Becen BC-M230 User manual

www.szbecen.com

USER’S MANUAL

Model: BC-M230

230w Beam Moving Head Light (White)

Package Includes:

1 x beam moving head light

1 x clamp,handle

1 x safe cable

1 x power cable

1 x DMX cable

Please read this manual before use

www.szbecen.com

CONTENTS

Chapter 1 Warnings and Operation Modes.................................................................................... 1

1.1 Warnings.......................................................................................................................... 1

1.2 Operation Modes........................................................................................................... 1

Chapter 2 Control Panel Instructions............................................................................................. 2

2.1 Main Interface.................................................................................................................. 2

2.2 Setting of Interface .......................................................................................................... 3

2.3 Information Interface....................................................................................................... 3

2.4 Information Interface....................................................................................................... 4

2.5 Advanced Interface.......................................................................................................... 4

Chapter 3 Channel description....................................................................................................... 5

3.1 Channel table................................................................................................................... 5

3.2 Channel Detail................................................................................................................. 5

3.2.1 COLOR WHEEL-channel 1.................................................................................... 5

3.2.2 STOP/STOBE-channel 2 ......................................................................................... 7

3.2.3 DIMMER-channel 3................................................................................................ 7

3.2.4 STATIC GOBO CHANGE-channel 4...................................................................... 7

3.2.5 PRISM INSERTION-channel 5............................................................................... 9

3.2.6 PRISM ROTATION-channel 6................................................................................ 9

3.2.7 PRISM ROTATION-channel 6................................................................................ 9

3.2.8 PRISM ROTATION-channel 6................................................................................ 9

3.2.9 FOCUS-channel 9.................................................................................................... 9

3.2.10 PAN-channel 10..................................................................................................... 9

3.2.11 PAN FINE-channel 11 ........................................................................................... 9

3.2.12 TILI-channel 12................................................................................................... 10

3.2.13 TILT FINE-channel 13......................................................................................... 10

3.2.14 FUNCTION-channel 14(NOUSED).................................................................... 10

3.2.15 RESET-channel 15............................................................................................... 10

3.2.16 LAMP CONTROL-channel 16............................................................................ 10

3.2.17 TIMING CHANNELS......................................................................................... 10

Chapter 4 Control signal connection ........................................................................................... 10

