Avid Power ACSW212 User manual

15AMP CIRCULAR SAW

MODEL: ACSW212

1

TABLEOF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .....................................................P2

SAFETY PRECAUTIONS FOR CIRCULAR SAW.......................................P4

SPECIFICATIONS........................................................................................P7

FUNCTIONAL DESCRIPTION.....................................................................P8

OPERATING PROCEDURES ......................................................................P8

MAINTENANCE...........................................................................................P11

TROUBLESHOOTING.................................................................................P12

PARTS LIST.................................................................................................P13

SCHEMATIC DRAWING ..............................................................................P14

2

IMPORTANT SAFETYINSTRUCTIONS

When using electric tools, machines or equipment, basic safety precautions

injury.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. WARNING

Read and understand all instructions. Failure to follow all instructions listed below may

2. WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

or fumes.

Keep bystanders, children and visitors away while operating a power tool. Distractions

can cause you to lose control.

3. ELECTRICAL SAFETY

Double insulated tools are equipped with a polarized plug (one blade is wider than the

a polarized outlet. Do not change the plug in any way. Double insulation eliminates the

need for the three wire grounded power cord and grounded power supply system.

Avoid body contact with grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked “W-A”or

“W”. These cords are rated for outdoor use and reduce the risk of electric shock.

4. PERSONAL SAFETY

Stay alert, watch what you are doing and use common sense when operating a

medication. A moment of inattention while operating power tools may result in serious

3

IMPORTANT SAFETYINSTRUCTIONS

personal injury.

Dress properly. Do not wear loose clothing or jewelry. Tie up long hair. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

Remove adjusting keys or switches before turning the tools on. A wrench or a key that

is left attached to a rotating part of the tools may result in personal injury.

balance enable better control of the tools in unexpected situation.

Use safety equipment. Always wear eye protection. Dust mask, Anti-skip safety shoes,

hard hat or hearing protection must be used in appropriate conditions.

5. TOOL USE AND CARE

Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

Do not force tool. Use the correct tools for your application. The correct tools will do

the job better and safer at the rate for which it is designed.

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing

accessories or storing the tool. Such preventive safety measures reduce the risk of

starting the tools accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

with sharp cutting edges are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts and any other

before using. Many accidents are caused by poorly maintained tools.

Only use accessories recommended by the manufacturer for your model. Accessories

that may be suitable for one tool, may become hazardous when used on another tool.

6. SERVICE

4

When servicing a tool, use only identical replacement parts. Follow instructions in

the maintenance section of the manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury.

7. HOLD TOOL BY INSULATED GRIPPING SURFACES WHEN PERFORMING AN

OPERATION WHERE THE CUTTING TOOL MAY CONTACT HIDDEN WIRING OR ITS

OWN CORD. CONTACT WITH A “LIVE” WIRE WILL MAKE EXPOSED METAL PARTS

OF THE TOOL “LIVE” AND SHOCK THE OPERATOR.

8.ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE FOR ITS

LENGTH.

Amps from Tool

Nameplate

Recommended Minimum Wire Gauge for Extension Cords

5.1-8 amps

8.1-12 amps

12.1-15 amps

16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

9. STAY ALERT.

tired.

DANGER! Keep hands away from cutting area and blade. Keep your second hand on

cut by the blade. Keep your body positioned to either side of the saw blade, but not

in line with the saw blade. Kickback could cause the saw to jump backwards. (See

Kickback.) Do not reach underneath the work. The guard can not protect you from the

blade below the work.

Check lower guard for proper closing before each use. Do not operate saw if lower

guard does not move freely and close instantly. Never clamp or tie the lower guard

the power to the saw disconnected, raise the lower guard with the Retracting Handle

and make sure it moves freely and does not touch the blade or any other part, in all

SAFETY PRECAUTIONSFOR CIRCULAR SAW

IMPORTANT SAFETYINSTRUCTIONS

5

angles and depths of cut.

spring are not operating properly, they must be serviced before use. Lower guard may

operate sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

and “Compound Cuts.” Raise lower guard by Retracting Handle. As soon as blade

enters the material, lower guard must be released. For all other sawing, the lower

guard should operate automatically.

