© 2012 – Banshee Helicopters GmbH Page 2

1. General information

Technical features:

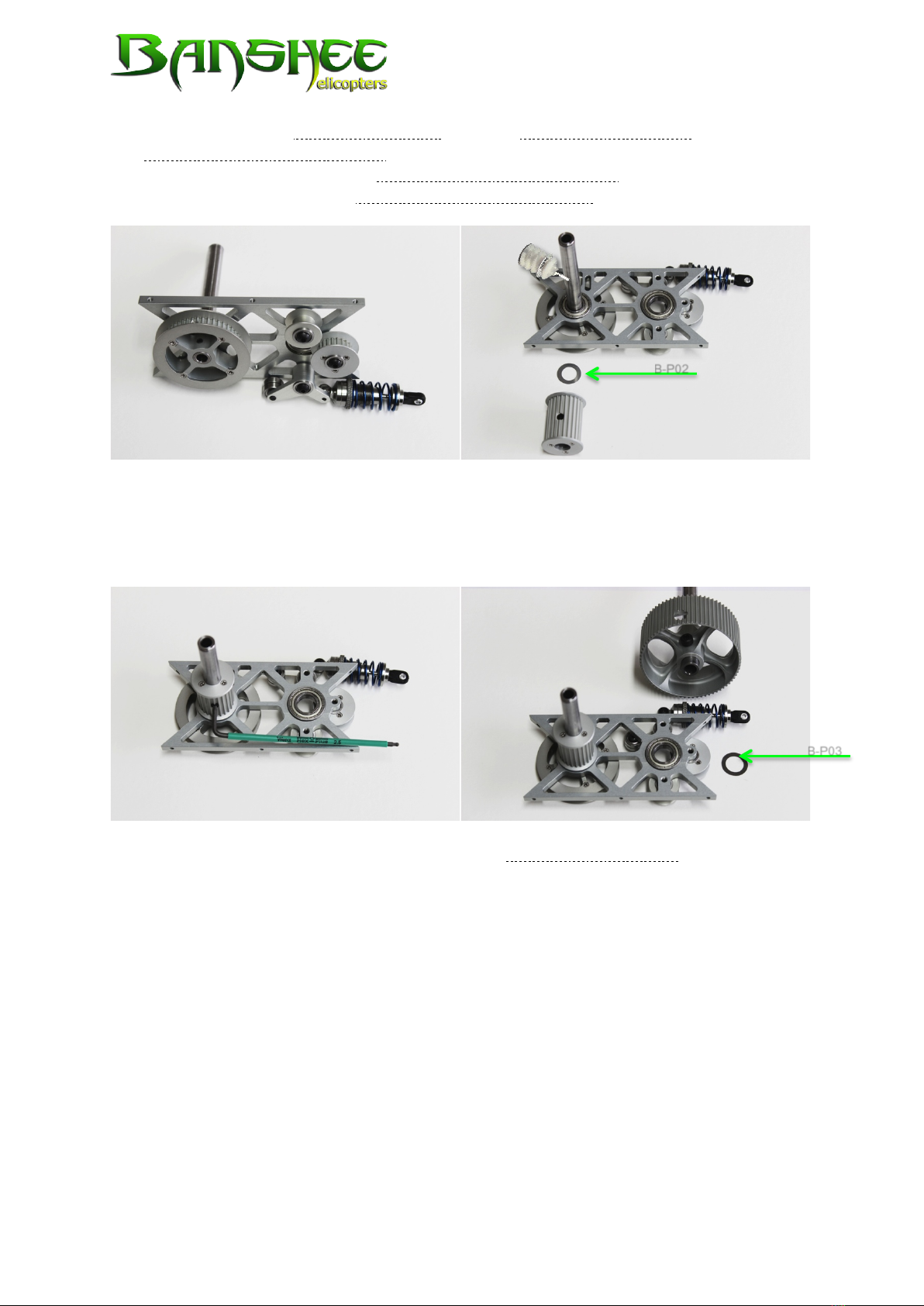

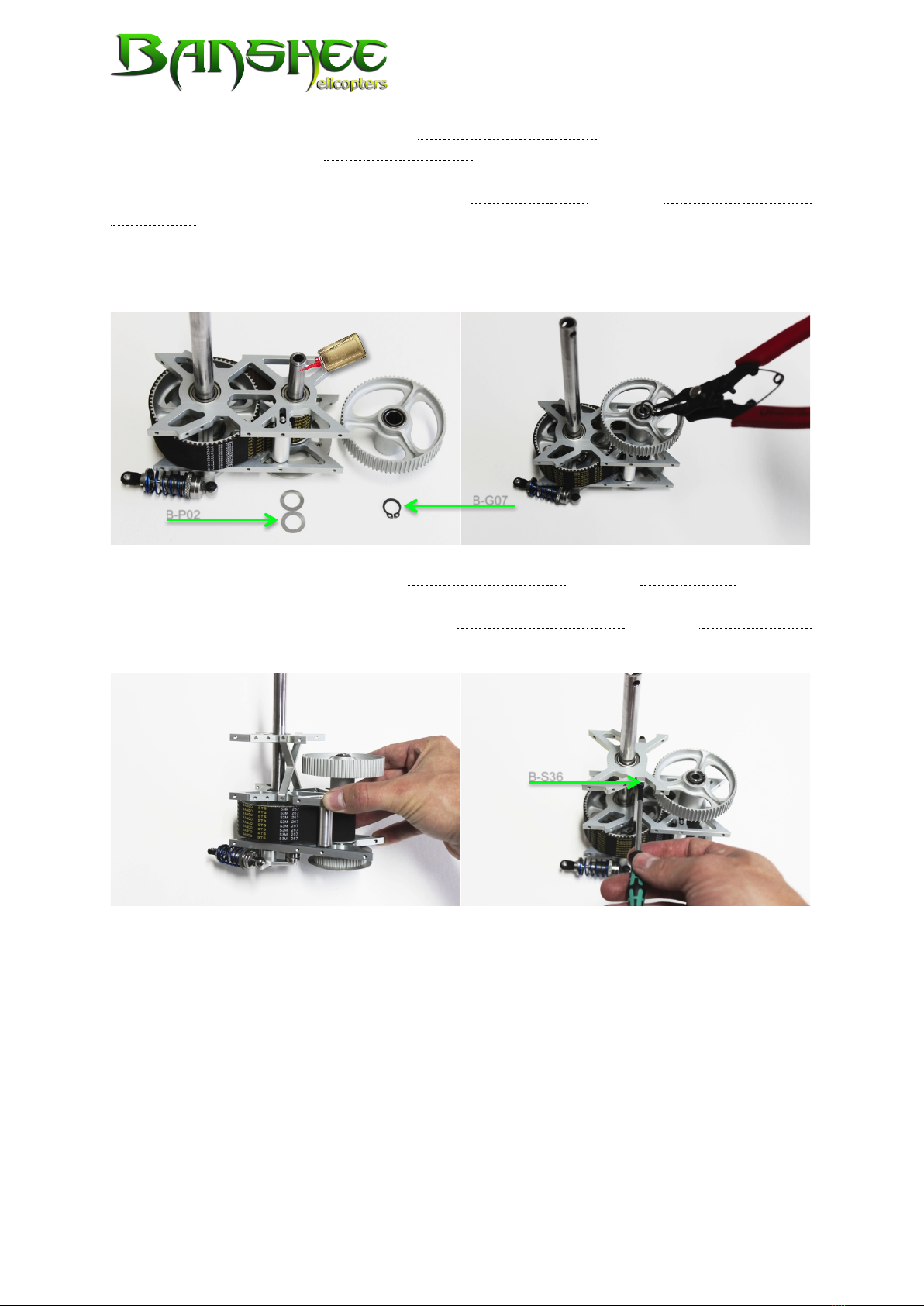

•3-speed belt drive

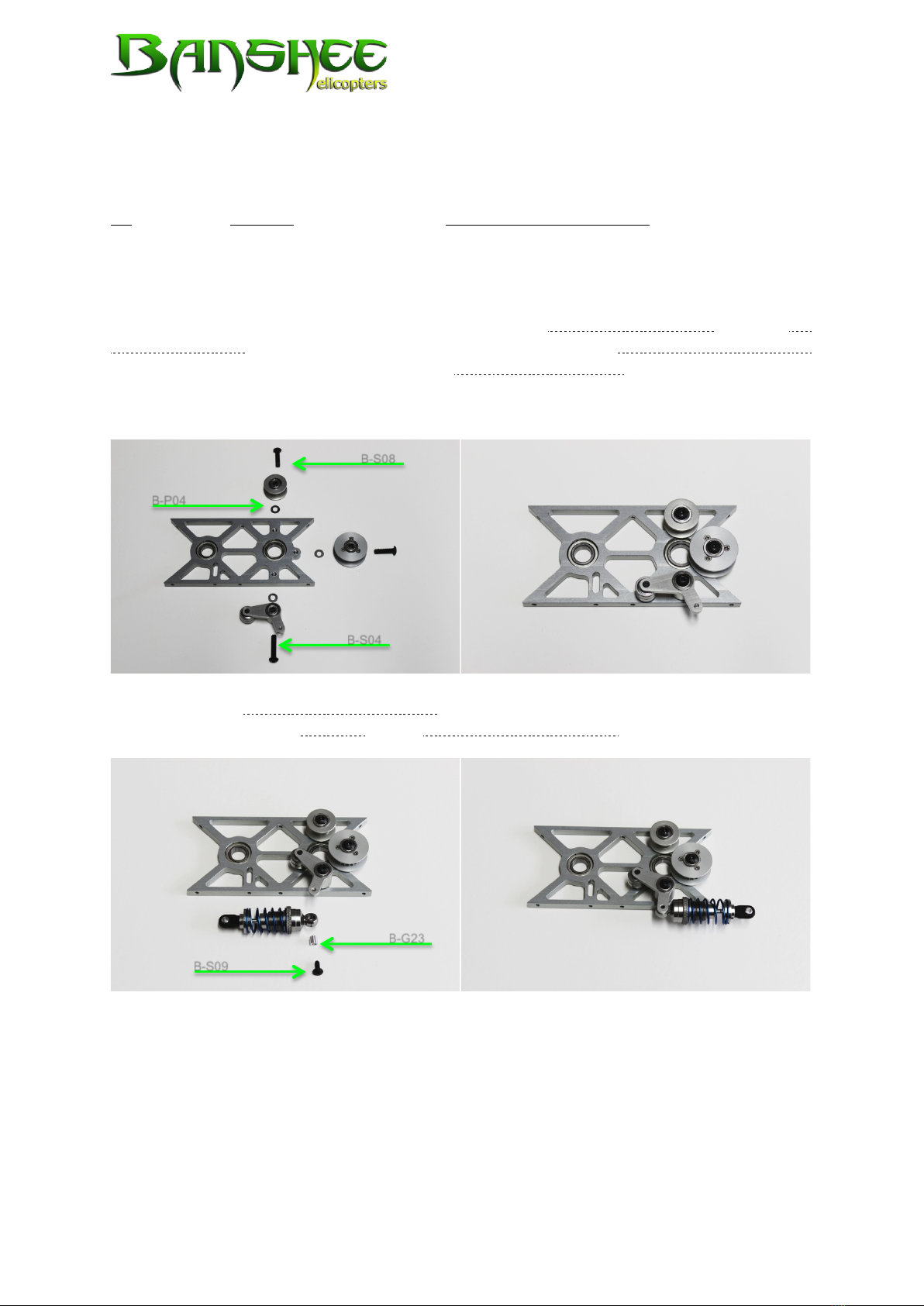

•Automatic tail rotor drive belt tensioner/-spring damper

