Bauer Compressors P0 Manual

Instruction Manual and Replacement Parts List

BAUER Compressors, Inc. Phone: (757) 855-6006

1328 Azalea Garden Road Fax: (757) 855-6224

Norfolk, Virginia 23502-1944 www.bauercomp.com

April 17, 2013 3rd Edition, Rev 0 Chg 6 MNL-0096

© Bauer Compressors, Inc.

Breathing Air Purification Systems

and

Industrial Air Purification Systems

Breathing Air Purification Models

P0 P1 P2 P4

P5 P10 P31 P41

P42 P43

with Securus®Electronic Moisture Monitor System

P2S P5S P10S P14S

P42S P43S P12 P14

Industrial Air Purification Models

IP41 IP42 IP43

with Securus®Moisture Monitoring System

IP2S IP5S IP10S

IP41S IP42S IP43S

Purification Systems

Page i 3rd Edition, Rev 0 Chg 6

This information is believed to be accurate by Bauer Compressors, Inc., as of it’s date of publication,

but Bauer offers NO WARRANTY regarding the accuracy, or continuing accuracy, of the information

set forth herein. Bauer shall not be liable for inaccuracies in, or consequences resulting from, your use

of this information. All information supplied is in connection with sales of Bauer’s products, and is thus

subject to Bauer’s standard terms and conditions of sale. Bauer reserves the right to change this infor-

mation and has no obligation to update these materials. This information is copyrighted by Bauer Com-

pressors, Inc., and Bauer reserves to itself all rights to this publication. Bauer’s customers have no right

to reproduce, rewrite, modify, license or permit anyone else’s use of this information, without the

express written permission of Bauer Compressors, Inc.

EDITIONS, REVISIONS AND CHANGES

• An Edition is the original or a complete rewriting of the entire Manual.

• A Revision occurs whenever a complete Section or Appendix is rewritten or added.

• A Change occurs when individual pages, drawings or tables are changed.

^WARNING

This Instruction Manual and Replacement Parts List contains safety information and instructions for the

Air Purification Systems.

You must read, understand and follow all safety precautions and instructions.

3rd Edition May 11, 2005

Rev Chg Date Notes Auth

0 0 May 11, 2005 JD

0 1 Dec. 12, 2005 Changed Manual Condensate Drain Valve to P/N 073793 JD

0 2 Aug. 1, 2006 Corrected Figures 5-1, 5-4, 5-9 & 5-12.

Added Figures 5-8 and 5-16. JD

0 3 Jan. 17, 2007 Add P/N N24788 to P31 Purification System Parts list JD

0 4 Mar. 19, 2007 Life Span of Oil/Water Separator Lengthened JD

0 5 July 9, 2010 Updated High Flow Cartridge Removal SS

0 6 Apr. 17, 2013 Updated P31 Part numbers to B61.1 SS

MNL-0096

April 17, 2013 Page ii

Table of Contents

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

1.1 HOW TO USE THIS MANUAL.........................................................................................................................................1

1.1.1 Manual Safety Notices.......................................................................................................................................................1

1.2 HOW TO USE THE REPLACEMENT PARTS LIST....................................................................................................2

1.3 HOW TO USE THE APPENDIX.......................................................................................................................................3

CHAPTER 2:- - - - - - - - - - - - - - - - PURIFICATION SYSTEM

2.1 INTRODUCTION................................................................................................................................................................4

2.1.1 General Purification System Procedures............................................................................................................................4

2.1.2 Chamber Safety Bore.........................................................................................................................................................4

2.1.3 Manual Condensate Drainage ............................................................................................................................................5

2.1.4 Model, Serial Number and Part Number Identification.....................................................................................................5

2.1.4.1 Compressor Dataplate.....................................................................................................................................................5

2.1.4.2 Purification System Dataplate ........................................................................................................................................6

2.1.4.3 Cartridge Installation Dataplate......................................................................................................................................6

2.1.5 Breathing Air Purification System Configurations............................................................................................................6

2.1.6 Industrial Purification System Configurations...................................................................................................................7

2.1.7 Cartridge Operating Life....................................................................................................................................................7

2.1.7.1 Calculating the Maximum Cartridge Operating Hours ..................................................................................................8

2.1.7.2 Calculating the Adjusted Cartridge Operating Hours.....................................................................................................8

2.1.7.3 Air Purification Cartridge Operating Hours Form........................................................................................................10

CHAPTER 3:- - - - SINGLE CHAMBER PURIFICATION SYSTEMS

3.1 APPLICABILITY..............................................................................................................................................................11

3.2 P0 PURIFICATION SYSTEM DESCRIPTION............................................................................................................11

3.2.1 Maintenance.....................................................................................................................................................................12

3.2.1.1 Replacing the Cartridge................................................................................................................................................12

3.2.1.2 Chamber Replacement Interval ...................................................................................................................................13

3.2.2 Replacement Parts List.....................................................................................................................................................15

3.3 P31 PURIFICATION SYSTEM.......................................................................................................................................17

3.3.1 Major Components...........................................................................................................................................................17

3.3.2 Configuration Options......................................................................................................................................................18

3.3.3 Maintenance.....................................................................................................................................................................19

3.3.3.1 Replacing the Cartridge................................................................................................................................................19

3.3.4 Replacement Parts List.....................................................................................................................................................20

CHAPTER 4:- - - - -MULTI-CHAMBER PURIFICATION SYSTEMS

4.1 APPLICABILITY..............................................................................................................................................................23

4.2 COMPONENTS LAYOUT...............................................................................................................................................23

4.3 COMPONENT DESCRIPTION ......................................................................................................................................24

4.3.1 Oil and Water Separator...................................................................................................................................................24

4.3.2 Chamber...........................................................................................................................................................................25

4.3.3 Cartridge...........................................................................................................................................................................25

4.3.3.1 Cartridge Handling .......................................................................................................................................................25

4.3.4 Condensate Drain Valve...................................................................................................................................................25

Purification Systems

Page iii 3rd Edition, Rev 0 Chg 6

4.3.5 Check Valves....................................................................................................................................................................26

4.3.6 Bleed Valve......................................................................................................................................................................26

4.3.7 Pressure Maintaining Valve .............................................................................................................................................26

