P. 2

Service Manual

Troubleshooting....................................................................................................................................................... 3

Part Testing ............................................................................................................................................................... 5

Controller Testing.................................................................................................................................................... 5

Evaporator Fan Motor Testing ............................................................................................................................. 5

Condenser Fan Motor Testing ............................................................................................................................. 5

Temperature Probes, Evaporator, Cabinet, Condenser ................................................................................ 5

Defrost Heater Element......................................................................................................................................... 6

Evaporator pan heat element .............................................................................................................................. 6

Drain line heater...................................................................................................................................................... 6

Door frame heater................................................................................................................................................... 6

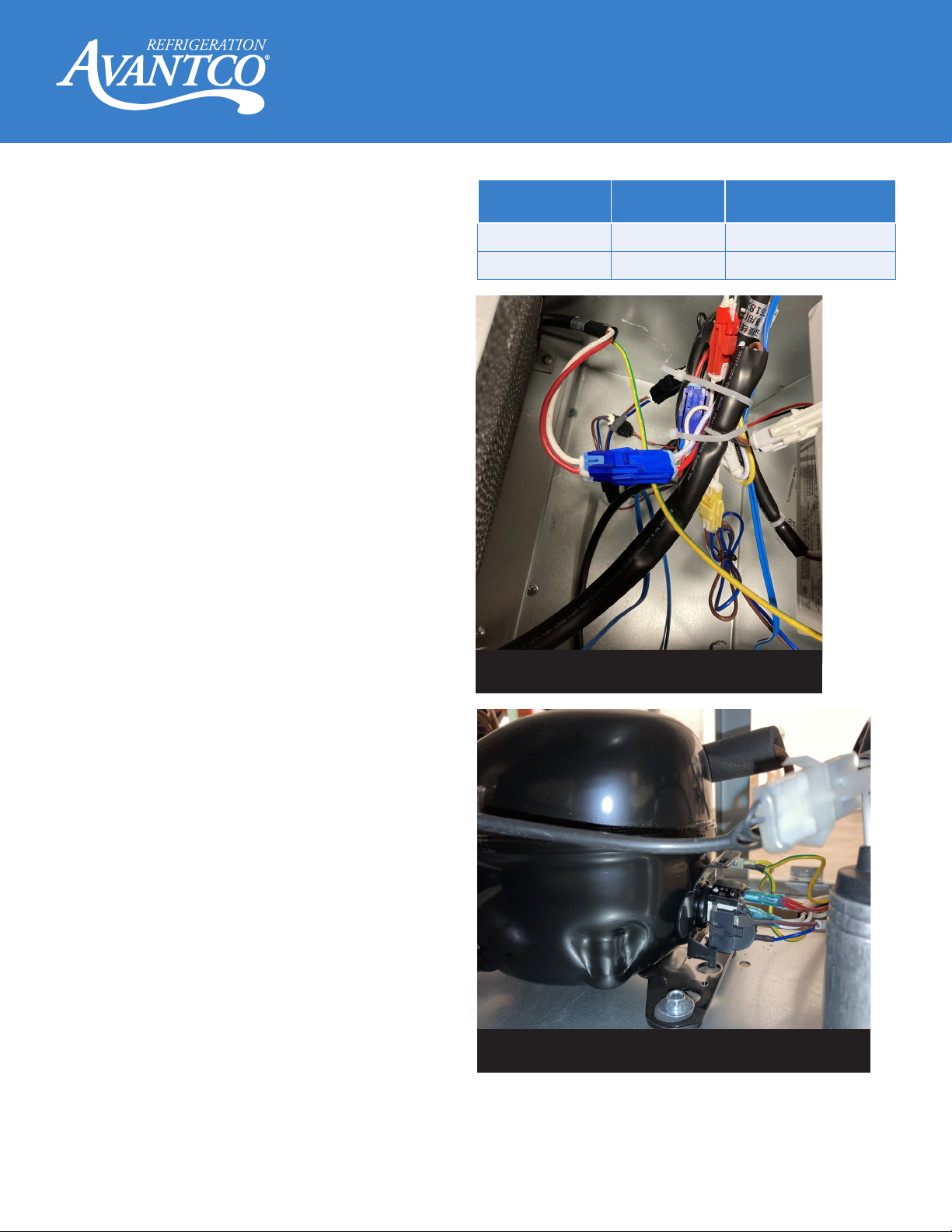

Compressor and Capacitor .................................................................................................................................. 7

