Baur TG 20/50 User manual

User Manual

Audio Frequency System Locator-Set

TG 20/50, TG 600

UL 30

Ref. No. 822-119 11/2005

Raiffeisenstrasse 8, A-6832 Sulz/Austria internet: www.baur.at Fax +43/5522/4941-3

2

3

Guide to this Operating Instruction

Copyright

Preface

For fast finding of important information the

corresponding text passages are marked with symbols

(symbols not stated here are self-explanatory).

More and special information concerning the

respective subject are available from BAUR.

Important information about the

instrument!

In any case, read carefully!

Important information text.

© BAUR Prüf- und Messtechnik GmbH, A-6832-

Sulz / Austria

All rights reserved.

No part of this publication may be reproduced,

transmitted, stored in a data processing system or

translated into another language without the

written permission of BAUR / Sulz, Austria.

In the interest of our customers we reserve the

right for modifications due to technical progress.

Illustrations, descriptions and delivery content are

therefore not binding.

This manual contains all information necessary for

the correct handling and operation of the

described system. Before using the system please

read carefully these Operating Instructions. If you

have any questions please contact directly:

BAUR Prüf- und Messtechnik GmbH,

Raiffeisenstraße 8

,

A

-6832 Sulz / Austria

BAUR Prüf- und Messtechnik GmbH, Raiffeisenstrasse 8

A-6832 Sulz / Austria

or refer to your nearest BAUR representative.

Tel. +43/5522/4941-0

Fax. +43/5522/4941-3

4

Safety precautions

The Audio Frequency System is built in accordance

with today’s state of engineering and is safe to

operate. Individual components and the finished unit

are inspected continually by our qualified staff within

the framework of our Quality Assurance Provisions.

Each unit is subjected to thorough testing prior to

shipment. It is imperative to every person who is

involved with the installation, start-up, operation and

maintenance to have read and understood the

complete Operating Instruction. It is the

responsibility of the customer to ensure that only

authorized persons may be allowed to use the unit.

Operators must notify immediately any changes to

the unit that detract from the its safety.

The Audio Frequency System Locator Set is

intended to be used exclusively for route tracing

and fault location of electrical cables and

metallic gas and water pipes.

Any other or additional use is deemed to be in

contravention of the intended use. The

manufacturer shall not be liable for damage

resulting from any such use. In such a case the risk

shall be borne solely by the user.

The local safety and accident prevention

regulations are always applicable to the

operation of the unit.

Warranty

At the customer’s written request we undertake to

repair or replace at our discretion and as quickly as

possible all parts that become faulty as the

demonstrable result of poor material, faulty design

or defective workmanship. We shall bear the costs

of any faulty parts requiring replacement, but not the

costs of transport to us and back to the customer,

nor the costs of packing and insurance! The 12

month warranty time starts from delivery. We shall

not be liable for any damage resulting from normal

wear and tear, improper handling, non-observance

of Operating Instructions and safety regulations. We

shall also refuse to accept any liability if the

customer carries out repairs or changes to the unit

themselves or has others carry them out! The

warranty does not cover damage in transit,

batteries, fuses and any readjustments in

accordance with the Operating Instructions!

We draw attention in addition to the ‘General Sales

and Business Conditions’ of:

BAUR Prüf- und Messtechnik GmbH

Raiffeisenstrasse 8

A-6832-Sulz / Austria

5

Contents

1Product information 6

2Description of Locator-Set 7

2.1 Audio Frequency Generator TG 20/50 and TG 600 8

2.1.1 TG 20/50 9

2.1.2 TG 600 10

2.2 Universal Locator UL 30 11

2.2.1 Menu 12

2.3 Magnetic and acoustic sensors 13

2.4 Technical data 15

3Put TG 20/50 into operation 18

4Put TG 600 into operation 21

5Put UL 30 into operation 24

5.1 Startup 24

6Fault location 25

6.1 Acoustic fault location 25

6.2 Distance manhole 28

6.3 Sheath fault 29

7Route tracing 33

7.1 Connection of frequency generator 34

7.2 Minimum and Maximum method 35

7.3 Depth determination 36

7.4 Terrain examination 37

7.5 Cable identification 37

7.6 Determination of joints (Twist method) 39

8Maintenance 41

9Packing and delivery 43

6

1 Product information

In combination with Surge Voltage Generators (SSG / STG) or Audio Frequency Generators