Always observe that the lower guard is covering the blade before placing saw down on

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after

switch is released.

the work properly to minimize body exposure, blade binding, or loss of control. Use

vises, clamps, or other appropriate supports to securely hold the workpiece.

When ripping always use a rip fence or straight edge guide. This improves the

accuracy of cut and reduces the chance of blade binding.

Always use blades with correct size and shape (diamond vs. round) and arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically,

causing loss of control.

Never use damaged or incorrect blade washers or bolts. The blade washers and

bolt were specially designed for your saw, for optimum performance and safety of

operation.

pinched, bound, or misaligned saw blade, causing an uncontrolled saw to lift up and

out of the workpiece toward the operator. When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly

teeth at the back edge of the blade can dig into the top surface of the wood causing

the blade to climb out of the kerf and jump back toward the operator. Kickback is the

•

you to resist kickback forces. Kickback forces can be controlled by the operator, if

SAFETY PRECAUTIONSFOR CIRCULAR SAW

6

proper precautions are taken.

• When blade is binding, or when interrupting a cut for any reason, release the trigger

and hold the saw motionless in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work or pull the saw backward

actions to eliminate the cause of blade binding.

• When restarting a saw in the workpiece, center the saw blade in the kerf and check

or kickback from the work piece as the saw is restarted.

• Support large panels to minimize the risk of blade pinching and kickback. Large

panels tend to sag under their own weight. Supports must be placed under the

panel on both sides, near the line of cut and near the edge of the panel.

• Do not use dull or damaged blade. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding, and kickback.

• Blade depth and bevel adjusting locking levers must be tight and secure before

kickback.

•

areas. The protruding blade may cut objects that can cause kickback.

using the Circular Saw. Using personal safety devices reduce the risk for injury.

Always connect the Line Cord to a Ground protected electrical outlet.

product. Electromagnetic fields in close proximity to a heart pacemaker could

• Avoid operating power tools alone.

•

•

is also a good precaution. This inexpensive device is a good safety measure

because it prevents a sustained electrical shock.

•

SAFETY PRECAUTIONSFOR CIRCULAR SAW

properly grounded. Do not modify the power cord plug provided with the tool or

product. Never remove the grounding prong from the plug. Do not use the tool

Circular Saw

Includes:

1 saw blade

1 cutting guide

1 wrench

SPECIFICATIONS

SAFETY PRECAUTIONSFOR CIRCULAR SAW

8

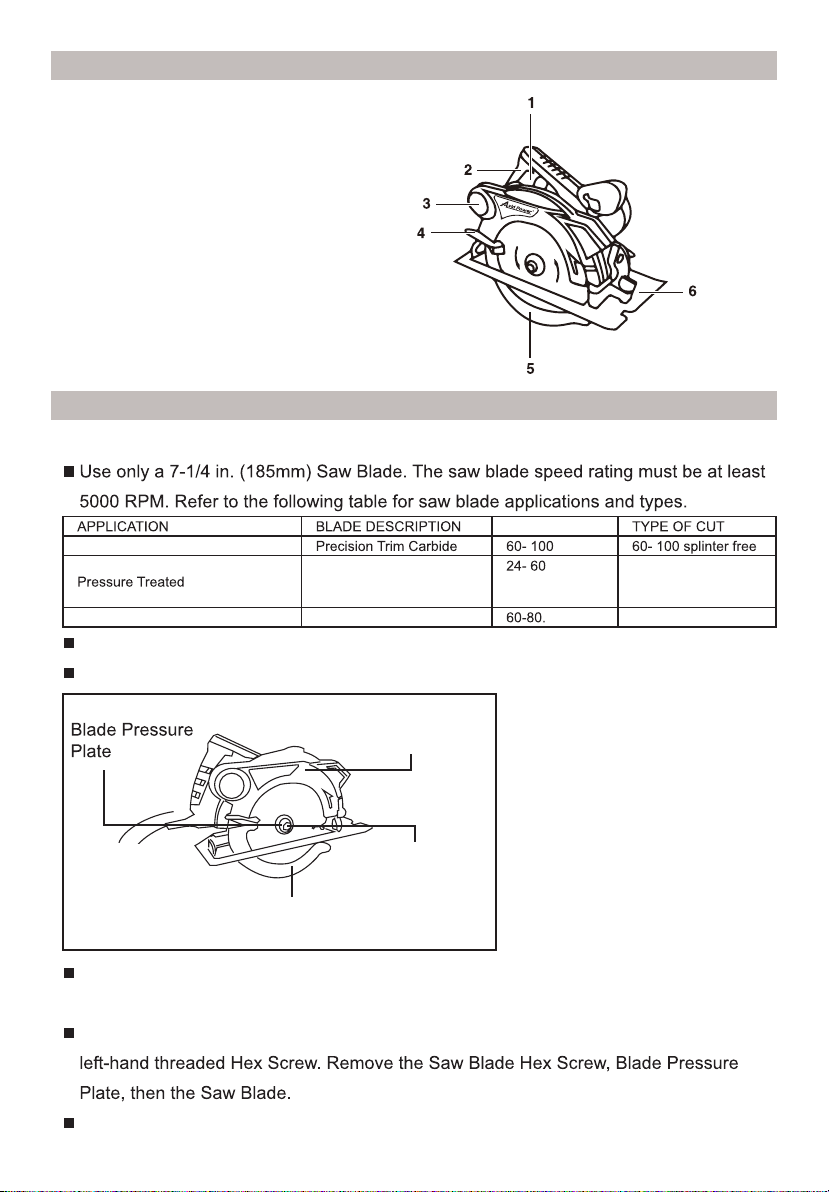

1. Switch trigger

2. Soft grip

3. Dust outlet

4. Spanner for blade guard

5. Blade guard

6. Base plate

Installing a Saw Blade

NO. OF TEETH

Fine Trim Molding

Trim, Framing.

