5

2.4. THEORY OF OPERATION

CRA Series STABILINE®Power Conditioners maintain

a constant regulated output AC voltage by simulating an

infinite number of taps, between two real taps, on the

input of an isolation transformer. This is accomplished

automatically by adjusting a POWERSTAT®Variable

Transformers connected between a boost tap and a

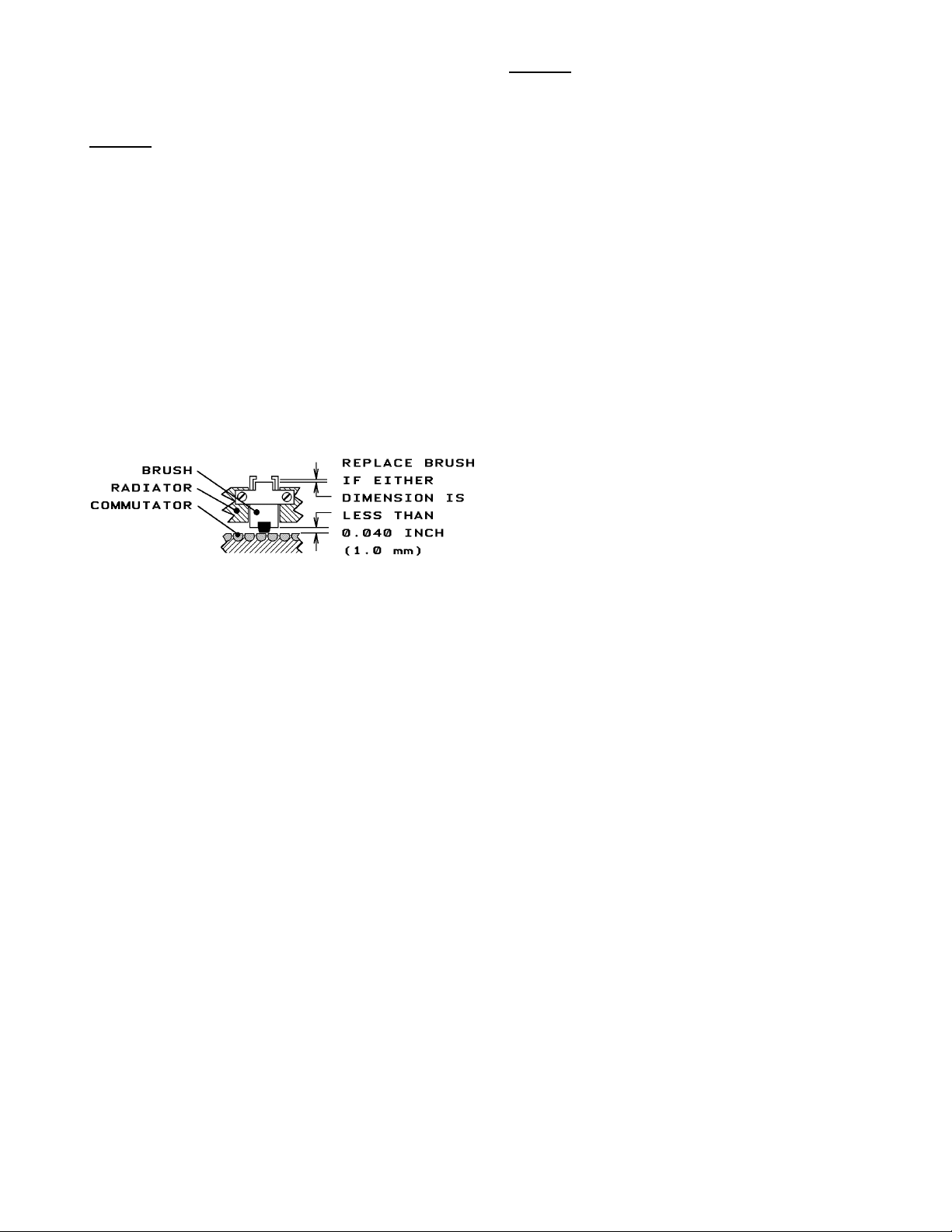

buck tap of the isolation transformer. Using the brush of

the POWERSTAT as the input point, the “input tap” and

thus the output voltage can be controlled with great

accuracy.