4.3.8 Safety Valve .....................................................................................................................................................................26

4.4 MAINTENANCE...............................................................................................................................................................26

4.4.1 Oil and Water Separator...................................................................................................................................................26

4.4.2 Cartridge Replacement.....................................................................................................................................................27

4.4.2.1 Leaking at the Safety Bore............................................................................................................................................28

4.5 PURIFICATION CARTRIDGE APPLICABILITY......................................................................................................29

4.5.1 Purification Chamber Position References.......................................................................................................................29

4.6 PURIFICATION SYSTEM REPLACEMENT PARTS LIST......................................................................................31

4.6.1 P1 Purification System.....................................................................................................................................................31

4.6.2 P2 Purification System ....................................................................................................................................................32

4.6.3 P2S and IP2S Purification System ...................................................................................................................................33

4.6.4 P4 Purification System.....................................................................................................................................................34

4.6.5 P5 Purification System.....................................................................................................................................................35

4.6.6 P5S and IP5S Purification System ...................................................................................................................................36

4.6.7 P10 Purification System...................................................................................................................................................37

4.6.8 P10S and IP10S Purification System ...............................................................................................................................38

4.6.9 P10S II Purification System .............................................................................................................................................39

4.6.10 P41 and IP41 Purification System....................................................................................................................................40

4.6.11 P41S and IP41S Purification System ...............................................................................................................................41

4.6.12 P42 and IP42 Purification System....................................................................................................................................42

4.6.13 P42S and IP42S Purification System ...............................................................................................................................43

4.6.14 P43 and IP43 Purification System....................................................................................................................................44

4.6.15 P43S and IP43S Purification System ...............................................................................................................................45

4.7 PURIFICATION COMPONENTS REPLACEMENT PARTS LIST..........................................................................46

4.7.1 Oil and Water Separator, P/N 079416 .............................................................................................................................46

4.7.2 10” Chamber, P/N 080143 ...............................................................................................................................................47

4.7.3 20” Chamber P/N 082135 ...............................................................................................................................................48

4.7.4 20” Securus® Chamber P/N 082136................................................................................................................................49

4.7.5 20” Securus II® Chamber P/N 082136............................................................................................................................51

4.7.6 27” Chamber P/N 080144 ...............................................................................................................................................53

4.7.7 27” Securus® Chamber P/N 080145 ...............................................................................................................................55

4.7.8 27” Securus II® Chamber P/N 080145 ...........................................................................................................................57

CHAPTER 5:- - - - - - - - HIGH FLOW PURIFICATION SYSTEMS

5.1 APPLICABILITY..............................................................................................................................................................59

5.2 P12 PURIFICATION SYSTEM.......................................................................................................................................59

5.2.1 Major Components and Configurations ...........................................................................................................................59

5.2.1.1 Oil and Water Separator ...............................................................................................................................................60

5.2.1.2 Condensate Drain Valve ..............................................................................................................................................60

5.2.1.3 Check Valves................................................................................................................................................................60

5.2.1.4 Dryer Cartridge.............................................................................................................................................................60

5.2.1.5 Bleed Valve...................................................................................................................................................................60

5.2.1.6 Pressure Maintaining Valve..........................................................................................................................................60

5.2.1.7 Safety Valve..................................................................................................................................................................60

5.2.1.8 Securus®Electronic Moisture Monitor System ............................................................................................................60

5.2.1.9 Securus®Cartridge........................................................................................................................................................60

5.2.1.10 Securus®Indicator.........................................................................................................................................................60

5.2.2 Maintenance .....................................................................................................................................................................61

5.2.2.1 Oil and Water Separator ...............................................................................................................................................61

MNL-0096

April 17, 2013 Page iv

5.2.2.2 Chamber........................................................................................................................................................................62

5.2.2.3 Cartridge Leaks after Installation.................................................................................................................................63

5.2.3 Replacement Parts List ....................................................................................................................................................64

5.3 P14 PURIFICATION SYSTEM.......................................................................................................................................72

5.3.1 Major Components...........................................................................................................................................................72

5.3.1.1 Oil and Water Separator ...............................................................................................................................................73

5.3.1.2 Condensate Drain Valve...............................................................................................................................................73

5.3.1.3 Check Valves................................................................................................................................................................73

5.3.1.4 Dryer Cartridge.............................................................................................................................................................73

5.3.1.5 Bleed Valve ..................................................................................................................................................................73

5.3.1.6 Pressure Maintaining Valve..........................................................................................................................................73

5.3.1.7 Safety Valve..................................................................................................................................................................73

5.3.1.8 Securus®Electronic Moisture Monitor System............................................................................................................73

5.3.1.9 Securus®Cartridge........................................................................................................................................................73

5.3.1.10 Securus®Indicator ........................................................................................................................................................73

5.3.2 Maintenance.....................................................................................................................................................................74

5.3.2.1 Oil and Water Separator ...............................................................................................................................................74

5.3.2.2 Chamber........................................................................................................................................................................75

5.3.2.3 Cartridge Leaks after Installation.................................................................................................................................76

5.3.3 Replacement Parts List ....................................................................................................................................................77

CHAPTER 6:- - - - - - - - - - - - - - - - - - - - - - - - APPENDIX

6.1 SAFETY..............................................................................................................................................................................86

6.1.1 General Safety Precautions ..............................................................................................................................................86

6.1.2 Safety Warning Labels.....................................................................................................................................................88

6.2 UNPACKING, HANDLING AND INSTALLATION ...................................................................................................89

6.2.1 Unpacking and Handling..................................................................................................................................................89

6.2.2 Installation of the Unit......................................................................................................................................................89

6.2.2.1 General..........................................................................................................................................................................89

6.2.2.2 Electrical Installation....................................................................................................................................................89

6.3 LONG TERM STORAGE.................................................................................................................................................90

6.3.1 General.............................................................................................................................................................................90

6.3.2 Preparations......................................................................................................................................................................90

6.3.2.1 Units Equipped with a Filter System............................................................................................................................90

6.3.3 Preserving the Compressor...............................................................................................................................................90

6.3.4 Preventive Maintenance During Storage..........................................................................................................................91

