Beck 12-8061-05 User manual

80-4281-05

Rev. 03

PURPOSE

The purpose of these instructions is to provide

a step-by-step method for replacing the Beck

Group 22 Control End assembly. The control end

is located on the rear face of the drive beneath the

Handswitch.

The screws and washers included in Table 1 are

provided as part of the replacement kit in the event

that some are lost while servicing the drive. The

subassemblies listed in Table 2 are included with the

control end assembly.

The replacement control end assembly has been fully

calibrated at the factory. This replacement procedure will

return the drive to a close approximation of its original

calibration. Do not calibrate the drive until this procedure

is complete, and then only if necessary. Refer to Beck

Instruction Manual 80-4280-02 for calibration instructions.

REQUIRED TOOLS

1/2” socket

3/32” hex driver

Torque wrenches appropriate for 12 lb-in (1 N•m)

and 10 lb-ft (14 N•m)

Fine point marker

3/16” at-tipped screwdriver

Grounding strap

WARNING

Electrical shock hazard—disconnect

power before proceeding. Remove

the drive from line voltage and shut off

any external power sources feeding the

auxiliary switches.

PROCEDURE

Refer to Fig. 1 for component identication.

Remove the old control end assembly:

1. Remove power from the drive.

2. Remove the control end cover, using care not to bend

the control shaft or damage the position-sensing

assembly inside.

CAUTION

To prevent Electro-Static Discharge damage

to the electronics, wear a grounding strap

during this procedure.

3. Disconnect the control end assembly electrical

circuits by unplugging the three multi-pin connectors

from the drive. Two connectors lead from the switch

subassembly and the other connector leads from

the Printed Circuit board. To disconnect the switch

subassembly connnectors, use a 3/16” flat-tipped

screwdriver to press the release tab straight back (see

Fig. 1) and pull the plug out of its socket. The connector

leading from the P.C. board slides off with modest force.

4. Loosen the two outermost setscrews on the coupling.

Do not loosen the inner setscrews.

5. Use a ne point marker to note the position of the

control end relative to the drive body. Mark the drive’s

face immediately adjacent to the top of the notch (see

Fig. 2).

6. Loosen (do not remove) the four mounting clamp button

head screws (3/8” long) and slide the top clamp up over

the edge of the shoulder in the body, immediately above

the stator ange (see Fig. 2). Snug one of the screws to

hold the clamp up while replacing the assembly. Allow

the bottom clamp to hang by the screws.

7. Slide the control end assembly away from the drive

body until it clears the control end shaft.

Install the new assembly:

8. Inspect the control end gasket and replace as necessary.

If the gasket’s condition is good, skip Steps 9–13.

9. Protect the CPS-4 with a static-free cover.

10. Clean the mating face of the drive body to remove any

remaining gasket material and adhesive. Use caution

not to damage or bend the control shaft. Ensure that

the mating surface is free from damage (such as dents

or gouges).

11. Apply a thin lm of gasket adhesive (Scotch™ 847 or

equivalent) to the body’s mating face to adhere the

gasket.

12. Press the new gasket into place.

13. Remove the protective cover from the CPS-4.

REPLACEMENT INSTRUCTIONS

CONTROL END ASSEMBLY, CPS-4

REPLACEMENT KIT P/N 12-8061-05 & 12-8061-35

MODEL GROUP 22

ELECTRIC ACTUATORS FOR INDUSTRIAL PROCESS CONTROL

14. Slide the new assembly onto the shaft, turning the

coupling (if necessary) to align the assembly with the

shaft. Align notch in the stator with the locating pin

situated to the left of the control end shaft (see Fig. 2).

15. Loosen the clamp screw to allow the top clamp to drop

into place over the upper rim of the stator. Rotate the

assembly as necessary to align the top of the notch

with the mark made earlier on the drive face. Snug the

screws down on the plate. Raise the bottom clamp

into position and snug the screws down. Check the

clamps for proper shoulder clearance and tighten the

screws to 12 lb-in (1 N•m) torque.

16. Plug the pin connectors into their respective sockets.

17. Tighten the outer 2 setscrews on the coupling. The

screw on the at of the shaft must be tightened rst

to properly align the assembly. Torque screws to 12

lb-in (1 N•m).

Test for proper operation:

18. Connect power to the drive.

19. Modulate the demand signal to run the drive through its

full range of motion. Verify the correct drive response.

20. Modulate the signal to several intermediate levels and

note if the drive attains the proper position.

21. If the drive responds correctly, replace the control end

cover, tighten the cover bolts to 10 lb-ft (14 N•m) torque,

and return the drive to service.

22. If the drive does not respond correctly, refer to the

troubleshooting and calibration sections of Beck

Instruction Manual 80-4280-02.

