Barnstead F46110CM User manual

1

BARNSTEAD|THERMOLYNE CORPORATION

High Temperature

Muffle Furnace

OPERATION MANUAL

AND PARTS LIST

Model Numbers

F46110CM F46230CM Automatic

F46110CM-33 F46230CM-33 Automatic

F46118CM F46238CM Automatic

F46120CM F46240CM Multi-Programmable

F46120CM-33 F46240CM-33 Multi-Programmable

F46128CM F46248CM Multi-Programmable

F46120CM-75 F46240CM-75 Multi-Programmable

F46120CM-33-75 F46240CM-33-75 Multi-Programmable

F46128CM-75 F46248CM-75 Multi-Programmable

LT1078X2 • 5/9/97

2

IMPORTANT INFORMATION

This manual contains important operating and safety information.The user must carefully read and understand

the contents of this manual prior to the use of this equipment.

Table of Contents

Safety Information ..........................................................................................................................................4

Alert Boxes.....................................................................................................................................................4

Warnings ........................................................................................................................................................5

Description .....................................................................................................................................................7

Intended Use .............................................................................................................................................7

General Usage ......................................................................................................................................... 7

Principles of Operation ..............................................................................................................................7

Types of Controllers.................................................................................................................................. 8

General Specifications ...................................................................................................................................9

General Specifications .................................................................................................................................10

Environmental Conditions........................................................................................................................10

Declaration of Conformity ........................................................................................................................11

Unpacking ....................................................................................................................................................12

Installation ....................................................................................................................................................13

Furnace Connection ................................................................................................................................13

Initial heat-up procedure:.........................................................................................................................13

General Operation of Furnace......................................................................................................................14

Power Switch...........................................................................................................................................14

Cycle Indicator.........................................................................................................................................14

Circuit Breaker.........................................................................................................................................15

Fans ........................................................................................................................................................15

Controllers ...............................................................................................................................................15

Operation of Automatic Models ....................................................................................................................16

Control Parameters .................................................................................................................................16

Tuning Your Furnace ...............................................................................................................................17

Single Set Point Operation ...................................................................................................................18

Program Ramp Rate................................................................................................................................19

Program Ramp Reset..............................................................................................................................19

Operation of Programmable Models.............................................................................................................20

Control Parameters .................................................................................................................................20

Tuning Your Furnace ...............................................................................................................................22

Operating the Controller ......................................................................................................................... 23

Single Set Point Operation ...................................................................................................................23

Programming Controller ..........................................................................................................................23

Multi-Programmable Controller Program Entry (Models F46120CM,

F46120CM-33, F46120CM-33-75, F46120CM-75, F46128CM, F46128CM-75, F46240CM,

F46240CM-33, F46240CM-33-75, F46240CM-75, F46248CM, F46248CM-75) ..................................24

Program Entry (all models)......................................................................................................................25

Implementing Programs ..............................................................................................................................27

Program Execution ................................................................................................................................. 27

Parameter Change While Running ..........................................................................................................27

Loop Count..............................................................................................................................................27

Program Hold ........................................................................................................................................ 27

Program Reset ....................................................................................................................................... 28

Table of Contents

3

Furnace Loading: .........................................................................................................................................29

FurnaceAtmospheres .............................................................................................................................30

Preventive Maintenance.............................................................................................................................. 31

General Cleaning Instructions ............................................................................................................... 32

Problem Solving Guide.................................................................................................................................33

Maintenance and Servicing ..........................................................................................................................34

Wiring Diagram............................................................................................................................................ 38

Wiring Diagram.............................................................................................................................................39

Wiring Diagram.............................................................................................................................................40

Wiring Diagram.............................................................................................................................................41

Replacement Parts List ............................................................................................................................... 42

Ordering Procedures ....................................................................................................................................43

Material Safety Data Sheet ..........................................................................................................................44

Warranty.......................................................................................................................................................47

TABLE OF CONTENTS

4

Safety Information

Your Thermolyne furnace has been designed with function,

reliability, and safety in mind. It is the user’s responsibility to

install it in conformance with local electrical codes. For safe

operation, please pay attention to the alert boxes through-

out the manual.

Because of the nature of this product, considerably more

care is required in operating and servicing this furnace than

for lower temperature laboratory furnaces. For maximum

safety and longest furnace life, be sure to observe the

various cautions and warnings throughout this manual.

Alert Boxes

WARNING

Warning alerts apply when there is a

possibility of personal injury.