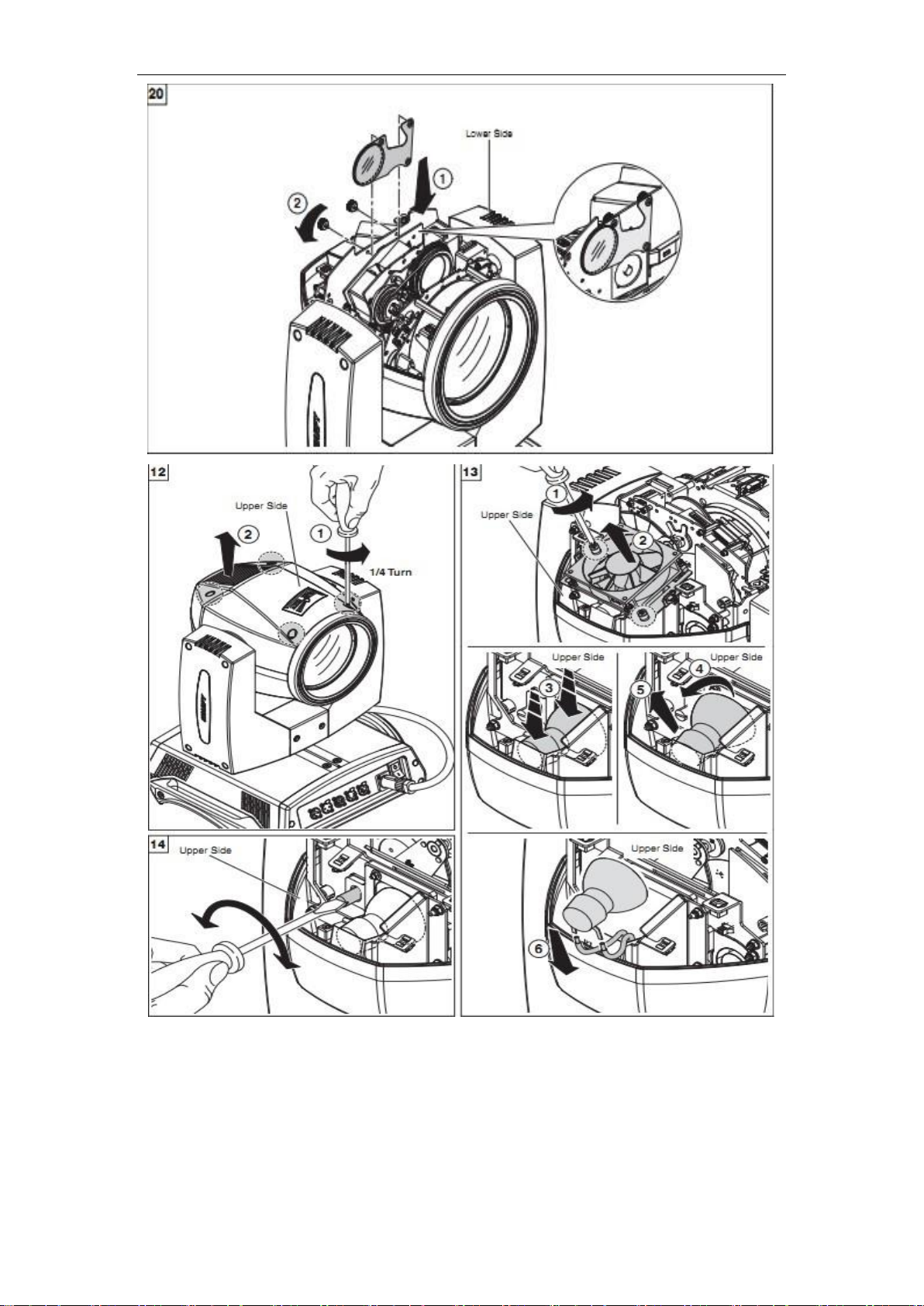

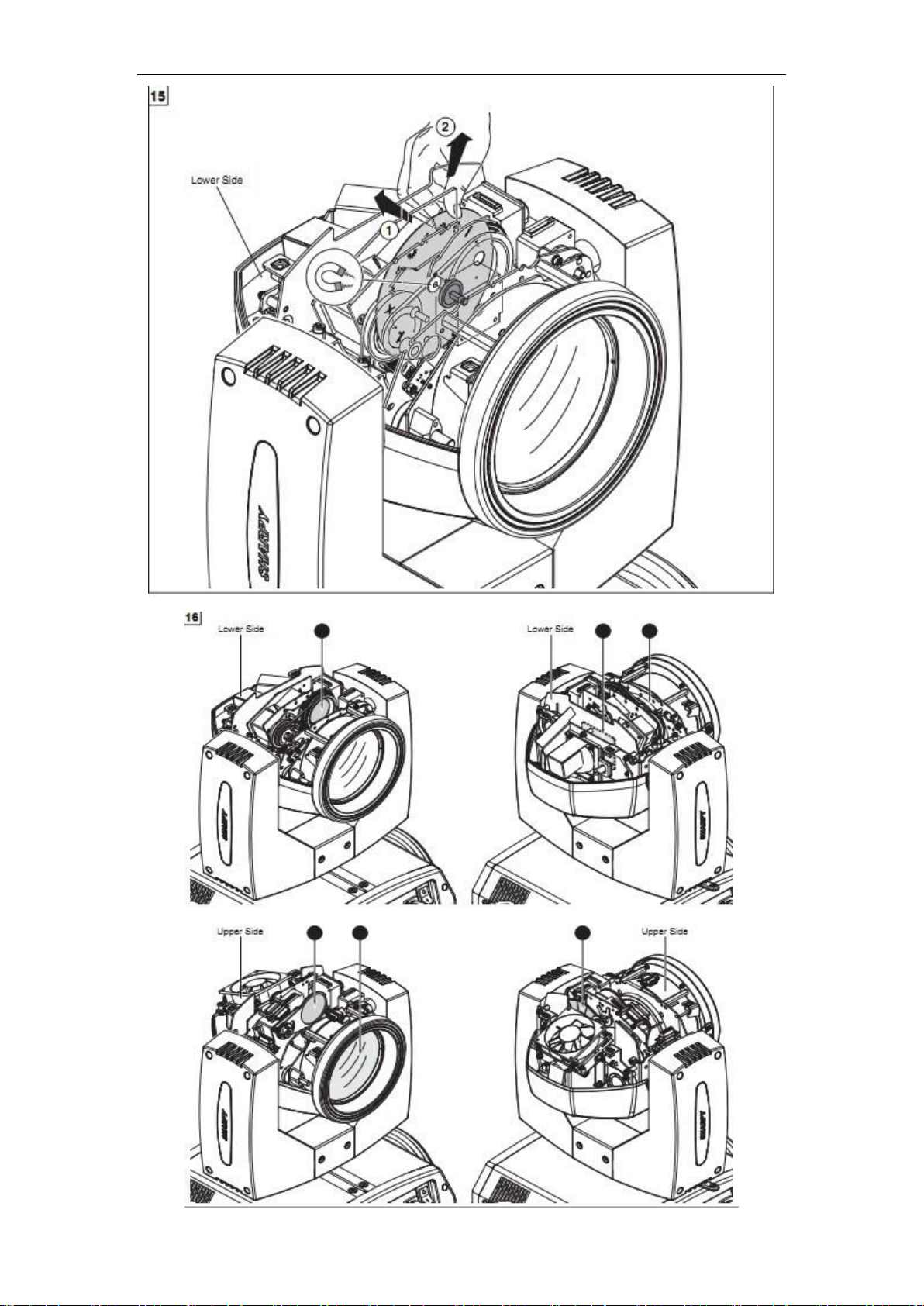

Chapter 5 Installation................................................................................................................... 12

Chapter 6 Protection and Maintenance........................................................................................ 18

6.1 Light cleaning................................................................................................................ 18

6.2 Statement ....................................................................................................................... 19

6.3 Problem solve method ................................................................................................... 19

1

www.szbecen.com

Chapter 1 Warnings and Operation Modes

1.1 Warnings:

Please check if there is any transportation damage before using. And if there is any

damage, please stop using it, and contact the distributor or manufacturer as soon as

possible. Please keep it away from Combustible materials, and unlock the X-, Y-axis

before using. The fixture should be installed in places with good ventilation, keep it

away from the wall at least 10cm above, and then check if the fans are in good

conditions.

Please don’t project the light beam on the combustible directly, and keep the fixture at

least 12m away from the projection objects.

Please don’t look directly into the light source lest any damage to your eyes. And

please make sure the using power voltage is in accordance with the stated voltages

before using.

Attention: Please power off before installing, repairing or cleaning

the fixture.

1.2 Operation Modes

For example, how to change DMX address?

Please press “Setting” in the main interface to enter “setting” interface.

There are 4 touch key-presses on the right side, namely, “Up” “Confirm” “Down”

“Return” buttons.

