B&C Technologies EL-6 User manual

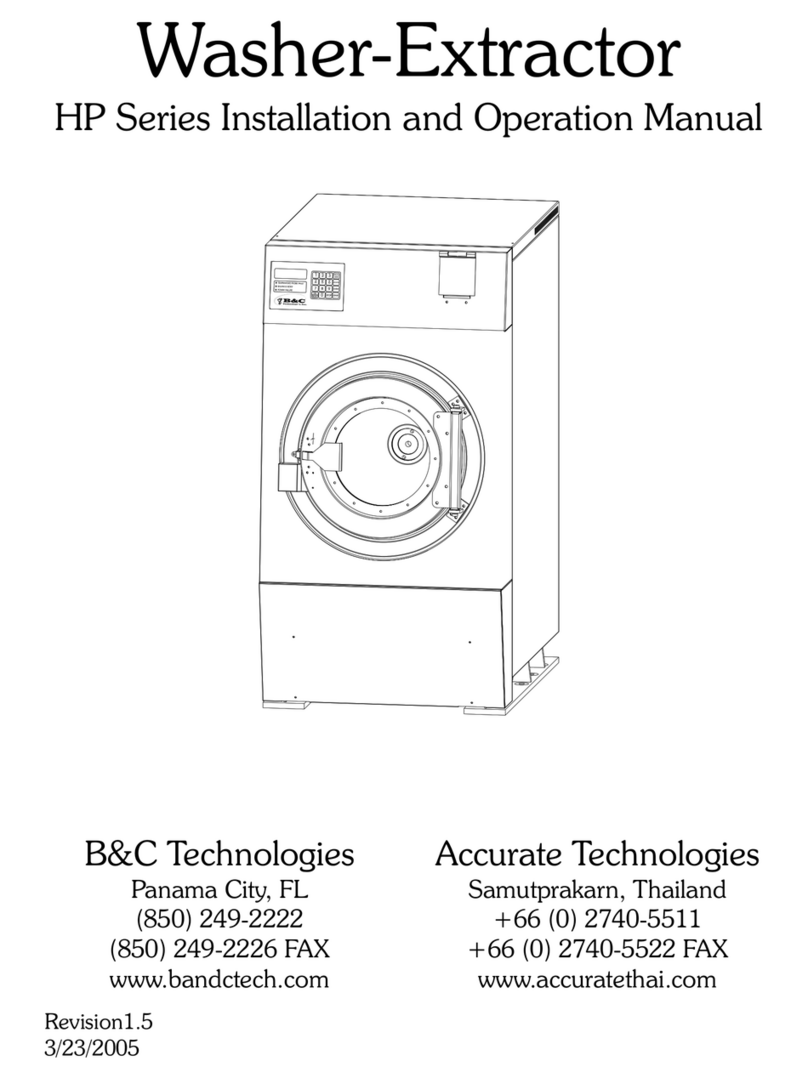

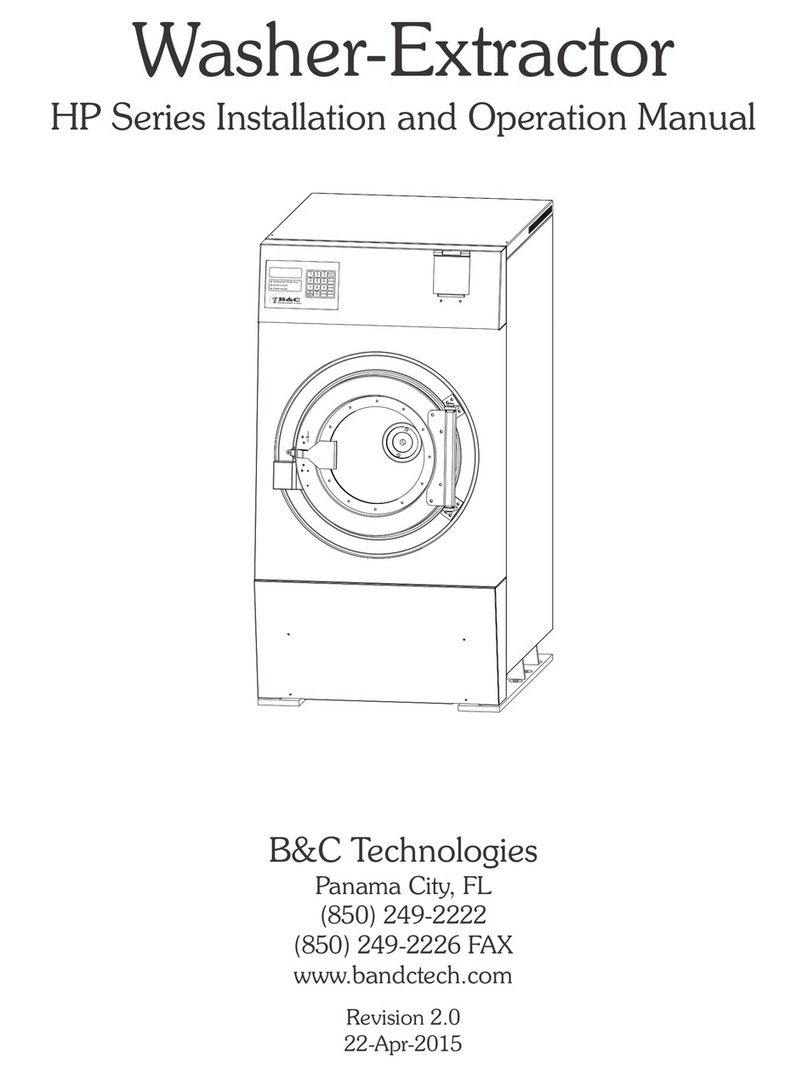

Washer-Extractor

EL-6 Computer Programming

and Operating Instructions

B&C Technologies

Panama City, FL

(850) 249-2222

(850) 249-2226 FAX

www.bandctech.com

Revision 2.1

8-Oct-2008

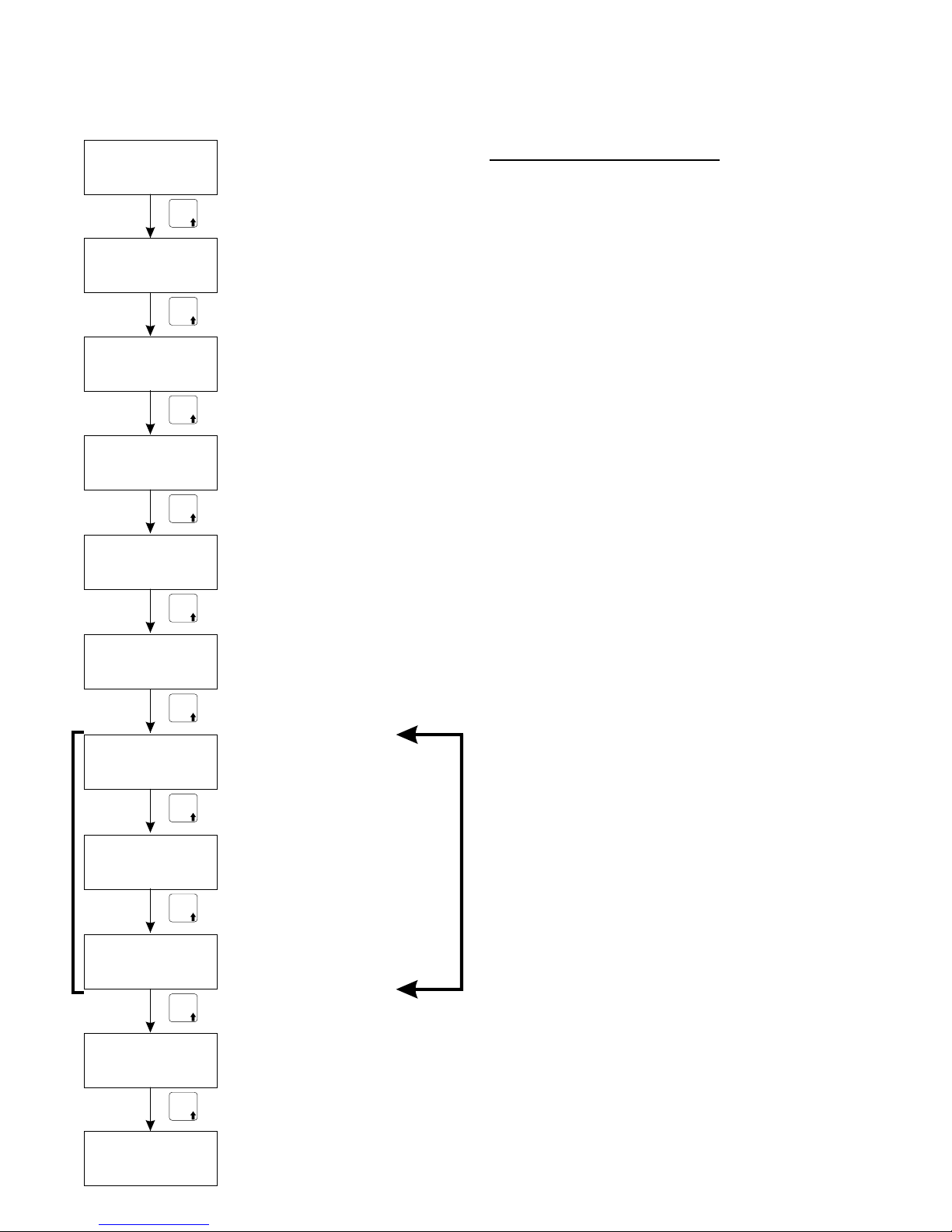

1 3

2

45 6

7 8 9

0

ENTER

PAUSE

INS

TEMP

DEC

LEVEL

INC

TIME

POWER FAILURE

BALANCE RETRY

TEMP PROBE FAULT

PN 230-004

ADVAN

DEL

RESET

PROGRAM N?

Table of Contents Introduction

Customer Service

Replacement Parts

Quick Reference

Safety Information

Key Symbols

Important Safety Information

Programming

Motor Programming

Motor Programming Flow Chart

Cycle Programming

Wash Program Creation

