Bassra Machine Tools BMT 2000 User manual

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

USER MANUAL

BMT 2000

HOTMELT BUTYL

EXTRUDER

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

BMT 2000 TECHNICAL CHARACTERISTICS

• 2Kg Max Per minute

• 50Kg Extrude Capacit

• 4 Temperature Controllers

• Digital Readout of all Temperature Zones

• Tamper Proof Factor set Operating Temperatures

• Programmable Temperature Controllers

• Progressive Sealant Heating Hopper, Pump, Hose & Gun

• Cool to Touch Moulded Gun Handle

• 3 Metre Hose

• Positive Displacement Gear T pe Pump

• Under Temperature on all Zones

• Miniature Circuit Breaker Protection

• 12- Month Warrant

BMT 2000 TECHNICAL DATA

• Voltage: - 220- 240 Volts

• Frequenc : - 50 Hz

• Control Voltage: - 12 Volts

• Amperes: - 13 Amp/3 Kw

• Electric Motor: - 0.55 Kw

• Length: - 880mm

• Width: - 570mm

• Height: - 1240mm

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

TABLE OF CONTENTS

NO. SUBJECT PAGE

1 Technical Information about the Machine 4

2 Introduction 5

- Operation Manual

- Questions

- Training

3 Signatures 6

4 Intended Use of the Machine 7

5 General Safet Rules 8 - 10

- General Rules

- Electrical S stem 10

6 Safet Rules for Filling The Hotmelt Material 11

7 Start up of the BMT 2000 Hotmelt Machine 12

8 To Stop the Machine 12

9 Maintenance and Cleaning 13

10 Basic Troubleshooting 13 - 14

11 Warning S mbols 15

12 Notes 16

13 BMT Manual for Controllers 17 - 18

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

1

.

Technica Information about the Machine

Customer Name - _______________

Name of Machine - Hotmelt Machine

Model/T pe - 2000

Serial Number -

_________________

Date of Construction - _______________

Warrant Start Date -

_______________

Warrant Finish Date -

_______________

Voltage/Frequenc -

_______________

Motor - 0.55 Kw

Tank Resistance - 30 Ω Cold

Pump Resistance - 72 Ω Cold

Hose Resistance - 80 Ω Cold

Gun Resistance - 600 Ω Cold

Probe T pe - ________________

Tank Capacit - _______________

Rate of Flow - 2000g/min

Min. Operating Temp - 165°C

Production Manager: -

__________________

Signature

Print Name

_____________________

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

2. Introduction

Dear User

Please specif the following serial number of the machine if ou have an enquiries,

or ou would like extra copies of this manual:

BMT 2000 --------------------------------

Operation Manual

This manual is exclusivel for the BMT 2000 machine.

Each operator must read this manual BEFORE operating the machine.

Make sure the manual is kept near the machine and is alwa s at hand for the

operating personnel.

Questions

Should ou have an questions or require an assistance after reading this manual,

please feel free to contact our Technical Services Department at: -

Bassra Machine Tools Ltd

99 Spring Road

T sele

Birmingham

B11 3DJ

Tel: +44 (0) 121 707 4343

Fax: +44 (0) 121 707 3535

Email: sales@bassra.com

Training

No person should be allowed to operate the machine – even for a short time –

without adequate training, either at our factor or b our field service staff

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

3. Signatures

Each authorised machine operator must have full read the operators manual before

working with the machine. The person responsible for plant safet should request all

operators to confirm this b asking them to sign below.

I have read and understood this Operating Manual

Date: Signature:

Owner : ______________ _____________________

Print Name: _________________________

Operator 1 : ______________ _____________________

Print Name: _________________________

Operator 2 : ______________ _____________________

Print Name: _________________________

Operator 3 : ______________ _____________________

Print Name: _________________________

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

4. Intended Use of the Machine

The BMT 2000 is designed for use b the Double Glazing Industr .

We recommend the use of Bostik Products when operating this machine. Please note

the address of Bostik supplier: -

Bostik (UK) Ltd

Ulverscroft Road

Leicester

LE4 6BV

Tel: +44 (0) 116 251 0015

Fax: +44 (0) 116 253 1943

Our compan will not be liable for the usage of an material other than that specified.

5. Genera Safety Ru es

Your BMT 2000 machine has been built to the latest engineering standards. It is safe

and reliable if properl operated. Safet has been a major design consideration.

