Autonumis WRCBS600 Troubleshooting guide

Document: JF000135 Issue: 4

Popular & Premier Cooler

Single Integral Unit

User & Installation Guide

This guide contains instructions for

Autonumis’ Single door model

Back-bar bottle coolers.

Serial Number:

Model

01

Installation 02

General Operation 02

Controls 03

Routine Maintenance 04

Repairs 04

End of Life Disposal 04

Spares Order 05

Spares Identification 06

Wiring Diagram: Popular & Premier 07

Wiring Diagram: Popular & Premier Ecochill 08

Your Notes 09

Contents

Installation

Store the unit upright. If the unit has been stored or transported on its back, front

or sides then it must be placed upright for at least an hour before switching on.

Place the unit on an even floor as far away as possible from any source of heat.

Note: Do not move unit by lifting either the door or door handle as this may

cause damage to the cabinet.

Please ensure the correct aperture size is made available for this unit:

02

Space Required

All dimensions exclude door handle

Height Width Depth

Single Unit 925mm 530mm 525mm

Unit Dimensions

All dimensions exclude door handle

Height Width Depth

Single Unit 900mm 525mm 500mm

The correct aperture size should

give a gap of approximately 25mm

between the top of the cabinet and

the underside of the back bar and

between the back of the unit and

the wall. Poor ventilation due to

insufficient aperture size is likely to

cause: reduced cooling; Icing up;

Premature compressor failure.

General Operation

The cabinet door should remain firmly closed during normal operation. This

prevents warm moist air entering and creating frost within the cabinet. If the

cabinet is left open for extended periods ice will form. This will prevent cooling

and the machine will then require defrosting (see page 03).

The unit should be left switched on, and should not be switched off between

trading sessions. The unit is designed to operate in an ambient temperature

range of 6°C -25°C, however for short periods of time (up to 8 hours) the unit

will operate normally at 32°C. The cabinet is designed to chill product in sealed

containers only i.e. bottles, cans etc. It is not recommended that glasses of

drink or similar are placed in the unit for cooling.

03

Note: Setting the unit at a colder thermostat setting will not make the unit cool

down faster. This unit has been installed with an automatic defrost system to

prevent the build-up of ice on interior panels. In the unlikely event of an ice

build-up; switch off the unit and allow several hours for the ice to melt; w

restart the unit.

ipe the

inside of the unit with an absorbent cloth and dry; then

Controls

The thermostat control is situated inside the cabinet on the back panel.

Refrigeration is switched on and off at the mains supply. The light is controlled

independently by using the toggle switch provided at the front of the unit.

Warning: If the supply cord is damaged, the manufacturer, its service agent or

similarly qualified person must replace it, in order to avoid a hazard.

Electronic Thermostat Control

To set the desired temperature:

Press the button (the current set temperature is now displayed).

Then press the or button to modify the displayed value.

Finally press the button to store the value and exit the adjustment. If no

more buttons are pressed within 10 seconds then the display will once more

show the current internal temperature of the unit.

04

Routine Maintenance

Wipe clean the inside of the cabinet once a week using a damp cloth. It is

recommended that the condenser is cleaned free of dirt and grime

approximately every 6 months. The condenser is accessed from the rear of the

machine and is the silver coloured object with metal ‘fins’ situated under the fan

on the refrigeration components deck. Failure to keep the condenser clean will

reduce the refrigeration performance of the unit.

Repairs

Warning: Ensure unit is switched off at the mains before attempting the

following maintenance and repair procedures.

Lamp Replacement:

"Open the front door and remove the lamp cover. This is achieved by

slightly compressing the cover and lowering from its holder.

"Twist the lamp from its socket and remove from the cabinet.

"Reverse the procedure to fit new lamp.

Starter replacement:

"Open the front door.

"Starter is located at top right hand corner of inner cabinet. Twist

anti-clockwise to remove.

"Twist new starter clockwise into position.

End of life disposal

This unit contains fluorinated greenhouse gas HFC-134a regulated by the

Kyoto protocol, the warming potential of which is 1300, and therefore must be

disposed of responsibly.