6.3.5 Lubrication Oils for Preservation.....................................................................................................................................91

6.3.6 Reactivating the Compressor Unit ...................................................................................................................................91

6.4 REFERENCE DATA.........................................................................................................................................................93

6.4.1 Tightening Torque Values................................................................................................................................................93

6.4.2 Torque Sequence Diagrams .............................................................................................................................................93

6.4.3 Conversion Formulas .......................................................................................................................................................93

6.4.4 Approved Lubricants Chart..............................................................................................................................................94

6.4.5 Glossary of Abbreviations and Acronyms.......................................................................................................................94

6.5 ADDITIONAL DOCUMENTS ........................................................................................................................................95

6.5.1 Diagrams and Drawings...................................................................................................................................................95

6.5.2 Other Documents..............................................................................................................................................................95

Purification Systems

Page v 3rd Edition, Rev 0 Chg 6

List of Figures

CHAPTER 1:- - - - - - - - - - - - - - - - - - - - - INTRODUCTION

Figure 1-1 Compressor Identification Label.............................................................................................................................2

CHAPTER 2:- - - - - - - - - - - - - - - - -PURIFICATION SYSTEM

Figure 2-1 Cartridge Safety Venting.........................................................................................................................................5

Figure 2-2 P0 & P31 Safety Venting.........................................................................................................................................5

Figure 2-3 Purification System Dataplates (typical) .................................................................................................................5

Figure 2-4 Correction Factor for Cartridge Operating Hours ...................................................................................................9

Figure 2-5 Example Record of Adjusted Operating Hours.......................................................................................................9

CHAPTER 3:- - - - -SINGLE CHAMBER PURIFICATION SYSTEMS

Figure 3-1 P0 Purification Chamber........................................................................................................................................11

Figure 3-2 P0 Purification System Cross Section ...................................................................................................................12

Figure 3-3 P0 Purification System ..........................................................................................................................................15

Figure 3-4 P31 Purification System ........................................................................................................................................17

Figure 3-5 P31 Purification System Cross Section .................................................................................................................18

Figure 3-6 P31 Purification System ........................................................................................................................................20

Figure 3-7 P31 Purification System Base Assembly...............................................................................................................21

Figure 3-8 P31 Purification System Check Valve...................................................................................................................22

CHAPTER 4:- - - - - MULTI-CHAMBER PURIFICATION SYSTEMS

Figure 4-1 Typical Bauer Purification System........................................................................................................................23

Figure 4-2 Oil and Water Separator ........................................................................................................................................24

Figure 4-3 OIl and Water Separator Labels ............................................................................................................................25

Figure 4-4 Oil and Water Separator ........................................................................................................................................27

Figure 4-5 Sintered Metal Filter Assembly.............................................................................................................................27

Figure 4-6 Cartridge Replacement ..........................................................................................................................................28

Figure 4-7 Purification Chamber Position...............................................................................................................................29

Figure 4-8 P1 Purification System ..........................................................................................................................................31

Figure 4-9 P2 Purification System ..........................................................................................................................................32

Figure 4-10 P2S and IP2S Purification System.........................................................................................................................33

Figure 4-11 P4 Purification System ..........................................................................................................................................34

Figure 4-12 P5 Purification System ..........................................................................................................................................35

Figure 4-13 P5S and IP5S Purification System.........................................................................................................................36

Figure 4-14 P10 Purification System ........................................................................................................................................37

Figure 4-15 P10S and IP10S Purification System.....................................................................................................................38

Figure 4-16 P10S II Purification System ..................................................................................................................................39

Figure 4-17 P41 and IP41 Purification System.........................................................................................................................40

Figure 4-18 P41S and IP41S Purification System.....................................................................................................................41

Figure 4-19 P42 and IP42 Purification System.........................................................................................................................42

Figure 4-20 P42S and IP42S Purification System.....................................................................................................................43

MNL-0096

April 17, 2013 Page vi

Figure 4-21 P43 and IP43 Purification System.........................................................................................................................44

Figure 4-22 P43S and IP43S Purification System ....................................................................................................................45

Figure 4-23 Oil and Water Separator, P/N 079416...................................................................................................................46

Figure 4-24 10” Chamber, P/N 080143 ....................................................................................................................................47

Figure 4-25 20” Chamber P/N 082135 .....................................................................................................................................48

Figure 4-26 20” Securus®Chamber P/N 082136......................................................................................................................49

Figure 4-27 20” Securus®Chamber P/N 082136......................................................................................................................51

Figure 4-28 27” Chamber P/N 080144 .....................................................................................................................................53

Figure 4-29 27” Securus®Chamber P/N 080145......................................................................................................................55

Figure 4-30 27” Securus II®Chamber P/N 080145 ..................................................................................................................57

CHAPTER 5:- - - - - - - - HIGH FLOW PURIFICATION SYSTEMS

Figure 5-1 P12 Purification System........................................................................................................................................59

Figure 5-2 Oil and Water Separator........................................................................................................................................62

Figure 5-3 Cartridge Replacement..........................................................................................................................................63

Figure 5-4 P12 Purification System........................................................................................................................................64

Figure 5-5 Oil and Water Separator........................................................................................................................................65

Figure 5-6 27” High Flow Chamber Assembly ......................................................................................................................67

Figure 5-7 Securus®Chamber Assembly................................................................................................................................69

Figure 5-8 CO Removal Chamber ..........................................................................................................................................71

Figure 5-9 P14 Purification System........................................................................................................................................72

Figure 5-10 Oil and Water Separator........................................................................................................................................75

Figure 5-11 Cartridge Replacement..........................................................................................................................................76

Figure 5-12 P14 Purification System........................................................................................................................................77

Figure 5-13 Oil and Water Separator........................................................................................................................................79

Figure 5-14 27” High Flow Chamber Assembly ......................................................................................................................81

Figure 5-15 Securus®Chamber Assembly................................................................................................................................83

Figure 5-16 CO Removal Chamber ..........................................................................................................................................85

CHAPTER 6:- - - - - - - - - - - - - - - - - - - - - - - - APPENDIX

Figure 6-1 Lifting Devices......................................................................................................................................................89

Figure 6-2 6 Bolt and 4 Bolt Torque Sequence.......................................................................................................................93

Purification Systems

Page 1 3rd Edition, Rev 0 Chg 6

CHAPTER 1: INTRODUCTION

1.1 How To Use This Manual

This manual contains the operating and maintenance instructions for the Bauer Compressors, Inc. prod-

ucts listed on the front cover.