Wash Program Flowchart

Cycle Execution

Malfunction Alarms

Service Functions

Metric Conversion Chart

Centigrade to Fahrenheit

Centimeters to Inches

Blank Programming Chart

Water Level Guide

Speed Guide

Appendix A - Build a Heat Cycle

3

3

4

5

6

7

8

10

11

19

21

22

24

25

29

29

30

31

32

33

34

B&C Technologies

Panama City, FL

(850) 249-2222

(850) 249-2226 FAX

www.bandctech.com

Introduction

3

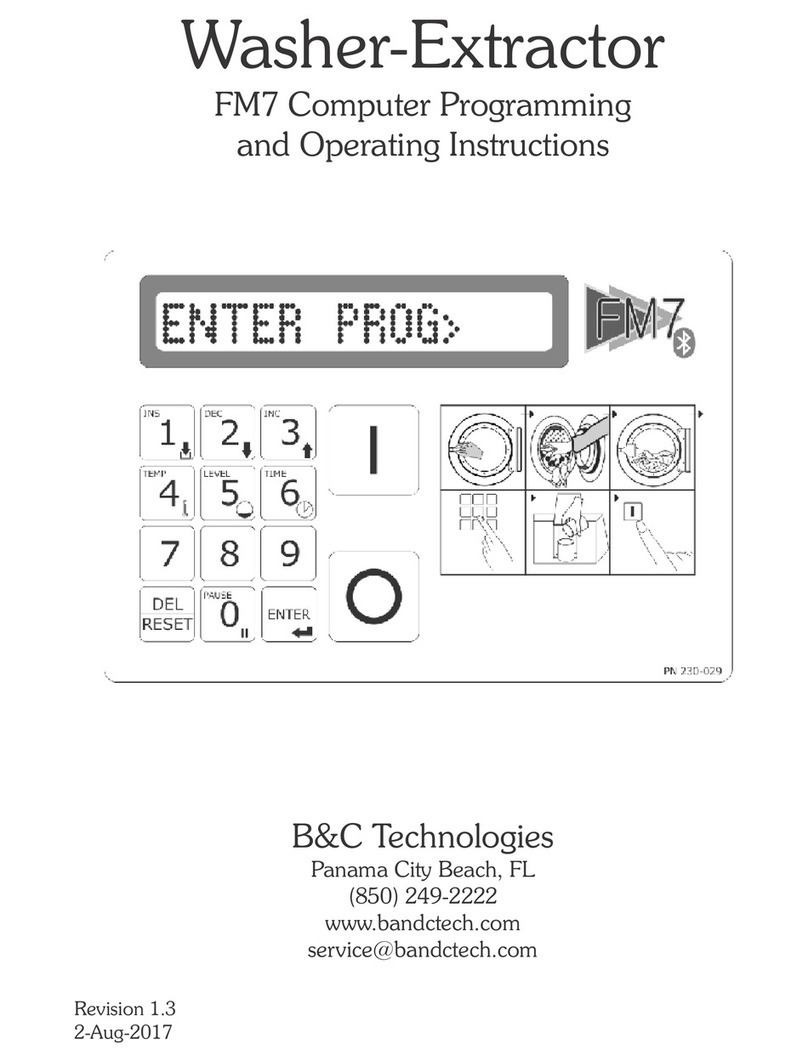

EL6 Computer

The EL-6 Computer is a powerful and

programable solid state controller. Up to 30

programs, each with up to 15 cycles can be

programmed. In addition, the EL-6 can display

5 languages - English, Italian, German, Spanish

and French. The water level can be

programmed, and is accurate to 1 cm (0.4 in).

