Autonnic A5023 Operating manual

A5023/24

1 of 19

A5023 A5024 FLUXGATE COMPASS USER AND

INSTALLATION MANUAL

Software releases:

V016

Hardware versions:

7310-4

Autonnic Research Ltd

UK

www.autonnic.com

A5023 A5024 manual 03.docx

Jan 2019

19 Dec 2018

A5023/24

2 of 19

Table of Contents

1 Introduction and description of fluxgate compass.

1.1 Description of compass

1.2 Connections

1.2.1 A5024

1.2.1 A5023

1.2.3 Variants with suffix -CP

1.3 Switches

1.4 Indicator light

1.5 Power supply.

1.6 Mounting

2 Connecting the compass to your application.

2.1 To a NMEA-0183 instrument.

2.2 To a PC serial port.

3 Output formats available from compass.

3.1 NMEA-0183

3.2 Furuno AD-10

4 Calibrating the compass.

4.1 Why the compass needs calibrating.

4.2 Starting calibration.

4.3 Aborting a bad calibration.

4.4 Setting reference NORTH heading

4.5 Set-up suggestions

5NMEA-0183 Inputs and Outputs

6 References

A5023/24

3 of 19

1. Introduction and description of fluxgate compass.

1.1 Description of compass.

The Autonnic NMEA compass unit is a complete component for a compass

indicating system, RADAR ‘North-up’ input or autopilot. It is housed in a

water-resistant enclosure so it can be mounted outside a steel hull. It

delivers heading data in two industry-standard forms.

The A5023 and A5024 contain a fluxgate with floating core surrounded by

high-precision interface circuits which, together with the special

clockwise/anticlockwise and offset nulling sequence allow a

microprocessor to acquire a binary value from two orthogonal sensors of

the horizontal component of the Earth’s magnetic field. The processor

calculates the vector from these values, uses a calibration table to correct

for local field disturbance errors, offsets the result and then presents the

data in a manner which has been requested. Such requests alter the

frequency of the data, the degree of filtering and the offset value.

Calibration sequences can also be commanded.

A5023/24

4 of 19

1.2 Connections

1.2.1 A5024

Conductor

Colour

Type

Function

1

Red

P

+Supply 8-30v

2

Yellow

O

NMEA OUT+

3

Brown

I

NMEA IN-

4

White

I

NMEA IN+

5

Black

P

GND

6

Blue

O

Furuno AD-10 Clock

7

Violet

O

Furuno AD-10 Data

8

Green

P

GND

Screen

Not connected

NOTE 1 Conductors 5 and 8 are connected together inside the A5024

NOTE 2 Wiring does not use the same colours as the A5022

1.2.2 A5023

Conductor

Colour

Type

Function

1

Red

P

+ Supply 10-30V

2

Yellow

I

NMEA IN -

3

Blue

O

NMEA IN +

4

Green

I

NMEA IN+

5

Screen

P

GND

A5023/24

5 of 19

1.2.3 Variants with suffix -CP

A5023

Conductor

Colour

Type

Function

1

Red

P

+ Supply

2

Yellow

I

NMEA IN +

3

Blue

P

GND and NMEA IN -

4

Green

O

NMEA OUT +

NOTE Cable foil and drain wire internally NOT connected to GND

1.3 Switch Inputs

S1

S2

Fig 1

Except for variants with suffix -S, two push-button switches are provided for

calibrating the compass in the field.

A5023/24

6 of 19

When the A5023-24 is viewed from the front face with the LED facing, then

Switch 1 is on the right and Switch 2 is on the left.

1Switch 1: Start the auto-calibration process

2Switch 2: Set reference NORTH heading. The A5024/4

must be mounted upright but at any azimuth. Pressing S2 sets the

heading to zero and so can be done when the whole installation is

headed North.

3Both together Pressing both together for at least one second causes

the auto-calibration process to halt and restores the previously saved

calibration values.

1.4 Indicator light

A blue light indicates three states of the A5023-24.

State 1 Uncalibrated long flash

State 2 In the process of calibration continuous

State 3 Calibrated short flash

After the reset command, $PATC,IIHDG,0CV<CR><LF>, the compass is

uncalibrated and will have a long flash.

Note that the LED can be turned off and on by the DLED command –see section

5.