Please press “Up” or “Down” keys to enter “DMX address”.

Please press “Confirm” to edit.

Please press “Up” or “Down” keys to change DMX address(the new DMX

address would be saved automatically and start to run)

Please press “Confirm” to exit editing.

Please press “Return” to exit main manual.

Operation modes for turning wheel:

Please press “Setting”button under the main interface, and turn the wheel.

Touch

Turning Wheel

Function

“Up”button

Turn left

Select、Edit

“Down”button

Turn right

Select、Edit

“Confirm”button(“OK”)

Press the wheel

Start running

Start editing、Stop editing

“Return”button

Press the wheel under

Return manual

Return to previous page

2

www.szbecen.com

Please press the wheel to enter “setting”interface.

Please turn the wheel to enter “DMX address”interface under “setting”interface.

Please press the wheel to edit.

Please turn the wheel to change the DMX address.

Please press the wheel to exit editing after the modification.

Please turn the wheel to enter “Return”, and then press the wheel to return the

main interface.

Chapter 2 Control Panel Instructions

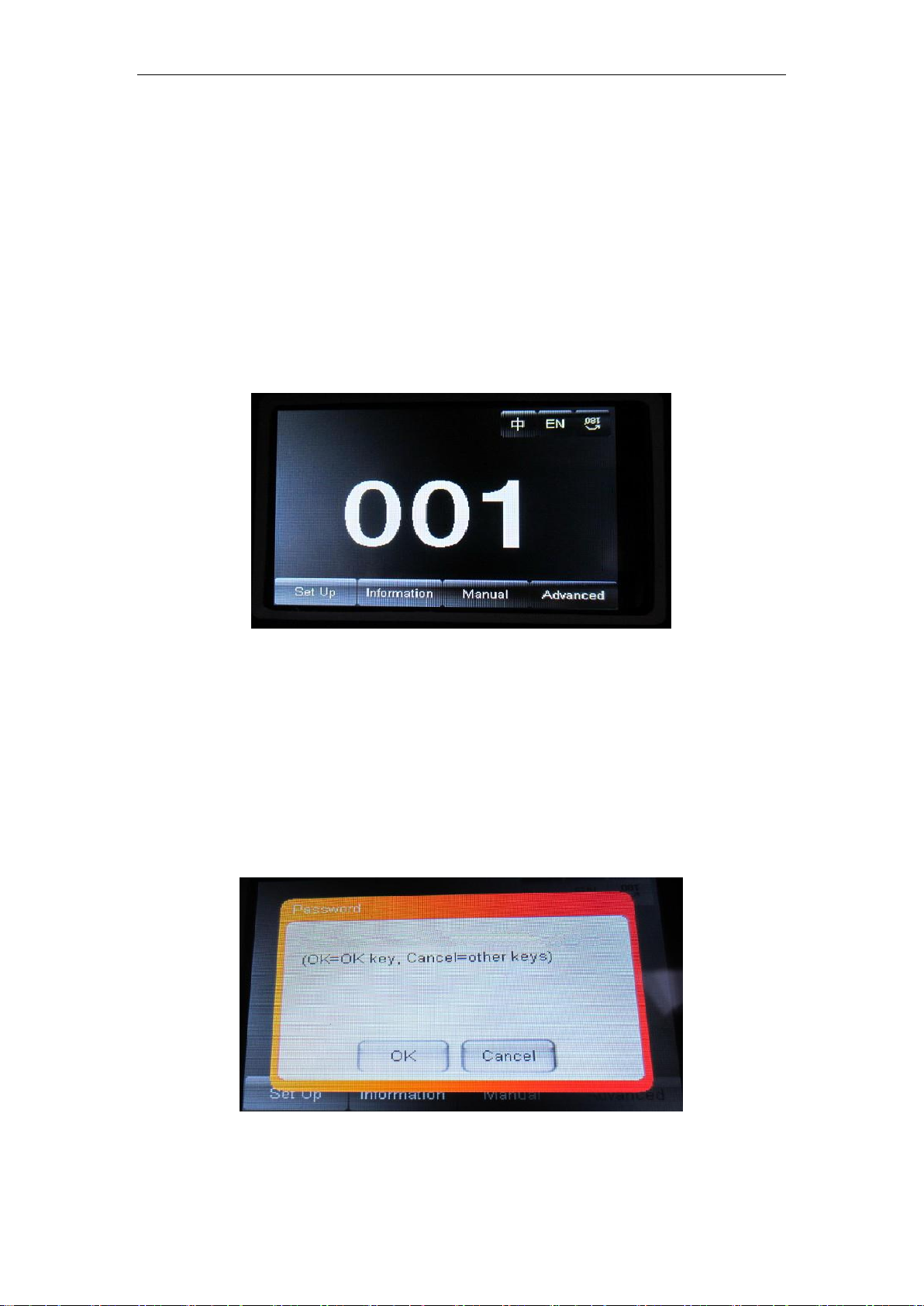

2.1. Main Interface

The 3 buttons on the up right corner are for language switch and screen rotation.

The 4 buttons on the bottom are for sub-interfaces.

How to use the wheel to control the sub-interface? Please see as follows::

For “Up”button: Please turn left.

For “Down”button: Please turn right.

For “Confirm”button: Please press the wheel.

Operation of Dialog by turning wheel:

If for “YES”, then press the wheel. And if for “No”, then turn the wheel.

3

www.szbecen.com

2.2. Setting of Interface

Options

Instructions

Running

Mode

DMX

Slave machines:accept DMX signals from controller or Master machine.

Auto

Master-Slave:running automatically, and send DMX signals to slave

machines.

Attention:If need to check the light effects, please power on the lamp

first to enter self-propelled state.