Spin speeds are fully programmable in RPM.

In the event of power failure, the operator is

prompted to continue the cycle, or abort it.

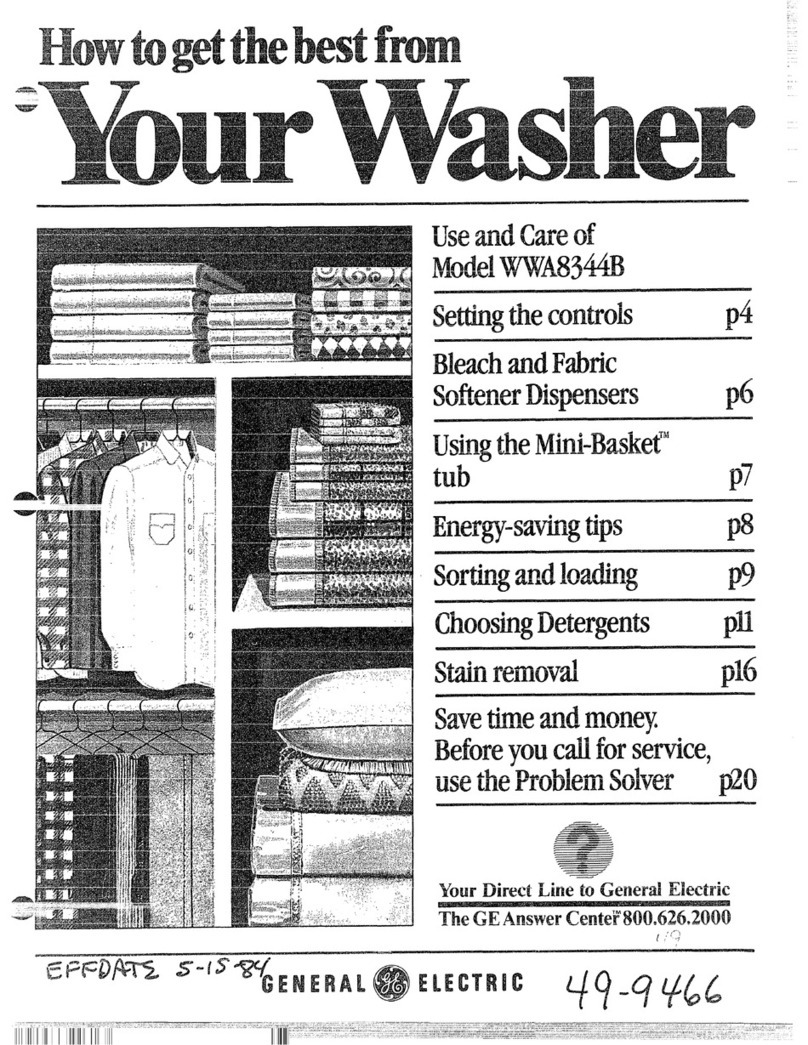

Keypad

7

8

9

DEL

RESET

Number key, Insert Key. Enables a new

cycle to be inserted in an existing program

during programming. During operation,

press and hold for cylinder RPM.

Number key, Decrement Key. Lowers the

current value during programming mode.

Number key, Increment Key. Raises the

current value during programming mode.

If pressed simultaneously with the TEMP or

LEVEL key, allows temporary

modification.

Number key, Temperature Key. Allows

temporary modification of the target

temperature if used with the INC and DEC

keys. Displays current temperature in wash

cylinder.

Number key, Level Key. Allows temporary

modification of the target water level if

used with the INC and DEC keys. Displays

current water level in wash cylinder.

Number key, Time Key. Displays the

watch dog timer value for the current step.

Number keys

Number key, Pause Key. If pressed during

operation, pauses the wash program

indefinitely. Not active during distribution

or spin.

Advances to the next program step.

During final spin, the remainder of the spin

is aborted. If pressed before starting a

program, it allows the operator to begin the

program at any segment. During

programing, skips to the next segment.

Confirms settings in creation and editing of

wash programs. During operation, shows

the current segment or program number.

Deletes any selection or setting.

Terminates the current activity (operation

or programming). While the machine is

powered but not executing a program, can

be pressed with RESET to see the current

firmware version.

Starts execution of the currently selected

wash program. Restarts a paused

program. When pressed with RESET,

function codes can be entered to program

and setup the machine. See the quick

reference list on the next page.

1

3

2

4

5

6

0

ENTER

PAUSE

INS

TEMP

DEC

LEVEL

INC

TIME

ADVAN

Quick Reference

4

To access this mode, press START and RESET together, then at the

prompt (n?), key in the desired number. Detailed explanation of each

function starts on page 25.

Highlighted items are safety related and SHOULD NOT BE

CHANGED!

DO NOT ALTER THESE VALUES WITHOUT CONSULTING B&C

TECHNOLOGIES OR A QUALIFIED TECHNICIAN!

12 Programming cycles

27 Creation of Programs

45 Programming motors

144 EL6 Win communications mode

118 Disable Machine (Display shows ! - exclamation point)

181 Resets controller - erases all memory

201 Language option (1 - Italian, 2 - English, 3 - German, 4 - Spanish, 5 - French)

205 16 or 24 outputs (B&C uses the 24 output version)

207 Maximum RPM

209 Temperature Hysterisis (min 1 deg, max 10 deg) Default is 3 deg.

210 Display temperature in degrees C

211 Display temperature in degrees F

212 Maximum water level that can be set (10 - 100 cm)

213 Minimum water level for heating (2 - 30 cm)

214 Display number of hours of operation

215 Display total number of washes

216 Display number of washes since the last maintenance

217 Reset maintenance request

218 Display and set number of washes until maintenance request

219 Spin slow down time (40 - 200 sec)

220 Erases Programs and cycles

221 Copy from control to memory card

222 Copy from memory card to control (only programs and cycles)

223 Copy from memory card to control (programs, cycles, and parameters)

225 Disables Advance Key

230 Maximum water level allowed during spin (2 - 60 cm)

P r o g r a mmi n g

S ys t em S e t u p

.

Anyone operation or servicing this machine must follow the safety rules in

this manual. Particular attention must be paid to the DANGER,

WARNING, and CAUTION blocks which appear throughout the manual

The lightening flash and arrowhead within the triangle is a

warning sign alerting you of the presence of dangerous

voltage.

