Cutting Disc (fitted)

Metal Cut-off Saw

Hex Key

4. Remove the cutting disc

bolt, washer and outer

ange.

5. Cleananygrindingdustfromtheinnerangeand,

after checking that it is in good condition, mount a new

cutting disc onto the spindle.

6. Replacetheouterange,washerandcuttingdiscbolt.

7. Whilst holding the spindle lock

button use the hex key to tighten

the cutting disc bolt in a clockwise

direction.

8. Turn the new cutting disc by

hand, ensuring that it rotates fully

and does not vibrate or oscillate

excessively.

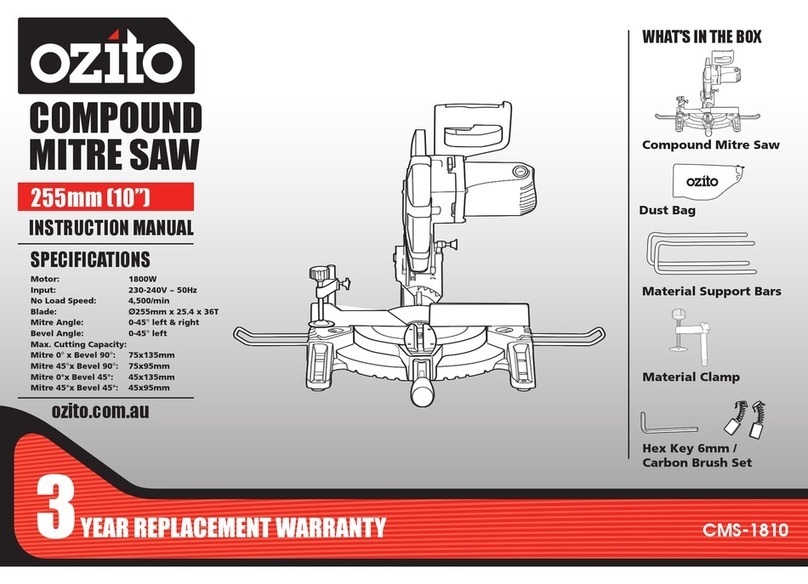