However, an machine can be a source of potential danger if improperl handled or

operated b unqualified, untrained and careless personnel, or if used outside the

scope of its intended use.

Be sure to observe all instructions given in this manual and strictl compl with all

local safet and accident prevention rules and regulations.

General Rules

• The machine should be operated, maintained and repaired b authorised and full

trained personnel that have been thoroughl instructed about potential hazards. No

one should be allowed to operate or be near this machine unless he or she is both

ph sicall and mentall alert.

• The owner should clearl establish the responsibilities for assembling, disassembling

and reassembling the machine, or putting the machine into operation, setting up,

operating and servicing the machine.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

• The owner is allowed to operate the machine onl if it is in a safe condition.

Major repairs must onl be carried out b the manufacturer or b speciall

authorised, qualified personnel.

• The operator must report and defects or alterations which affect the safet of

the machine.

• Product safet signs or decals should be periodicall inspected, cleaned or

replaced when the no longer meet the legibilit requirements for safe viewing

at a reasonable distance.

• Do not operate the machine outside the scope of its intended use. Application

outside the scope of intended use constitutes a safet hazard.

• The manufacturer will not be liable for applications outside the scope of the

machines intended use. The owner shall in such cases bear the sole

responsibilit for an resulting injuries or damage.

• Make sure the enclosures removed for maintenance work or repairs are refitted

before starting the machine.

• Do not begin an maintenance or set-up work before the machine has been

switched off and has come to a complete standstill.

• Do not open enclosures, doors or hinged covers before the machine has come

to a complete standstill. Observe all relevant safet procedures.

• Do not remove, alter or deactivate an machine parts or safet equipment.

• Onl use original BMT spare parts for our machine. We do not undertake an

liabilit for possible damage caused to the machine as a result of unauthorised

use of non-BMT parts or unauthorised changes/alterations.

• Keep the working area clean and tid . Dirt (e.g. oil or dust on the floor) and

obstacles constitute a safet hazard.

• BMT will not undertake an liabilit for injuries or damage caused b

misconduct or failure to observe these safet instructions.

• Make sure that the control voltage is switched off (Master Switch OFF) and

secured against accidental restart before installing and setting up the machine.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

Electrical S stem

• Observe the following safet precautions when doing an work on the control

cabinet.

• Separate the machine from the power suppl (Master Switch OFF) and secure it

against accidental restart before starting an work on an electrical

components.

• Onl qualified electricians are allowed to do an work on the electric s stem.

• Be sure to test all protective measures (e.g. grounding resistance) before

restarting the machine after service or repairs.

• Do not remove electrical devices that function as safet equipment.

• It is advisable that the machine is protected b an RCD Unit.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

6. Safety Ru es for Fi ing the Hotme t Materia

The following rules must be taken into attention while filling the Hotmelt material.

• The level of the Hotmelt material should be checked ever time before starting

the machine. If the machine is working non-stop, the operator should check

the level of the material. It should never drop below the tank tubes.

• Hotmelt material is taken out of its package in a solid state, and must be put

inside the tank without touching an external material.

• The material in its solid state must be put slowl into the tank. Material must

not be thrown from a higher place otherwise this can damage the tubes.

• E eglasses and masks must be used while the tank is open. Direct contact of

hot air rising from the tank should be avoided.

• High temperature warning signs must be taken into consideration while

working in the tank cap and its surroundings.

• Use the machine in a well ventilated area.

• Gloves must be worn while gunning to prevent burns.

• The material’s chemical composition, which is defined in the closure, has no

toxic propert . An kind of toxic material should not be used. BMT strongl

refuses liabilit in case of an hazards that could arise from misuse of the

machine and material.

• The machine should be positioned on a level surface.

• Ensure that in between operations, the gun is placed in a safe place to ensure

that nobod touches the hot parts.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

7. Start up of the BMT 2000 Hotme t Machine

• Plug the machine in to a 220 – 240V 50Hz power suppl .

• Switch on the main switch. Tank, Pump, Hose, Gun, Temperature Control

will read the temperatures of their respective zones.

• A BMT 2000 will take approximatel 2 hours (Refer to table on Page

17 to 19) to reach 185 - 190°C depending on ambient temperature.

• The machine will not run until all temperatures are above 165°C.