Decking

Combination,

multi-purpose

Smooth, fast cut

Aluminum Non-ferrous metal cutting ······

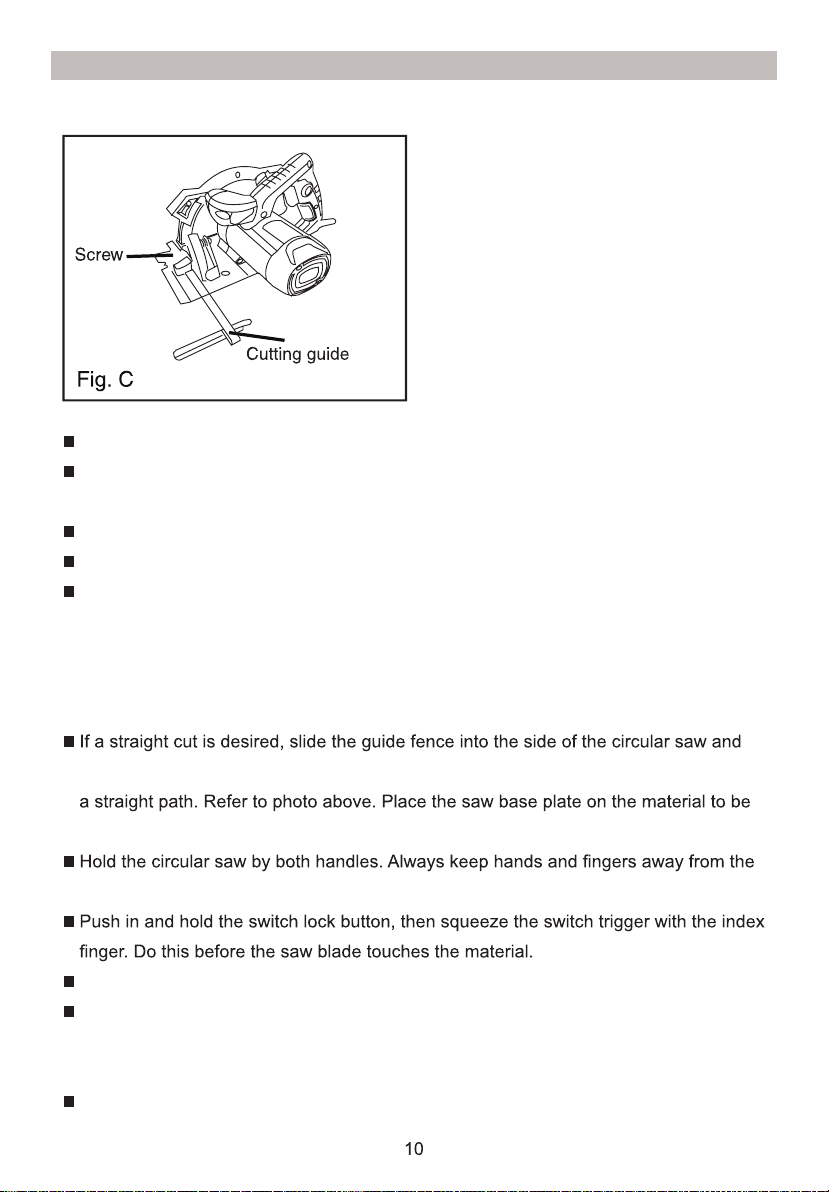

Unplug the Circular Saw Line Cord from the electrical outlet.

Raise the Blade Guard as far as possible. See the picture below.

Blade Guard

Blade Cover

Hex Screw

Hold the Blade Guard up and press the Spindle Lock Button with one hand. Rotate

the Saw Blade until the Spindle Lock catches and the blade stops.

Using the supplied Saw Blade wrench in the other hand, loosen Counter-clockwise the

Clean out Blade Cover of any debris.

FUNCTIONAL DESCRIPTION

OPERATING PROCEDURES

the saw blade should be pointing toward the back of the Circular Saw.

using the wrench with the other hand.

Adjusting the Saw Prior to Cutting

CAUTION: Always make sure the Power Cord is unplugged from its electrical

outlet prior to making any adjustments to the tool.

the lock valve to lock the base plate after confirming the angle.(Fig.A)

To adjust the depth of the cut, loosen depth lever and move base plate down (or up)

while observing the amount of saw blade exposed under base plate. Tighten the depth

lever to lock in new depth setting. (Fig. B)

