BAUMOT B 200 User manual

Operating Manual

Electric Kiln B 200

2

TABLE OF CONTENTS Page

1.

Important safety information

3

1.1.

General information

3

1.2.

Safety information

3

1.3.

Safety equipment and protective clothing

4

1.4.

Safety information for usage

4

2.

Start-up

5

2.1.

Delivery details

5

2.2.

Operation area/assembly site requirements

5

2.3.

Power source information/RC device

5

2.4.

Firing with the kiln

6

3.

General operating information

7

3.1.

Operating the control unit

7

3.2.

Entering program –Starting program

7

3.3.

The exhaust air hole

10

3.4.

The air intake opening

10

3.5.

Proper handling during firing

11

4.

Maintenance/care and cleaning

12

5.

Trouble-shooting tips

13

5.1.

The control unit

13

5.2.

The combustion chamber

13

6.

Warranty obligation

14

7.

Property rights/trade-marks/disclaimer

15

8.

Service addresses

15

3

1. IMPORTANT SAFETY INFORMATION

1.1. General information

It is imperative that the safety information –but also the safety approval markings –be

observed in order to avoid potential hazards. It is in your own best interest that you read

the following safety information in its entirety prior to starting up the shuttle kiln. Keep the

operating instructions in a safe place for future reference.

1.2. Safety Information

Caution:

Hot surface! Do not

open when kiln is hot!

Caution:

Disconnect the kiln from

the mains prior to

opening the electric

panel.

Caution:

Voltage carrying components -

Risk of fatal injury!

The CE mark verifies that

the conformity assessment

procedure was carried out

in accordance with EU

guidelines.

4

1.3. Safety equipment and protective clothing

When opening, loading, or unloading the kiln, the operating personnel must wear

protective clothing. The high temperatures emitted can cause injury. The kiln

manufacturer cannot be held liable for material damage or bodily injury!

1.4. Safety information for usage

A risk-free operation of the kiln is only possible if the following safety information is

observed:

•

In commercial enterprises, the kiln and control unit must be inspected by a

qualified electrician for proper and optimal functioning condition in accordance

with “BGV A3” (German equipment testing procedure) prior to start of

operation and every 4 years.

•

Repairs and maintenance procedures on electric components may only be

carried out by a qualified electrician.

•

For safety reasons, the shuttle kiln must be disconnected from the mains

prior to performing maintenance procedures.

•

No extension cables may be used!

•

Never exceed the maximum temperature listed on the type plate.

5

2. START-UP

2.1. Delivery details

The BAUMOT shuttle kiln is generally delivered by a transport company. The

delivery must always be inspected for damage to the packaging immediately upon

delivery. Should damage be evident, unpack the delivery together with the driver and

inspect the goods for signs of damage. Write a description of all signs of damage on

the delivery slip. It is essential to have the driver countersign the document. Retain a

copy of the damage complaint. Inform the transport company of the damage

immediately. Subsequent complaints will not be considered.

2.2. Operation area/assembly site requirements

Select a suitable location that complies with the following rules and prepare the

location accordingly:

General assembly information:

•

Place the shuttle kiln on an even surface.

•

There must be at least 50 cm of space between all sides of the kiln and the

walls.

•

The floor, ceiling insulation, walls, dividing walls, covers, etc. must be made of

heavy-duty inflammable materials.

•

Ensure that the assembly site is well ventilated. Otherwise an exhaust unit

must be installed. In all cases, a ventilation technician must be consulted.

2.3. Power source information/RC device

To operate the kiln in workshops, laboratories, etc., it is imperative that a separate

power supply with its own safeguard be prepared. If the building network is

safeguarded by a circuit interrupter, then the operation of the heat-treatment and

annealing furnaces must also be operated from and safeguarded by an RC device

(ground fault circuit interrupter) with a rated current of 0.03 A.

If necessary, the power supply for the workshop area must be retrofitted with a

RC device that has a release current of >300mA.

An RC device with a lower release current can cause premature release and impede

the heat-treatment process.

6

2.4. Firing with the kiln

The Baumot kiln’s regulator is pre-set at the factory to the exact times and

temperatures necessary for firing ceramic diesel particle filters.

The preheating phase takes approx. 1 hour, during which the temperature is

increased up to 550° C with a subsequent holding time of 3.5 or 8 hours. Therefore,

the firing time without the cooling phase takes either 4.6 or 9 hours.

The temperature for ceramic filters may not exceed 550°C.

7

3. GENERAL OPERATING INFORMATION

3.1. Operating the control unit

Process controller Jumo cTRON 316.