All instructions in this manual should be observed and carried out as written to prevent damage or prema-

ture wear to the product or the equipment served by it.

If your unit is equipped with nonstandard accessories and or options, supplemental information is nor-

mally included in other documentation; i.e. OEM Manuals or additional Bauer Manuals.

While every effort is made to ensure the accuracy of the information contained in this manual, Bauer

Compressors, Inc. will not, under any circumstances be held accountable for any inaccuracies or the con-

sequences thereof.

1.1.1 Manual Safety Notices

Important instructions concerning the endangerment of personnel, technical safety or operator safety will

be specially emphasized in this manual by placing the information in the following types of safety

notices.

^DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or seri-

ous injury. This is limited to the most extreme situations.

^WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

injury.

^CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or mod-

erate injury. It may also be used to alert against unsafe practices.

NOTICE

NOTE advise of technical requirements that require particular attention by the operator or the mainte-

nance technician for proper maintenance and utilization of the equipment.

MNL-0096

April 17, 2013 Page 2

1.2 How to Use the Replacement Parts List

• A lozenge in the Item Number column indicates the part number for a complete assembly.

• a dagger (†) in the Qty column with or without an ellipse (…) in the Part Number column means the

part is illustrated for assembly purposes only and is not available for sale as an individual component.

This part can be obtained by ordering the complete assembly.

• AR in the Qty column means that the item is cut or manufactured to the size which the customer spec-

ifies.

• A dash (—) in the Item Number column indicates that there is more than one part number applicable

to the preceding Item Number.

• The letters in the columns labeled Kit indicate the number of operating hours when the part is to be

replaced; a = replaced every 1,000 hours, b = replaced every 2,000 hours and c= replaced every 4,000

hours.

• NS in the Item Number column indicates the part is not illustrated but is available.

When placing an order for spare parts, please provide the following information to ensure delivery of the

correct parts. The model number, date of manufacture and serial number can be found of the compressor

unit identification plate on the compressor unit frame.

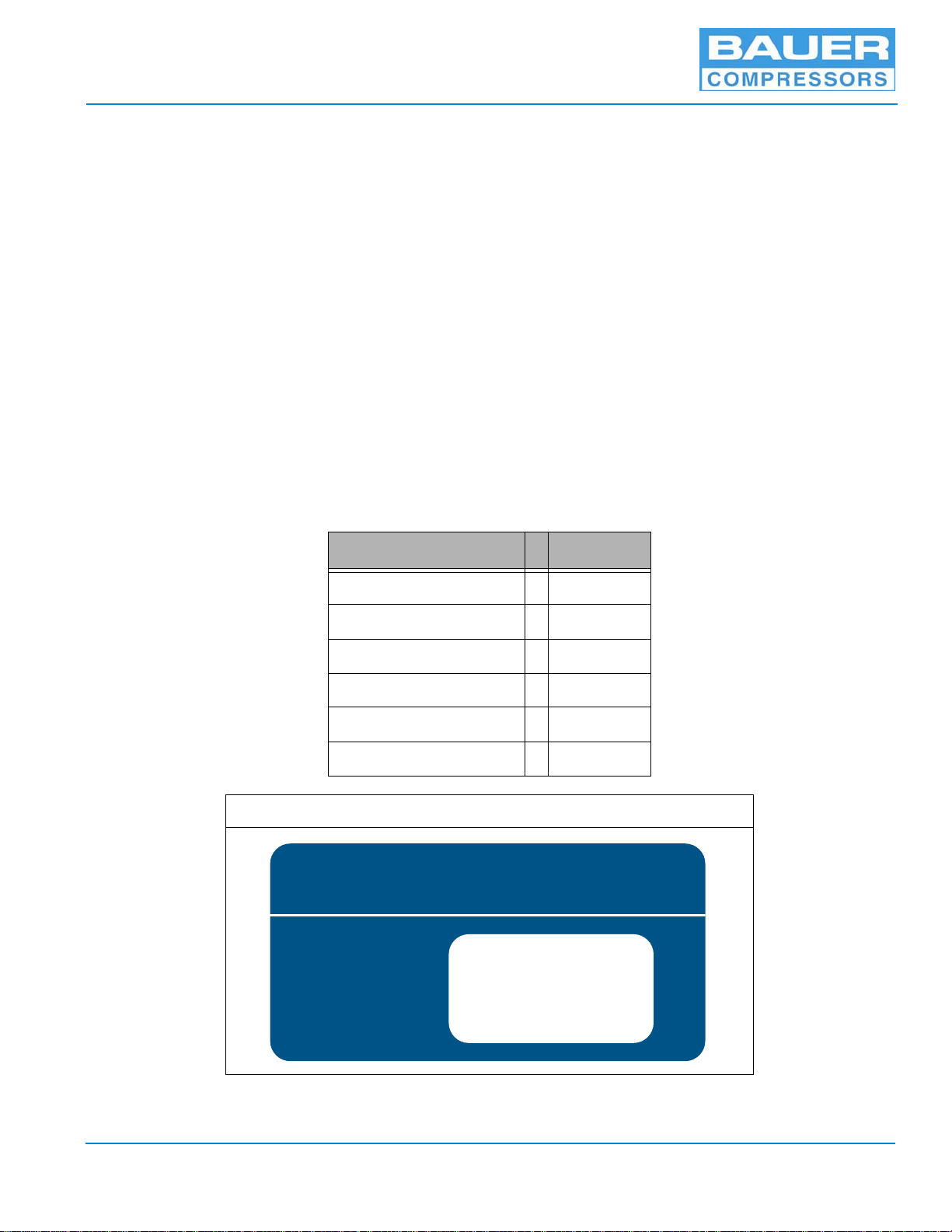

Information Example

Model Number VC 120

Serial Number 143156

Date of Manufacture 02/2013

Part Number VAL-0500

Part Description Valve

Part Quantity Required 1

Figure 1-1 Compressor Identification Label

BAUER COMPRESSORS, INC.