The exclamation point within the triangle is a warning sign

alerting you of important instructions concerning the machine

and possible dangerous conditions.

This warning symbol alerts you to the presence of possible

dangerous drive mechanisms within the machine. Guards

should always be in place when the machine is in operation.

Be careful when servicing any drive mechanism.

This warning symbol indicates the presence of possibly

dangerous chemicals. Proper precautions should be taken

when handling corrosive or caustic material.

This warning symbol indicates the presence of hot surfaces

that could cause serious burns. Stainless steel and steam lines

can become extremely hot and should not be touched.

This warning symbol indicates the presence of possible

dangerous pinch-points. Moving mechanical parts can crush

an/or sever body parts.

Before servicing any equipment, make certain it is

disconnected from the electrical power source. Never allow

operation of the machine when any safety device is

malfunctioning. Never bypass safety devices.

Key Symbols

5

Important Safety Information

SAFETY CHECK LIST

Before Initial start up of a B&C washer –

extractor perform the following safety check:

A. Make sure all electrical and plumbing

connections have been made in

accordance with applicable codes and

regulations.

B. Make sure the machine is

grounded electrically.

C. Make sure the machine has

flexible water fill and drain

connections of the correct size,

length and type, with no kinks,

and that they are securely

attached and/or clamped.

D. Make sure any transport brackets have

been removed.

Before servicing any equipment, make certain it

is disconnected from the electrical power

source. Never allow operation of the machine

when any safety device is malfunctioning.

Never bypass safety devices.

6

Before machine is placed in operation, the door

safety interlock must be checked for proper

operation as follows:

A. When the washer is energized

electrically and in operation, the

loading door must be locked in

the closed position. Verify this by

attempting to open the loading

door when the machine is

operating. If necessary, check the

door safety interlock and sensors

for proper operation. Consult

the service manual, or call a

qualified service technician if

necessary.

B. When the washers loading door

is open, it should not be possible

to start the machine. Verify this

by attempting to start the washer

with the door open. Also, close

the door without locking it

and verify that it is not possible to

start the machine with the door

not locked. If necessary, check

the door lock sensors for proper

operation,. Consult the service

manual, or call a qualified

service technician. If additional

information is required, contact

your local distributor or call the

manufacturer of the machine.

Programming

Programming the EL-6 takes place on three

levels:

1. Programming motors (Function 45)

Allows 15 different agitation profiles to be

created. For each profile, the clockwise rotation

time, the counterclockwise rotation time and

the pause time can be programmed. (Factory

defaults are shown on page 9).

2. Programming cycles (Function 12)

Each grouping of steps creates a sequence of

events in which various functions can be

activated or deactivated (drain, cold fill, spin,

etc.). Going from one step to another requires

reaching a water level, temperature, or a time

value. There are five different programmable

cycle types: Prewash, Wash, Rinse, Spin and

Unroll (Shakeout). Each cycle can be assigned

a number between 1 and 99. (See the EL6

Stock Programs Listing for details on factory

settings).

3. Wash Programs Creation (Function 27)

Consists of putting the various cycles as

programmed above together to form a

complete wash program. Up to 30 programs

can be stored, each with 15 cycles. (See the

EL6 Stock Programs Listing for details on

factory settings).

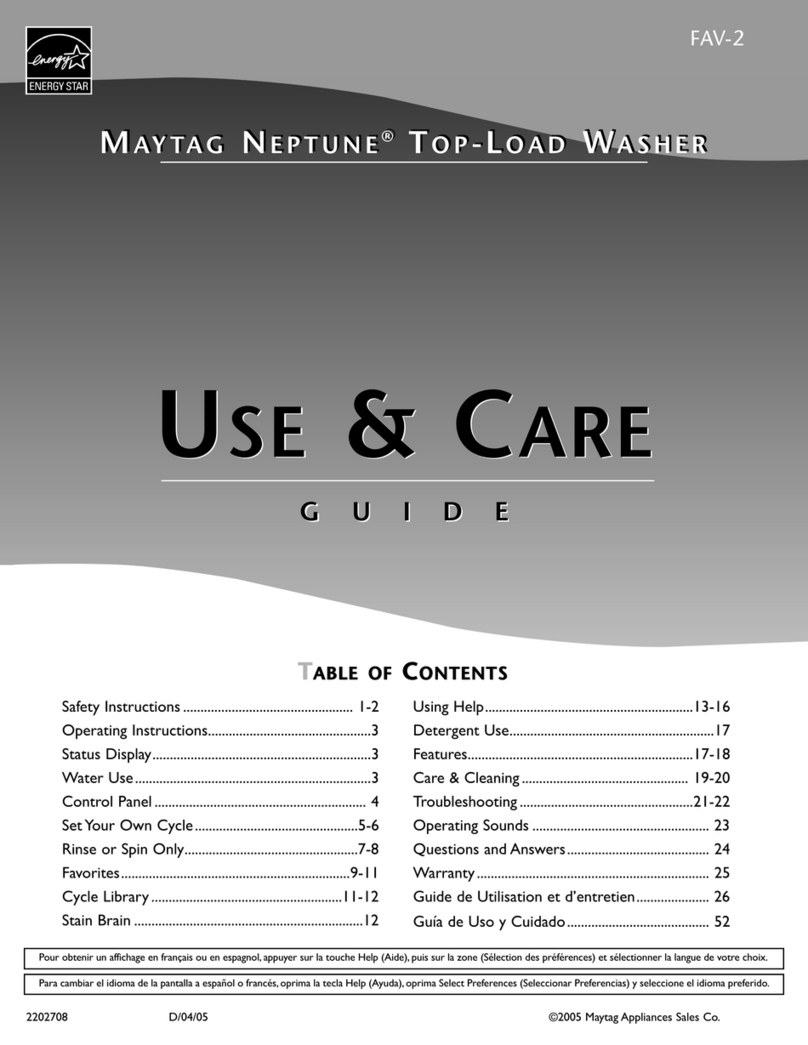

POWER

PROGRAM #

RUN?

EXECUTE CYCLE

END

n?

PROGRAM

CREATION

MOTOR

PROGRAMMING

CYCLE

PROGRAMMING OPTIONS

START + RESET

NO

RESET

YES START ACCESS CODE ACCESS CODE ACCESS CODE ACCESS CODE

7

Programming

8

Motor Programming

To access the motor programming mode, press

START and RESET together. The display

shows:

n?

Enter 45 at this prompt, followed by the

ENTER key. For two seconds, the display will

show:

* EDIT MOTORS *

You are then asked to enter the motor routine

number to be programmed (1 - 15).

MOTOR No.