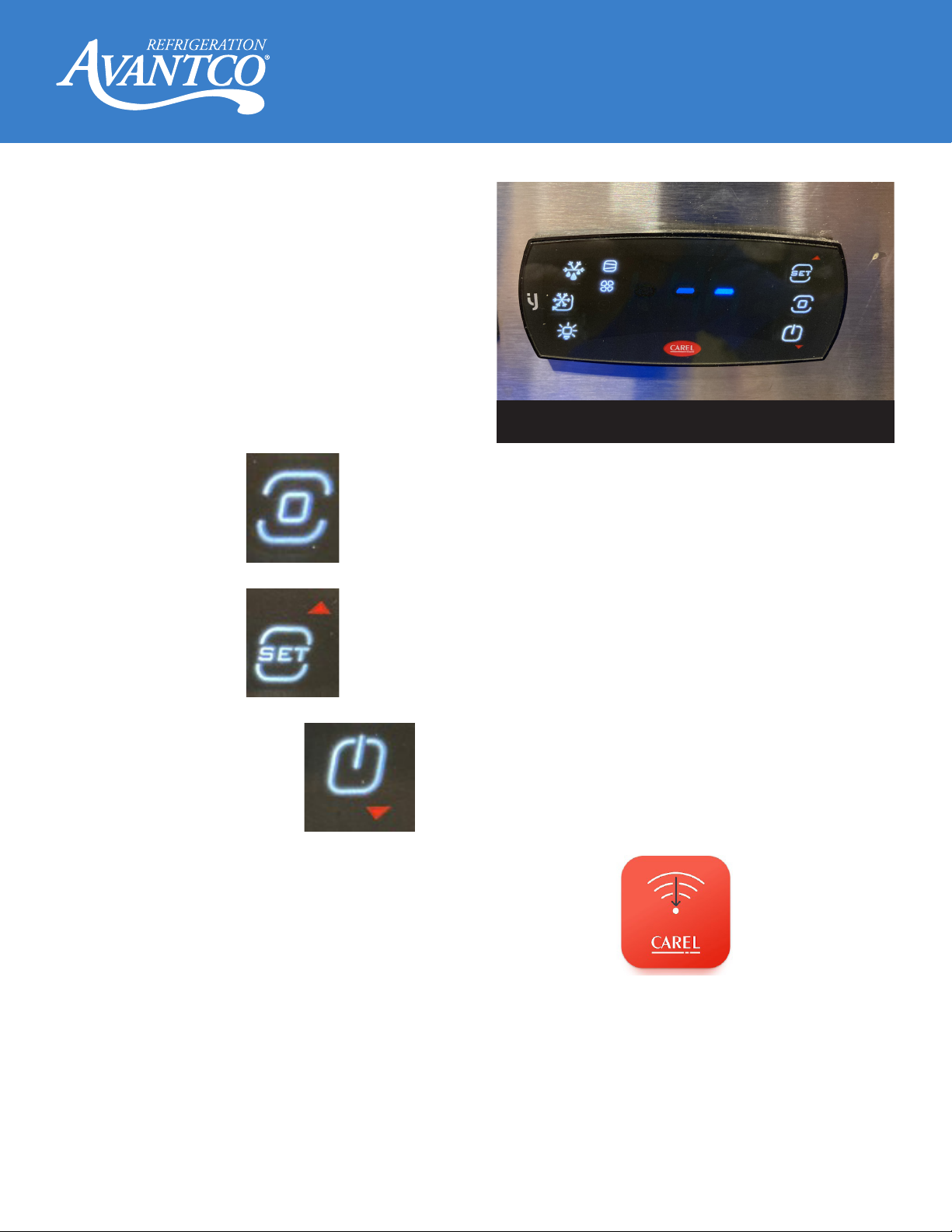

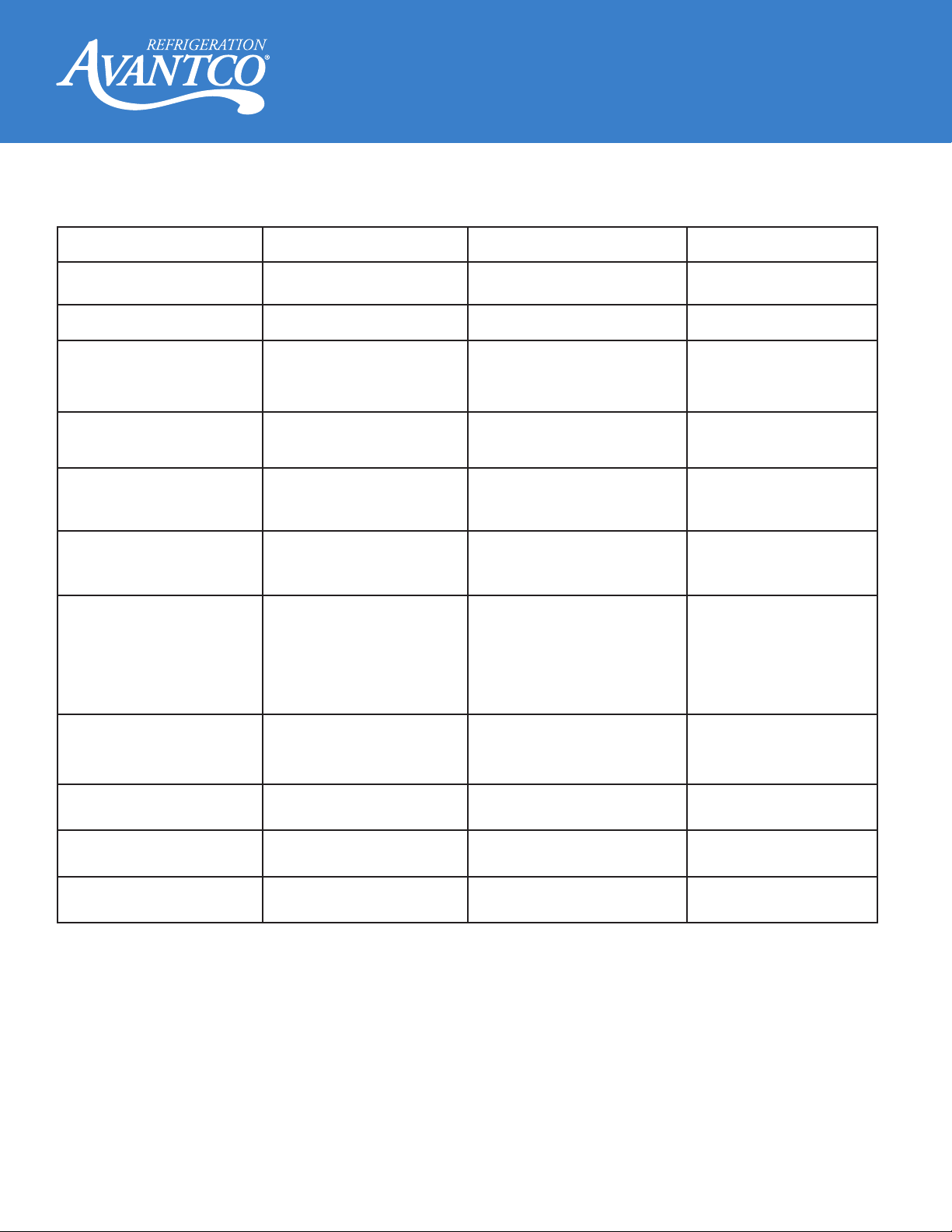

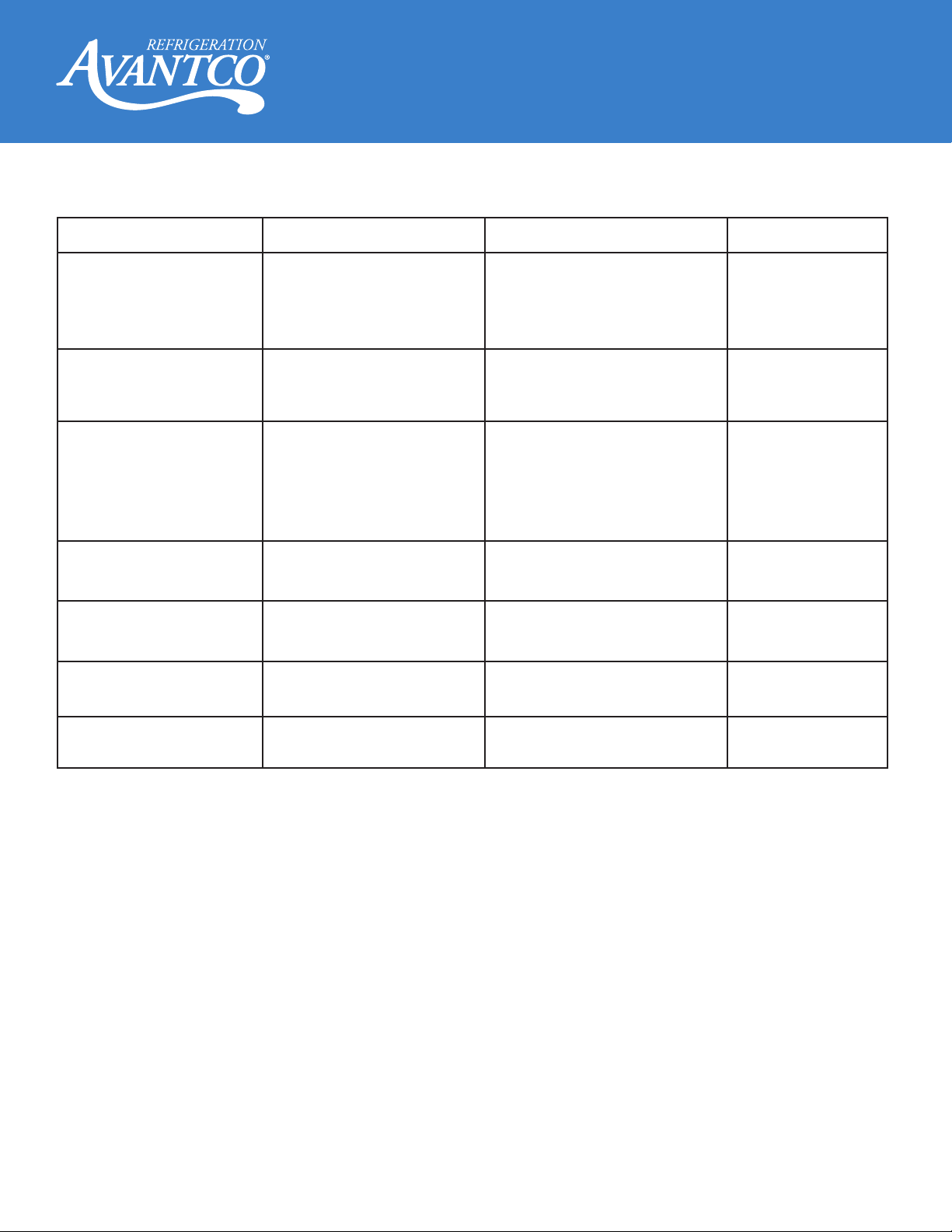

Temperature Controller Settings......................................................................................................................... 8

Part Repair................................................................................................................................................................. 11

Evaporator Parts ...................................................................................................................................................... 11

Evaporator Fan Blade ............................................................................................................................................ 11

Evaporator Fan Motor ............................................................................................................................................ 11

Cabinet Temperature Sensor............................................................................................................................... 12

Evaporator Coil ........................................................................................................................................................ 12

Condenser Parts...................................................................................................................................................... 13

Condenser coil......................................................................................................................................................... 13

Condenser Fan Blade ............................................................................................................................................ 13

Condenser Fan Motor............................................................................................................................................ 13

Capacitor ................................................................................................................................................................... 14

Compressor .............................................................................................................................................................. 14

Filter Drier.................................................................................................................................................................. 14

Wire Diagram............................................................................................................................................................ 15

178Z1RHC............................................................................................................................................................. 15

178Z1RWMS ......................................................................................................................................................... 15

178Z2RHC............................................................................................................................................................ 16

178Z2RWMS........................................................................................................................................................ 16

Parts Diagram List ................................................................................................................................................... 17

178Z1RHC............................................................................................................................................................. 17

178Z1RWMS ......................................................................................................................................................... 17

178Z2RHC............................................................................................................................................................ 18

178Z2RWMS........................................................................................................................................................ 18