DMX

Address

1-512

Press “Confirm” button to edit. First is for “hundred's digit”, and press

“Up” and “Down” to change the address codes. Press “Confirm” button

the second time to edit “ten's digit”, and press again the “Confirm”

button to edit “unit's digit”. Please press it again to exit editing.

Channels

16

17-20 CH Invalid

20

17-20CH to control speed(please refer to Channel chart)

X Reverse

off

on

Y Reverse

off

on

XY Exchange

off

on

Exchanging XY channels(Pan/Tilt fine included)

XY Encorder

on

Use Encorder (optocoupler) to judge out of sync or not, and self-correct

the position.

off

Don’t use Encorder (optocoupler) to rectify the position

No DMX

signal

stay

Stay the same

reset

Stop running

Screen Save

mode

on

Screen light off automatically after 30secs

off

Screen stay on

Starting up

off

Reset directly when power on,lamp stay off(need to operate the manu or

console to light up the lamp)

on

Lamp on when power on,and reset after the lamp is fully lighted up.

Recover

default setting

Press “Confirm” button to see the confirm dialog, and press “Confirm”

button again to recover default setting.

2.3.Information Interface

Options

Illustrate

Software

version

The current software version

Total time

Total time (accurate to the minute)

The use of

time

Since the boot (accurate to the minute)

DMX

Channel

Click here to go to the sub-interface, numerical and percentage display channel

for viewing.

System error

records

If the red ERR indicator light, illustrate lamps run error, Details Click here go to

the sub-interface view. After you finish, press "OK" key to delete error records.

Note: sometimes it is not Hall or optocoupler installation problems, but the motor

line reversed.

4

www.szbecen.com

2.4. Manual Control Interface

This interface is used to control the current lighting, neither belong to slave state (does

not receive DMX signal), nor belong to the host state (do not send DMX signal)

Options

Illustrate

Reset

Press the OK button after see a confirmation dialog box, click "OK" key

to enter the reset interface, all motor reset again.

Color

Wheel

0-255

Press “Confirm” button to edit. First is for “hundred's digit”, and press

“Up” and “Down” to change the address codes. Press “Confirm” button

the second time to edit “ten's digit”, and press again the “Confirm” button

to edit “unit's digit”. Please press it again to exit editing.

。。。。。。

0-255

Gobo

Wheel

Speed

0-255

Bulb

Control

Turn

on

Turn

off

2.5. Advanced Interface

The code is “up down up down”,and code for the wheel is “ left right left right”.

Manu Operation modes:Press “Up” to see the first “*”,and press “Down” key to see

the second “*”,and press “Up” to see the third “*”,and press “Down” key to see the

fourth “*”,and last press “Confirm” key to enter password confirmation.

Turning wheel Operation modes:Turn one bit left to see first “*”, and Turn one bit

right to see the second “*”,and turn one bit left to see the third “*”, and Turn one bit

right to see the fourth “*”,and last press the wheel to enter password confirmation.

Options

Instructions

Touch Screen

Calibration

Please touch the place according to the prompt of the cross cursor in the

Calibration interface. If the 4 values received the right data, then save

the data. If failed, it will keep repeating. Please press “Confirm”

button to stop Calibration any time.

Reset Calibration

When enter sub-menu, the reset location of X.Y axis motors is

adjustable. It is not able to edit “unit’s digit”, “ten's digit” or

“hundred's digit” or long-time press for Reset Calibration which

needs to be calibrated step by step, which is different from address code

and channel values.

Attention:Please don’t conduct Reset Calibration, when the motors are

working.

And please reset the fixture before Reset Calibration when necessary.