You may now enter the number and press the

ENTER key. There are now two cases:

1. The motor routine does not exist.

2. The motor routine does exist.

New Motor Routine

In this case, you are prompted to enter a

clockwise rotation time with this message:

T. FORWARD = S

Enter the desired time in seconds (0 through

239), followed by the ENTER key. The display

will change to:

T. PAUSE = S

Enter the desired time in seconds (0 through

239), followed by the ENTER key. The display

will change to:

T. REARWARDS = S

Enter the counterclockwise time in seconds (0

through 239), followed by the ENTER key.

The display will show:

Pressing ENTER will store the motor timing

routine and the display will change to request a

new access code:

n?

Enter 45 at the prompt to program additional

motor timing sequences as required. Pressing

RESET instead of ENTER will exit

programming.

Editing an Existing Routine

If the motor routine number you entered is

already present, the display will show:

EXISTING!

Pressing the INC and DEC keys allow you to

step through the values for Forward, Pause,

and Backwards. Pressing ENTER will allow

you to modify the value on the display

After having viewed or modified the backwards

value, pressing the INC or ENTER key displays:

Pressing the ENTER key again displays the

forward rotation time:

T. FORWARD = XXs

STORE?

STORE?

Pressing ENTER confirms the changes made (if

any) and exits programming

Pressing RESET exits the current programming

mode and leaves the existing values as they

were.

Programming

Motor Programming continued

Notes on Motor Programming

There are a number of different modes

available for motor programming:

1. Forwards - Pause - Backwards

T. FORWARD = XXs

T. PAUSE = XXs

T. BACKWARDS = XXs

2. Forwards - Pause

T. FORWARD = XXs

T. PAUSE = XXs

T. BACKWARDS = S0

3. Forwards

T. FORWARD = XXs

T. PAUSE = S0

4. Pause - Backwards

T. FORWARD = S0

T. PAUSE = XXs

T. BACKWARDS = XXs

5. Backwards

T. FORWARD = S0

T. PAUSE = S0

T. BACKWARDS = XXs

The minimum pause time that can be

programmed between forward and backwards

is 2 seconds. The maximum time is 239

seconds.

Cylinder speed is programmed during cycle

programming. In this mode, each step can be

programmed with different values if desired.

B&C Stock Motor Assignments

9

Motor Number Forward Pause Reverse

1 16 4 16

2 4 16 4

3 5 115 5

14 0 0 1

15 1 0 0

Motor 1 - used for normal wash agitation.

Motor 2 - used for gentle wash agitation.

Motor 3 - used for soak formulas

Motor 14 - Used for Unroll cycles (reverse only)

Motor 15 - Used for Spin cycles (forward only)

10

Programming

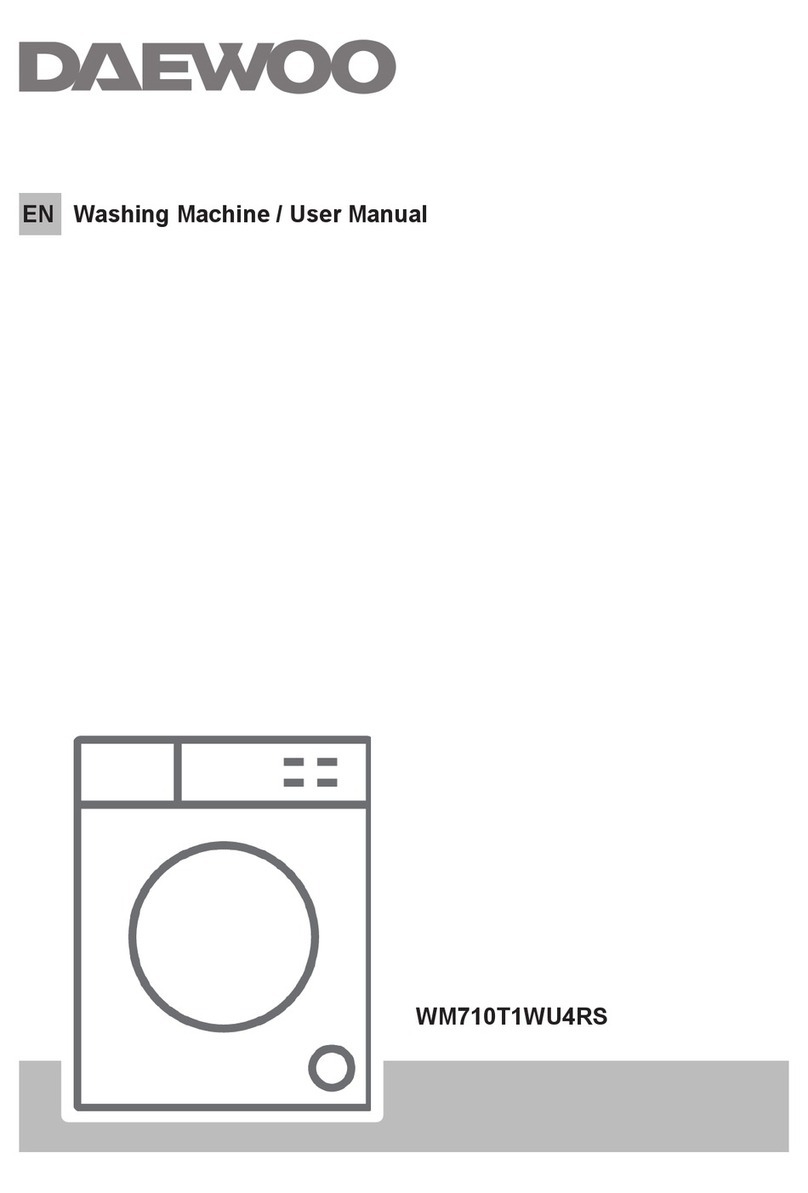

Motor Programming Flow Chart

POWER

PROGRAM #

EXIST?

n?

START +

RESET

RESET

45

ENTER

*EDIT MOTORS*

MOTOR N

YESNO

T. FORWARD = S

T. PAUSE = S

T. BACKWARDS = S

# OF SEC

ENTER

# OF SEC

ENTER

# OF SEC

ENTER

T. FORWARD = S0

T. PAUSE = XXs

T. BACKWARDS = XXs

EXISTING!

ENTER

INC

DEC

DEC

INC

STORE?

yes

ENTER

STORE

VALUES

no

RESET

Programming Sequence

Cool Down

3

INC

Bal. Load

3

INC

Drain

3

INC

Cold Water

3

INC

Hot Water

3

INC

Heating

3

INC

Detergent 1

3

INC

Detergent 2

3

INC

Detergent 3

3

INC

Detergent 4

3

INC

11

To turn on a function, press Enter, to turn off a function press Reset. Note: Setting a function to

zero DOES NOT disable that function.

Min. Level

ENTER

3

INC

Max Level

3

INC

Temp.