OPERATING PROCEDURES

Push down

Lock Valve for

angle adjustment

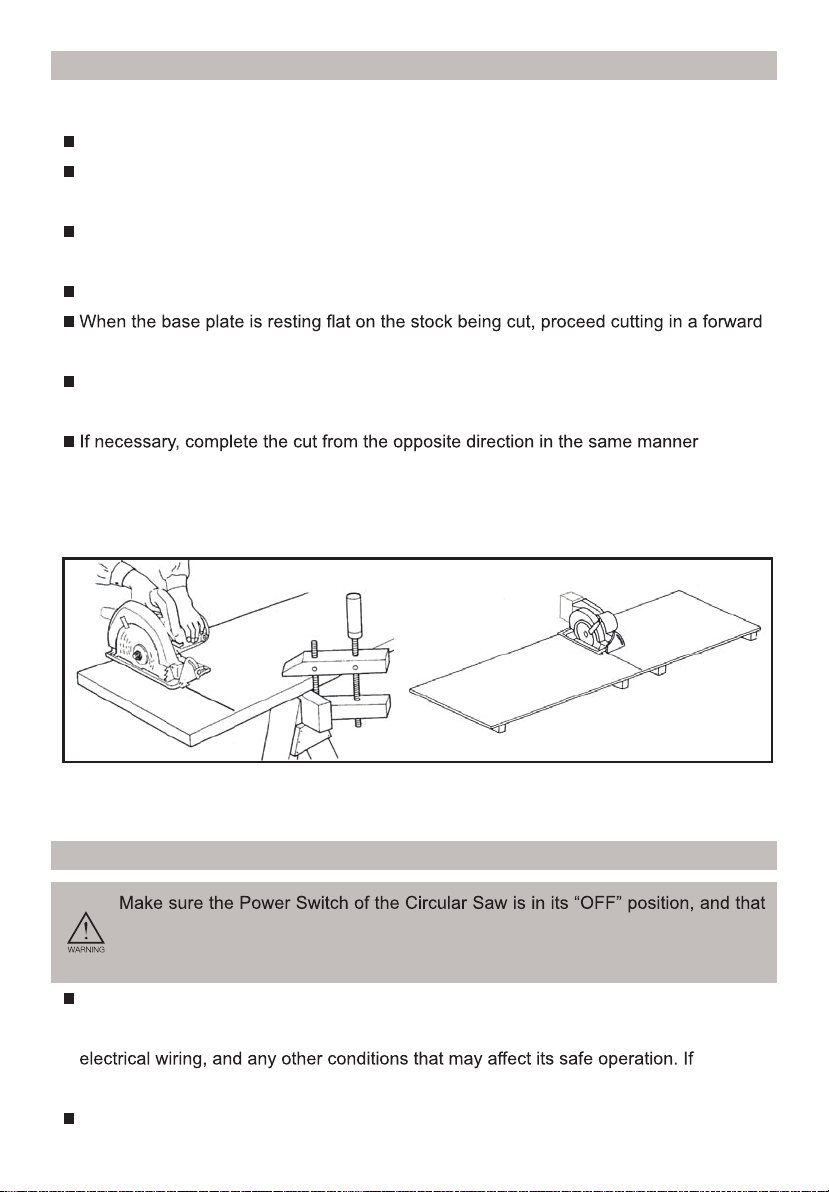

Prepare Material Before Cutting (Fig. C)

Support large panels to minimize risk of blade pinching and saw kickback.

Use the supplied guide fence when ripping material by sliding it into the base plate,

and tightening screw.

Securely clamp material to be cut to work bench.

Be cautious that Circular Saw does not cut into supports or workbench.

Use the appropriate type of blade for the material you are cutting.

General Cutting

Caution: Verify that Saw Blade is securely tightened and both angle and

height adjusting nuts and levers are tight. Read and understand all safety

precautions listed on this instruction manual.