(TG20/50 and TG600) and accessories like BM 30, earth sticks, the Universallocator UL 30

is used for:

-pin-pointing of cable faults

-route tracing of buried cables or metallic pipes

-propagation time measurement

-Cable sheath fault location

-Combined tracing and pin pointing

With the help of an audio frequency transmitter (TG20/50 or TG600) an electromagnetic field

in the cable is generated.

Depending on selected tracing and measuring methods, the detection is done by an

electromagnetic sensor

The received electromagnetic and acoustic signals are amplified and indicated by the Audio

Frequency Receiver UL 30:

-acoustically via the integrated loudspeaker or a headphone (to be connected)

-optically on the integrated LCD display.

In connection with a Surge Voltage Generator SSG the surge voltage impulse (magnetic

field) is indicated on the pointer UL 30 when performing a coincidence measurement. The

impact noise is heard via headphone of the loudspeaker.

With the propagation time measurement the time difference between magnetic and acoustic

impulse is evaluated. The minimum of the time difference indicates the cable fault position.

Special advantages:

-at cable faults which acoustically are very difficult to locate, the coincidence

measuring method gives additional help to verify the faulty point.

-with cables in pipes the fault position can be located accurately above the cable

route.

7

2 Description of Locator-Set

The Audio Frequency System Locator-Set is used for route tracing and fault location of:

-electrical cables

-metallic gas and water pipes.

Functions and procedures

With the help of an audio frequency transmitter (TG20/50 or TG600) an electromagnetic field

in the cable is generated. The field is detected by sensors (e.g., detecting rod SP 30,).

The signal is amplified by the audio frequency receiver UL 30 and indicated acoustically via a

headphone or a loudspeaker or optically on the display.

Fields of application

With its various sensors and by selecting specific tracing and measuring methods a wide

range of applications is possible:

-Routing of cables and metallic pipes

-Depth determination of cables and metallic pipes

-Cable selection

-Cable detection even on live cables and lines

-Location of cable joints and branches

-Accurate pin-point fault location according to the BAUR twist method in conjunction

with the powerful Audio Frequency Transmitter TG20/50 or TG600.

-Accurate pin-point fault location in conjunction with the Surge Voltage Generator

SSG.

-Accurate pin-point fault location in piped cables by application of the acoustic

propagation time measurement.