3

INC

WDT

3

INC

Motor

3

INC

RPM

More information on page 15

Level

3

INC

Temp.

3

INC

WDT

3

INC

Motor

3

INC

RPM

More information on page 16

Yes drains the machine.

No means the drain is closed.

Yes to turn on the cold water valve.

No means the valve is off.

Yes to turn on the hot water valve.

No means the valve is off.

Yes turns on the heat output, you

will be prompted to enter the temperature.

No means the heat output is off.

Yes to turn on chemical signal 1, and

flush cup 1 in the supply dispenser.

No means the supply is off.

Yes to turn on chemical signal 2, and

flush cup 2 in the supply dispenser, if

equipped. No means the supply is off.

Yes to turn on chemical signal 3, and

flush cup 3 in the supply dispenser, if

equipped. No means the supply is off.

Yes to turn on chemical signal 4, and

flush cup 4 in the supply dispenser, if

equipped. No means the supply is off.

continued

Programming Sequence

12

Hard Water

3

INC

Relay 16

3

INC

Relay 11

3

INC

Relay 12

3

INC

Relay 13

3

INC

Motor

3

INC

RPM

3

INC

Relay 17

3

INC

Relay 18

3

INC

Relay 19

3

INC

To turn on a function, press Enter, to turn off a function press Reset. Note: Setting a function to

zero DOES NOT disable that function.

Yes to turn on chemical signal 5, and

flush cup 5 in the supply dispenser, if

equipped. No means the supply is off.

Not Used

Yes turns on Auxiliary Fill.

No means the valve is off.

Injection flush - only used on machines

with stainless steel vacuum breaker.

No means the supply is off.

Yes turns on drive balance relay - only

used in extract cycles. No means the relay

is off.

Yes enables the machine to rotate, in

concert with RPM, below. No means

no cylinder rotation. More information

on page 8.

Set the RPM - see chart on page 29 for

details on recommended speeds for a

particular machine.

Yes to turn on chemical signal 6.

No means the supply is off.

Yes to turn on chemical signal 7.

No means the supply is off.

Yes to turn on chemical signal 8.

No means the supply is off.

continued

Programming Sequence

13

Relay 20

3

INC

Relay 21

3

INC

Relay 22

3

INC

Relay 23

3

INC

Relay 24

3

INC

End Step

3

INC

Level

3

INC

Temp.

3

INC

Time

3

INC

WDT

3

INC

Store?

To turn on a function, press Enter, to turn off a function press Reset. Note: Setting a function to

zero DOES NOT disable that function.

Yes to open Auxiliary Drain, if

equipped. No means drain is

closed.

Not Used

Yes to activate the buzzer.

No means buzzer is off.

Yes to turn on Cold Spray, if

equipped. No to disable.

Flashes for 1 sec.

Pick only one of the three!

Yes ends the step based

on water level. Use Watch

Dog Timer.

Yes ends the step based

on Temperature. Use Watch

Dog Timer. See Heat cycle

tutorial in Appendix A.

Yes ends the step based

on time. Do not use Watch

Dog Timer.

Example Cycle Construction:

Step 1 (Fill Step)

Turn on hot, cold or both.

Turn on Motor, and enter RPM.

Turn on Level and enter water level (see chart, pg 31)

Turn on WDT and enter a time (9m, 0s typically)

Press enter to store.

Step 2 (Chemical Dose Step)

Turn on Chemical output

Turn on Motor, and enter RPM.

Turn on Time and enter a time (ex: 0m, 10s)

Press enter to store.

Step 3 (Top off - make sure we are still at level)

Turn on hot, cold or both.

Turn on Motor, and enter RPM.

Turn on Level and enter water level (see chart, pg 31)

Turn on WDT and enter a time (9m, 0s typically)

Press enter to store.

Step 4 (Wash/Agitation Time)

Turn on Motor, and enter RPM.

Turn on Time and enter a time (ex: 9m, 30s)

Press enter to store.

The EL6 Stock program list (with your machine, also

available on our website, www.bandctech.com) is of

great use when customizing and creating wash programs.

There are many built in cycles available for use or

modification in custom programs. Here some commonly

used cycles:

Spin9: Drain routine - used after each bath cycle, but

not prior to the final spin.

Spin1: Low speed extract, 30 seconds

Spin2: Medium speed extract, 5 minutes.

Spin3: High speed extract, 5 minutes.

Note: Intermediate spins are not recommended - if the

EL6 cannot achieve a good balance, the program will be

terminated.

Note

OR

OR

Press ENTER to store.

Yes turns on the Watch Dog Timer.

Enter minutes and seconds.

No turns off the Watch Dog Timer.

Yes to turn on Hot Spray, if

equipped. No to disable.

14

Programming

Cycle Programming

Cycle libraries can be created for later use in

the Wash programming step. When the

machine is stopped, press the START and

RESET buttons together. The display is:

n?

Using the keypad, type 12 and press ENTER.

For two seconds, the display shows:

* EDIT CYCLES *

The message for choosing the programming

cycle is then displayed:

PREWASH = ?

Pressing INC or DEC will show the other cycle

types in succession:

WASH = ?

SPIN = ?

RINSE = ?

UNROLL = ?

When the cycle type you wish to edit is

displayed, press ENTER to begin creating or

editing of the cycle. As an example, we will go

through programming a Prewash cycle.

PREWASH = ?

Using the numerical keypad, enter the cycle

you wish to create or modify. After you have

entered the number and pressed ENTER, there

are two possible cases:

>The cycle chosen does not exist and has

to be programmed. (This Page)

>The cycle chosen does exist. If this is

the case, you can view and modify the

cycle as needed. (See page 17, and

charts beginning on page 11).

New Cycle Creation

If the cycle you chose does not exist, you will

be taken directly into the programming mode.

For two seconds, the display will show:

START STEP 1

The display then changes to:

COOL DOWN? NO

You can now define for step 1 whether the cool

down feature is activated. If you wish to

activate cooldown, press ENTER, and the

display changes to:

COOL DOWN? YES

To implement the cooldown phase, five

additional parameters must be entered. These

are discussed in the next section. If you do not

wish to activate the cooldown phase, press INC.

The display will show:

BAL LOAD? YES

You can now define for step 1 whether the load

balancing is enabled. Load balancing is

essentially a modulated fill. A target

temperature can be programmed and the

machine will use a combination of the hot

water fill valve and the cold water fill valve to

maintain a given temperature. If you wish to

activate temperature controlled fill, press

ENTER. The display will change to:

BAL LOAD? NO

To implement temperature controlled fill, four

additional parameters must be entered. These

are discussed in the next section. If you do not

wish to activate temperature controlled fill,

press INC. The display will show:

DRAIN? NO

15

Programming

Cycle Programming continued

To activate the Drain and end Step 1, press

ENTER. Pressing INC or DEC will scroll

through the other functions to end the step.

