DE PUBLIC OR

COPIED. IT IS LOANE D

SUBJECT TO RETURN UPON

DEMAND, IS NOT TO BE USED

DIRECTLY OR INDIRECTLY IN

ANYWAY DETRIMENTIAL TO

THE INTEREST OF AUT O

CRANE.

PROPRIETARY INFORMATION

2 ADDED 308525 3/11/2011 MCM

1REPLACED (2) 929806-100 WITH 929806-125 7/7/2008 MCM

REVISION HISTORY

REV DESCRIPTION DATE ENG

9

4

3

3

11

18

16

18

19 2

1

14

13

8

7

12

5

6

17

1

22

10

15

21

2

10/09

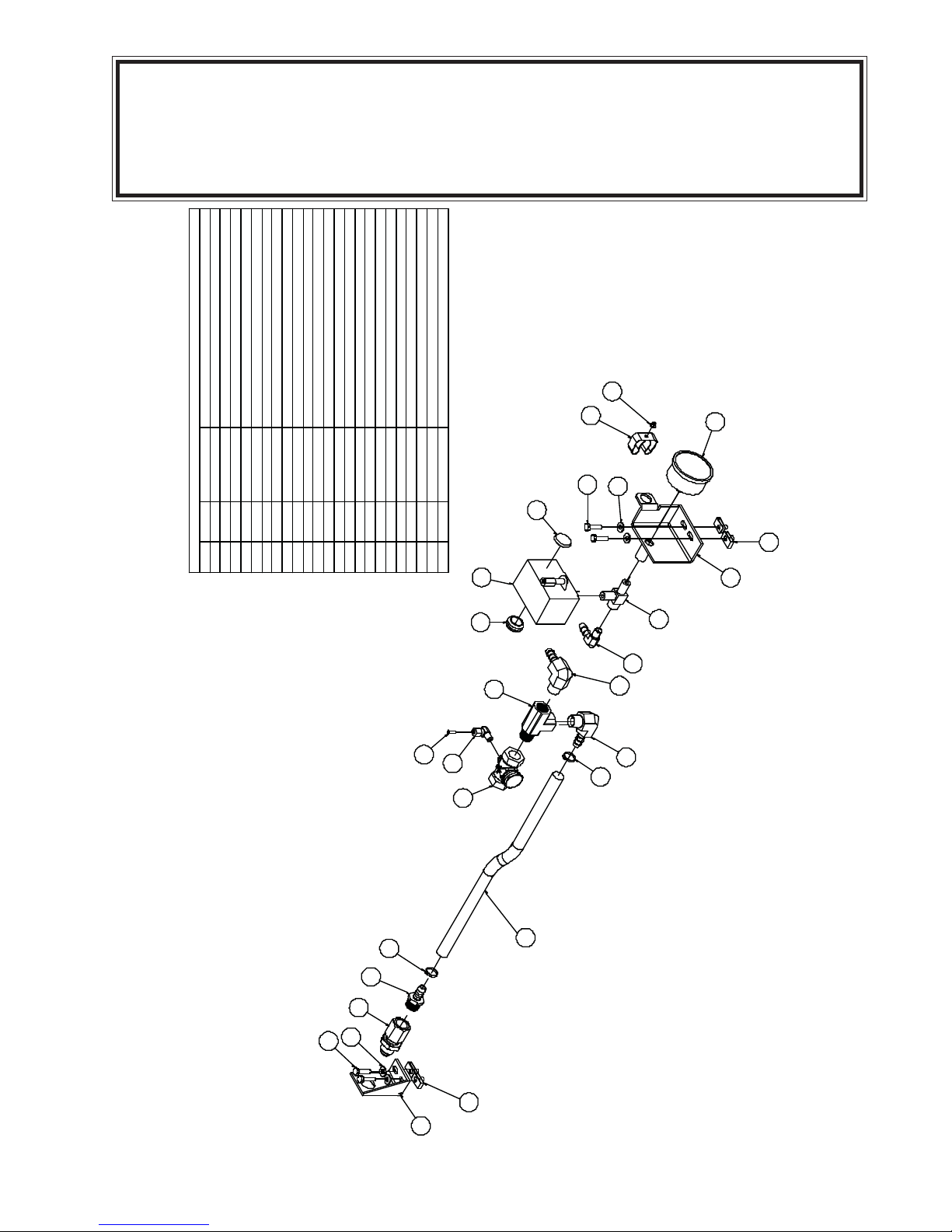

3-2.0.0

AC30A DISCHARGE & PARTS SYS.