CAUTION

Caution alerts apply when there is a

possibility of

damage to the equipment.

NOTE

Notes alert the manual user to

pertinent facts and

conditions.

HOT SURFACE

Hot surfaces alert you to a possibility

of personal

injury if you come in contact with a

surface during use or for a period of

time after use.

Safety Information

5

WARNING

To avoid electrical shock, this furnace must:

1. Be installed by a competent, qualified electrician who

insures compatibility among furnace specifications,

electrical source and grounding code requirements.

2. Always be disconnected from the electrical supply

prior to maintenance and servicing.

To avoid personal injury:

1. Do not stand directly in front of the chamber without

wearing a heat resistant face shield, gloves and apron.

2. Do not operate or clean furnace without proper eye

protection.

3. Do not use in the presence of flammable or combus-

tible materials; fire or explosion may result.This

device contains components which may ignite such

materials.

4. Refer servicing to qualified personnel.

5. Caution: Hot Surface. Avoid Contact.

6. To AVOID EYE DAMAGE in operating or cleaning

furnace, proper eye protection must be worn.

7. To AVOID BURNS, do not stand directly in front of the

chamber without wearing a heat resistant faceshield,

gloves and apron.

8. To AVOID FIRE, do not place combustible materials

where exposed to heat from open door.

HOT SURFACE

Caution: Hot Surface. Avoid Contact.

SAFETY INFORMATION

6

Please note the following WARNINGS:

WARNING

This warning is presented for compliance with California Proposition 65 and other regulatory agencies and only

applies to the insulation in this product.This product contains refractory ceramic, refractory ceramic fiber or

fiberglass insulation, which can produce respirable dust or fibers during disassembly. Dust or fibers can cause

irritation and can aggravate pre-existing respiratory diseases. Refractory ceramic and refractory ceramic fibers

(after reaching 1000°C) contain crystalline silica, which can cause lung damage (silicosis).The International

Agency for Research on Cancer (IARC) has classified refractory ceramic fiber and fiberglass as possibly

carcinogenic (Group 2B), and crystalline silica as carcinogenic to humans (Group 1).

The insulating materials can be located in the door, the hearth collar, in the chamber of the product or under the

hot plate top.Tests performed by the manufacturer indicate that there is no risk of exposure to dust or respi-

rable fibers resulting from operation of this product under normal conditions. However, there may be a risk of

exposure to respirable dust or fibers when repairing or maintaining the insulating materials, or when otherwise

disturbing them in a manner which causes release of dust or fibers. By using proper handling procedures and

protective equipment you can work safely with these insulating materials and minimize any exposure. Refer to

the appropriate Material Safety Data Sheets (MSDS) fo information regarding proper handling and recom-

mended protective equipment. For additional MSDS copies, or additional information concerning the handling

of refractory ceramic products, please contact the Customer Service Department at Barnstead|Thermolyne

Corporation at 1-800-553-0039.

WARNING

REFER SERVICING TO QUALIFIED PERSONNEL.