8

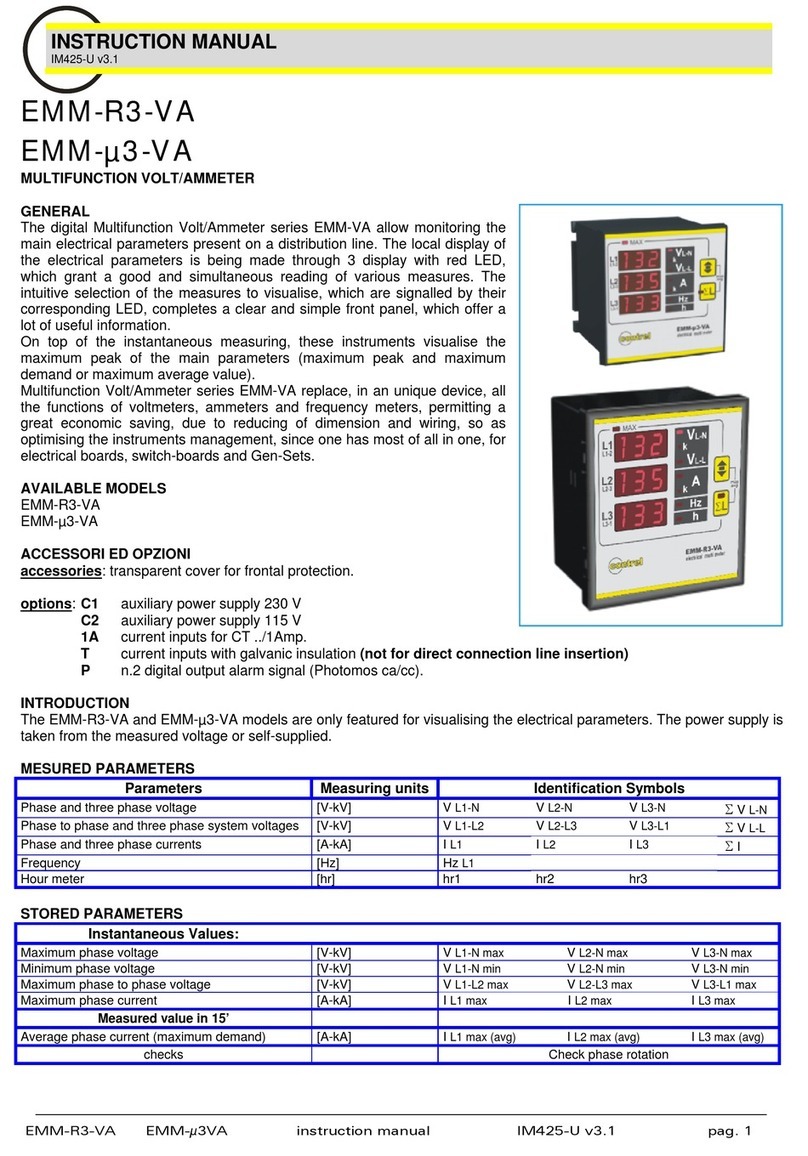

2.1 Audio Frequency Generator TG 20/50 and TG 600

Audio Frequency Generator TG 20/50

Description TG 20/50

The Audio Frequency Transmitter Locator TG

20/50 is a powerful, battery operated instrument

with an integrated power supply unit. An output of

50 VA is available during mains operation and

therefore application for accurate pin-point fault

location on twisted multi-core cables is possible.

As well, cable tracing can e done.

Audio Frequency Generator TG 600

Description TG 600

The Audio Frequency Transmitter Locator TG 600 has

been special designed for the pin-pointing location of

cable faults and joints.

Due to indication of input and output current, selection

of the correct adjustment is facilitated.

Beside the use for cable fault location, also high

frequency burn down processes can be carried out,

particularly on signal or telecommunication cables.

The maximum output current can be switched

between 60VA and 600VA.

9

2.1.1 TG 20/50

3 9 14 13 13 11

15 7 8 6 2 5 10 1 4 12

Display elements:

1Power control

2Charge control

3Pointer instrument for Iout and Iin and battery control

4Indication of impedance level

Operating elements:

5 ON switch and mode selector

6Button for battery control and instrument illumination

7 Button for indication of Iin

8Button for switching measuring range x 0.1 for Iout

9Button for automatic or manual impedance adjustment

10 Regulating switch for output current

Interfaces:

11 Mains connection

12 Connection for external battery

13 Output socket

14 Protective earth terminal

15 Connection for loop antenna

10

2.1.2 TG 600

18 17 16 4 4 6 8 10 2 3 14 15

1 5,7,9,11,20,19,12 13

Display elements:

1Input current of adjusting transformer

2Output current of adjusting transformer

3Overtemperature indication

Operating elements:

4 Mains ON

5Mains OFF

6Frequency selection 2 kHz

7Frequency selection 10 kHz

8Continuous operation

9Impulse operation

10 Output power 60 VA

11 Output power 600 VA

12 Impedance selector switch Zi

13 Power control

14 Measuring range selector for output current

15 Push-buttons for compensation capacitors

Interfaces:

16 Mains connection

17 Protective earth terminal

18 Output sockets

19 Fuse F1

20 Fuse F2

11

2.2 Universal Locator UL 30

Display

Switch button

Right – for navigation

or increase

OK

ON / OFF button

Loudspeaker

Backlight

Left – for navigation or

decrease

Down – for navigation

or increase

Up – for navigation

or increase

Input sockets for sheath

fault sticks

Headphone outlet Socket for BM 30 / SP 30

Removable rear cover

with battery compartment

12

2.2.1 Menu

A application-oriented menu structure allows fast and easy operation of the UL 30. At main

menu the application could be selected. The following submenus contain the special fault

location- respectively tracing methods.

Fault location:

Route tracing:

Setup:

13

2.3 Magnetic and acoustic sensors

Several sensors are available for reception of magnetic and acoustic signals which are used

depending on selected tracing and measuring method.

BM 30

KH 30

The highest sensitivity of the ground microphone is at

the range of 200Hz. Therefore, it is most suitable for

pin-pointing of flashover faults according to the Surge

Voltage method. Its special decoupled housing

suppresses possible ambient noises.

Included into the BM 30 is a magnetic sensor to

enable the propagation time measurement and a

tracing of cable line while pin pointing.

The headphone KH 30 is connected to the Audio

Frequency Receiver via a 3-pin jack plug (6.3mm).

For suppressing ambient noises the type KH20/S

headphone is used.

14

SP 30

The detecting rod consists of a searching coil

adjusted to an oscillating circuit by condensers. Using

the switch on the handle of the detecting rod the

frequency can be adapted to the signal frequency of

the Audio Frequency Generator. The hinged

searching coil can be turned by 45° or 90°. The 45°

position is used for determination of the depth of

buried cables.

15

2.4 Technical data

Audio Frequency Generator TG20/50

Output power

0 - 50VA in mains operation

0- 20VA in battery operation

Output current max. 8 A

Output impedance in 7 steps

1 / 3 / 10 / 30 / 100 / 300 / 1000 W

with automatic adaptation

Frequencies 2 frequencies, switchable

standard: 2kHz and 10kHz

other frequencies optionally

480 Hz

800 Hz

1030 Hz Df - ± 0.1 %

1090 Hz k-faktor k - 1,5 % at 4 VA

1350 Hz

1450 Hz

2000 Hz

9820 Hz Df - ± 0.1 %

10000 Hz k-faktor k - 3 % at 4 VA

12000 Hz

Operating modes Continuous operation and impulse operation

Display Illuminated instrument with indication of Iout (in A); switchable via button Iin

(in A);

Battery test

Indication of impedance levels with LED

Output Non-contacting pole terminals (safe from contact) and socket for loop

antenna on side cover

Power supply Mains connection

110/120, 220/230, 240 V, 50-60Hz

Power consumption 150VA at 50VA output power

Internal lead acid battery 12V / 9.5Ah

External battery

12V - 24V (reverse battery protection)

Charging unit Overcharge protection

80% of battery capacity is reached within 14 hours; when in mains supply,

charging is made in all operating modes

Low level discharge

protection Unit is switched off before battery is completely discharged

Operating time battery at 20VA approx. 2.5 hours

Operating temperature -20°C to +50°C

Dimensions 290 x 130 x 250 mm

Weight approx. 9.5 kg

16

Audio Frequency Generator TG 600

Output power at 2 kHz in 2 steps 600VA / 60VA

at 10kHz in 2 steps 450VA / 45VA

Output current max. 30 A

Output impedance in 8 steps

0.3 / 0.8 / 1.8 / 4 / 10 / 30 / 100 / 300 W

Frequencies Quarz-stabilized: 2kHz and 10kHz;