P/N: 200283-999

Parts List

ITEM QTY PART NUMBER DESCRIPTION

1 1 962010-050 BULKHEAD, 5/8 JIC X 1/2 FNPT

2 1 9 75 1 04 - 01 2 EL BO W , C O M PRS N 1/ 4 TU BE X 1/ 8 M NP T

3 3.083FT 302636 HOSE, .500 OIL DRAIN GRAY 2

4 2 970308-050 ELBOW, HYD .500 BARB X .500 MNPT

5 1 964808-050 TEE, PIPE 1/2F X 1/2M X 1/2F

6 4 300033-075 CLAMP, HOSE 3/4 WORM GEAR

7 4 929104-100 BOLT, HEX GR5 1/4-20 X 1

8 4 938604-071 WASHER, FLAT GR5 1/4

9 1 305480 BRACKET, AIR DISCHARGE AC30 06 (REV 1)

10 4 961504-090 NUT, TINNERMAN 1/4-20

11 1 974808-050 CONNECTOR, 1/2 BARB X 1/2 MNPT

12 1 303815 VALVE, CHEC K 1/2

13 2 975200-025 INSERT, COMPRSN FITTING 1/2 BRASS

14 1 302613 CLIP, 1/2" HYD HOSE HOLDER

15 1 943103-025 RIVET, POP 3/16 X 1/2 ALUMINUM

16 1 305463 BRACKET, GAUGE & LIGHT (REV 2)

17 1 970308-025 ELBOW, HYD 1/2 BARB X 1/4 MNPT

18 1 77041369 SWITCH, PRESSURE WITH UNLOADER F

19 1 305162 CAP, 7/8 ID PLASTC

20 1 305799 GROMMET, 3/4 OD X 1/2 ID X 1/8 THICK

21 1 304998 GAUGE, 0-200 PSI 1/4 MNPT LIQUID FILLED

22 1 307054 TEE, .250MNPT X .250MNPT X .250FNPT

NS 1.083FT 89034176 TUBE, AIR BRAKE .25

14

15

4

4

6

13

2

12

6

11

1

7

8

10

9

4

21

10

16

8

7

22

17

18

19

20

5

10/09

3-3.0.0

AC30A FRAME & PARTS

P/N: 200280-999

Part s List

ITEM QTY PART NUMBER DESCRIPTION

1 1 970508-106 CONNECTOR, 1/2 MJIC X -12 MSAE

2 1 970512-106 CONNECTOR, 3/4 MJIC X -12 MSAE

3 1 305479 FRAME, AC30 06 (REV 1)

4 4 300540-001 ISOLATOR, 60A HARD BULLET (REV 2)

5 4 300541-001 WASHER, ISOLATOR 60A HARD (REV 2)

6 2 9 29 1 04 - 32 5 BO LT , H EX G R 5 1/4 -20 X 3 1 /4

7 4 9 38 6 04 - 07 1 W AS HER, FLA T G R 5 1/4

8 1 80056-13-12 KIT, HYD VALVE BLOCK 13GPM FLOW CONTROL

9 2 988912-106 PLUG, 12 SAE PLASTIC

10 4 961504-090 NUT, TINNERMAN 1/4-20

11 1 304762 BRACKET, VALVE BLK 35 PISTON A (REV 2)

12 2 9 29 1 04 - 10 0 BO LT , H EX G R 5 1/4 -20 X 1

13 1 304930 PLATE, VIBRATION ISOLATOR AC30

NS 1 3 06 8 12 - 21 5 OR I FIC E, SI LV ER .2 15

1

2

3

4

5

6

7

8

9

10

11

7

12

13

10

200280-999 (REV 1)

NOTE:

WHEN REPLACING HYDRAULIC

VALVE BLOCK (P/N 80056-13-12),

YOU MUST REMOVE ORIFICE

(P/N 306812-215) FROM THE OLD

BLOCK AND INSTALL ON THE

NEW BLOCK.