The step can end with a Water Level, a Water

Temperature, or an elapsed Time. Select one

of the functions by pressing ENTER changes

the display and prompts you to enter a value

for the particular function.

Example

LEVEL NO

LEVEL = cm

ENTER

Type the required value in using the numerical

keypad and press ENTER.

In the event that you choose a level or a

temperature to end the step, you will be

prompted with:

WDT = NO

This is the Watch Dog Timer. Press ENTER to

set the value.

WDT = m

Set the time in minutes, press ENTER

WDT = s

Set the time in seconds, press ENTER. This is a

time limit in which the temperature or water

level you have programmed should be reached.

If the level or temperature cannot be reached in

the given amount of time, the control will

display an alarm. Press ENTER to continue

after an alarm. Be sure to enter a time that is

reasonably longer than the presumed time for

filling or heating. 9:00 (nine minutes, zero

seconds) is good for a fill, 30:00 (thirty minutes,

zero seconds) is good for a heat step.

The display now shows:

STORE?

Pressing STOP will cancel the programming

and abort any parameters you have entered.

To save, press ENTER. Now the start of a new

step will be indicated. For two seconds the

display shows:

START STEP 2

At this point, you may continue adding steps to

the cycle using the same programming

sequence as used for Step 1. If programming is

complete, press STOP. The display now shows:

The display then changes to:

COOLING? NO

PREWASH = ?

You may now program another Prewash cycle,

or select one of the other cycle types and

continue programming. To exit from cycle

programming, press RESET.

Cooldown Phase

The cooldown phase allows you to specify a

temperature to reach before draining the

machine. There are five parameters to be

programmed: Minimum Level, Maximum

Level, Temperature, WDT, and Motor. The

cooldown phase operates as follows:

>The water is drained to the minimum

level as mentioned above.

>Cold water is then added up to the

maximum level as mentioned above,

and the temperature is monitored.

>Draining and filling continue until either

the temperature is reached, or the WTD

(watch dog timer) has expired.

The motor profile chosen is active throughout

this step.

16

Programming

Cycle Programming continued

Load Balancing /

Temperature Controlled Fill

The Load Balancing option is essentially a

temperature controlled, or modulated, fill. Cold

and Hot water are added to the machine while

the temperature and level are monitored. Four

parameters must be entered: Level,

Temperature, WDT, and Motor. The option

functions as follows:

Cold or Hot water is added to the machine

depending upon the temperature set (Hot if the

water temperature is lower than programmed,

or Cold if it is higher) until the programmed

water level is reached. Then the next step of

the cycle can begin. During this phase, the

WDT (watch dog timer) is active, which will flag

a fault if the fill time is longer than the

programmed WDT. The chosen motor routine

is active for this entire process.

Heating

Throughout the programming of the steps,

when heating is inserted, this tells the control to

regulate the temperature. In a step that ends

with a required temperature, the heating value

must be greater than or equal to the step

ending temperature. For example, if 50

degrees was set for heating, but 70 degrees was

required to end the step, the machine could

never reach 70 degrees, causing a fault from

the Watch Dog Timer. In cases where the step

is ended by time or level, the temperature can

be selected from 30 to 93 degrees C. See

Appendix A for details on building a Prewash,

Wash, or Rise cycle that uses heating.

RPM =

Enter the desired value and press ENTER to

confirm. In Prewash, Wash, Rinse, and Unroll,

the maximum speed is 100 RPM. Use

Programming Code 207 to set maximum Spin

RPM.

Programming Sequence

For Prewash, Wash, Rinse and Unroll, the

programming sequence is as follows:

>Cooling

>Load Balanced (Temp Controlled Fill)

>Drain

>Cold Water

>Hot Water

>Heating

>Detergent 1

>Detergent 2

>Detergent 3

>Detergent 4

>Hard Water (Detergent 5)

>Relay 16 (Not Used)

>Relay 11 (Aux Fill)

>Relay 12 (Injection Flush)

>Relay 13 (Drive Balancing)

>Motor (Agitation profile and speed)

>Relay 17 (Detergent 6)

>Relay 18 (Detergent 7)

>Relay 19 (Detergent 8)

>Relay 20 (Aux Drain)

>Relay 21 (Not Used)

>Relay 22 (Beeper)

>Relay 23 (Cold Spray, HP Series)

>Relay 24 (Hot Spray, HP Series)

Motor

For the motor function, after pressing ENTER,

you are asked to enter a motor function

(programmed earlier, see pages 8-10). When

you have confirmed the selection with ENTER,

the display shows:

17

Programming

Cycle Programming continued

Editing an existing cycle

If the cycle you chose already exists, the display

will show:

EXISTING!

At this point, four choices are possible:

KChoose another cycle by pressing STOP

LAccess the existing cycle by pressing

ENTER. In this case, INC or DEC will

display the various segments, and the

configuration can be modified by using

the ENTER and RESET keys as

described in the previous section.

MInsert one or more steps. To do so,

scroll through the steps by using the

ADVAN key. The display will show

START STEP X for two seconds,

followed by EXISTING! To insert a step,

press INS and the display changes to:

START STEP 1

COOLING? NO

Followed by:

You may now proceed to program the new step

using the techniques described earlier. After

confirming storage of the new steps, press

STOP.

NRemove one or more of the steps from

the existing ones. Proceed by pressing

ADVAN as describe above in (3). When

the message

EXISTING!

appears after the step you wish to

remove, press the DEL key. The

following message appears:

DELETE?

To confirm deletion of the step, press the

ENTER key or press RESET to cancel the

operation. After confirmation, press the STOP

key to exit.

Each cycle can comprise a maximum of 100

steps.

A total of 400 steps can be programmed.

See the EL6 Stock Programs Listing, included

with your machine, or available from our

website (http://www.bandctech.com) for details

of the cycles included with your machine from

the factory.

Note: The factory programs and cycles can be

altered at will. There is no way to restore the

factory programming without manually

inputting them, or via download with the EL6

Win 2 programming software, also available for

download on our website.