other frequencies on request

Operating modes Continuous operation and impulse operation

Display 2 instruments for indication of Iin and Iout

Reactive power

compensation adjustable in 63 steps

Power supply 110/120, 220/230 V, 50-60Hz

Power consumption 1800VA at 600VA output power

Overload protection Overtemperature switch-off and indication

Operating temperature -20°C to +40°C

Dimensions 505 x 255 x 330 mm

Weight approx. 38 kg

17

Universal Locator UL 30

Receiving frequency 50Hz – 10kHz, 815Hz, 2kHz, 10kHz

+ 2 additional frequencies on request

Filter digital

Üassive reception 50/60Hz mains signal

amplification 0-38 dB

propagation velocity range 0-96ms

operating temperature -20°C….+55°C

protection water- and dust protected

power supply 4x1.5V cells (IEC LR 6)

battery life

(normal operation) approx. 50h

weight 550g

18

3 Put TG 20/50 into operation

Operating the Audio Frequency Transmitter TG20/50 either

-with mains supply (110/120V, 220/230V or 240V / 50Hz or 60Hz), output power of

50VA

-via an internal battery (for mobile use), output power approx. 20VA

-via external battery (12V to max. 24VDC)

Remark: Pay attention to correct polarity (+ red, -black)!

Designed for continuous operation

In all operating modes the unit is designed for continuous operation. The output power of

50VA is only reached with:

-mains operation or external battery operation (with 24VDC)

-optimum adjustment.

During mains and battery charging operation, please observe that:

The voltage setting of the mains voltage socket must correspond to the local mains voltage!

Carry out battery test

The integrated battery (=lead-acid battery) is protected by a low discharge protection circuit

causing the TG20/50 unit to be switched off at a discharge voltage of 10.5V.

Before each mobile use and battery operation, please check the battery state of charge.

Check state of charge using control button

Charge battery

If pointer of instrument is below the marked range:

-Connect TG20/50 to mains the charging control lamp „charge” lights up. The battery

is charged by the built in charger (with an overload protection).

-General battery charging time should be at least 12 to 14 hours!

The TG20/50 unit can also be used during the battery charging process. That means, the

integrated battery is also charged during each mains operation.

Do not store lead acid battery in a discharged state. Charge the battery all 14 days during the

night!

☞

19

Connection of Audio Frequency Generator

Connecting the TG20/50 unit is made either via the output sockets “output” (galvanic con.),

the clip on device AZ 10 or the loop antenna RA 10

Do not connect live cables and lines (e.g. interference noises, mains pick-ups) to the sockets

‘output’! Danger of unit destruction!

Before connection, always check if line is zero potential!

Carry out galvanic or inductive connection

1 2 2a

4

Step Procedure

1 Connect earth lead.

2a Make galvanic connection: Connect a dead

cable/line to the two black sockets ‘output’.

2b Make inductive connection: Remove side cover

and connect loop antenna.

3 Turn output regulator completely to the right stop.

Observe max. permissible voltage of connected

line.

4 Set mode selector to the desired operating

frequency. Power Control lamp lights up.

Carry out either

step 2a or 2b

Switch on

Audio Frequency

Generato

r

3

2b

U = 0V !!

20

Carry out automatic or manual load adaption

1a,1b

4 3

Condition for automatic load adaption:

-output current Iout > 10mA!

Make a manual load adjustment at:

-high impedance load

Carry out automatic (1a) or manual (1b) load adjustment

Step Procedure

1a Press button to pos. „auto“.

If an LED of the impedance adjusting level lights up:

- the output impedance is adjusted

- a voltage is on the „output“ sockets

1b Press button to pos. „man“ as long as the desired adjusting level is reached.

2 Adjust desired output current using the output regulator.

3 Press button Iout = instrument range is switched to 1A.

4 Press button Iin. The current consumption of the amplifier is indicated. With battery

operation:

Iin=3A-battery 9Ah=approx. 3 hours of operating time

Audio Frequency Generator TG20/50 is ready for operation.

Overload protection

The power output stage of the TG20/50 unit is protected by a terminal circuit breaker.

After a switch off:

-using the mode selector - switch on again after a certain cooling period

2

This manual suits for next models

2

Table of contents

Other Baur Measuring Instrument manuals