SAFETY INFORMATION

7

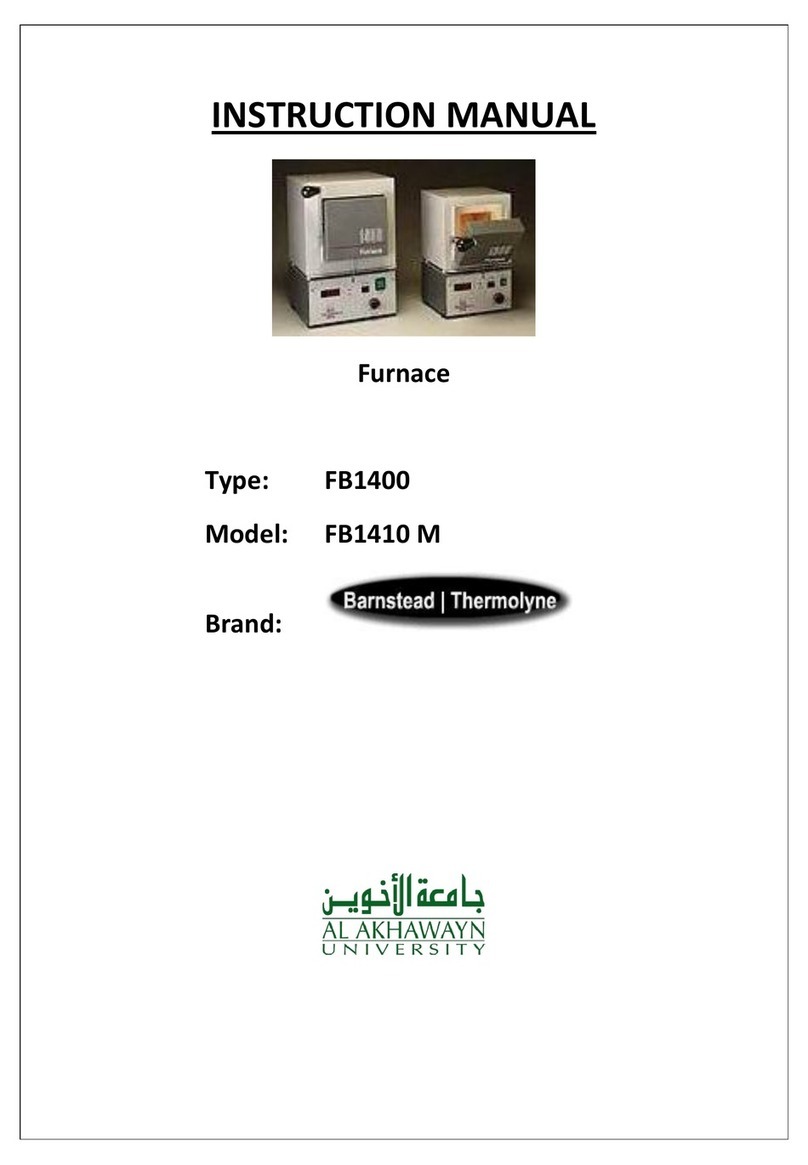

Intended Use

Types 461 and 462 are general purpose laboratory

furnaces

intended for applications requiring temperatures from

800-1700

degrees C.

General Usage

Do not use this product for anything other than its

intended usage.

Principles of Operation

The chamber section is heated by six (in type F46100

urnaces) or eight (in type F46200 furnaces) Super

Kanthal 33 heating elements suspended in a chamber

made of alumina and silica high temperature refractory

fiber.

This high temperature refractory fiber is in the form of

blocks which line the inside of the chamber. Because of

the

stresses caused by extremely high temperature opera-

tion, these blocks will show some surface cracking.This

cracking is not detrimental to the operation of the fur-

nace.

A precious metal type B thermocouple senses the

temperature in the chamber and transmits this informa-

tion to the temperature control in millivolts.

NOTE

The fans operate continuously, even

when the circuit breaker is OFF, to assure

that the control section and the terminals

of the heating elements are continuously

ventilated. Without ventilation, residual

heat from the furnace chamber can cause

overheating after the furnace is turned off.

CAUTION

Do not completely remove electricity from

the furnace until chamber temperature

falls below 500°C. Do not touch exposed

elements.

Description

8

The control section consists of a temperature controller, a

current controller, a transformer, a contactor (relay), a

circuit breaker, and a pilot light.

The temperature controller senses the furnace temperature

(by means of the thermocouple) and adjusts electricity to

the heating elements by means of the current controller.

The current controller controls electricity to the heating

elements by adjusting the magnitude of the electrical

current (rather than turning the electricity completely on or

off).This is the preferred method of controlling electricity to

molybdenum disilicide heating elements.

The transformer supplies the proper electrical voltage to the

heating elements.

The contactor removes electricity from the heating elements

if the furnace temperature equals or exceeds the high limit

set point of the controller

The circuit breaker is used to turn the furnace on and off

and also protects the electrical supply in the event that the

furnace draws too much electrical current.

The pilot light indicates that the circuit breaker is ON and

that the controller is being supplied with electricity.

A fan is provided in each section of the furnace to provide

forced air cooling.

Types of Controllers

1. The automatic (single set point) digital model enables the

user to program a single set point temperature which the

furnace will heat and hold.

2. The 4 program, programmable digital model enables the

operator to program up to 8 ramp segments (heat-up or

cool-down rate) and 8 dwell segments (soak) for applica-

tions that require time and temperature relationship for

up to 4 separate or linkable programs.

3. The 15 program, programmable digital model enables

the operator to program up to 8 ramp segments (heat-up

or cool-down rate) and 8 dwell segments (soak) for up to

15 separate or linkable programs.