•Main drive belt tensioner

•30 mm carbon-fibre, strutless, tail boom

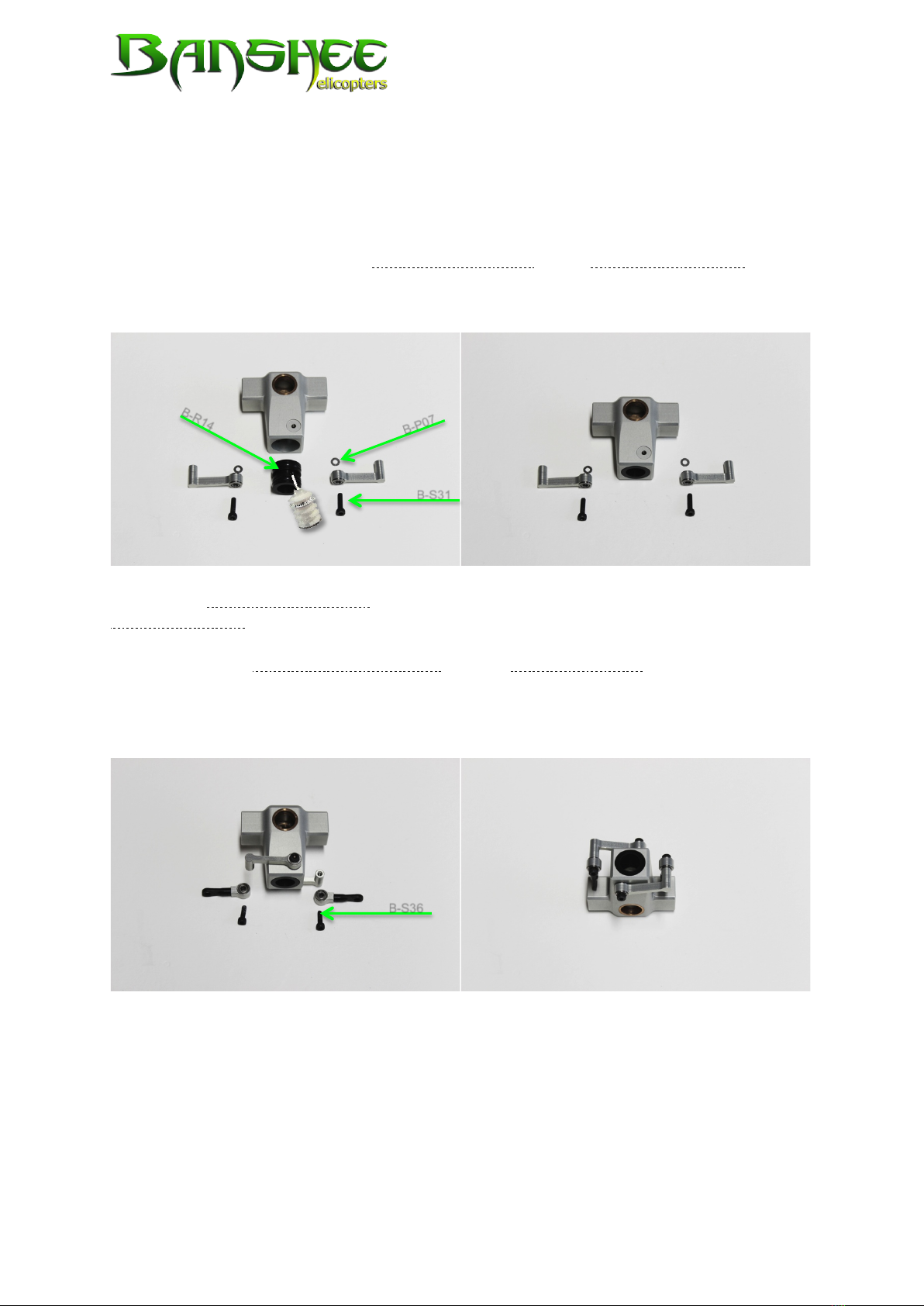

•Straight swashplate linkage

•Extremely small, compact design with high torsional stiffness

•Centre of gravity close to the rotor plane

•Double (x 2 separate units) needle bearing clutch

Technical specifications:B

•Basic weight of the mechanics including canopy: 1,7 Kg´s

•All up weight with standard equipment (3xBLS452, 1xBLS251, Jive 120+ HV,

Pyro 700, BeastX, Maniac³710 mm, 115 mm tail blades, canopy): ~2950 g´s

•Main rotor speed: 1000-2300 U/min

•Variable reduction ratio between motor an main rotor:

o18Z !1 : 12

o19Z !1 : 11,37

o20Z !1 : 10,8

o21Z !1 : 10,28

o22Z !1 : 9,81

o23Z !1 : 9,39

o24Z !1 : 9

o25Z !1 : 8,64

•Ratio between main rotor and tail rotor: 1 : 5,54

•Battery cell size: Maximum 60 mm width and 60 mm height