NORFOLK, VA 23502 U.S.A. (757) 855-6006

MODEL NO.

BLOCK NO.

SERIAL NO.

QUANTITY

MFG. DATE

Purification Systems

Page 3 3rd Edition, Rev 0 Chg 6

1.3 How to Use the Appendix

Information contained in the Appendix to this manual includes the following.

• The safety instructions applicable to this product. They must be read, understood and complied with

prior to operating the product.

• The instructions for installing this product. They must be read, understood and complied with prior to

operating the product.

• Reproducible Forms

• Reference Data

• Torque Values

• Torque Sequence

• Conversion Formulas

• Approved Lubricants

• Glossary of Abbreviations & Acronyms

• Additional Documents

^WARNING

The use of repair parts other than those included in the Bauer Replacement Parts Lists may create unsafe

conditions over which Bauer has no control. Such unsafe conditions can lead to accidents that may be life-

threatening, cause substantial bodily injury, and/or result in damage to the equipment. Therefore, Bauer

Compressors, Inc. can bear no responsibility for equipment in which unapproved repair parts are installed.

MNL-0096

April 17, 2013 Page 4

CHAPTER 2: PURIFICATION SYSTEM

2.1 Introduction

The purpose of all Bauer breathing air purification systems is to remove carbon monoxide, oil, water,

taste and odor from the compressed air stream before final delivery.

The purpose of all Bauer industrial air purification systems is to remove oil and water from the com-

pressed air stream before final delivery.

The quality of gas produced by the compressor is directly related to the quality and temperature of the gas

taken in by the unit. Intake gas should as close as possible to 50 °F (10 °C) and cleanest available and as

dry as possible. Bauer compressors normally add approximately 18 °F (10 °C) to the intake gas tempera-

ture. The purification cartridges perform their best at approximately 68 °F (20 °C). Adequate ventilation

enhances the quality and life of the purification cartridges.

2.1.1 General Purification System Procedures

1. Keep an accurate record of operating hours to ensure exact attention to maintenance intervals

2. Change all cartridges before reactivating a compressor unit that has been out of service more than

three months. Leave cartridges in the unit as long as it is out of service.

3. While out of service keep all condensate drain valves closed. Maintain a pressure of 700 - 1,100 psi

(50 to 80 bar) within the system to prevent moisture from entering the compressor and purification

system.

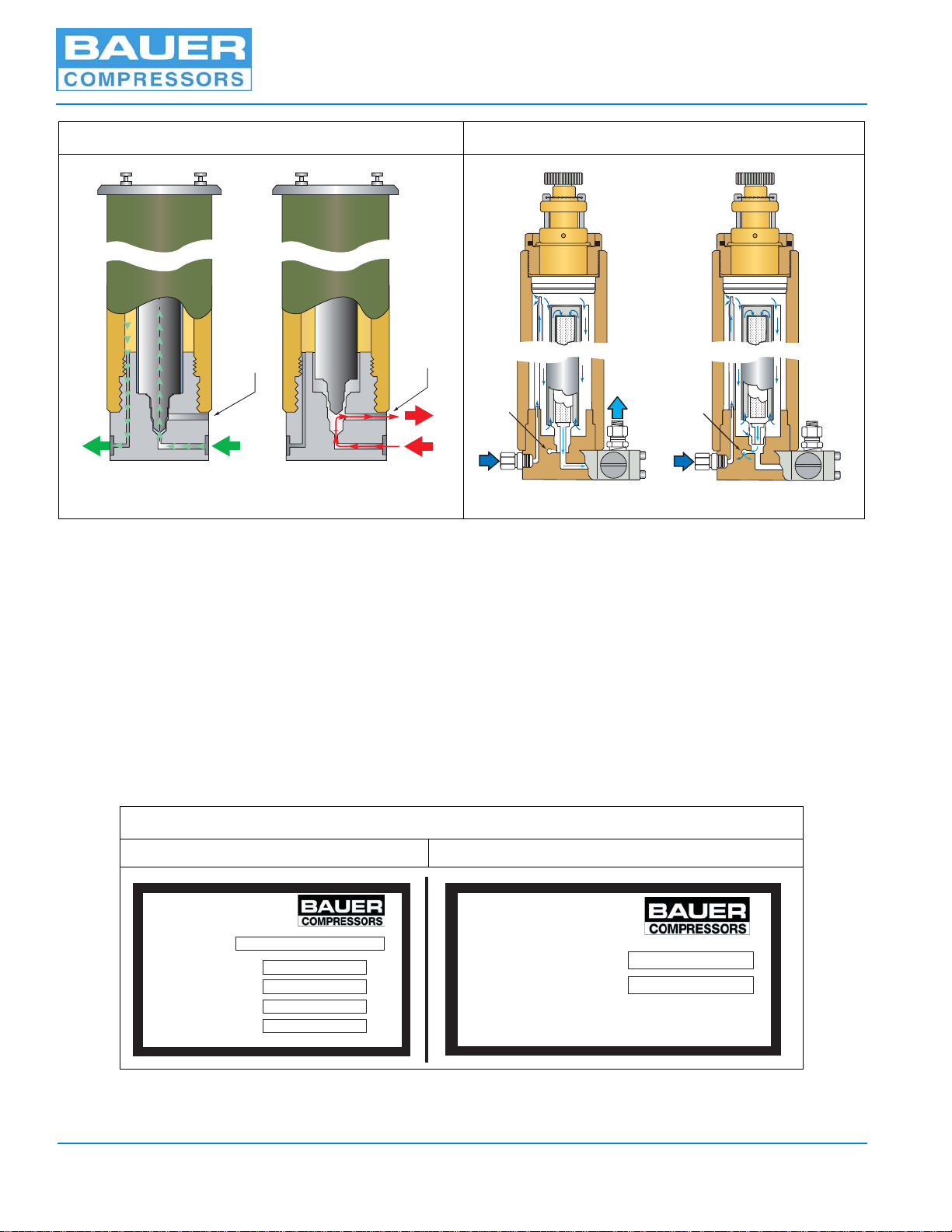

2.1.2 Chamber Safety Bore

The chambers in all Bauer purification systems are designed to prevent pressurization if the cartridge is

missing, not seated properly or damaged (Figure 2-1 & Figure 2-2). Without a cartridge properly in place

the safety bore is not sealed, the air escapes into the atmosphere, no pressure can be built up and thus it is

ensured that unfiltered air is not supplied to the consuming device. If air is escaping from the safety bore

remove and check cartridge. If necessary replace the cartridge or O-rings.