DESCRIPTION

9

General Specifications

Model# F46110CM, F46118 F46120CM F46128 F46120CM-75 F46128CM-75

F46110CM-33 F46120CM,-33 F46120CM-33-75

Dimensions Overall-in Width 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8 28-1/8

(cm) (71.4) (71.4) (71.4) (71.4) (71.4) (71.4)

Height 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2 18-1/2

(47) (47) (47) (47) (47) (47)

Depth 19 19 19 19 19 19

(48.3 (48.3) (48.3) (48.3) (48.3 (48.3)

Chamber- Width 6 6 6 6 6 6

in (cm) (15.2) (15.2) (15.2) (15.2) (15.2) (15.2)

Height 6-1/2 6-1/2 6-1/2 6-1/2 6-1/2 6-1/2

(16.5) (16.5) (16.5) (16.5) (16.5) (16.5)

Depth 6-1/4 6-1/4 6-1/4 6-1/4 6-1/4 6-1/4

(15.9) (15.9) (15.9) (15.9) (15.9) (15.9)

Weight LBS.(kg) 156 (70.9) 156 (70.9) 156 (70.9) 156 (70.9) 156 (70.9) 156(70.

Electrical Volts 240 208 240 208 240 208

Rating Amps 40*/10.4# 40*/12# 40*/10.4# 40*/12# 40*/10.4# 40*/12#

Watts 9600* 8320* 9600* 8320* 9600* 8320*

2500# 2500# 2500# 2500# 2500# 2500#

Phase 1 1 1 1 1 1

Temp. Range Cont. 1700°C 1700°C 1700°C 1700°C 1700°C 1700°C

Controller Automatic Automatic 4-Program. 4-Program. Multi-Prog. Multi-Prog.

NOTES:*Inrush power and current.

# Power and current required to maintain maximum temperature after stabilization.

The maximum current is determined by the limiting factor set by the current controller.In the event that 40 amperes is not available, the

current controller may be set to limit the current to some smaller value at the expense of a somewhat longer heat-up time.

The variation in current is a result of molybdenum disilicide heating elements

having a large decrease in resistance with increasing temperature.

NOTES:The maximum ramp rates for this furnace for heat-up are: 100°C per minute from 25°C-1000°C and

15°C per minute from 1000°C-1700°C.

General Specifications

10

Model# F46230CM, F46238 F46240CM F46248 F46240CM-75 F46248CM-75

F46230CM-33 F46240CM,-33 F46240CM-33-75

Dimensions Overall-in Width 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8 34-1/8

(cm) (86.7) (86.7) (86.7) (86.7) (86.7) (86.7)

Height 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2 22-1/2

(57.2) (57.2) (57.2) (57.2) (57.2) (57.2)

Depth 23 23 23 23 23 23

(58.4) (58.4) (58.4) (58.4) (58.4) (58.4)

Chamber- Width 10 10 10 10 10 10

in (cm) (25.4) (25.4) (25.4) (25.4) (25.4) (25.4)

Height 10-1/4 10-1/4 10-1/4 10-1/4 10-1/4 10-1/4

(26) (26) (26) (26) (26) (26)

Depth 9-3/4 9-3/4 9-3/4 9-3/4 9-3/4 9-3/4

(24.8) (24.8) (24.8) (24.8) (24.8) (24.8)

Weight LBS.(kg) 234 (106.3) 234 (106.3) 234 (106.3) 234 (106.3) 234 (106.3) 234 (106.3)

Electrical Volts 240 208 240 208 240 208

Rating Amps 40*/20.8# 40*/24# 40*/20.8# 40*/24# 40*/20.8# 40*/24#

Watts 9600* 8320* 9600* 8320* 9600* 8320*

5000# 5000# 5000# 5000# 5000# 5000#

Phase 1 1 1 1 1 1

Temp. Range Cont. 1700°C 1700°C 1700°C 1700°C 1700°C 1700°C

Controller Automatic Automatic 4-Program. 4-Program. Multi-Prog. Multi-Prog.

# Power and current required to maintain maximum temperature after stabilization.

The maximum current is determined by the limiting factor set by the current controller.In the event that 40 amperes is not available, the

current controller may be set to limit the current to some smaller value at the expense of a somewhat longer heat-up time.

The variation in current is a result of molybdenum disilicide heating elements

having a large decrease in resistance with increasing temperature.

NOTES:The maximum ramp rates for this furnace for heat-up are: 100°C per minute from 25°C-1000°C and

15°C per minute from 1000°C-1700°C.