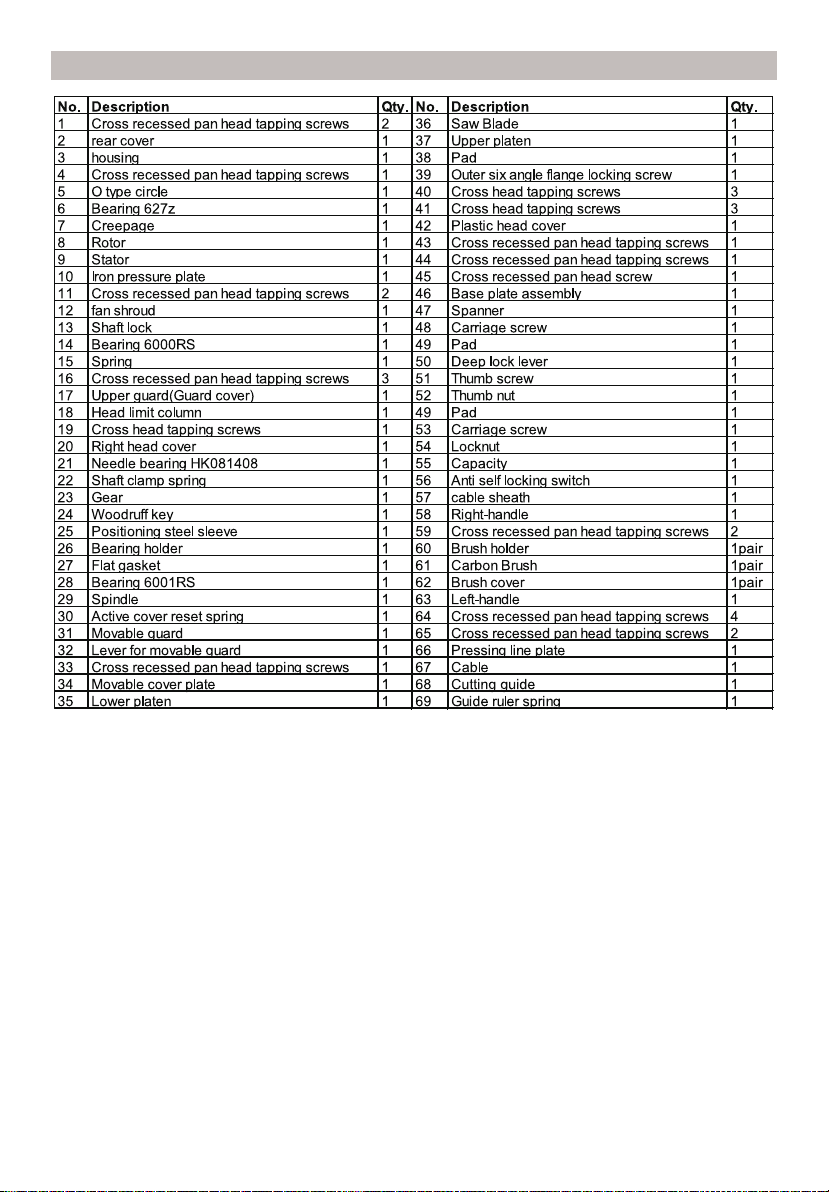

tighten with screw (65), or clamp a straight edge to the material to guide the saw on

cut. Align the front notch (right edge aligns with saw blade) on the cut line.

saw blade.

With the saw at full speed, move the saw slowly forward to complete the cut.

When the cut is completed, release the switch trigger. Do not set the saw down until

the blade stops turning.

Pocket Cuts

Tilt the saw forward with the cutting guide notch of the base plate on the line drawn for

OPERATING PROCEDURES

11

the cut.

Raise the blade guard with the blade guard lever.

With the saw blade just above the material to be cut, start the saw and allow the saw

blade to come to full speed.

Gradually lower the saw blade onto the stock using the front end of the base plate as

a pivot point.

When the cutting begins, release the blade guard.

direction to the end of the cut.

When the cut is completed, release the switch trigger and wait for the saw blade to

come to a stop before lifting the saw out of the cut.

described above.

Caution: Never pull the saw backwards since the saw blade will climb out of the

cut and kickback will occur.

the tool is unplugged from its electrical outlet, before performing any inspection,

maintenance, or cleaning procedures.

Before each use, inspect the general condition of the circular saw. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, damaged

abnormal noise or vibration occurs, have the problem corrected before further use.

Before remounting the saw blade, remove all sawdust that has accumulated around

MAINTENANCE

OPERATING PROCEDURES

12

the safety guard.

Regularly inspect and tighten all mounting screws and knobs.

Keep saw blade clean and sharp. Sharp blades minimize stalling and kickback.

Keep guards in good working order.

Keep motor air vent clean of dust and debris. Clean periodically.

using it immediately and get it repaired.

Clean tool with a damp cloth and light detergent. Do not use solvents as they can

damage and crack the plastic parts.

Replacing the Carbon Brushes

Unscrew the Carbon Brush Covers.

worn more than half way down, replace them. Sometimes they are just dirty. They can be

cleaned using an ink eraser.

Replace the carbon brushes and covers.

Symptom Possible Cause Remedy

Saw does not start when trigger

is pulled.

1. No power to line cord. 1. Check electrical

outlet for power.

2. Switch Lock Button not

pushed in while pulling while pulling

trigger.

3. Defective switch. 3. Replace switch.

4. Carbon brushes dirty or

worn down.

4. Clean or

replace carbon

brushes.

While cutting, saw slows down. Carbon brushes dirty or

worn down.

Clean or replace

carbon brushes.

Saw blade slips while cutting. Hex Screw (42) loose. Securely tighten

Hex Screw (42)

not open easily.

Debris buildup in the Blade

Cover(11).

Remove Saw

Blade and clean

out Blade Cover

(11).

Wood burns or smokes while

being cut. Saw Blade dull.

Sharpen or

replace Saw

Blade,

TROUBLESHOOTING

MAINTENANCE

13

PARTS LIST

14

SCHEMATIC DRAWING

Table of contents