Summit Ice Melt Systems

PO Box 6 28, Tahoe City, CA 6145

Ph: 530-583-8888 Fax: 530-583-7777

www.

SummitIceMelt.com

Introduction

Radiant Edge is a roof edge ice melt system that minimizes ice formations

on the following applications:

• Roofs made from standard roofing materials, including shakes,

shingles, rubber, hot tar, wood, metal, and plastic.

• Gutters and downspouts made from standard materials, including

metal and plastic.

The guide does not cover applications in which any of the following

conditions exist:

• Preventing snow movement on roofs — Radiant Edge will not keep

snow or ice from falling off the roof. Radiant Edge is designed to minimize

ice formations and safely remove melt water from roof eaves. Snow fences

or snow guards should be used to eliminate snow movement.

• Melting snow off a roof and/or reduction of snow load. Radiant Edge is

designed to melt ice, not accumulated snow.

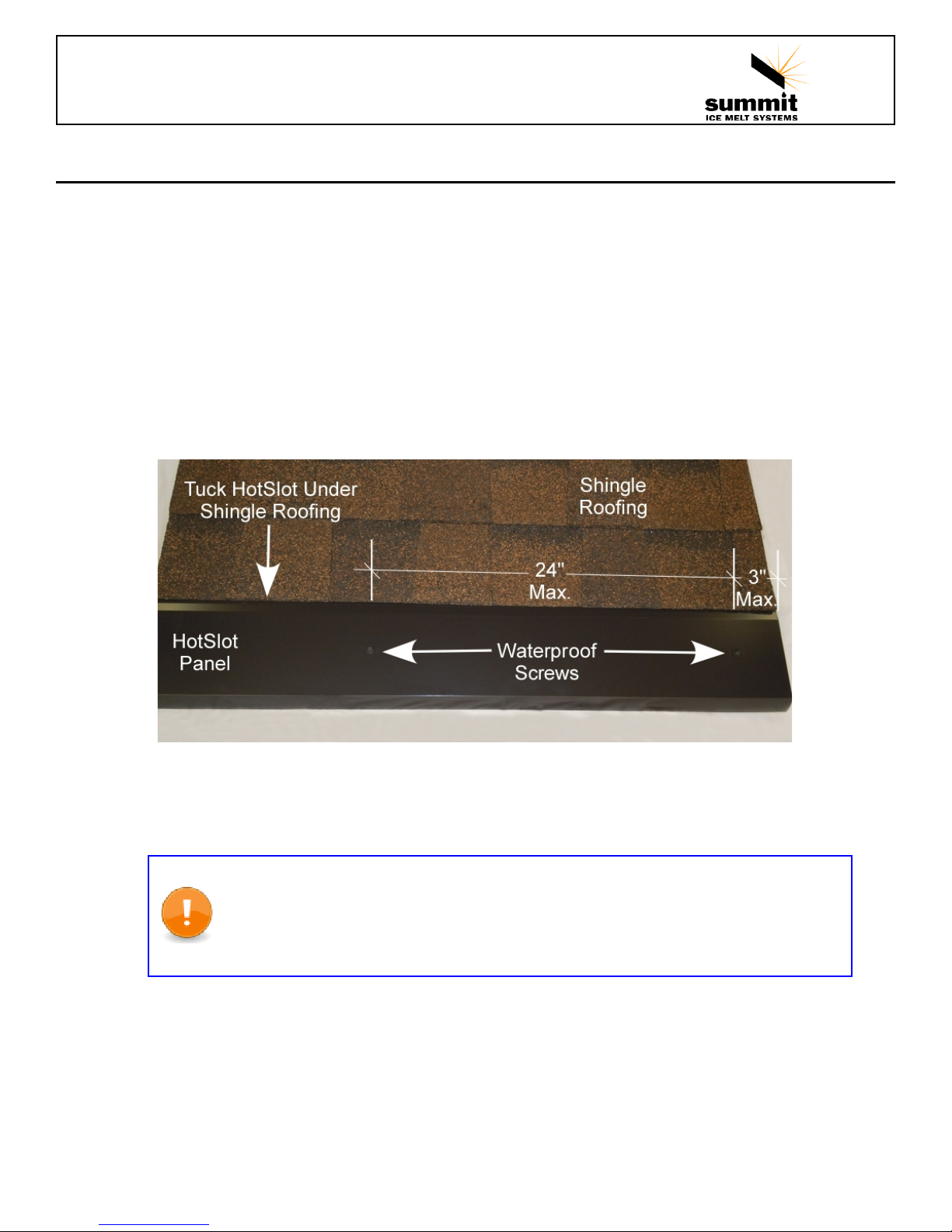

HotSlot is intended for lighter ice and snow conditions on certain metal and

composition shingle roofs. If conditions warrant, consider the more robust,

patented Radiant Edge PRO

TM

or LT

TM

ice melt systems.

For the names of manufacturers of snow guards or snow fences, contact

your Summit Ice Melt Systems' representative, or contact Summit Ice Melt

Systems' directly at (530) 583-8888.

If your application conditions are different, or if you have any questions,

contact your Summit Ice Melt Systems' representative, or contact Summit

Ice Melt Systems directly at (530) 583-8888.

How To Use This Guide

This installation guide presents Summit Ice Melt Systems’

recommendations for installing the Radiant Edge HotSlot roof edge ice

melt system. It provides design and performance data, heating cable

layout installations, electrical hookup and testing. Following these

recommendations will result in a reliable, energy-efficient system. Read

and understand this entire guide before installation.

Page 3 of 2