Environmental Conditions

Operating:17°C-27°C; 20% to 80% relative humidity,

non-condensing. Installation Category II (over- voltage) in accordance with IEC 664.

Pollution Degree 2 in accordance with IEC 664. Altitude limit: 2,000

meters.

Storage: -25°C to 65°C; 20% to 80% relative humidity.

GENERAL SPECIFICATIONS

11

Declaration of Conformity

(-33 models only)

Barnstead|Thermolyne hereby declares under its sole

responsibility that this product conforms with the techni-

cal requirements of the following standards:

EMC: EN 50081-1 Generic Emission Standard;

EN 50082-1 Generic Immunity Standard;

Safety: IEC 1010-1-92 Safety requirements for

electrical equipment for measurement,

control, and laboratory use; Part I:

General Requirements

IEC 1010-2-010 Part II: Particular

requirements for laboratory equipment

for the heating of materials

per the provisions of the Electromagnetic Compatability

Directive 89/336/EEC, as amended by 92/31/EEC and

93/68/EEC, and per the provisions of the Low Voltage

Directive 73/23/EEC, as amended by 93/68/EEC.

The authorized representative located within the Euro-

pean Community is:

European Manager

Barnstead|Thermolyne

Saarbrückener Str. 248

D-38116 Braunschweig

Germany

Copies of the Declaration of Conformity are available

upon request.

NOTE

The Type 46100 and 46200 furnaces do

not come with an electrical cord because

current requirements are too great to be

handled by ordinary electrical cords and

standard wall electrical outlets.

Declaration of Conformity

12

Unpacking

Visually check for any physical damage to the shipping

container. Inspect the equipment surfaces that are adjacent

to any damaged area. Open the furnace door and remove

packing material from inside the furnace chamber.Vacuum

the chamber prior to use to remove the insulation dust due

to shipment. A hearth plate is supplied with the furnace to

be placed on bottom of furnace chamber.

Retain the original packaging material if re-shipment is

foreseen or required.

CAUTION

Be sure ambient temperature does

not exceed 104°F (40°C). Ambient

temperatures above 104°F (40°C)

may result in damage to the controller.

Allow at least six inches (15 cm) of

space between the furnace on all

sides and the top.This permits the

heat from the furnace case to escape.

WARNING

To avoid electrical shock, this furnace

must be installed by a competent,

qualified electrician who insures

compatibility among furnace specifi-

cations, electrical source and ground-

ing code requirements. Ensure unit is

properly grounded.

CAUTION

For supply connections, use 8 AWG or

larger wires suitable for at least 90°C.

Failure to observe this caution could

result in damage to furnace.

Unpacking

13

Installation

Site Selection: Install furnace on a sturdy surface and

allow space for ventilation.

The electrical specifications are located on the specifica-

tion

plate on the back of the furnace. Consult Barnstead/

Thermolyne if your electrical service is different than

those listed on the specification plate. Prior to connecting

your Type 46100 or 46200 furnace to your electrical

supply, be sure the front circuit breaker is in the OFF

position.

Furnace Connection

Remove cover plate for access to the electrical connec-

tions. Connect electricity to the three terminals found

behind this plate; one side of the 208 or 240 volt service

to the top terminal, L1; the other side of the 208 or 240

volt service to the bottom terminal, L2, and the ground

(usually green wire) to the center terminal marked GND.

For 220 volt service,connect the neutral to the top

terminal (marked L1); the 220 volt line to the bottom

terminal, L2, and the ground to the center terminal

marked GND. Electricity must be brought to the furnace

through an appropriate conduit system, through the hole

in the back panel at the bottom left rear of the furnace,

and connected as described. Be sure to observe local

wiring codes in connecting.

Initial heat-up procedure:

The elements may bend slightly sideways due to electro-

magnetic forces generated between the element shanks.

To prevent this bending, heat the furnace up to 1650°C

for 10-20 minutes.Then let furnace cool to ambient

temperature. See Operation for your particular controller

for information on setting temperature setpoints.

Installation

14

General Operation of Furnace

Observe these Warnings before operating your furnace:

WARNING

To avoid electrical shock, this furnace must:

1. Be installed by a competent, qualified electrician who

insures compatibility among furnace specifications, electri-

cal source and grounding code requirements.

2. Always be disconnected from the electrical supply

prior to maintenance and servicing.

To avoid personal injury:

1. Do not stand directly in front of the chamber without

wearing a heat resistant faceshield, gloves and apron.

2. Do not operate or clean furnace without proper eye

protection.