10/09

3-4.0.0

AC30A CYLINDERS & VALVES

10/09

II = PART OF VALVE KIT

III = PART OF PISTON + RINGS + CYLINDER KIT, LOW PRESSURE

IV = PART OF PISTON RING KIT

VI = PART OF PISTON, CYLINDER HEAD ASSEMBLY LH

VI I= PART OF PISTON, CYLINDER HEAD ASSEMBLY RH

ITEM KITS QTY P/N DESCRIPTION

1 - 1 N/A CRANKCASE ASSEMBLY

2 - 8 755080-001 SCREWED STUD

3 III, VI, VII 1 N/A PISTON ASSEMBLY

4 III, VI, VII 1 N/A CYLINDER

5 - 8 755080-002 WASHER

6 III, IV, VI, VII 8 755080-003 LOCK NUT

7 III, VI, VII 4 755080-004 PIN

8 II, VI, VII 2 N/A SUCTION DISC

9 VI, VII 2 755080-005 VAVLE SEAT

10 II, VI, VII 2 N/A DELIVERY DISC

11 VI, VII 2 755080-006 GUARD

12 II, VI, VII 2 755080-007 SPRING

13 II, VI, VII A/R 755080-008 CORD

14 II, VI, VII 2 755080-009 O-RING

15 VI, VII 10 755080-010 BOLT

16 VI 1 755080-011 CYLINDER HEAD LLP

17 VII 1 755080-012 CYLINDER HEAD RLP

18 - 4 755080-013 BOLT

19 - 1 REF INLET SILENCER (SEE Aw-461)