A solid-state control unit detects the output voltage and

continually compares it with output and accuracy

settings selected by the user. If the voltage is out of

specifications, the control unit drives the POWERSTAT

variable transformer, by means of a synchronous motor,

to the required new position.

These units attenuate transverse-mode (line-to-line)

transients by 60 dB (1,000 to 1). This is accomplished

with a low-pass filter that attenuates regardless of

where on the sine wave or in which direction the

transient is applied, and does not rely on an absolute

amplitude before attenuation occurs. Peak clipping

devices are also included to assist in handling larger

transients.

Voltage transformation and common-mode (line and

neutral to ground) noise attenuation of 120 dB

(1,000,000 to 1) is provided by the double shielded

isolation transformer. Shield 1 in the isolation

transformer should be connected to the secondary

ground and increases the common mode noise

rejection. Shield 2 is between the primary and the

grounded shield, need not be connected, and is used to

reduce the conversion of common mode input noise to

normal mode output noise.

3.0. INSTALLATION

3.1. TRANSPORTING THE POWER CONDITIONER

Due to its weight and size, proper lifting procedures

must be followed when transporting the unit and moving

it into the location where it is to be installed.

The proper method for moving these units is to place a

forklift under the base. A heavy frame is provided in this

area to allow lifting the unit in this manner without

damage. The 26 inch (559 mm) wide enclosures can

also be lifted by removing the top cover and using the

lifting eyes provided in the sides of the cabinet.

3.2. MECHANICAL INSTALLATION

The power conditioner is designed for floor mounting.

When mounting the unit, allow a minimum clearance of

4 inches (100 mm) behind the unit for proper ventilation.

All internal components and wiring connections are

accessible through the front panels. A 3 foot (1000 mm)

area in front of the unit should be kept clear for

installation and service.

3.3. ELECTRICAL INSTALLATION

All CRA Series Power Conditioners are designed to be

hard-wired to the input power and the load using copper

wire. When these units increase low input voltage to

give nominal output voltage, the input current is

substantially higher than the nominal input current.

Maximum rated input and output currents for each unit

are given in the enclosed rating charts. Select a wire

size that is adequate to carry the maximum rated

current as specified by local and national code

requirements.

The front panel(s) of the power conditioner must be

removed to allow access to the input and load

terminals. To remove a panel, use a screwdriver to

release the ¼ turn fasteners, which hold the front panel

in place, and lift the panel off the base. A full range of

knockouts is provided in the base and the rear panel of

the unit for wire entry and exit.

The location of the power connections varies depending

on the options provided. On units with an input circuit

breaker, input connections are made directly to the

circuit breaker. The input connection for other options or

no options varies. Input connections are labeled L1

and L2. Load connections are made directly to the

isolation transformer on units without any options.

These output connections are labeled X1 and X2.

Units that have output options (ex. ammeters) will not

have the output connections on the isolation

transformer. These output connections are labeled

T1 and T2.

The outputs of the CRA Series Power Conditioners are

floating (not referenced grounded). If the unit’s output is

to be grounded the installer must make the ground

connection to the proper terminal.

For optimum common mode noise attenuation, it is

usually best to ground the shield 1 connection and allow

shield 2 to float. The unit is shipped with shield 1

connected to X1. If the installation’s ground is on X1

this is fine. If the installation requires the ground on X2,

the shield 1 connection should also be moved from X1

to X2.

The safety ground terminals are a ground stud on the

cabinet wall, or a lug on the base, and must be

connected to a suitable earth ground to reduce the

chance of electrical shock.

4.0. START UP

Set the Output Voltage Range toggle switch on each

control module to the 120 volt position to turn on the

control. The Output Voltage Adjustment and the

Sensitivity potentiometers are set at the factory for a

nominal output voltage and approximately 2% accuracy,

and should not be readjusted until the power

conditioner is initially energized.