3. Do not use in the presence of flammable or combustible

materials; fire or explosion may result. This device contains

components which may ignite such materials.

4. Refer servicing to qualified personnel.

5. Caution: Hot Surface. Avoid Contact.

6. To AVOID EYE DAMAGE in operating or cleaning

furnace, proper eye protection must be worn.

7. To AVOID BURNS, do not stand directly in front of the

chamber without wearing a heat resistant faceshield, gloves

and apron.

8. To AVOID FIRE, do not place combustible materials

where exposed to heat from open door.

HOT SURFACE

Caution: Hot Surface. Avoid Contact.

Power Switch

Controls power to the furnace. Switch to the “ON” position

to energize the elements and the controller.

Cycle Indicator

The amber cycle light will illuminate when electricity is

being supplied to the elements.

CAUTION

Remember that when the power switch

is turned “ON”, the furnace will begin to

heat to the set point temperature that

was previously set in the controller. This

value will remain unchanged for up to a

year without electricity being supplied to

the controller.

CAUTION

If the electrical supply must be discon-

nected from the furnace at any time, be

sure the chamber temperature is 500°C

or less before doing so.

General Operation of Furnace

15

Circuit Breaker

A double pole circuit breaker is located at the bottom of

the control section. It serves to turn electricity ON and

OFF and to protect the electrical circuit.

Fans

The fans, located in the rear of the heating section and

the control section, will run continuously as long as

electricity is supplied to the furnace, even when the

furnace panel circuit breaker is OFF.This serves to

remove residual heat after the furnace is turned OFF so

the heat does not cause damage to the controls.

Controllers

Your furnace’s controller consists of a microprocessor

based three-mode (Proportional, Integral, Derivative),

programmablecontrol with overtemperature protection

and appropriate output switching devices to control the

furnace.The digital readout continuously displays

chamber (upper display) and set point (lower display)

temperatures unless the scroll button is depressed.

If the scroll button is depressed and released, the lower

display will indicate output power (OP) or set point (SP).

This is referred to as the “short scroll”. Continued single

step depression of scroll button will cause lower display

to alternate between set point (SP) and output power

(OP).

To enter the main scroll list (list of all controller param-

eters that are accessed through front keyboard), the

scroll button should be held depressed.On the Automatic

Models, PR (program ramp rate) will appear. On the

Programmable Models, PR1 (program ramp rate 1) will

appear.To progress through the parameter list, the scroll

button must first be released, subsequent single step

depression will advance you through the list. Rapid

progression through the parameter list is achieved by

holding the scroll button depressed. (See Control Param-

eters for your particular controller for a list of param-

eters.)

NOTE

When performing operations on the

controller, remember that if you depress

and release either the “scroll”, “up”, or

“down” push buttons and more than 8

seconds elapse before the buttons are

used again, the display screen will

automatically switch back to displaying

set point temperature. If this happens,

you will have to step through each

parameter until you reach the point at

which the interruption occurred. The

parameter values you

adjusted earlier, however, will not be lost

or altered.

NOTE

Due to the High Temperature design of

the thermocouple, the controller will

indicate a temperature of 70°-90°C at

ambient temperature.

GENERAL OPERATION OF FURNACE

16

Operation of Automatic Models

(ModelsF46110CM, F46110CM-33,F46118CM,

F46230CM, F46230CM-33, F46238CM)

Control Parameters

PR = program ramp rate, the rate of heat increase or

decrease in °C/minute. Pushing the up or down button will

give the current setting of this ramp. Push up or down

button to set.

SP2. SP2 is not configured into control and nonfunctional.

Set to 20.

ST = Self-tune automatically loads PID values on initial

start up.This function does not have a value, it is

either “ON” or “OFF”. (See Furnace Operation for

function of Self-tune).

AT = Adaptive Tune, which analyzes and inputs optimum

PID values when temperature has reached set point.This

function does not have a value, it is either “ON” or

“OFF”. (See Furnace Operation for function of Adaptive

Tune).

SAT = Self-Adaptive Tune when engaged starts controller in

self-tune mode then automatically switches to Adaptive

Tune (AT).This function does not have a value, it is either

“ON” or “OFF”. (See Furnace Operation for function of

Adaptive Tune).

ATR = Adaptive Tune Range setting determines the

operational band width of the adaptive tuning function.

Self-tuning automatically determines this setting.

AL1 = Alarm 1 is a full scale alarm which protects load

and furnace when temperature exceeds preset value.