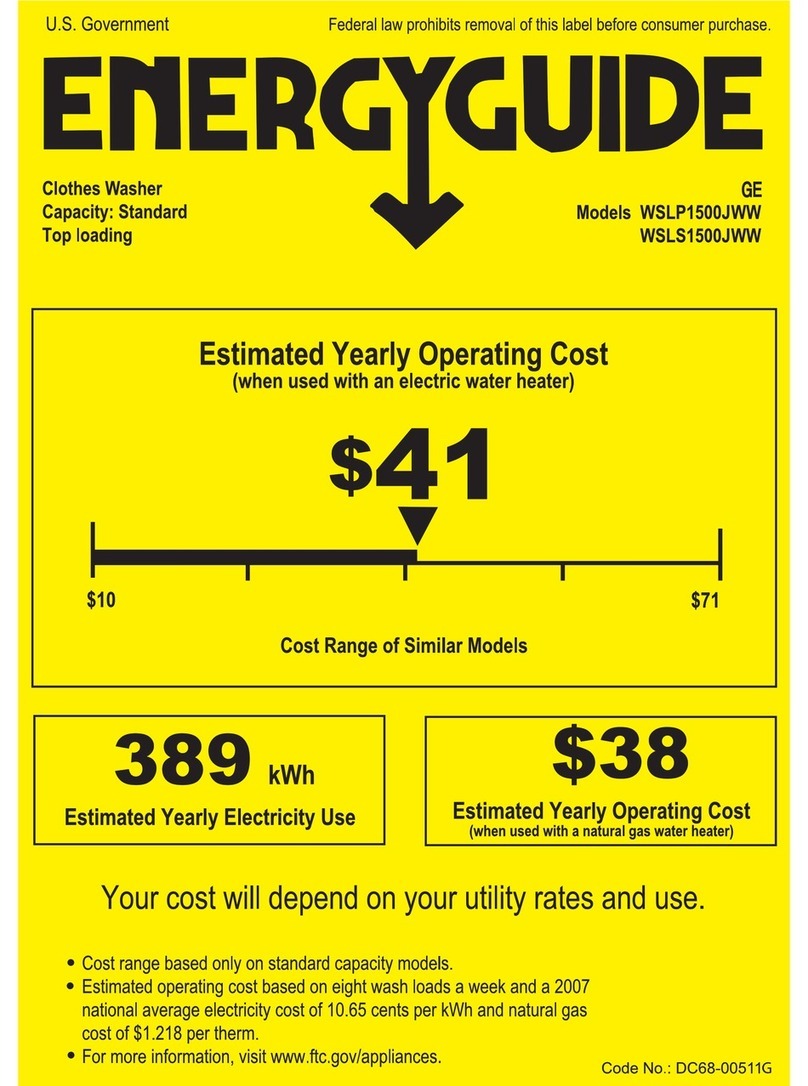

Funct ion 1 2 3 4

Cool Down

Bal Load

Drain

Cold Water

Hot Water Yes Yes

Heating

Chem 1

Chem 2 Yes

Chem 3

Chem 4

Hard Water (Chem 5)

Relay 16

Relay 11 (Aux Fill)

Relay 12 (Injection Flush) Yes

Relay 13 (Balancing)

Motor 1 1 1 1

Speed RPM 42 42 42 42

Relay 17 (Chem 6)

Relay 18 (Chem 7)

Relay 19 (Chem 8)

Relay 20 (Aux Drain)

Relay 21

Relay 22 (Buzzer)

Relay 23 (Cold Spray)

Relay 24 (Hot Spray)

Level cm 24 24

Temp C

WDT m:s 09:00 05:00

Time m:s 1:00 7:00

End Step

Step

The figure at the right shows a typical fill

bath.

Step 1 - Fill to a water level with hot

water. Watchdog timer of 9:00 allows

time to fill before an alarm is generated.

Step 1 ends when the water level is

reached.

Step 2 - Chemical 2 output is on, Relay

12 (injection flush) is on (not required

for machines with plastic vacuum

breaker). Step 3 ends when a time of

1:00 elapses.

Step 3 - Top off step, same as step 1,

except for a shorter Watch Dog Time.

Step 4 - This is the wash step. No

relays/outputs are on. Step 4 and the

entire cycle are complete when a time of

7:00 elapses.

A note about the Watch Dog Timer:

The Watch Dog Timer makes sure that

the machine reaches level or

temperature in a timely fashion, and

ensures that the water or heat doesn’t

stay on until someone notices a

problem. Don’t be confused - Step 1 will

end when the programmed water level is

reached, NOT when 9 minutes has

elapsed.

Programming

Example Cycle

18

19

Programming

Wash Program Creation

When the machine is stopped, press the START

and RESET buttons together. The display is:

n?

Using the keypad, type 27 and press ENTER.

For two seconds, the display shows:

EDIT PROG. No.

At this prompt, type the program number you

wish to create or edit, followed by the ENTER

key. Again, two situations are possible:

>The Program does not exist and must be

created.

>The Program already exists and can be

viewed and modified.

Creating a new Wash Program

The display reads

NOT FOUND!

for two seconds, then:

C1>?

At this prompt, press ENTER. The display

changes to:

C1>PREWASH = ?

Using the INC or DEC key, you can select the

type of cycle to insert: Prewash, Wash, Spin,

Rinse, and Unroll. For example, if you wish to

insert a wash cycle you have named 3, press

INC until the display changes to:

C1>WASH = ?

Confirm the selection by pressing ENTER. The

display changes to:

C1>WASH = No.

Type 3 on the keypad, the press ENTER. Wash

3 is now stored as the first segment of the

program. The display will prompt you to enter

a second cycle:

C2>?

At this prompt, press ENTER. The choice of

cycle will be displayed as previously. Programs

can be compiled with up to 15 cycles chosen

from those in available in the cycles library (see

the EL6 Stock Programs Listing). The same

cycle can be used repeatedly in a wash

program. After you are through programming,

and have confirmed the last cycle, press STOP

to terminate programming. The display then

shows:

STORE?

Press ENTER to store the program. Press

RESET to cancel and return to the beginning If

while programming, you enter a wash cycle

that does not exist, the following message will

appear:.

NOT FOUND!

Since the wash cycle doesn’t exist, you will

have to create it before adding it to a wash

program.

Editing an Existing Program

In the event the wash program already exists,

the display will change to:

EXISTING!

for two seconds, followed by the display of the

program contents. For example:

C1>RINSE = 1

By using the INC or DEC keys, the various

cycles comprising the wash program can be

viewed. The program can be modified, and

cycles can be added or deleted.

Deleting a Cycle

Using the INC and DEC keys, find the cycle

you wish to delete. While the cycle is

displayed, press the delete key, then press the

Table of contents

Other B&C Technologies Washer manuals

Popular Washer manuals by other brands

Philco

Philco PLDI 138 CQTL owner's manual

Hotpoint Ariston

Hotpoint Ariston WMSD 723B EU Instructions for use

Whirlpool

Whirlpool W10860701C Use and care guide

Hotpoint Ariston

Hotpoint Ariston FMG 723 Instructions for use

Indesit

Indesit IWSC 5085 Instructions for use

Samsung

Samsung R1031GWS YLR Service manual