Table 1: Control End Replacement Kit

Description Part Number

Control End Assembly 23-2500-01 or 23-2500-51

Screw, 8-32 x 1/2" (4) 30-0329-35

Washer, Flat #8 (4) 30-0313-31

Washer, Lock #8 (4) 30-0327-20

Gasket, Control End 10-8080-02

Table 2: Subassembly Kits

Description Part Number

Switch Assembly 12-8061-06 or 12-8061-36

CPS-4 P.C. Board 12-8065-07

CPS-4 Coupling 12-8061-08

3/14

11 TERRY DRIVE NEWTOWN, PENNSYLVANIA 18940 USA

PHONE: 215-968-4600 FAX: 215-860-6383 E-MAIL: [email protected]

www.haroldbeck.com

HAROLD BECK & SONS, INC.

R

Made in USA

Figure 2

Figure 1

SWITCH

ASSEMBLY

SWITCH ASSEMBLY

PIN CONNECTOR

PIN CONNECTOR

PRINTED

CIRCUIT

BOARD

PRINTED

CIRCUIT BOARD

Press tabs straight back to

release connectors

KEEPER

ASSEMBLY

KEEPER

ASSEMBLY

PIN

CONNECTORS

PIN

CONNECTORS

SWITCH CAMS

COUPLING

INNER SETSCREWS (2)

(Do Not Adjust)

OUTER SETSCREWS (2)

NOTE: Tighten the setscrew

on the at of the shaft rst.

Mark actuator

face to locate

notch

align

notch with

locating pin

Button head

ScrewS (4)