^WARNING

Industrial Air Purification System cartridges do not remove Carbon Monoxide

and must not be used in breathing air applications.

Purification Systems

Page 5 3rd Edition, Rev 0 Chg 6

2.1.3 Manual Condensate Drainage

The condensate must be drained from the oil and water separator before changing any cartridge, before

beginning each filling procedure and in the absence of an Automatic Condensate Drain (ACD) system,

every fifteen minutes during the filling procedure. This is done by slowly opening the condensate drain

valves. They are opened approximately 1/3 of a turn to the left and held open until the condensate is com-

pletely drained. The condensate drain valves close by spring pressure but if necessary may be tightened

by hand to ensure they are completely air tight.

2.1.4 Model, Serial Number and Part Number Identification

2.1.4.1 Compressor Dataplate

The model number, date of manufacture and serial number can be found on the compressor unit identifi-

cation plate in the main electrical enclosure and frame.

Figure 2-1 Cartridge Safety Venting Figure 2-2 P0 & P31 Safety Venting

Figure 2-3 Purification System Dataplates (typical)

Purification System Cartridge Installation

Safety

Vent

Cartridge Installed

correctly

Safety

Vent

No Cartridge Installed

or Installed incorrectly Cartridge Installed

Correctly No Cartridge or Installed

Incorrectly

Safety

Vent

Safety

Vent

CARTRIDGE FOR

CARTRIDGE NO.

LBL-0044

CARTRIDGE TO BE

INSTALLED

1328 Azalea Garden Road - Norfolk Virginia 23502-1944

Phone: (757) 855-6006 Fax: (757) 855-8224

MODEL NO.

MAX. PRESSURE

AIR PROCESSED

O-RING

BACK-UP RING

psig

cu. ft.

LBL-0191

PURIFICATION

SYSTEM

MNL-0096

April 17, 2013 Page 6

2.1.4.2 Purification System Dataplate

Refer to the compressor unit purification system data plate (Figure 2-3) on the compressor front to deter-

mine your purification system model and specifications.

2.1.4.3 Cartridge Installation Dataplate

The function performed by each chamber in the purification system is determined by the type of cartridge

installed in that chamber. Refer to the cartridge installation data plate on the chamber to determine the

purpose and part number of the cartridge installed in that chamber. (Figure 2-3).

2.1.5 Breathing Air Purification System Configurations

Purification System Number and Type of Cartridges Processing Capacity

Dryer Purification Securus®cubic ft (ft)3

P0 Combined 3,200

P1 … 1 … 15,000

P2 … 1 … 40,000

P2 with Securus®… … 1 67,000

P4 1 1 … 60,000

P5 1 1 … 90,000

P5 with Securus®1 … 1 150,000

P10 2 1 140,000

P10 with Securus®2 … 1 230,000

P12a

a. P12 and P14 have the Securus®Electronic Moisture Monitor System as standard equipment.

1 1 420,000

P14 a2 1 650,000

P31 Combined 11,760

P41 … 1 28,700

P41 with Securus®… … 1 47,000

P42 1 1 … 64,000

P42 with Securus®1 … 1 107,000

P43 2 1 … 100,000

P43 with Securus®2 … 1 164,000

P81 1 1 124,000

P81 with Securus®1 ... 1 198,000

Purification Systems

Page 7 3rd Edition, Rev 0 Chg 6

2.1.6 Industrial Purification System Configurations

2.1.7 Cartridge Operating Life

Every Bauer Purification System is designed to process a certain volume of air before the cartridges

require replacement. By using special test equipment that measures the quality of air at the outlet any

quality reduction may be detected. However as most compressor owners do not have this test equipment

the recommended method of determining cartridge operating life is to maintain a written record of the

volume of air processed by the purification system.

Each Bauer compressor block is rated to produce a standard volume of air per minute and by using this

number and the air processing capability of the purification system it is possible to calculate the maxi-

mum operating hours before the cartridges need to be replaced. See Paragraph 2.1.7.1 for the method of

determining this figure.

The ambient air temperature and its ability to cool the compressor will effect the operating life of the car-

tridge. See Paragraph 2.1.7.2 for the method of calculating this adjustment factor.

The optimum place to measure the temperature is at the inlet to the final separator as this best reflects the

temperature of the air as it enters the chambers. Experience has shown that this temperature is approxi-

mately 18 °F above the ambient temperature. Therefore for the purpose of calculating cartridge operating

life use the Ambient Air Temperature plus 18 °F.

A form titled Air Purification Cartridge Operating Hours is found in Paragraph 2.1.7.3 and in the

Appendices. It is used for recording the ambient temperature, operating time and adjustment factor. It

Purification System Number and Type of Cartridges Processing Capacity

Dryer Purification Securus®cubic ft (ft)3

P0 Combined 3,200

P1 … 1 … 15,000

P2 … 1 … 40,000

IP2 with Securus®… … 1 67,000

P4 1 1 … 60,000

P5 1 1 … 90,000

IP5 with Securus®1 … 1 150,000

P10 2 1 140,000

IP10 with Securus®2 … 1 230,000

P31 Combined 11,760

IP41 with Securus®… … 1 47,000

IP42 with Securus®1 … 1 107,000

IP43 with Securus®2 … 1 164,000

MNL-0096

April 17, 2013 Page 8

is suggested that it be copied, placed in a protective folder and kept with the unit to record the adjusted

operating hours. An example of how this form is used is shown in Figure 2-5.

2.1.7.1 Calculating the Maximum Cartridge Operating Hours

1. From the purification system data plate (See Figure 2-3) on the purification chamber determine the

Air Processed (cu.ft.)

2. From the paragraph titled Compressor Specifications in the instruction manual for your compressor

unit determine the Charging Rate in SCFM of your compressor.