5

www.szbecen.com

Chapter 3 Channel Description

3.1 Channel Table

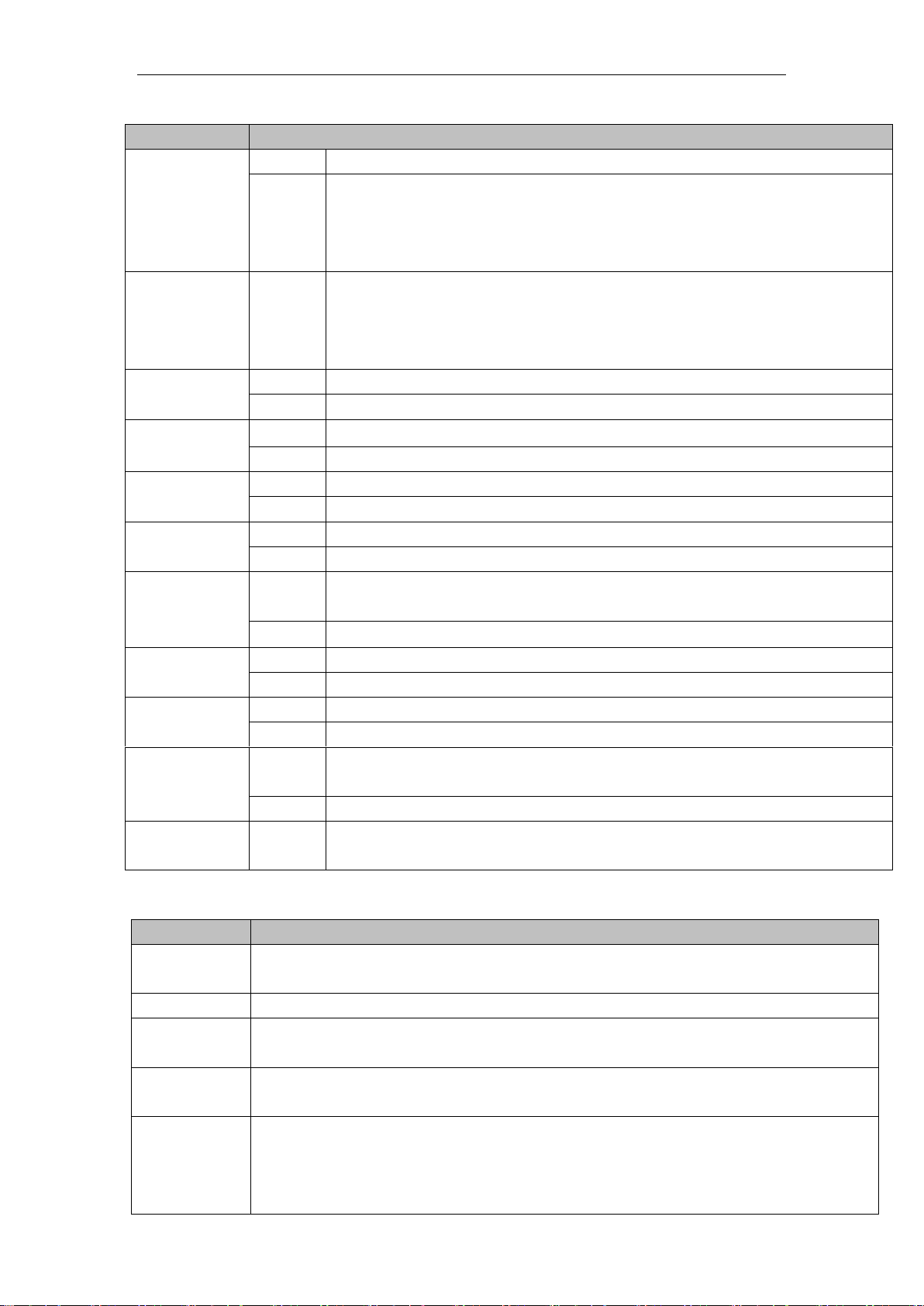

CHANNEL

CHANNEL MODE

16

20

1

COLOUR WHEEL

COLOUR WHEEL

2

STOP/STROBE

STOP/STROBE

3

DIMMER

DIMMER

4

STATIC GOBO CHANGE

STATIC GOBO CHANGE

5

PRISM ROTATION

PRISM ROTATION

6

PRISM ROTATION

PRISM ROTATION

7

EFFECTS

MOVEMENT(UNUSED)

EFFECTS MOVEMENT(UNUSED)

8

FROST

FROST

9

FOCUS

FOCUS

10

PAN

PAN

11

PAN FINE

PAN FINE

12

TILT

TILT

13

TILT FINE

TILT FINE

14

FUNCTION(UNUSED)

FUNCTTON(UNUSED)