3.2. Entering program/Starting program

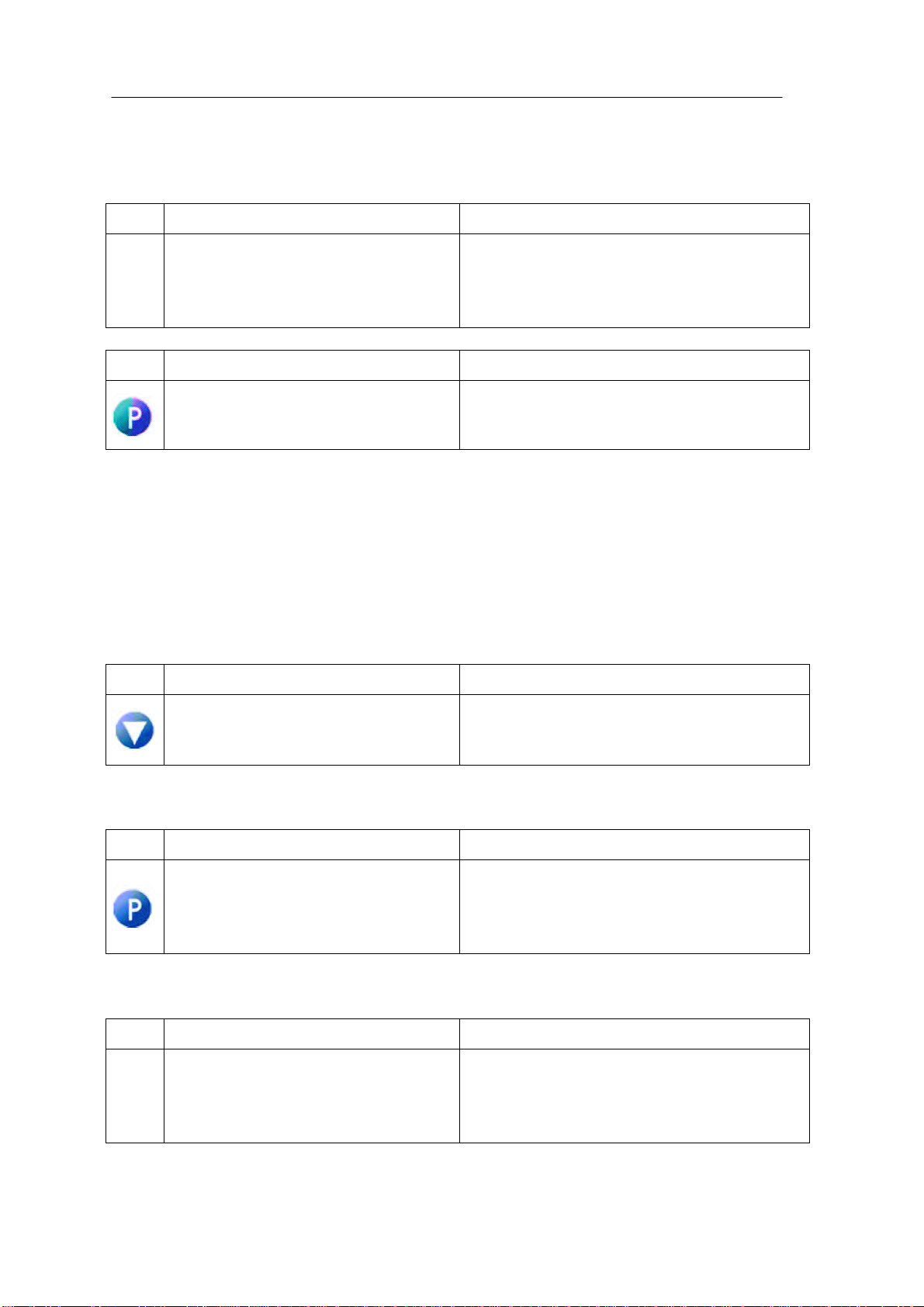

Entering program set value of final temperature:

Button

Description

Display

To access the “USER” menu,

press the “P” button.

“USER” appears in the green display

Button

Description

Display

To access the “set temperature”

menu item, press the “P” button

again.

“SET” appears in the green display

Button

Description

Display

To activate the “set temperature”

menu item, press the “P” a third

time.

“SET” flashes in the green display

8

Button

Description

By pressing the ▲ button, you can

increase the set value, and with

the ▼button, you can decrease the

value.

TIP: The set value can also be

changed during the firing operation

with the ▲ and ▼ buttons.

Button

Description

To save the entered program

values, press the “P” button.

Entering program set value of gradient:

Button

Description

Display

To access the “gradient” menu

item, press the ▼ button.

“rA” appears in the display

Button

Description

Display

To activate the “gradient”

menu item, press the “P”

button.

“rA” is flashes in the display

Button

Description

By pressing the ▲ button, you

can increase the gradient value,

and with the ▼button, you can

decrease the value.

9

Programing holding time after reaching final temperature

Time selector switch

You can select the duration of the holding time of the programmed

final temperature with the aid of the time selector switch:

“3 h” position: Holding time of final temperature is 3 hours

“5 h” position: Holding time of final temperature is 5 hours

“8 h” position: Holding time of final temperature is 8 hours

Starting/stopping the program:

The firing program is started by pushing the “Exit/F” button. The program is

stopped by pushing the button once again.

10

3.3. The exhaust air hole

Close the exhaust air hole in

the kiln cover with the

chimney stone included in

delivery.

Caution:

Do not look directly into the exhaust air hole when the kiln is hotter

than 150°C. This can cause injury to the face.