A5023/24

7 of 19

1.5 Power supply

The compass is compatible with any DC power supply of between 8 and 30 Vdc.

Typical supply current during operation is approx. 25mA. The compass is

protected against reversed polarity.

Note that the operation of the LED adds another 10mA and that during auto-

calibration the consumption can be as high as 60mA.

Care should be taken to make sure the compass is not situated too close to the

power supply, as it’s accuracy may be affected by either the iron in the mains

transformer, or by magnetic field ‘noise’ from a switching power supply. It is not

possible to cover all possible scenarios here, and it remains up to the user to

determine the suitability of a possible location for the compass.

Note that the output takes several seconds to stabilize after a power is applied;

the time taken depends on the damping settings. There is a command - see

section 5 –which can be used to suppress the output after power-up.

1.6 Mounting

The compass is fixed to the chassis of the vessel or vehicle in the upright position

using the fixing holes shown in the data sheet. It does not matter which way it

faces as the azimuth can be set to North at any time the chassis is orientated

North. Alternatively if the azimuth of the chassis is known, then the compass

may be rotated before fixing to North using a protractor. S2 is then pressed and

then the compass can be mounted on the chassis.

A5023/24

8 of 19

A5022

COMPORTD

CONNECTOR

2

3

5

4NMEAIN+

3NMEAIN-

5GND

6NMEAOUT+

7GND

+POWER

SOURCE -1+8-30V

2 Connecting the compass to your application

2.1 Compass to a NMEA-0183 instrument

The hardware on which the NMEA-0183 standard is based on is a balanced serial

protocol called RS422. This means that two wires are need for send and two for

receive.

Fig 2

Note that the GND wire is used for the current return path. This might be

shared with the NMEA- wire in some installations.

2.2 Compass to a PC serial port

In many cases the wires can be joined directly as shown in Fig 2.

Alternatively use the Autonnic A3036 serial interface unit.

Fig 3

External NMEA device

6 NMEA OUT +

4 NMEA IN+

3 NMEA IN-

5 GND

NMEA current

source

+

-

A5023/24

9 of 19

3 Output formats available from compass

3.1 NMEA-0183

The serial output format is: 4800 Baud, 8 data bits, 1 stop bit, no parity.

The compass sends information using the standard NMEA-0183 sentence

‘HDG’: Magnetic Heading, Deviation, and Variation. But note that the

information of Deviation and Variation is not sent and so blank fields are

defined by consecutive commas. In the A5024/4 the sentence may have

one of several forms typically of the general form:

$HCHDG,hhh.h etc

Where hhh.h is the magnetic heading from 000.0 to 359.9 degrees

Also the Rate-of-turn data is sent either with or without the heading

sentence.