20 II 2 755080-014 GASKET

21 - 4 755080-015 WASHER

22 VI 10 755080-002 WASHER

23 - 4 755080-016 WASHER

24 II 4 755080-017 LOCK NUT

3-4.1.0

AC30A CYLINDERS & VALVES

Other manuals for AC30A

1

Table of contents

Other Auto Crane Air Compressor manuals

Popular Air Compressor manuals by other brands

Gardner Denver

Gardner Denver L Series Operating and service manual

FScurtis

FScurtis FCT02C48V3 Series Operating instructions and parts manual

Powermate

Powermate LA1683066 Operator's & parts manual

Metabo

Metabo HWW 3000/ 20 S operating instructions

Champion

Champion D15 Installation and start-up data

Easylife

Easylife EL5408 instruction manual

VIAIR

VIAIR 40045-400P-A user manual

Certa

Certa CT150ARCMPA quick start guide

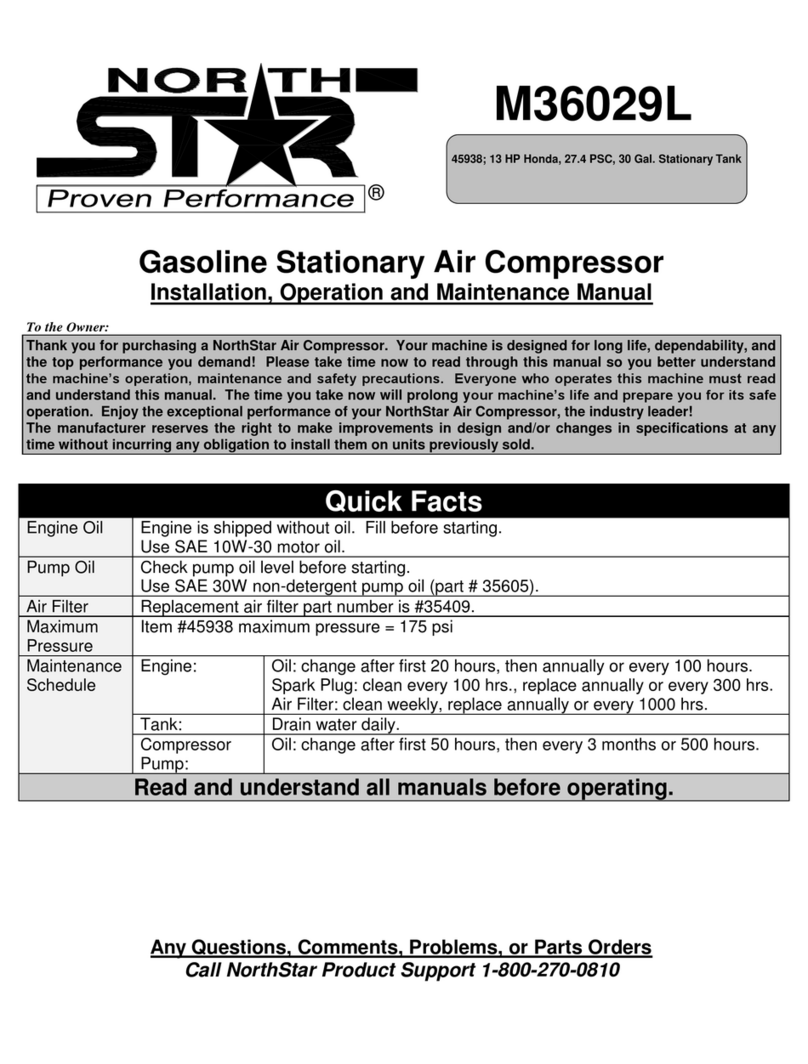

NorthStar

NorthStar M36029L Installation, operation and maintenance manual

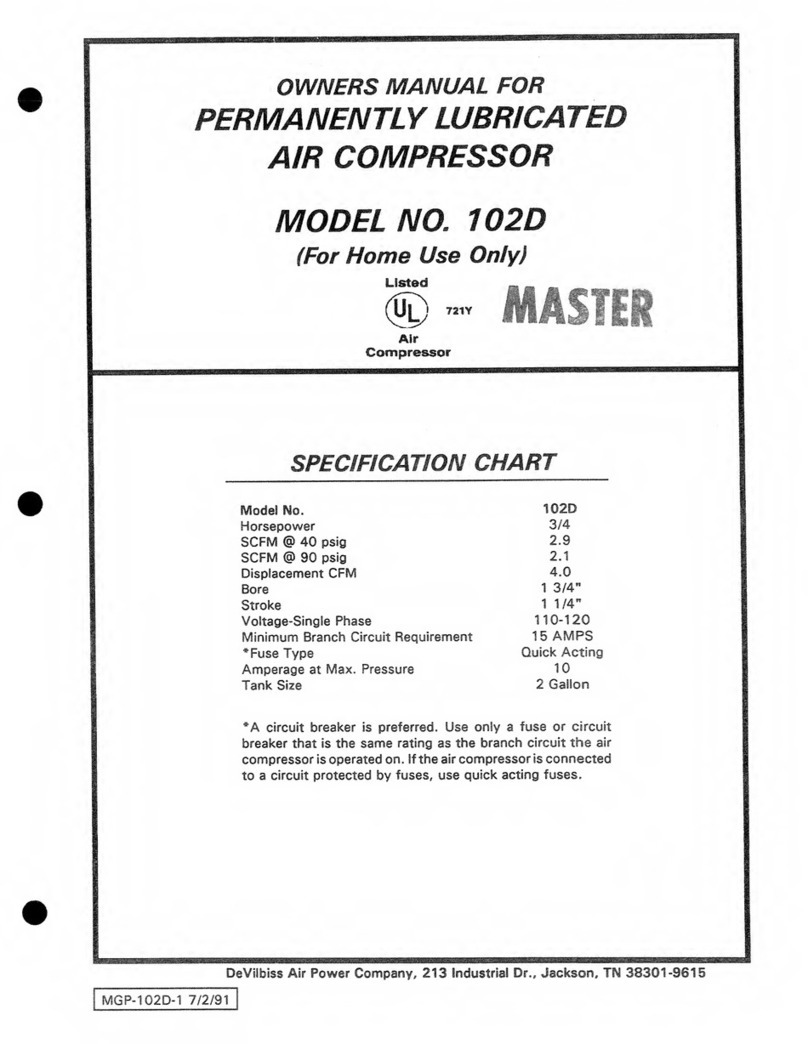

DeVilbiss Air Power Company

DeVilbiss Air Power Company 102D owner's manual

Sullair

Sullair ShopTek ST45 Operation & maintenance manual

ISANTA

ISANTA Senco AC19306BL operating instructions