• Turn the Pot Knob halfwa , or to the speed desired.

• Pull the trigger on the Gun to extrude Hotmelt. NEVER POINT THE GUN AT

ANOTHER PERSON!

8. To stop the Machine

• Place the Gun and Hose in a safe position.

• Switch off the Isolator.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

9. Maintenance and C eaning

• The machine should be visuall inspected dail to check for damage to the

Hose and Gun.

• The maintenance and cleaning operations must be done periodicall to extend

the machines running time.

10. Basic Troubleshooting

Problem Cause Remed

Temperature Controllers Machine is not Plug the machine into a

do not light up. plugged in. 220V/240V mains suppl .

Check fuse (if fitted) in

Plug top.

Isolator is not Switch on Isolator.

switched on. Check timer settings.

M.C.B has tripped Unplug the machine

from the mains. Open

the panel and check that

all the breakers are in the

up position.

Contact BMT LTD

Tank; Pump; of Hose not Machine has not been Leave the machine for

reaching the desired left on for specified + 2 hours for temperature

temperature. period of warm-up. to rise up.

M.C.B has tripped Unplug the machine

from mains, open the

panel, check that all

breakers are in the up

position.

Contact BMT LTD

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

If problem continues, please telephone the BMT Technical Department.

Problem Cause Remed

No Hotmelt is extruded Speed Control is on Turn the knob

when trigger is pulled. minimum or OFF. clockwise to desired

speed.

Temperature is below

165°C. Contact BMT LTD

.

Blockaged inside the gun

Temperature Controllers Probe failure. Contact BMT LTD

read - - -

If problem continues, please telephone the BMT Technical Department.