For a complete list of output formats available see Section 5.11

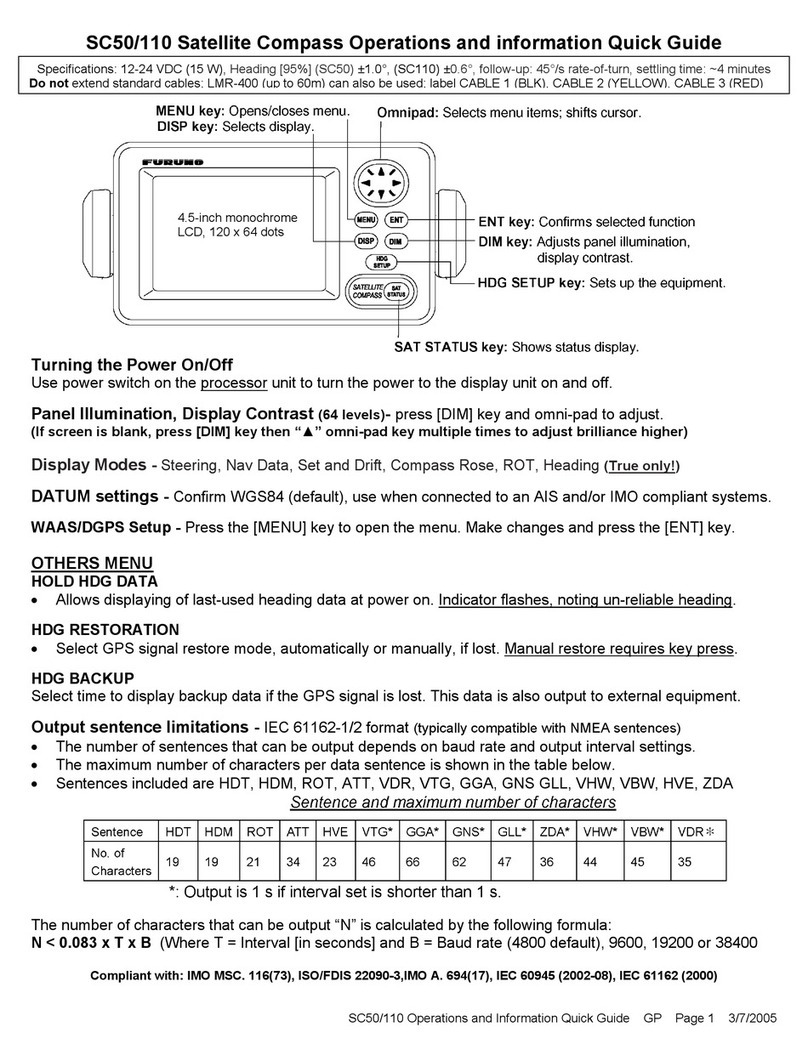

3.2 Furuno AD-10 -A5024 only

The compass has a separate, dedicated output in Furuno AD-10 format.

This is a proprietary 4 character serial format, which gives heading in

degrees and tens of minutes. The string 0872 represents the heading 87°

20’ so that the precision is to 1/6 of a degree. At the same time the

A5024 would be also sending the NMEA data to a precision of 1/10 of a

degree.

480µs

100ms minimum

Duration of data is 16 clocks each

high=low=30µs. Total = 480µs.

Frequency of data packets is set by

the interval command. Max = 10Hz

Clock

Data

Fig 4

A5023/24

10 of 19

4 Calibration

4.1 Why the compass needs calibrating

When any compass is installed the magnetic characteristics of the whole

installation affect the way the Earth’s field reaches the detector inside the

device. Each individual installation will be different and so the A5023 and

A5024 are equipped with an auto-calibration routine which corrects for

these installation distortions.

4.2 Starting calibration

-A NMEA-0183 command can be sent to initiate the process –

section 5.2.9

OR

-Switch 1 can be pressed.

There are two compass calibration techniques in common use:

1Constant angular velocity

2Double rotation without constant velocity.

The Autonnic compasses use the first method. The process consists of

rotating the whole installation in the Earth’s field so that both permanent

magnets and induced magnets are corrected. The method used is the

single turn at a constant rate and this rate should be in range 60 to 180

seconds for the full 400 degrees needed. The whole arrangement is turned

at constant angular velocity because the method relies on applying a

correction when the heading measured is uneven with time.

The second method is not used by us. Autonnic has evaluated the method

which uses a mathematical model of an ideal compass and treats errors as

arising from distortion due to magnetic objects. The ideal error plot of the

field vector would be a circle with no offset from the origin. Permanent

magnets (‘hard’) have the effect of shifting the centre from the origin and

induced magnets (‘soft’) modify the circle into an ellipse. The results of

A5023/24

11 of 19

our investigation show that there is always a residual error due to the fact

that real magnetic objects do not behave exactly according to the model

outlined. Autonnic is aware that the need for a constant angular velocity

is onerous but the benefit is that it provides a very low residual error –

less than 0.5°.

Note that the calibration is different if the unit is mounted upside-down.

Calibration must always be done with the unit in its final mounted

position. The essential point of the calibration is remove the influence of

external magnetic components in the vicinity –the nearby pieces of iron

and steel –so it is essential that these remain unchanged after calibration.

If any significant iron component is altered –such as the installation of

new equipment or replacement of equipment such as winches or engines

–then the calibration must be re-done.

4.3 Terminating a bad calibration

If the process is faulty in any way –such as would happen if the

manoeuvre cannot be completed, the process can be terminated by the

NMEA command (see 5.2.17) and the original factory default (linear) table

is restored. Alternatively, this can be done by pressing both Switches

together for at least 1 second.

NOTE that there should be a delay of at least 5 seconds after termination

before a new calibration process is initiated.