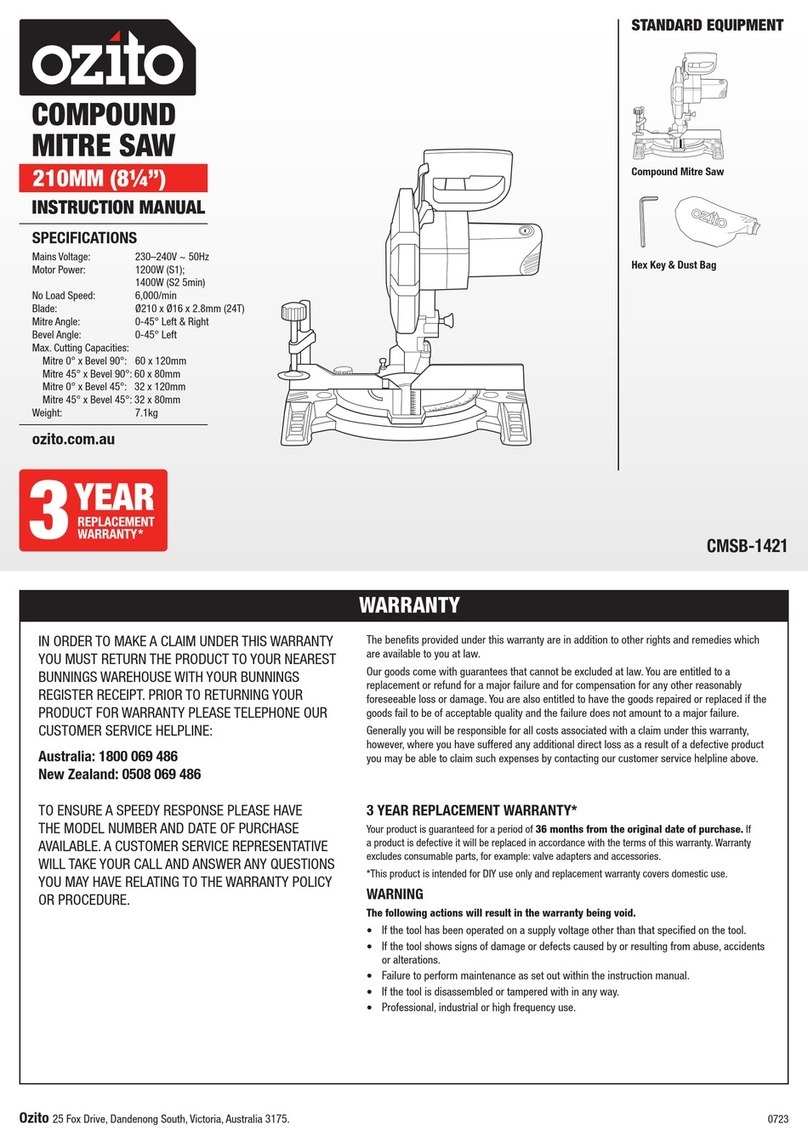

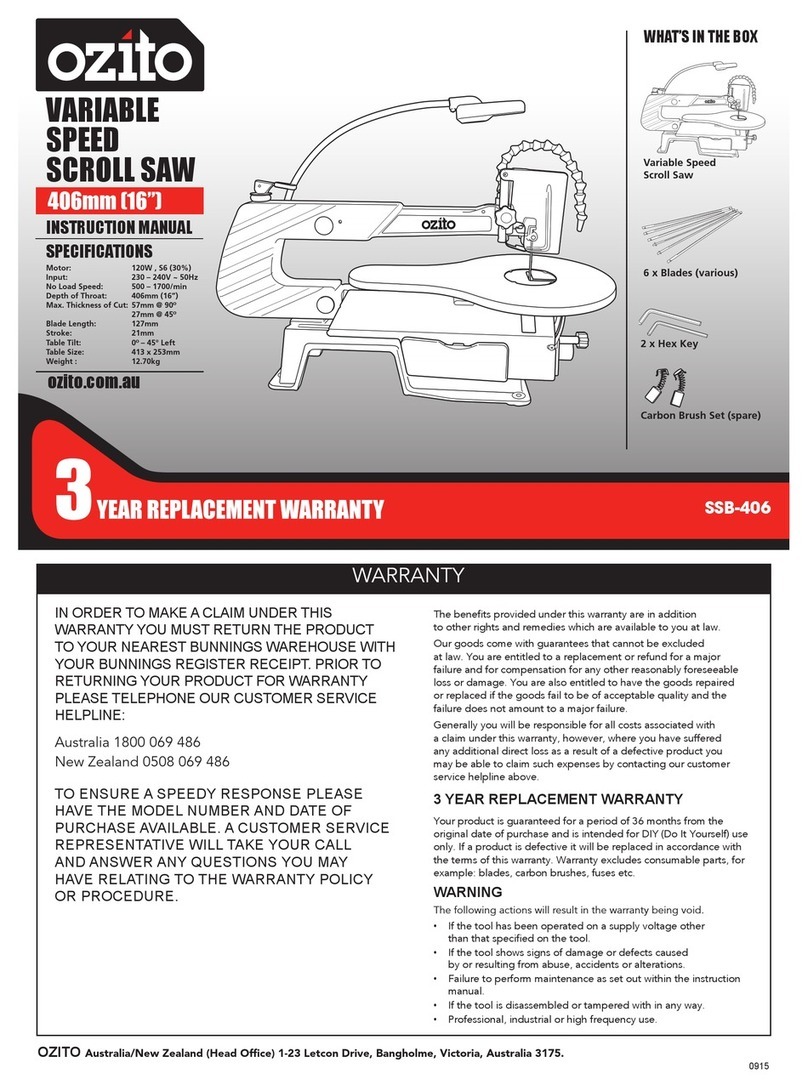

METAL

CUT-OFF SAW

2300W

ORIGINAL INSTRUCTIONS

SPECIFICATIONS

Motor: 2300W

Input: 220

–

240V~50Hz

No Load Speed: 4,000/min

Cutting Disc

Max. Diameter: 355 x 3.2mm

Arbour Size: 25.4mm

Cutting Angle Capacity: -15º to 45º

Max. Cutting Capacities: Round steel 130mm

Square steel 120mm

Rectangle steel 120x130mm

Weight: 16.8kg

MCS-2355U

WHAT’S IN THE BOX

MAINTENANCE DESCRIPTION OF SYMBOLS

WARRANTY

SPARE PARTS

ozito-diy.co.uk

responsible person to ensure that they can use the appliance safely.

WARNING!