Operating personnel must wear adequate protective clothing!

Baumot GmbH will not accept liability for personal injury or material

damage!

11

3.5. Proper handling during firing

Caution:

•

Do not place any flammable objects in the near vicinity of the kiln.

•

The kiln may only be assembled and operated in a well-

ventilated workshop.

•

The kiln must be freestanding. Nothing may obstruct the heat

radiation. Do not place objects on or near the kiln.

•

If you are firing materials that release hazardous gases and

vapours, it is imperative that a ventilation system be installed

and the fumes be released outdoors.

•

Never fire flammable materials or food in the kiln.

•

Only the operator is authorised to remain near the kiln.

Unauthorised persons should not be permitted to remain in

the area.

Caution:

The loading process may only be carried out by trained employees!

Use suitable loading aids to facilitate the loading process.

Caution:

In the event of an unforeseen incident, take appropriate safety

measures if the kiln has to be opened at high temperatures:

Operating personnel must wear adequate protective clothing!

Only the machine operator may be in the near vicinity of the heat

treatment furnace when it is being opened. Unauthorised persons

may not remain in the vicinity!

The high temperatures being released can cause burns and injury as

well as lead to the premature closing of the kiln.

Baumot GmbH will not accept liability for personal injury or material

damage!

12

4. MAINTENANCE/CARE and CLEANING

Maintenance procedures

Please note:

Voltage carrying components - Risk of fatal injury!

The kiln must be disconnected from the power source!

Authorised personnel may not begin the maintenance procedures

until a safety inspection has been carried out.

Care and cleaning

Ensure that no foreign matter is allowed inside the firing chamber or onto the heating

elements. This would inevitably cause the heating coils to malfunction during the next

firing. Should the firing chamber/heating elements come into contact with a foreign

substance, eliminate the problem immediately, because burnt-on foreign substances

can cause damage to the heating elements and the bricks. In the event of a serious

incident, contact us or your local specialist dealer.

Heating coils are subject to wear. Their resistance (ohm) increases with each firing,

and with time, causes a delay in the firing curve due to a decline in performance,

particularly in the higher temperature range. In the case of extreme wear, we

recommend replacing all of the heating coils, because replacing individual heating

coils can cause temperature differences within the kiln.

Please note: Previously fired heating coils are brittle and therefore prone to breaking

(not a warranty claim). Therefore, a subsequent correction to the heating coils should

be avoided!

Good to know:

Factors that affect the lifespan of a heating coil:

•

The interior kiln atmosphere: e.g., aggressive materials. Good ventilation is

particularly important for materials containing solvents, heavy sulphur or

fluoride.

13

5. TROUBLE-SHOOTING TIPS

5.1. The control unit cannot be switched on.

•

Check if the power connector for the kiln is plugged into the mains.

•

Check the fuses of the building’s power supply that protect the connection box

of the kiln.

•

Have your building connections, fuses and the current draw of the kiln checked

by a qualified electrician.

•

Check the microfuses in the junction box of the kiln. They must be protected

with T 2A.

5.2. The combustion chamber is not heating up or is kiln is heating up very

slowly.

•

Check if the cover of the kiln is completely closed. It is possible that the safety

switch is not closing the safety circuit.

•

The set temperatures are not achieved. The control unit is indicating an error.

Examine the heating conductor for signs of breakage. It may be that heating

elements are broken and therefore not functioning!

•

Have an authorised electrician check if all the phases are completely carried.

6. WARRANTY OBLIGATION

We refer to the legal warranty obligation with a warranty period of 24 months

guarantee as of the invoice date:

Along with the heating coils (components subject to wear), the following items are

also not included:

•

Damage caused by the customer.

•

Damage caused by the fired products, i.e., exceeding the maximum temperature.

•

Damage caused by improper transport.

•

Damage caused by an impermissible chemical reaction during firing (e.g., salt-

firing).

•

The manufacture cannot be held liable for damages caused by improper handling.

Please note: The lightweight refractory bricks used in the brick lining are subject to

severe temperature fluctuations. This can cause cracking in the brick lining. This is

normal and does not interfere with the function of the shuttle kiln. They are therefore

also not cause for a complaint.

What to do in a warranty case or in case of damage:

Inform your local specialist dealer before any costs are incurred. Your specialist

dealer will decide what further measures to take after consulting with us, the

manufacturer.

In the case of a complaint, indicate the type of kiln, product no. and the date of

purchase or date of manufacture (see type plate on the side of the kiln).

15

7. PROPERTY RIGHTS/TRADEMARKS/DISCLAIMER

The content of this operating manual is solely for informational purposes and can be

modified without advance notice.

The registered names, trademarks, brand names etc. listed in this operating manual

are not specifically indicated, because they are commonly known. These names and

designations can however be the property of companies or institutes.

8. SERVICE ADDRESSES

If you have questions regarding your kiln, replacement parts or additional

accessories, please contact your specialist dealer or Baumot GmbH.

We wish you much success and only good firing results!

Your Baumot-Team

Table of contents