4.4 Setting reference NORTH heading

Switch 2 (and also a NMEA command) is provided to set ‘zero’. The

compass should

a. first be auto-calibrated

b. then be aligned to North

A5023/24

12 of 19

4.5 Set-up suggestions

When the device is fixed in place and connected it can be calibrated as

described above. Choose a calm day and a region of water where there

are no currents. Set the boat turning to left or right at a slow rate and fix

the wheel or tiller. Then, when the turning is steadily under way, press

the auto-calibrate button and watch the LED.

When calibration is completed the boat can be on its way and the next

task is to set North. This is best done by identifying transits on a chart

and heading the boat on the transit. Again, this should be done in the

same conditions so that the heading can be lined up on the transit and

maintained while the set-zero button is pressed.

5 NMEA-0183 commands

The compass can be configured by sending various proprietary sentences

to its NMEA-0183 input. Once configured, the compass will remember

those settings every time it is powered up.

Response:

When any of the input sentences are received the A5023 and A5024 will

reply with an ‘acknowledge’ output sentence of the format:

$PATC,HCHDG,ACK<CR><LF>

Unless the command results in response which contains data.

A5023/24

13 of 19

5.1 List of Commands

Section

Command

Function

5.2.1

0CV

Factory default: calibration

values; fluxgate heading output

rate; fluxgate damping factor;

last calibration error code

5.2.2

AHD

Set heading offset

5.2.3

CEC

Read calibration error code

5.2.4

CFG

Configure NMEA sentence output

format

5.2.5

DHD

Set heading damping value

5.2.6

DLED

Disable LED(s)

5.2.7

DLY

Set power up delay

5.2.8

ELED

Enable LED(s)

5.2.9

IAC

Initialise autocalibration

5.2.10

RCV

Read calibration values

5.2.11

RHD

Read heading damping value

5.2.12

RHO

Read heading offset

5.2.13

RID

Read device serial number

5.2.14

SR

Read software version

5.2.15

TXP

Set NMEA output period

5.2.16

UPLOAD

Enter bootloader

5.2.17

XCL

Abort autocalibration

A5023/24

14 of 19

5.2.1 $PATC,IIHDG,0CV<CR><LF>

Sets the following:

Output rate u= 100 milliseconds (10 updates/second),

output damping d= 50 percent

heading offset f= 0 degrees.

5.2.2 $PATC,IIHDG,AHD,fff.f<CR><LF>

Set heading:

Forces the heading to a certain value by supplying an offset which is

stored and used thereafter.

Where f is in degrees with a valid range of 000.0 to 359.9

When f = 000.0 the result is the same as pressing switch 2 –see 1.3.

5.2.3 $PATC,IIHDG,CEC<CR><LF>

Read calibration code

The response is a proprietary sentence containing a code, k, for the

status:

$PATC,HCHDG,CEC,k<CR><LF>

Where k has the following values:

k=0 the last auto-calibration was successfully completed.

k=1 Resetting the calibration data to factory default was completed

successfully.

k=2 The autocalibration has been aborted internally due to the rotation

being too slow.

k=3 The autocalibration has been aborted internally due to the rotation

being too fast.

k=4 The autocalibration has been aborted internally because of rotation

inconsistency.

k=5 The autocalibration has been aborted by an external command.

A5023/24

15 of 19

5.2.4 $PATC,IIHDG,CFG,abc<CR><LF>

Configures the output sentence structure and type.

[Replies with the standard acknowledge sentence

$PATC,HCHDG,ACK<CR><LF>]

Where 'a' specifies the heading of the output sentence as follows:

a=0 : $HCHDG,hhh.h,,,,<CR><LF>

a=1 : $HCHDT,hhh.h,T<CR><LF>

a=2 : $HCHDM,hhh.h,M<CR><LF>

a=3 : $HCHCC,hhh.h<CR><LF>

a=4 : $HEHDT,hhh.h<CR><LF>

a=5: no heading data sent

hhh.h is the compass heading in degrees

(this compass heading field will be omitted when auto-calibration is in

process)

and 'b' is sentence end structure as follows:

b=0 : direction sentence will NOT include checksum nor unit ID serial

number.

e.g. $HCHDG,hhh.h,,,,<CR><LF>

b=1 : direction sentence will include a checksum.