05

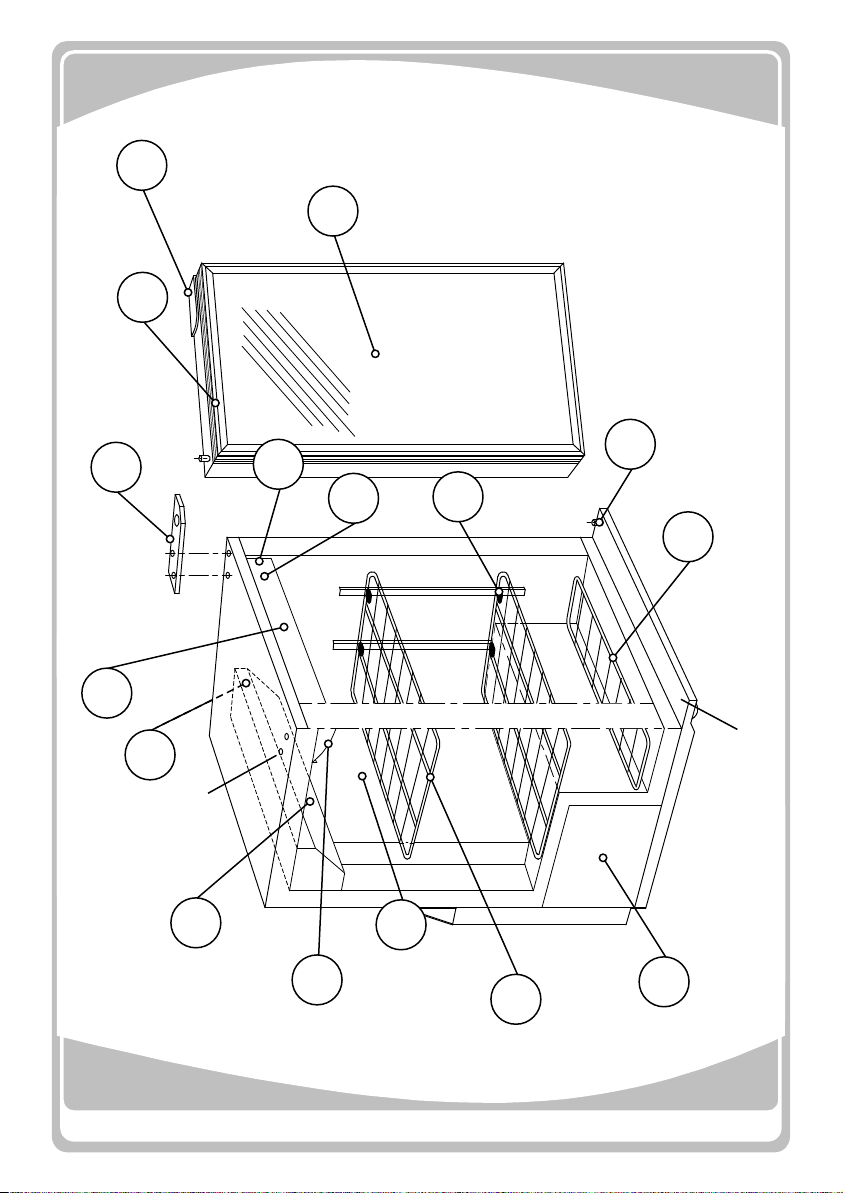

To Order Spares

"Find out the 'Diagram Number' of the spare(s)

wanted from the exploded diagram below.

"Refer to the parts Identification list (right) and find

the Description' of the spare(s).

"Find out the 'Serial Number' & 'Variant Number' of

your unit. These are shown on the serial label (a

metallic label located on the inside left wall of the

cabinet) and repeated on the front of this guide.

"Telephone our Sales Department on 01666 502641

with this information.

Spares Policy

The recommended spares for this unit are indicated in the

diagram below. These parts will be made available for a

period not less than five years after a machine has ceased to

be produced or a change has been introduced. Where a

change of part results in a lack of interchangeability, the old

part will continue to be available for five years. Where a

change of part or assembly of parts retains

interchangeability, the company reserves the right to supply

the new part or assembly only.

Description

1 Door seal

2 Evaporator Fan

3 Light Tube

4 Thermostat

5 Lamp Starter

6 Door handle

7 Evaporator

8 Light Diffuser

9 Shelf clip

10 Door bush

11 Door black metal Right

12 Hinge plate

13 Shelf

14 Light Switch

15 Bottom Shelf

Diagram Number

16 Condenser & Fan,

Compressor,

Condensate Pot,

Drier, Choke

06

16

13

8

7

2

4

12

16

3

10

5

14

9

11

Blanking

Plugs

Left Hand Hinge Point

Standard Hinge Point

Top

Hinge

Plate

15 Not all Models

07

Wiring Diagram Popular & Premier single units

Compressor

Evaporator Fan

Cabinet base earth stud (P.E.)

Condenser Fan

Thermostat

Light switch

Fluorescent light tube

Mains lead

Choke

Starter

Drawing Not to scale

Wires drawn green are

green with yellow tracer

Wires drawn grey are

actually white

Green Yellow

Blue

Blue

Blue

Red

Red

Brown

Brown Brown

Brown

Yellow

Yellow

Yellow Yellow

Orange

Black

Black

Orange

Yellow

Yellow

WhiteWhite

Thermostat probe

Green Yellow

Red

Blue

Brown

Brown

Green Yellow

Green

Yellow

L

N

Blue

Red

Blue

Brown

Blue

Yell

Blue

Brown x3

Red

Blue

Brown

Blue

08

Wiring Diagram Ecochill single units

Evaporator Fan

Cabinet base earth stud (P.E.)

Condenser Fan

Thermostat

Light switch

Fluorescent light tube

Mains lead

Choke

Starter

Drawing Not to scale

Wires drawn green are

green with yellow tracer

Wires drawn grey are

actually white

Blue

Blue

Red

Brown

Brown Brown

Brown

Yellow

Yellow

Yellow Yellow

Orange

Black

Black

Orange

Yellow

Yellow

WhiteWhite

Thermostat probe

Green Yellow

Red Red

Blue

Brown

Brown

Blue

Brown

Green Yellow

Green

Yellow

L

N

Blue

Brown

Blue

Yell

Blue

Brown x3

Red

Blue

Brown

Blue

Compressor

Compressor Speed Controller

Relay

09

Notes

10

Notes

Autonumis Ltd, Cirencester Rd,

Tetbury, Gloucestershire.

GL8 8SA United Kingdom

Tel +44 (0) 1666 502641

Fax +44 (0) 1666 504397

www.autonumis.com

Table of contents