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

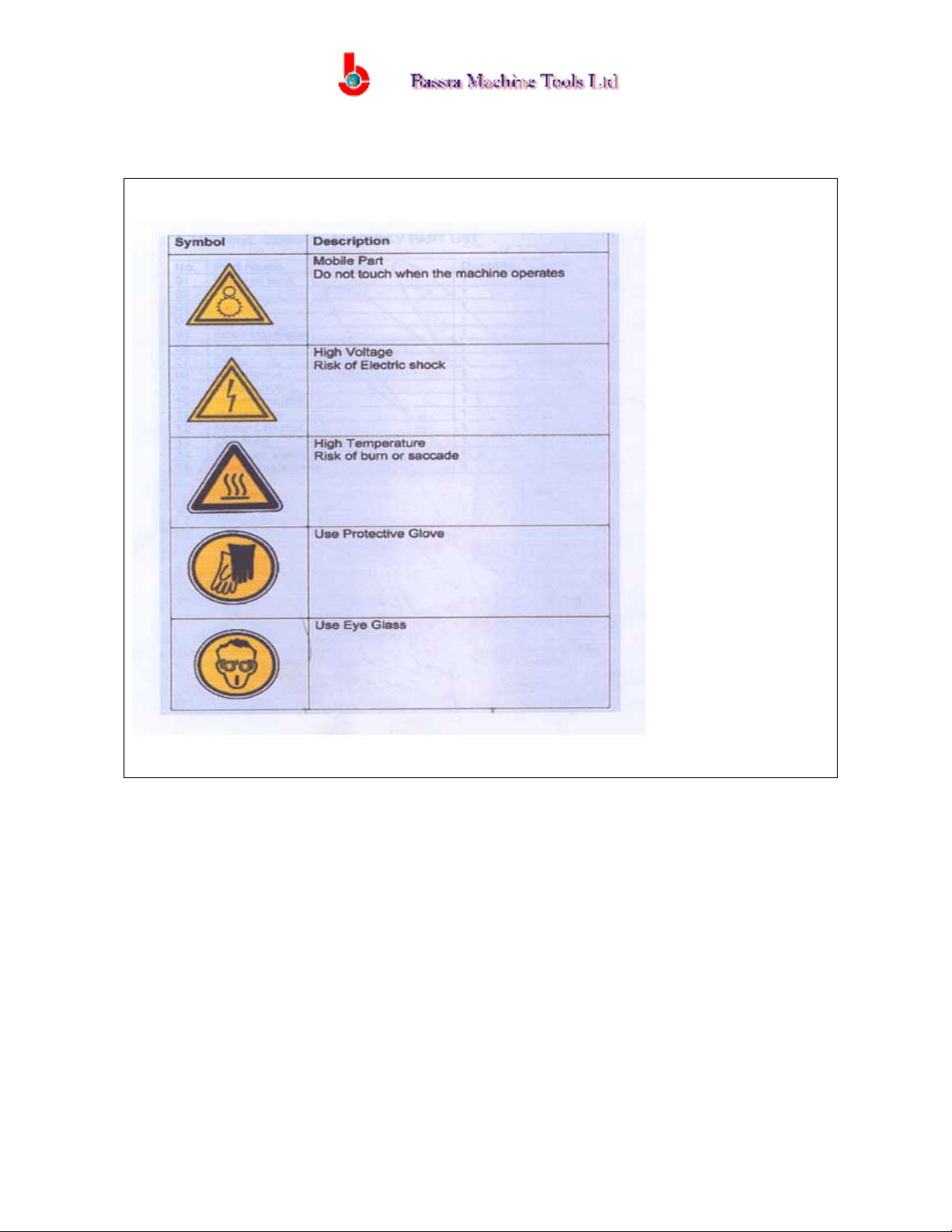

11. Warning Symbo s

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

12. Notes

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

13. BMT Manua for Contro ers

BMT 1000/2000/3000/4000 MANUAL

Thank ou for purchasing machiner from Bassra Machine Tools Limited. The

following are some simple to follow instructions for safe and effective use.

The machine should be full with sealant and special care should be taken to

avoid the sealant level dropping below the top row of heaters.

All temperatures should be set to manufacturers recommended values.

Do not drag the machine b the hose as this can cause severe damage.

The lid should be kept closed to avoid an debris getting into the hopper.

The machine should never be left on without use for an length of time.

When the machine operative is read to begin sealing the units, the machine

should be run back into the hopper for a few seconds to ensure no cold sealant

is injected into the unit.

Non-compliance will result in the guarantee being void.

Refer to the table below for hours 1st time prior to use etc.

TYPE OF

MACHINE

NO. OF HOURS 1ST

TIME PRIOR TO USE

NO. OF HOURS

PRIOR TO USE

TIMER

BMT 1000 3 Hours 2 Hours Not Fitted

BMT 2000 4 Hours 3 Hours Fitted

BMT 3000 5 Hours 3 and a half Hours Fitted

BMT 4000 6 Hours 4 Hours Fitted

SET-UP

TIMER

The timer is 7-da timer with an override option. Each segment of the dial is

equivalent to one hour. To set the timer to switch on/off, simpl pull out the

appropriate segments.

For winter/summer time adjustments then simpl turn the hands of the clock to the

new correct time. Refer to the table above and check the numbers of hours the timer

should be set prior to use.

CONTROLLERS

During commission of our machine the temperatures will be set for the t pe of

sealant ou intend to use. If however, ou need to alter the set temperature, follow

the following procedure: -

BASSRA MACHINE TOOLS LTD.

99 Spring Road, Tyseley, Birmingham, United Kingdom, B11 3DJ

Tel: 0044 0) 121 707 4343 / Fax: 0044 0) 121 707 3535

Website: www. bassra.com / Email: [email protected]

CAREL CONTROLLER

The SEL s mbol should be pressed for two seconds. ST1 will start to flash and its

setting will be displa ed. Press the up and down s mbols until the desired

temperature is reached. Press SEL again and ST2 will be displa ed. (Care should be

taken not to adjust ST2 set point as this could stop the machine working if done

incorrectl ). Press SEL again to exit setup.

TECHNOLOGIC CONTROLLER

Push ke “P” then release it and the displa will visualise “SP1”. To modif the valve,

press “UP” ke to increase it or the “DOWN” ke to decrease it. Once the desired

valve has been reached b pushing “P” it is possible to check AL1, (the under

temperature valve set and locked at 165°C). Push “P” once again to exit

programming.

Care should be taken not to adjust an other set points, as this could stop the

machine if done incorrectl .

MAINTENANCE

All maintenance should be carried out b approved B.M.T. engineers.

Keeping the machine clean is often overlooked, particularl with regard to the hose.

The hose should have a piece of carpet, or similar, placed under it where contact is

made with the floor. This prolongs the life of the hose, but onl if the carpet is kept

clean and free from pieces of debris, especiall glass.

This manual suits for next models

3

Table of contents