e.g. $HCHDG,hhh.h,,,,*cc<CR><LF> (cc is the checksum)

b=2 : include the serial number.

e.g. $HCHDG,hhh.h,,,,*ssss<CR><LF> (ssss is the unit’s

serial number)

A5023/24

16 of 19

and where 'c' has the following significance:

c = 0 or is missing means no ROT

c = 1 ROT with 8s average

c = 2 ROT with 16s average

c = 3 ROT with 32s average

The form of the transmitted sentence is:

$HFROT,zxxx.x,A*cc<CR><LF>

c = 4 ROT with 64s average

The form of the transmitted sentence is:

$HEROT,zxxx.x,A*cc<CR><LF> (note the E)

and where z = sign as follows:

+ (or missing) turning to starboard (i.e. heading value is

increasing)

- turning to port (i.e. heading value is decreasing)

and cc = checksum

xxx.x = Rate of Turn in degrees per minute

NOTE: The HEROT (or HFROT) sentence is transmitted every 2s

regardless of the sentence rate set using the TXP command

5.2.5 $PATC,IIHDG,DHD,ddd.d<CR><LF>

Set the internal filtering: ('damping')

Valid range for d is 0 to 100.0%

A5023/24

17 of 19

5.2.6 $PATC,IIHDG,DLED<CR><LF>

Disable LED:

Replies with the standard acknowledge sentence

($PATC,HCHDG,ACK<CR><LF>).

Note : LED will be automatically enabled during calibration process.

5.2.7 $PATC,IIHDG,DLYn.n<CR><LF>

Startup Delay

Sets a delay from Power-up to the transmission of the first output

sentence where n.n is in seconds with a maximum of 6.5

5.2.8 $PATC,IIHDG,ELED<CR><LF>

Enable LED:

Replies with the standard acknowledge sentence

($PATC,HCHDG,ACK<CR><LF>).

Default: LED enabled.

5.2.9 $PATC,IIHDG,IAC<CR><LF>

Start Auto-Calibration

Refer to section 4.2. Same as pressing Switch 1 –see 4.4.

A5023/24

18 of 19

5.2.10 $PATC,IIHDG,RCV<CR><LF>

This command is to read the calibration table values and the response is

in the form of the example shown below:

$TCF0,0000071C0E381554

$TCF1,1C70238C2AA831C4

$TCF2,38E03FFC47184E34

$TCF3,55505C6C63886AA4

$TCF4,71C078DC7FF88714

$TCF5,8E30954C9C68A384

$TCF6,AAA0B1BCB8D8BFF4

$TCF7,C710CE2CD548DC64

5.2.11 $PATC,IIHDG,RHD,nn<CR><LF>

Internal filter response

Where nn is the damping value within the range 0 to 99

5.2.12 $PATC,IIHDG,RHO<CR><LF>

$PATC,IIHDG,RHO,nnn.n<CR><LF>

Where nnn.n is the heading offset Note that leading zeros are suppressed

eg 0.0

5.2.13 $PATC,IIHDG,RID<CR><LF>

Request the serial number:

A special proprietary reply sentence follows:

$PATC,IIHDG,RID,ssss<CR><LF> where ssss is the serial number in

ASCII decimal.

5.2.14 $SR <CR><LF>

Read device firmware release

A typical response from a unit is as follows:

$SR,A5024,016,02<CR><LF>

showing the release is 016.

A5023/24

19 of 19

5.2.15 $PATC,IIHDG,TXP,uuuu<CR><LF>

Set the Output update period:

Valid range is u=100 to 2500 milliseconds. This is limited by the

maximum data rate of NMEA-0183 output at 4800 baud.

5.2.16 UPLOAD

This command is used by Autonnic’s updater software which runs under

Microsoft Windows. It is used to send .aeh files to install a new version of

firmware.

5.2.17 $PATC,IIHDG,XCL<CR><LF>

Abort Auto-Calibration.

Refer to section 1.3.

6References

1A5023-24 data sheet

2NMEA-0183 specification

Autonnic and the *A logo and Fluxgateworld are registered Trade Marks of Autonnic

Research Ltd

©2006 - 2018

Autonnic Research Ltd Tollesbury Essex CM9 8SE UK

www.autonnic.com www.fluxgateworld.com

This manual suits for next models

1

Table of contents