Ensure the guard is in the

maximum cutting disc covering position over the workpiece. Do not use the cutting off

grinders without guards in position.

cutting disc. It is important to position your body and the guard to minimize body exposure

from the possible fragments of a disintegrating cutting disc.

Cutting discs running over the rated speed

can disintegrate and cause injury.

This includes face shield,

safety goggles, dust mask and gloves.

Do not use a cutting

disc that may be damaged. Fragments from a cutting disc that disintegrates during

operation can cause serious injury or property damage.

Proper support of the workpiece is

important to keep the cut-off and over-hanging metal from falling and striking the operator.

Avoid bouncing the cutting disc or giving it rough treatment. If

the cutting disc is damaged due to misuse, it may develop cracks and disintegrate without

warning.

The cutting disc should have

marked speed equal to or greater than that marked on the machine. Read the operating

instructions supplied by the cutting disc manufacturer.

These blades are not intended

for this machine and could create loss of control during use or cause injury to persons and

damage to property.

Cutting wood and plastic could

cause them to burn due to friction heating.

Dust generated by cutting masonry will clog the motor

causing premature failure and thereby voiding the warranty.

Sparks from the motor

or cutting may ignite dust and fumes.

The dust generated when cutting magnesium is

highlyammableandmaybeexplosiveundercertainconditions.

Excessive accumulation of

powered metal inside the motor housing may cause electrical failures.

The wide vice opening and high pivot point provide cutting capacity for many large pieces. Use

the cutting capacity chart below to determine the maximum size of cuts that can be made with

a new wheel.

Capacity shown on the chart assumes no cutting disc wear and optimum fence position.

CUT-OFF SAW SAFETY WARNINGS

WARNING!

Read the whole manual carefully and make sure you know how to switch the tool off in an

emergency, before operating the tool.

Save these instructions and other documents supplied with this tool for future reference.

Before you connect the equipment to mains supply make sure that the data on the rating plate are

identical to the mains data.

This tool is double insulated therefore no earth wire is required.

Always use an approved extension lead suitable for the power input of this tool. Before use, inspect

the extension lead for signs of damage, wear and ageing. Replace the extension lead if damaged

or defective.

When using an extension lead on a reel, always unwind the lead completely. Use of an extension

lead not suitable for the power input of the tool or which is damaged or defective may result in a risk

ofreandelectricshock.

WARNING! Failure to follow the

warningsandinstructionsmayresultinelectricshock,reand/orseriousinjury.

a. . Cluttered or dark areas invite accidents.

b.

Power tools create sparks which may ignite the dust or fumes.

c. Distractions can cause

you to lose control.

a.

Unmodiedplugsand

matching outlets will reduce risk of electric shock.

b.

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c. Water entering a power tool will

increase the risk of electric shock.

d.

Damaged or entangled

cords increase the risk of electric shock.

e.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f.

Use of an RCD reduces the risk of electric shock.

3. Personal safety

a.

A moment of inattention while operating power tools may result in serious personal injury.

b. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c.

Carrying power

toolswithyourngerontheswitchorenergisingpowertoolsthathavetheswitchoninvites

accidents.

d.

A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e. This enables better control

of the power tool in unexpected situations.

f.

Loose clothes, jewellery or long hair can be caught in moving parts.

g.

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

a. The correct

power tool will do the job better and safer at the rate for which it was designed.

b. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c.

Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d.

Power tools are

dangerous in the hands of untrained users.

e.

Many accidents are caused by poorly maintained

power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g.

Use of the

power tool for operations different from those intended could result in a hazardous situation.

a.

This will ensure that the safety of the power tool is maintained.

b.

itsserviceagentorsimilarlyqualiedpersonsinordertoavoidahazard.

GENERAL POWER TOOL SAFETY WARNINGS

ELECTRICAL SAFETY

0217

5. REPLACING A DISC cont. 6. GENERAL MAINTENANCE

• Keeptheventilationslotsofthemetalcut-offsawcleanatalltimes

and prevent any foreign matter from entering.

• Ifthehousingofthemetalcut-offsawrequirescleaningdonotuse

solvents but a moist soft cloth only.

• Thegreaseinthegearboxwillrequirereplacement/replenishment

after extensive use of the saw. Please see a power tool repairer to

provide this service.

• Blowdustfromthesawthroughtherearventilationslotswith

compressed air periodically to ensure a dust free tool.