15

RESET

RESET

16

LAMP CONTROL

LAMP CONTROL

17

PAN-TILT TIME

18

COLOUR TIME

19

DIMMER-PRISM-FROST TIME

20

GOBO TIME

3.2 Channel Detail

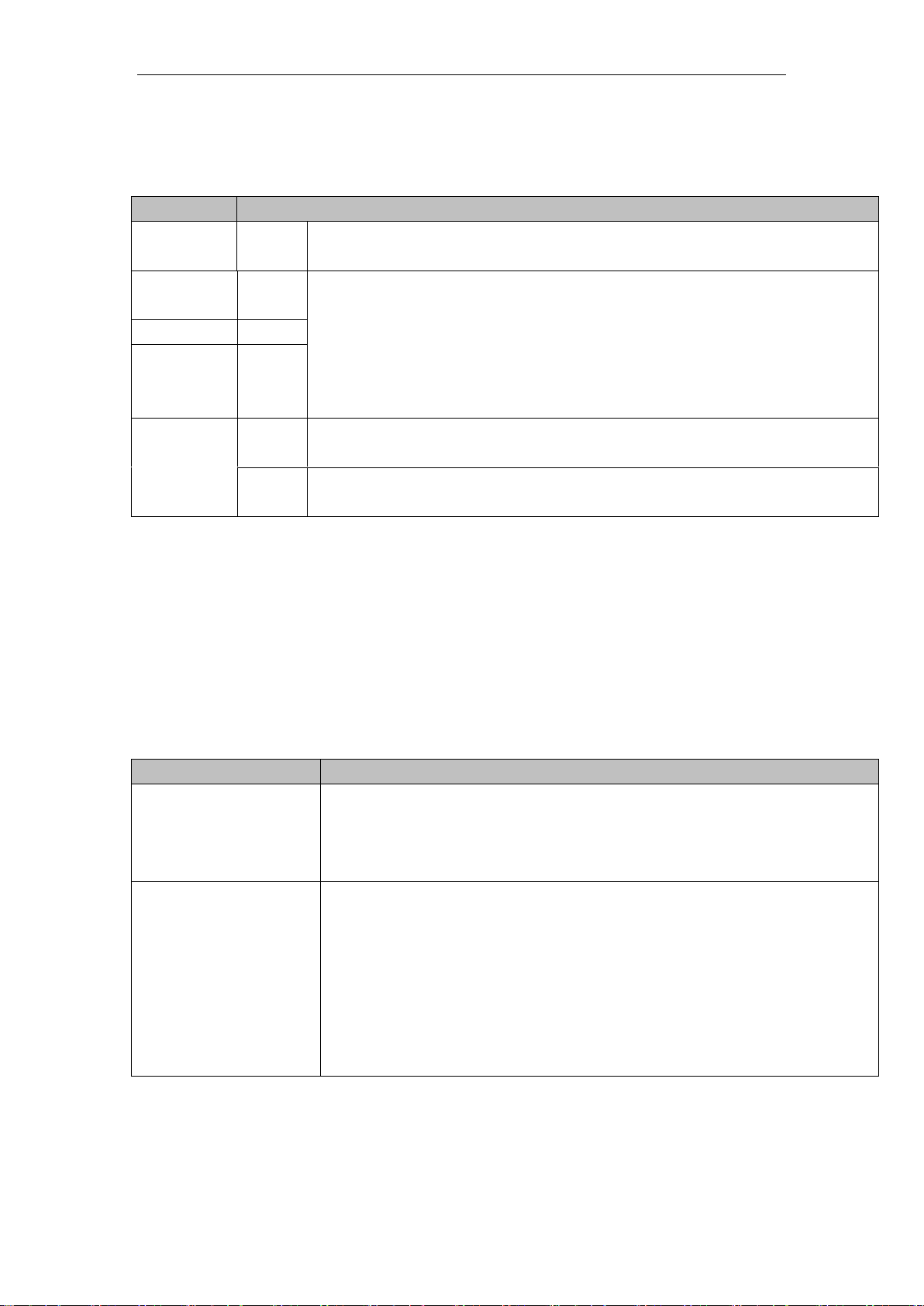

3.2.1 COLOR WHEEL-channel 1

6

www.szbecen.com

BIT

EFFECT

备注

255

FAST ROTATION

......

……

150

SLOW ROTATION

145

COOL COLOR +WHITE

In order to facilitate

memory, color value is

always a multiple of five.

Color ratio can be adjusted,

for example: when the

value is five, so it should

be 50% white, dark red

50%, if the value is 4, so it

should be 60% white, dark

red 40%: If the value is six,

so it should white 40%

dark, red 60%.

140

COOL COLOR

135

BROWNISH YELLOW+COOL COLOR

130

BROWNISH YELLOW

125

LIGHT BLUE-PURPK+BROWNISH YELLOW

120

LIGHT BLUE-PURPK

115

MAGENTA+LIGHT BLUE-PURPK

110

MAGENTA

105

YELLOW GREEN+MAGENTA

100

YELLOW GREEN

95

LIGHT YELLOW+YELLOW GREEN

90

LIGHT YELLOW

85

BLUISH GREEN+LIGHT YELLOW

80

BLUISH GREEN

75

PURPLISH RED+BLUISH GREEN

70

PURPLISH RED

7

www.szbecen.com

65

FLUORESCENCE+PURPLISH RED

60

FLUORESCENCE

55

BROWN+FLUORESCENCE

50

BROWN

45

GREEN+BROWN

40

GREEN

35

BLUE+GREEN

30

BLUE

25

DARK YELLOW +BLUE

20

DARK YELLOW

15

RED+DARK YELLOW

10

RED

5

WEITE+RED

0

WEITE

3.2.2 STOP/STOBE-channel 2

BIT

EFFECT

Remarks

252-255

OPEN

Controlled by a dimmer channel

239-251

RANDOM FAST STROBE

226-238

RANDOM MEDIUM STROBE

213-225

RANDOM SLOW STROBE

208-212

OPEN

Controlled by a dimmer channel

207

FAST PULSATION

……

……

108

SLOW PULSATION

104-107

OPEN

Controlled by a dimmer channel

103

FAST STROBE

……

……

4

SLOW STROBE

0-3

CLOSED

3.2.3 DIMMER-channel 3

BIT

EFFECT

Remarks

255

100%

……

……

0

0%

3.2.4 STATIC GOBO CHANGE-channel 4

8

www.szbecen.com

BIT

EFFECT

Remarks

255

GOBOI 17 SHAKE,FAST SPEED

Every five values is correspond to a

pattern.