Furnace will control temperature at the preset

temperature value, it will not shut off furnace.

The next five parameters: proportional (PB), integral (+i),

derivative (+d), cutback low (cbl) and cut back high (cbh)

are for high accuracy control.These parameters are set

during Self-Adaptive Tune. (See Tuning Your Furnace.)

NOTE

Thermolyne recommends that you set

the value of AL 1 either at 1710°C

(3092°F) or at a value of 20 degrees

above your working temperature if you

desire to provide protection for your

workload.

NOTE

“OR” will be displayed if an open thermo-

couple condition exists.

NOTE

To change from °C indication to °F

indication, contact Barnstead/

Thermolyne.

NOTE

The automatic control has automatic

tuning features which install optimum

tuning parameters to give the best

temperature accuracy. No manual

loading of tuning parameters is needed.

We recommend that you tune the

furnace to your specific application to

obtain the best

results.To provide the best temperature

accuracy possible, use these features

when you install yourfurnace and

whenever you change your application

orprocedure.

Operation of Automatic

Controls

17

HL = Output Power limits the average maximum percent-

age

of electricity that is applied to the heating elements.

Depress and release up or down button, if 100 is not

displayed, contact Barnstead/Thermolyne.

Sbr = the power that is required to indicate an open

thermocouple condition exists. Push up or down button, if

0.0 is not displayed, contact Barnstead/Thermolyne.

Tuning Your Furnace

The SAT Self and Adaptive Tuning feature starts the

controller in the Self-tune mode, then automatically

switches over to the Adaptive Tuning mode. Self-Tuning

is a one-time function which permits the user to tune the

instrument control parameters to suit new process

conditions.

Adaptive tuning takes over when the self-tune is com-

pleted and continuously evaluates tuning parameters.

Adaptive tuning automatically installs new values if better

accuracy is

possible.

To Tune Your Furnace:

1. Load your furnace with a load characteristic of those

you intend to heat in it.

2. Depress scroll button until SAT is displayed. Depress

the up and down buttons simultaneously to start self-

tuning.

During Tuning, the A-T indicator is illuminated (upper

right hand corner) and the lower display indicates the set

point at which the self-tune sequence will occur.The “SP”

indicator will flash for 1 minute, during which time the set

point may be changed (use temperature set point that

your application requires). At the end of one minute, the

“SP” indicator will stop flashing, indicating that the set

point can no longer be changed.The A-T indicator will

start flashing and continue to flash until the self-tune is

completed. After the self-tune is completed, adaptive

tune takes over and the A-T indicator will remain illumi-

nated.

NOTE

The self-tune feature will be inactive if you

implement a ramp to setpoint. If your

implement a ramp to setpoint, the adaptive

tune feature will be active only after you

reach your setpoint. See Program Ramp

Rate for more information on ramping to

setpoint.

CAUTION

Minimize operation of furnace under

800°C. Element life is reduced when

operating below 800°C because the

protective layer of silica glass takes

longer to form.

NOTE

Once the desired parameter has been

selected, depressing either the raise or

lower button will cause the parameter to

be replaced with the new value.At this

point, the “top dot” of the least significant

digit of the secondary display will flash on

and off. Any further use of up or down

buttons will change parameter value. In all

cases, the value shown on the display is

the current working

NOTE

The two center push buttons are non-

functional.

NOTE

The program ramp rate is designed to

reduce the heat-up rate or cooling rate

that the furnace normally exhibits. When

not using this feature, the furnace will

operate at its maximum heating and

cooling capability.

OPERATION OF AUTOMATIC CONTROLS

18

3. To stop tuning function, scroll until SAT is displayed

and simultaneously push up and down buttons.

Single Set Point Operation

The automatic control is used as a single set point control,

which includes one ramp to set point capability.To use as a

single set point control, simply push up or down buttons to

choose a specific temperature.The control will cause the

furnace chamber to heat to the chosen temperature and

hold it at this temperature until you turn off the front circuit

breaker switch or select another temperature.

To operate the control:

1. Turn power switch to the “ON” position.The set point

temperature presently set in the control will appear on

the lower display.

2. To change this set point, depress the “UP” or “DOWN”

push button until the desired set point value is displayed

then release the button.

3. The furnace will begin to heat if the new set point

temperature you have chosen is higher than the present

chamber temperature.

4. The upper display indicates actual chamber tempera-

ture.

