6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Basic operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.1 Display during idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.2 Display during a process or in menus . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.3 Entering text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.4 Using the external keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Melting point determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

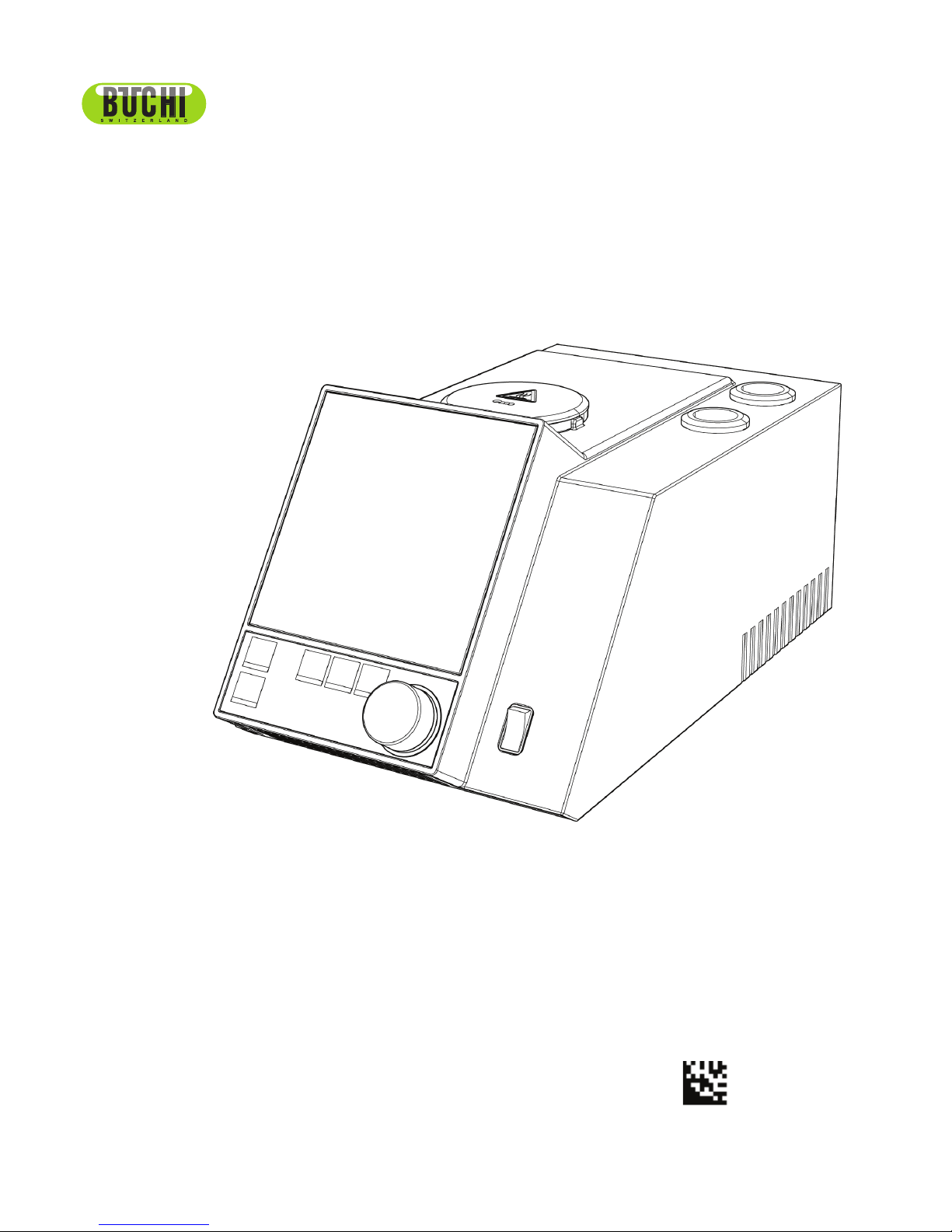

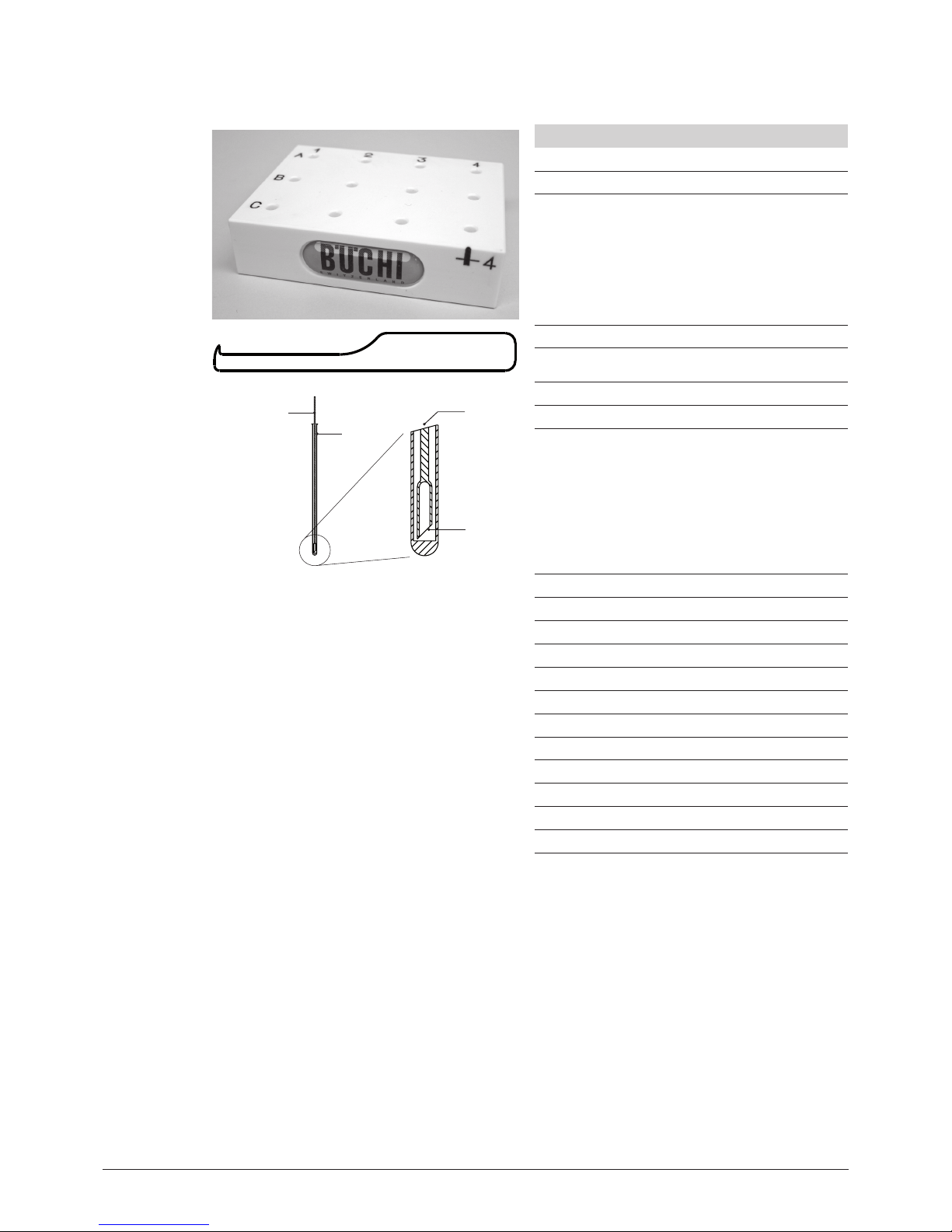

6.2.1 Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.2 Determination without pre-registered melting point method . . . . . . . . . . . . . . 27

6.2.3 Creating a method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.4 Using and handling methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.5 Adjusting parameters during a determination . . . . . . . . . . . . . . . . . . . . . 31

6.2.6 Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.7 Melting result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Boiling point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.1 Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.2 Determination without pre-registered boiling point method . . . . . . . . . . . . . . 38

6.3.3 Creating a method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.4 Adjusting parameters during a determination . . . . . . . . . . . . . . . . . . . . . 40

6.3.5 Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.1 Calibration principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.3 Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.4 Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5 Settings, SysInfo, Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5.1 Test protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.5.2 SysInfo protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6. User Managment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.7 XML to PC data export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2 Glass window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3 Upkeep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 Cleaning the heating block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1.1 Setting the printer baud rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 Shutdown, storage, transport, and disposal . . . . . . . . . . . . . . . . . . . . . . . 58

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 60