……

……

251

GOBO 17 SHAKE,SLOW SPEED

250

GOBO 16 SHAKE,FAST SPEED

……

……

246

GOBO 16 SHAKE,SLOW SPEED

……

……

180

GOBO 2 SHAKE,FAST SPEED

……

……

176

GOBO 2 SHAKE,SLOW SPEED

175

GOBO 1 SHAKE,FAST SPEED

……

……

171

GOBO 1SHAKE,SLOW SPEED

170

FAST ROTATION

……

……

135

SLOW ROTATION

130-134

STOP

129

SLOW ROTATION

……

……

90

FAST ROTATION

85

GOBO 17

Value is always five multiple

80

GOBO 16

75

GOBO 15

70

GOBO 14

65

GOBO 13

60

GOBO 12

55

GOBO 11

50

GOBO 10

45

GOBO 9

40

GOBO 8

35

GOBO 7

9

www.szbecen.com

30

GOBO 6

25

GOBO 5

20

GOBO 4

15

GOBO 3

10

GOBO 2

5

GOBO 1

0

WHITE

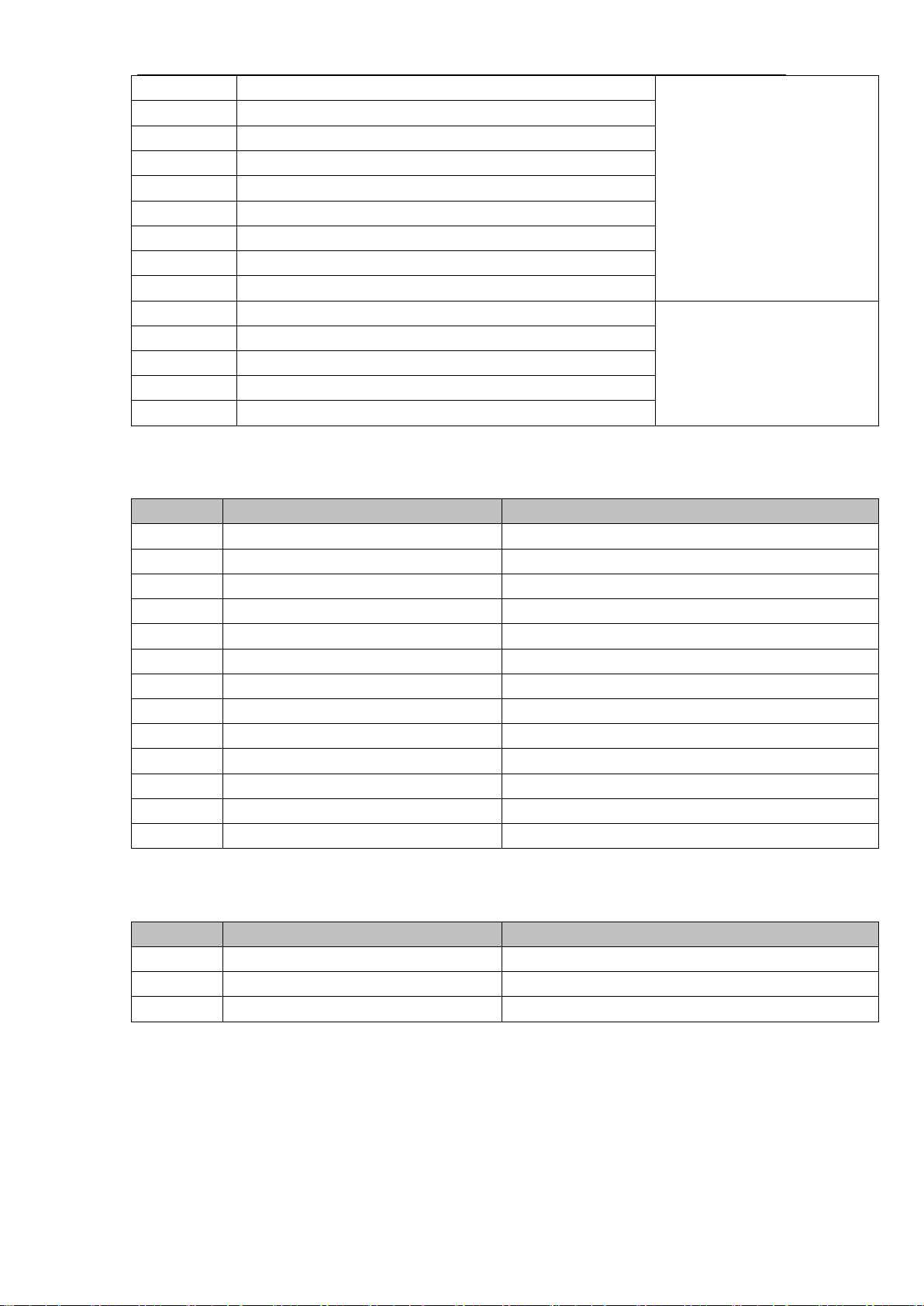

3.2.5 PRISM INSERTION-channel 5

BIT

EFFECT

Remarks

128-255

PRISM INSERTED

0-127

PRISM EXCLUDED

3.2.6 PRISM ROTATION-channel 6

BIT

EFFECT

Remarks

255

FAST ROTATION

……

……

193

SLOW ROTATION

191-192

STOP

190

SLOW ROTATION

……

……

128

FAST ROTATION

0-127

POSITION

3.2.7 EFFECTS MOVEMENT channel 7(NOUSED)

3.2.8 FROST-channel 8

BIT

EFFECT

Remarks

128-255

FROST INSERTED

0-127

FROST EXCLUDED

3.2.9 FOCUS-channel 9

BIT

EFFECT

Remarks

255

100%

……

……

0

0%

3.2.10 PAN-channel 10

(………)

3.2.11 PAN FINE-channel 11

(………)

10

www.szbecen.com

3.2.12 TILI-channel 12

(………)

3.2.13 TILT FINE-channel 13

(………)

3.2.14 FUNCTION-channel 14(NOUSED)

3.2.15 RESET-channel 15

BIT

EFFECT

Remarks

128-255

COMPLETE RESET

Reset is activated passing through the unused range

and staying 5 seconds.

77-127

PAN/TILT RESET

26-76

EFFECTS RESET

0-25

UNUSED RANGE

3.2.16 LAMP CONTROL-channel 16

BIT

EFFECT

Remarks

128-25

5

LAMP ON

Lamp switch passing through the unused range and staying 5

seconds.

10-100

LAMP OFF

0-9

UNUSED RANGE

3.2.17 TIMING CHANNELS

Timing Channel

Channel function

Remark

17

Pan-Tilt time

Pan-Tilt-(Pan fine-Tilt

fine)

255 SLOW SPEED

….. ……

0 FAST SPEED

18

Color time

Color wheel

19

Beam time

Dimmer-Prism-Frost

20

Gobo time

Static Gobo

Chapter 4 Control signal connection

XLR-XLR control cable from the DMX output of the controller connected to

each projector DMX input port, and from the first fixture in the DMX output port

connected to the second fixture in the DMX input port, and so on, until the All

lighting connection is completed, and then plug the supplied loop connected to the

signal output of the last fixture to complete the connection, as shown:

11

www.szbecen.com

Note: Keep in mind that in the last fixture's output circuit connected to a plug, this

circuit is connected to a 120 ohm resistor inserted between the CANON (XLR) plug 2

feet and 3 feet, this loopinterpolation can effectively avoid the reflection signal

generated by DMX512 signal in transfer input process.