When the carbon brushes wear out, the metal

cut-offsawwillsparkand/orstop.Discontinue

use as soon as this happens.

They should be replaced prior to recommencing

use of the cut-off saw. Carbon brushes are

a wearing component of the cut-off saw and

therefore not covered under warranty.

Continuing to use the cut-off saw when carbon brushes need to be

replaced may cause permanent damage to the tool.

Carbon brushes will wear out after many uses but when the carbon

brushes need to be replaced take the cut-off saw to an electrician or

a power tool repairer for a quick and low cost replacement. Always

replace both carbon brushes at the same time.

Ozito Industries will not be responsible for any damage or

injuries caused by the repair of the cut-off saw by an unauthorised

person or by mishandling of the cut-off saw.

Transporting the tool

The head lock pin is located on the left side of motor arm to allow the

tool to be transported safely.

To store or transport

the tool, lower the main

handle and push in the

head lock pin.

To release the head lock

pin, push down on the

main handle and pull out

the head lock pin.

Thesawmotorheadarmistted

withahightensionspring.Keephand

pressure on the main handle and slowly

allow the saw head to raise. Cutting Capacity @ 90º

Round 130mm

Square 120mm

Rectangular 120 x 130mm

VHz

~

W

Protective Earthed

n

o

Volts Hertz

Alternating current Watts

/min Revolutions or

reciprocation per minute No load speed

Read instruction manual Wear hearing protection

Wear eye protection

Wear breathing protection

Disconnect from power supply

when performing maintenance

Do not use in raining

Note the rotating direction of the cutting disc!

Double insulation

Unit 9 Stadium Court, Wirral International Business Park, Plantation Road, Bromborough, Wirral, CH62 3QG

All of our products undergo strict quality checks to ensure that they reach

you in perfect condition. In the unlikely event that your device develops a

fault, please contact our service department at the address shown on this

guarantee card. You can also contact us by telephone using the customer

service number shown. Please note the following terms under which

guarantee claims can be made:

1. These warranty terms regulate additional warranty services, which the

manufacturer mentioned below promises to buyers of its new products

in addition to their statutory guarantee claims are not affected by this

guarantee. Our guarantee is free of charge to you.

2. The warranty services only covers defects due to material or

manufacturing faults on a product which you have bought from the

manufacturermentionedbelowarelimitedtoeithertherecticationofsaid

defects on the product or the replacement of the product, whichever we

prefer.

Please note that our devices are not designed for use in commercial, trade

or professional applications. A guarantee contract will not be created if the

device has been used by commercial, trade or industrial business or has

been exposed to similar stresses during the guarantee period.

3. The following are not covered by our guarantee:

- Damage to the device caused by a failure to follow the assembly

instructions or due to incorrect installation, a failure to follow the operating

instructions (for example connecting it to an incorrect mains voltage or

current type) or a failure to follow the maintenance and safety instructions

or by exposing the device to abnormal environmental conditions or by lack

of care and maintenance.

- Damage to the device caused by abuse or incorrect use (for example

overloading the device or the use or unapproved tools or accessories),

ingress of foreign bodies into the device (such as sand, stones or dust,

transport damage), the use of force or damage caused by external forces

(for example by dropping it).

- Damage to the device or parts of the device caused by normal or natural

wear or tear or by normal use of the device.

4. Your Product is guaranteed for a period of 36 months from the original

date of purchase and is intended for DIY (Do It Yourself) use only. Lithium

Ion batteries and chargers are covered by a 12 month warranty. Warranty

excludes consumable parts. Guarantee claims should be submitted

before the end of the guarantee period within two weeks of the defect

being noticed. No guarantee claims will be accepted after the end of the

guarantee period. The original guarantee period remains applicable to the

device even if repairs are carried out or parts are replaced. In such cases,

theworkperformedorpartsttedwillnotresultinanextensionofthe

guarantee period, and no new guarantee will become active for the work

performedorpartstted.Thisalsoappliesifanon-siteserviceisused.

INORDERTOMAKEACLAIMUNDERTHISWARRANTYYOUMUST

RETURNTHEPRODUCTTOTHEPLACEOFPURCHASEWITHYOUR

REGISTER RECEIPT.

Please refer to the restrictions of this warranty concerning wearing parts,

consumables and missing parts as set out in the service information in

these operating instructions.

CUSTOMERSERVICEHELPLINE

GB: 0151 294 4488

IRL: 1850 882711

Ozito-diy.co.uk