3. Divide the Air Processed by the Charging Rate to obtain the Maximum Operating Time in minutes

4. Divide the Maximum Operating Time in minutes by 60 to obtain the Maximum Operating Hours.

5. Record the answer on the Air Purification Cartridge Operating Hours form.

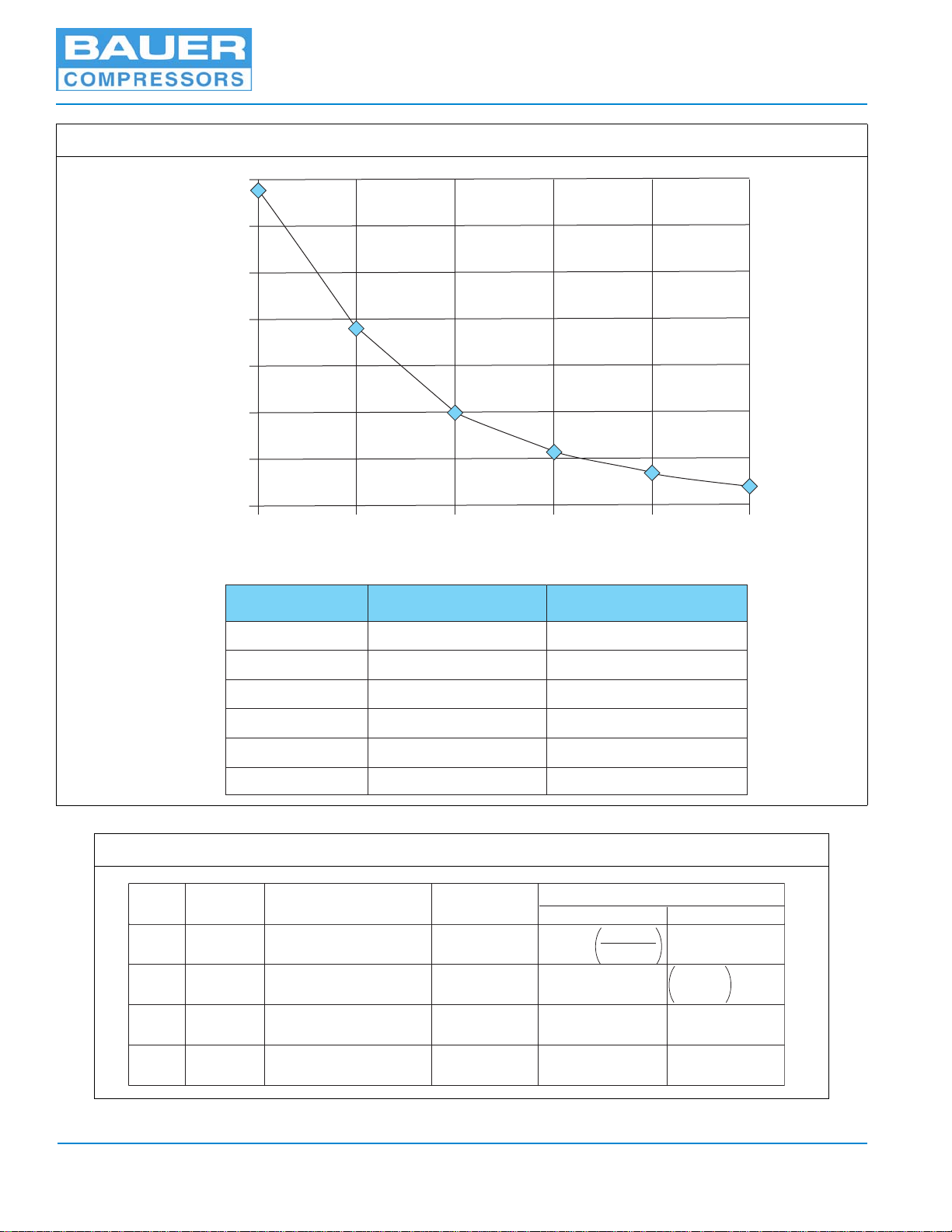

2.1.7.2 Calculating the Adjusted Cartridge Operating Hours

1. Using the Air Purification Cartridge Operating Hours form record the Date, Operating Hours and

Ambient Air Temperature plus 18 °F.

2. Using either the graph or the chart in Figure 2-4 determine the Correction Factor.

3. Divide the Operating Hours by the Correction Factor and record it under the column labeled Today.

4. Add the hours recorded in Today to the previous Total and record it as the current Total.

5. When the Total approaches the Maximum Operating Hours replace the Cartridges.

Purification Systems

Page 9 3rd Edition, Rev 0 Chg 6

Figure 2-4 Correction Factor for Cartridge Operating Hours

Figure 2-5 Example Record of Adjusted Operating Hours

°F

[°C x 9/5 +32]

°C

[(°F - 32) x 5/9]Correction Factor

50 122 0.21

40 104 0.34

30 860.58

20 681.00

10 50 1.81

032 3.44

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0 °C 10 °C 20 °C 30 °C 40 °C 50 °C

Conversion Factor

32 °F 50 °F 68°F 86 °F 104 °F 122 °F

Date Operating

Hours Ambient Temp.

during Compression +18 °F Correction

Factor Adjusted Cartridge Hours

Today Total

10/19/04 8 92°F

(33 °C)

0.5 16.00 16.00

11/01/04 4 45°F

(7.2 °C)