The moving head light utilization the 3-pin XLR socket (head),if you are using the

controller uses a 5-pin XLR socket (head), you must use a 5-pin to 3-pin converter

cable, as shown below:

3-pin and 5-pin control cable plug (male and female) connector.

Three pin(Canon)DMX512 connector

12

www.szbecen.com

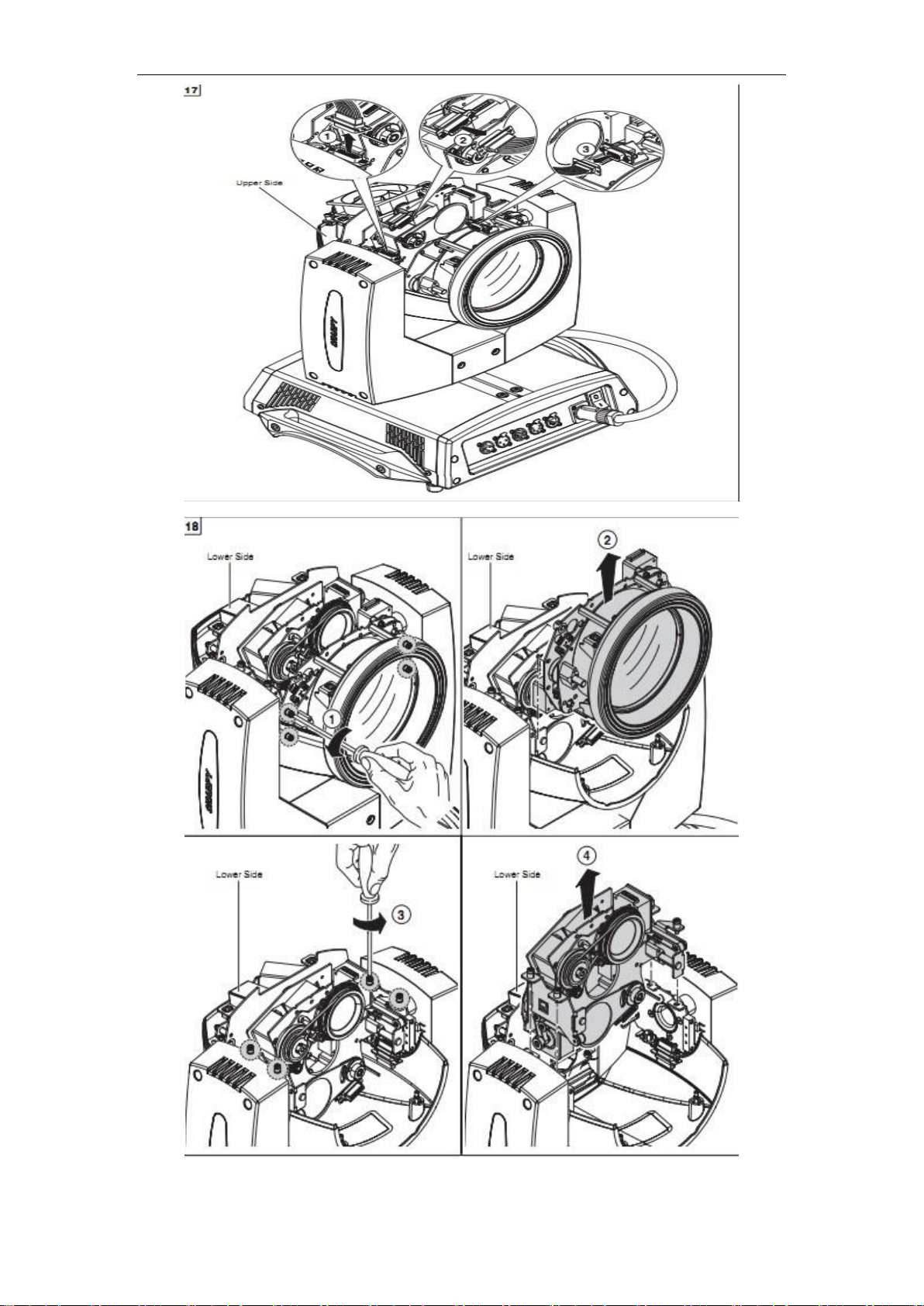

Chapter 5 Installation

13

www.szbecen.com

14

www.szbecen.com

15

www.szbecen.com

16

www.szbecen.com

17

www.szbecen.com

18

www.szbecen.com

Chapter 6 Protection and Maintenance

You should exchange the lens timely, if you find the led has damaged. You

should instant replacement the bulb when you find the deformation damage. The

aging bulb has a danger of blowout. Please check the power fuse of light when the

light unable to start. Install the corresponding specification fuse 6.35X32 T15A/250V

when burning. Light has overheating protection device, Protection device will

automatically cut off power supply when overheating. Please check the fan’s

operation, dirt jam between fan and fan nets when the situation happened. Find the

reason and repair then restarting light. Attention only qualified technical personnel

can repair it.

6.1 Light cleaning

It is necessary to keep the light cleaning to ensure its reliable use. The fan should

clean every 15 days. It needed to clean periodically of the internal and external optical

lens, mirror and coating color filter in order to optimize the efficacy output. Do not

use any chemical solvents containing to clean color filter. The frequency of cleaning

is according to the operation of light and the environment of operation.

Table of contents

Popular Floodlight manuals by other brands

Lithonia Lighting

Lithonia Lighting HGX LED 2RH ALO SWW2 120 PIR installation instructions

Chauvet

Chauvet Swarm 4FX user manual

EuroLite

EuroLite TC-150 user manual

Berner

Berner 409038 instruction manual

luceco

luceco SOLAR GUARDIAN Installation & operating instructions

American Pro

American Pro Neo Plat 15R Beam user manual