System Operation Cycle Functions 5

RevC

• Working water pressure range is 20 to 120 psi (1.38 to 8.27 bar).In

Canada the acceptable working waterpressure range is20 to 100 psi

(1.38 to 6.89 bar).

• Use only regenerant salts designed forwater softening. Do not use ice

melting, block, or rock salts.

• Follow state andlocal codes for water testing.Do notuse waterthat is

microbiologically unsafe or of unknown quality.

• When filling media tank, do not open water valve completely. Filltank

slowly to prevent media from exiting the tank.

• When installing the water connection (bypass or manifold) connect to

the plumbing system first. Allow heated parts to cool and cemented

parts to set before installing any plastic parts. Do not get primer or

solvent on O-rings, nuts, or the valve.

System Operation Cycle Functions

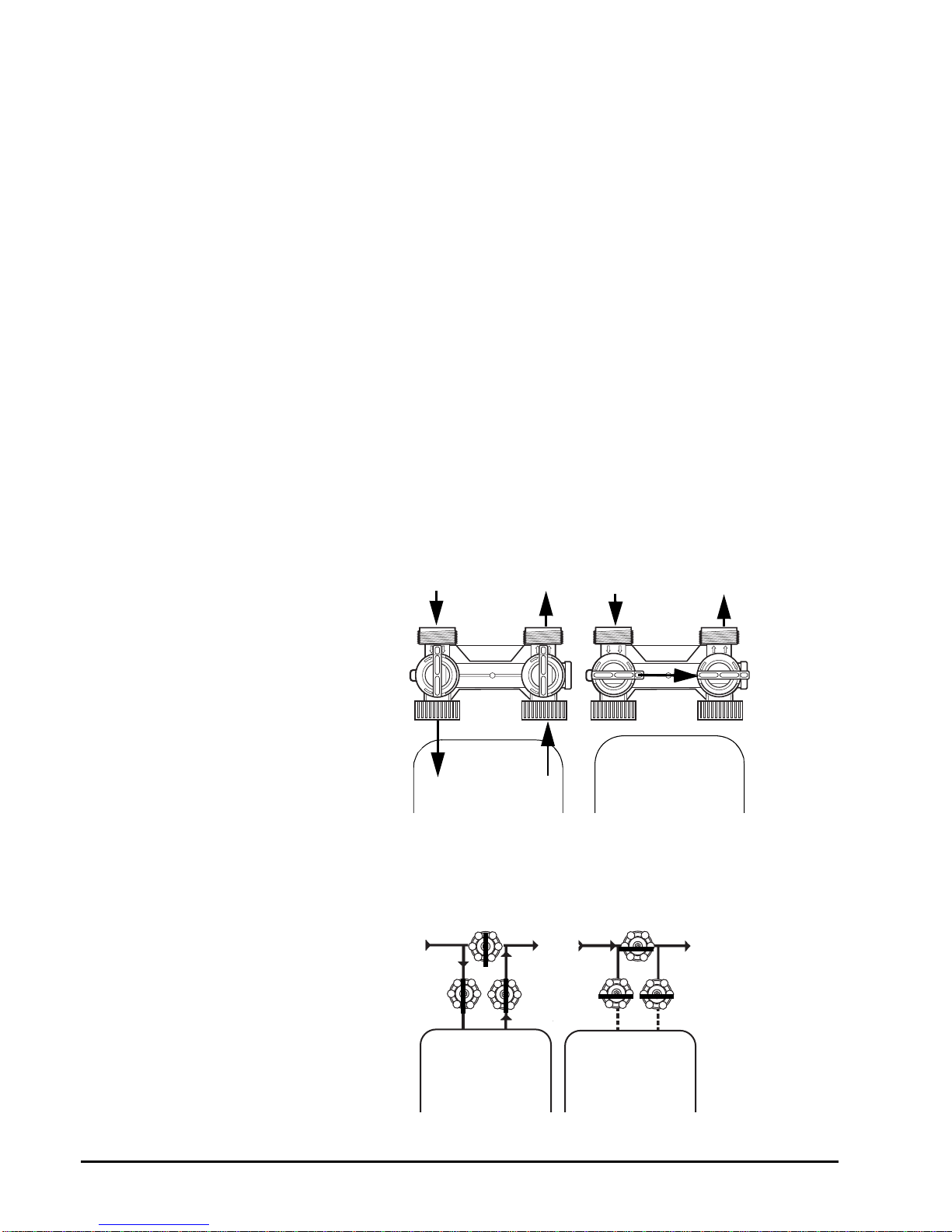

1. Service (Downflow)

Untreated water isdirected down through the resin bed and up

through the riser tube. The water is conditioned as it passes through

the resin bed.

2. Brine Refill

Water is directed down through the resin bed to the regenerant tank

at a controlled rate, to create brine for the nextregeneration.

3. Brine Preparation

The refill water is allowed to dissolve the salt and prepare brine.

4. Brine/Slow Rinse (Upflow)

The control directs water through the brine injector and brine is drawn

from the regenerant tank. The brine is then directed down the riser

tube up through the resin bed and up to the drain.The hardness ions

are displacedby sodium ions and are sent to the drain. The resin is

regenerated during thebrine cycle. Brine drawis completed when the

air check closes.

5. Repressurized Cycle (Hard Water Bypass Flapper Open)

This cycle allows the airand waterto hydraulically balancein the

valve before continuing the regeneration.

6. Backwash (Upflow)

The flow of water is reversed by the control valve and directed down

the riser tube and up through the resin bed. During the backwash

cycle,the bed is expandedand debris is flushed to the drain.

7. Fast Rinse (Downflow)

The control directs water down through the resin bed and up through

the risertube to the drain. Any remaining brine residual is rinsedfrom

the resin bed.