2.25 1.78 17.78

Op hrs

Corr. factor

Total hrs

+Today hrs

MNL-0096

April 17, 2013 Page 10

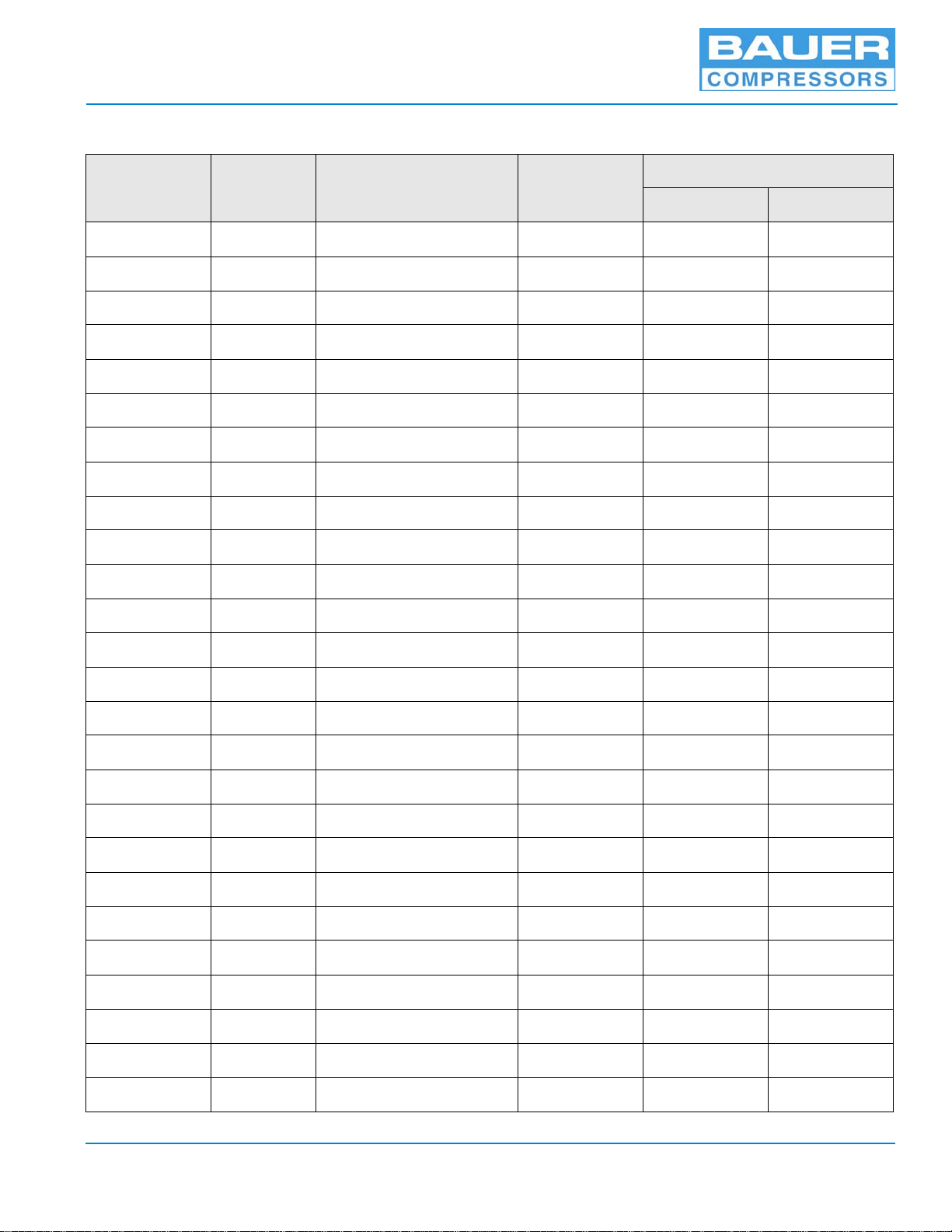

2.1.7.3 Air Purification Cartridge Operating Hours Form

Date Operating

hours Ambient temp. + 18°F

during compression Correction

factor Adjusted cartridge hours

Today Total

Purification Systems

Page 11 3rd Edition, Rev 0 Chg 6

CHAPTER 3: SINGLE CHAMBER PURIFICATION SYSTEMS

3.1 Applicability

This chapter applies to Bauer Purification Systems P0 and P31 Only.

3.2 P0 Purification System Description

The P0 Purification System consists of a separator and a cartridge chamber. In the separator surround-

ing the cartridge chamber, liquid oil and water particles are separated from the compressed air by a pipe

nozzle. Residual oil and water particles are then removed by the filter cartridge and the air leaving the

P0 Purification System is free of water, oil, taste and smell.

Figure 3-1 P0 Purification Chamber

1. Inlet Connection

2. Condensate Drain Connection

3. Condensate Drain Valve

4. Bleed Port

5. Bleed Valve

6. Pressure Maintaining Valve

7. Outlet Connection

8. Safety Valve

1

2

345

6

7

8

MNL-0096

April 17, 2013 Page 12

3.2.1 Maintenance

3.2.1.1 Replacing the Cartridge

See Figure 3-2

1. Depressurize system before starting any maintenance, by opening the condensate drain valve and

bleed valve.

2. Unscrew plug (5) on top of the housing (4).

3. Extract old cartridge. (2)

4. Dry inside of the housing (4) with a clean cloth. Check for corrosion. Replace if necessary.

5. Lubricate all threads and O-rings on both the Plug (5) and the Cartridge (2) with petroleum jelly.

6. Insert new cartridge and secure in place with plug (5).

Figure 3-2 P0 Purification System Cross Section

1. Inlet

2. Cartridge

3. Jet Pipe

4. Housing

5. Plug

6. Final Pressure Safety Valve

7. Adjustment Knob

8. Separator Chamber

9. Outlet

10. Pressure Maintaining Valve

11. Bottom

1

11

2

3

4

5

6

7

8

9

10

Cartridge Removal

Purification Systems

Page 13 3rd Edition, Rev 0 Chg 6

3.2.1.2 Chamber Replacement Interval

The maximum number of load cycles for the P0 Purification Assembly is 45,000 if operated at 5,000 psi

(300 bar) or 63,000 if operated at 3,200 psi (225 bar).

If the number of load cycles of four per hour (i.e. the condensate is drained every fifteen minutes) is not

exceeded then the maximum number of operating hours before the P0 Purification System must be

replaced is 11,125 hours at 5,000 psi (300 bar). To avoid exceeding the maximum number of load cycles

the operating hours should always be recorded.

NOTICE

The used filter cartridge must be disposed of in accordance with local regulations.

^WARNING

The P0 Purification System is subject to dynamic loading. It is designed for a certain number of load

cycles. A load cycle equates to an abrupt pressure loss caused by draining the condensate.

The P0 Purification System must be replaced after reaching the maximum number of load cycles, other-

wise the housing may fail due to material fatigue.

This manual suits for next models

26

Table of contents