NOTE

When the program ramp has ended or

has been reset, the furnace will

continue to maintain set point tem-

perature. It will not cool to ambient

temperature unless set point is set to

ambient temperature.

OPERATION OF AUTOMATIC CONTROLS

19

Program Ramp Rate

If you desire to ramp to the set temperature at a specified

rate, depress scroll button until “PR” appears. (“PR” =

program ramp rate, which is the rate of heat increase or

decrease in °C/minutes). Depress up or down button to

give current setting of ramp rate. Depress up or down

button again until you achieve desired setting.

To start the temperature ramp, push the run button.With

the run initiated, the program will commence and the

legend on the display will indicate “RAMP”. While a

program is running, the short scroll will contain three

parameters. SP = set point. OP = output power.Time =

time remaining in program ramp to reach set point

temperature. Single depression of the scroll button will

allow you to view each of these parameters.

When the program ramp has ended, an “E” will appear

on the display.

Program Ramp Reset

A running or finished program can be reset by depress-

ing the run/hold button.

After depressing the run/hold button, the parts of the

display associated with programming will be extinguished

and the controller will operate as a single set point

control as described before.

OPERATION OF AUTOMATIC CONTROLS

20

Operation of Programmable Models

(F46120CM, F46120CM-33, F46120CM-33-75, F46120CM-

75, F46128CM,

F46128CM-75, F46240CM, F46240CM-33, F46240CM-33-

75, F46240CM-75,

F46248CM, F46248-75)

Control Parameters

PR1 = program ramp rate is the rate of heat increase or

decrease in °C/minute. Pushing the up or down button to

set.

PL1 = program level is the temperature which the furnace

needs to attain. Push up or down button to set.

PD1 = program dwell “1” is amount of time, in minutes, to

hold the PL1 program temperature level entered. Push up

or down button to set.

The remaining Program Ramp Rates PR2 - PR8, Program

Levels PL2 - PL8, and Program Dwells PD2 - PD8 follow in

the same manner as PR1, PL1 and PD1. (After PD8).

HB = “Holdback” automatically places the programmer into

“Hold” if the measured value deviates more than a specified

amount from programmer setpoint. When measured value

re-enters the holdback band, the timing for the segment

resumes. (Parameter is expressed in °C and only functions

when running a program). Push up or down button to set.

PLC = Program Loop Count is the number of times a

program will be repeated. Push up or down button to set.

SP1 = setpoint one which indicates current setpoint. Push

up or down button to set.

SP2=Setpoint two. Not configured into control and

nonfunctional. Set to 20.

Operation of Programmable

Models

NOTE

Once the desired parameter has been

selected, depressing either the raise

or lower button will cause the param-

eter to be replaced with the new

value. At this point, the “top dot” of the

least significant digit of the secondary

display will flash on and off. Any

further use of up or down buttons will

change parameter value. In all cases,

the value shown on the display is the

current working value of that param-

eter

MODELS F46120CM, F46120CM-33,

F46120CM-33-75, F46120CM-75,

F46128CM, F46128CM-75,

F46240CM, F46240CM-33,

F46240CM-33-75, F46240CM-75,

F46248CM, F46248CM-75

NOTE

These models have two additional

parameters at the beginning of the

parameter list;

Pnr is the program number selected.

By pushing the up or down button,

you can select a program from 1 to

15. On the F46120CM, F46120CM-

33, F46128CM, F46240CM,

F46240CM-33 and F46248CM

models, this is selected between 1-4.

Cnt is used to allow linking of pro-

grams. Cnt (continued) may be

selected as “y” (yes) or “n” (no) by

pushing the up or down button.The

remaining parameters will follow in the

sequence listed.

Other manuals for F46110CM

1

This manual suits for next models

17

Table of contents

Other Barnstead Furnace manuals

Popular Furnace manuals by other brands

Suburban

Suburban NT-12S Service manual

Winchester

Winchester WEFC**48 installation manual

Ingersoll-Rand

Ingersoll-Rand S9V2B040U3PSBC Service facts

Allied

Allied A97US2V installation instructions

Bryant

Bryant 361AAN Installation, start-up, and operating instructions

Amana

Amana AMS9 installation instructions

International comfort products

International comfort products F9MXE0401410A Service and technical support manual

Lennox

Lennox EL296DFE Series manual

ICP

ICP NDN5050BFA1 installation instructions

Bryant

Bryant A02182 owner's manual

ECR International

ECR International GTH User's information manual

Williams

Williams 0743512 owner's manual