Stator flange

lift claMp

over

Shoulder

This manual suits for next models

1

Table of contents

Popular Industrial Electrical manuals by other brands

Siemens

Siemens SIMATIC ET 200pro FC-2 operating instructions

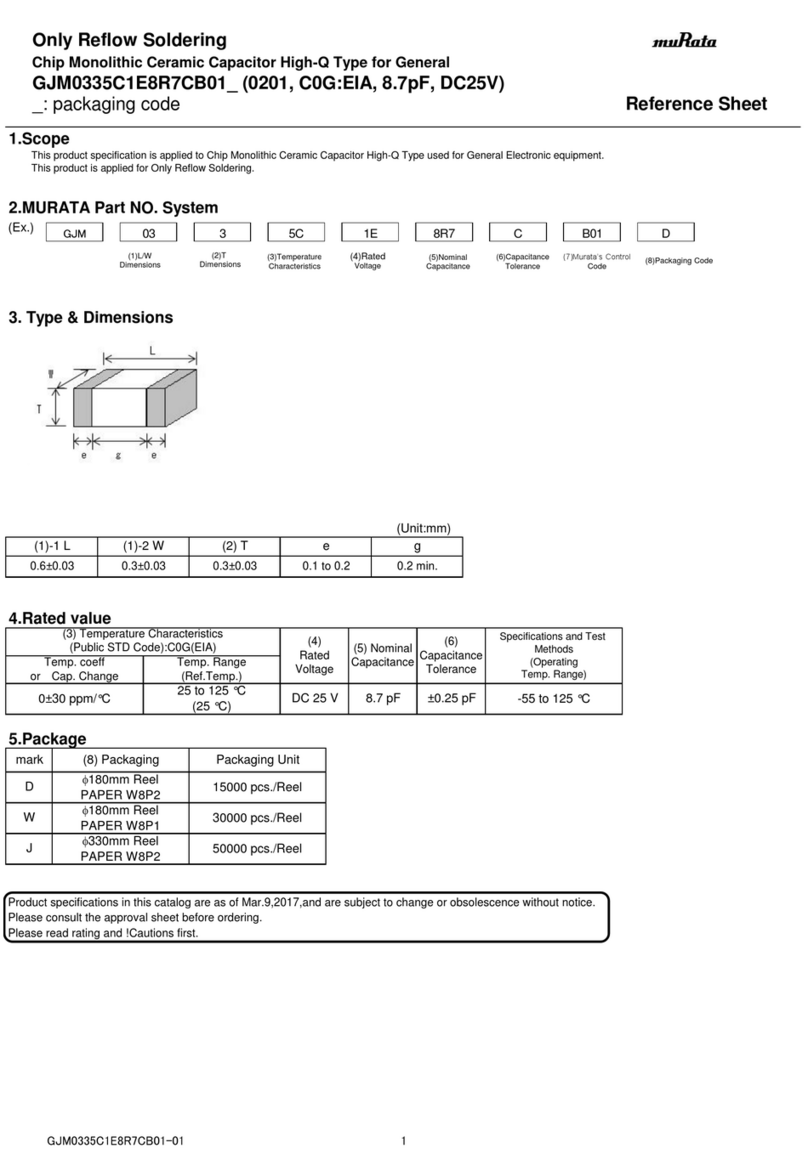

Murata

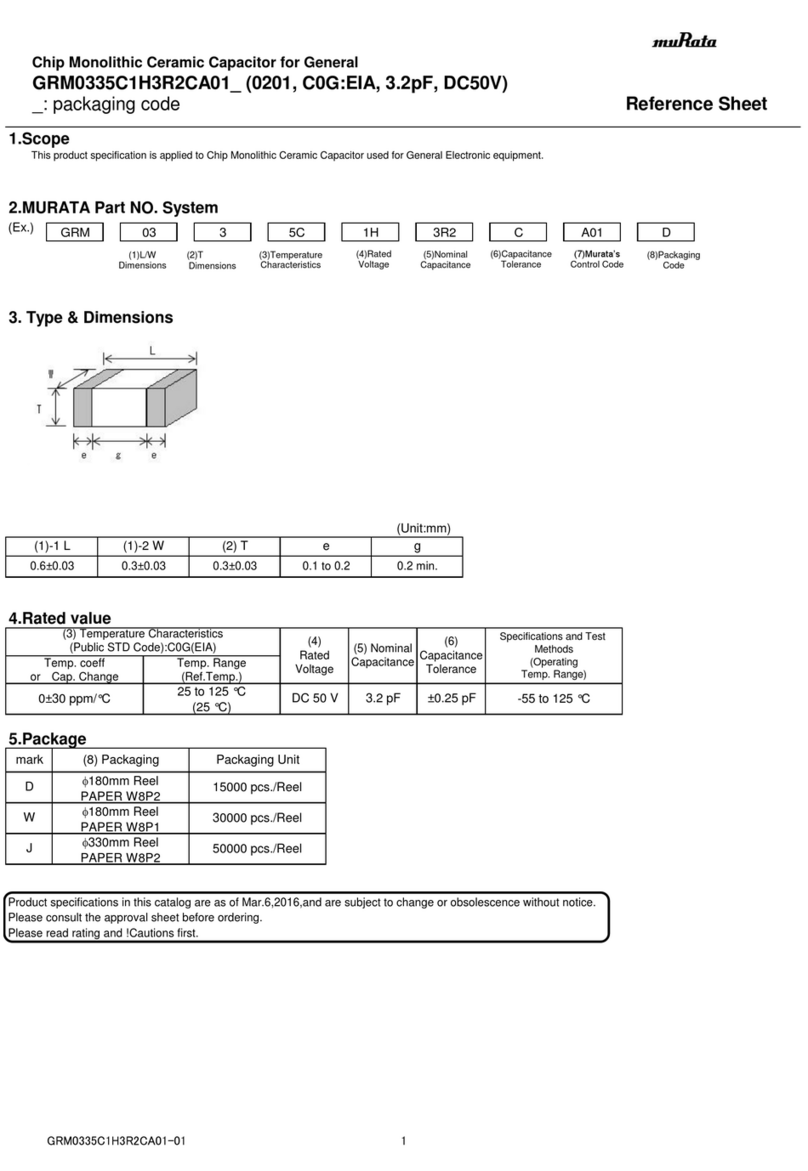

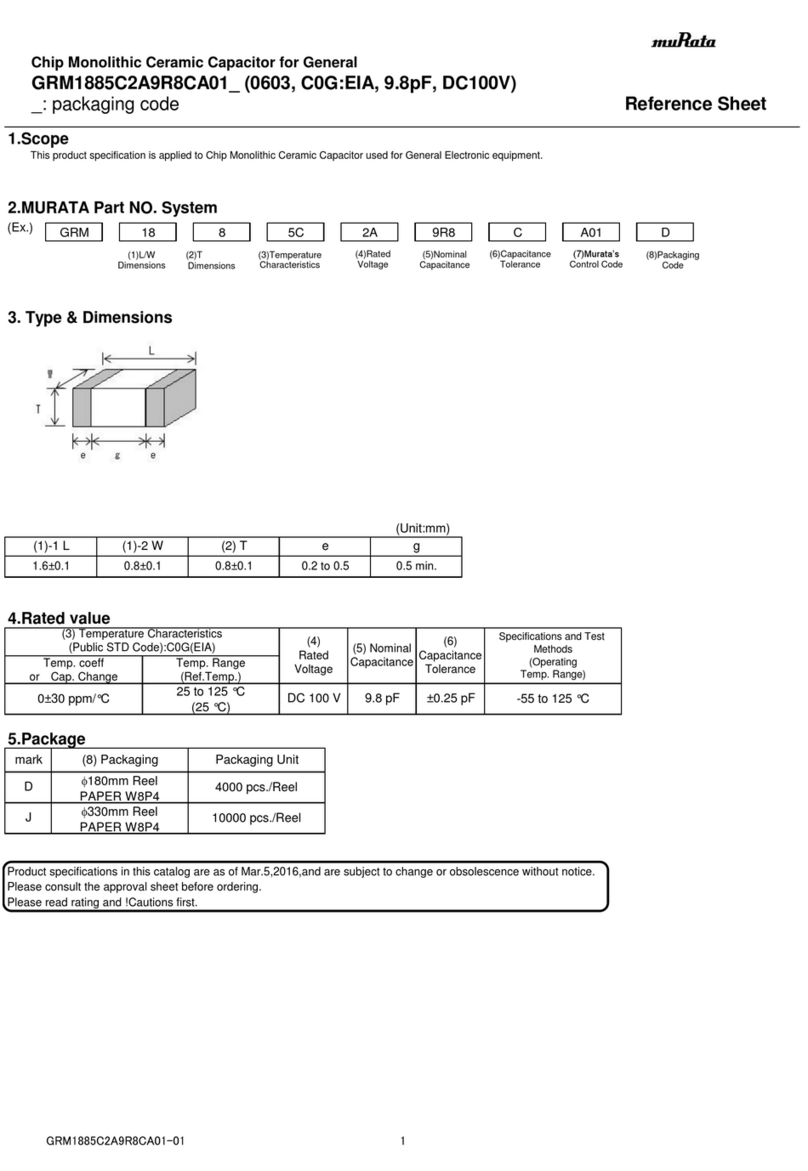

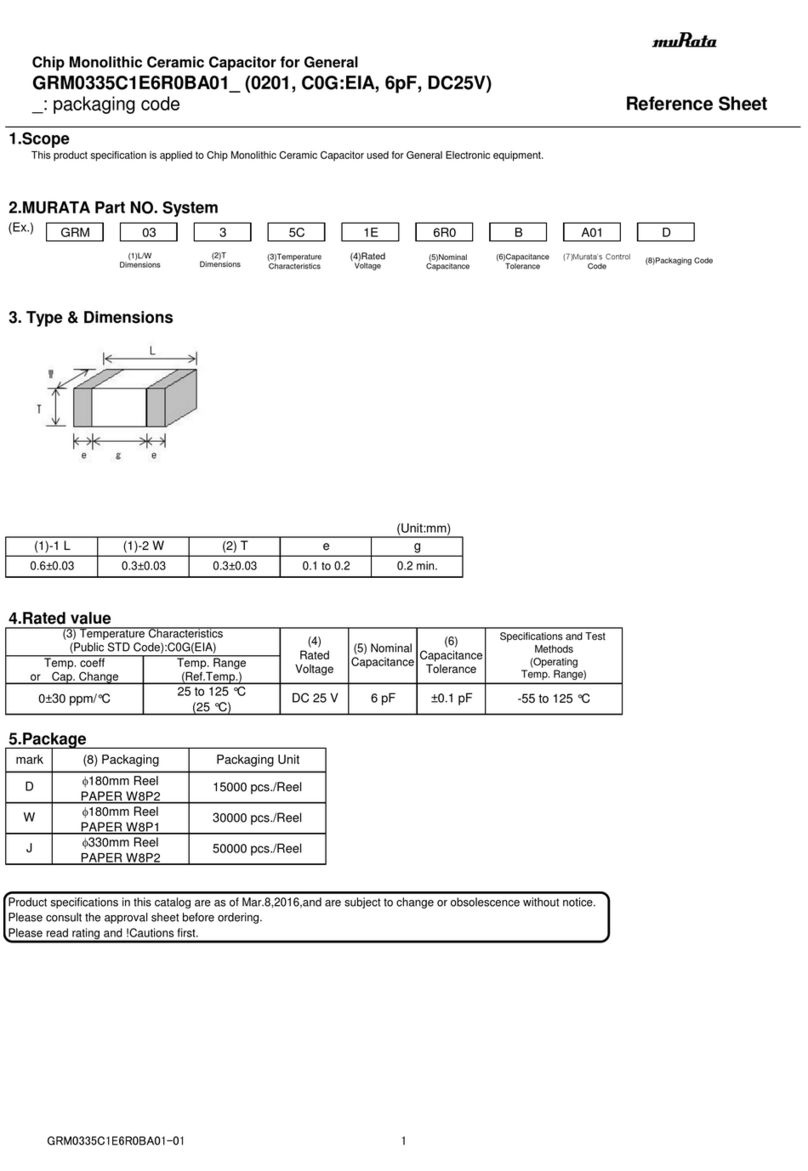

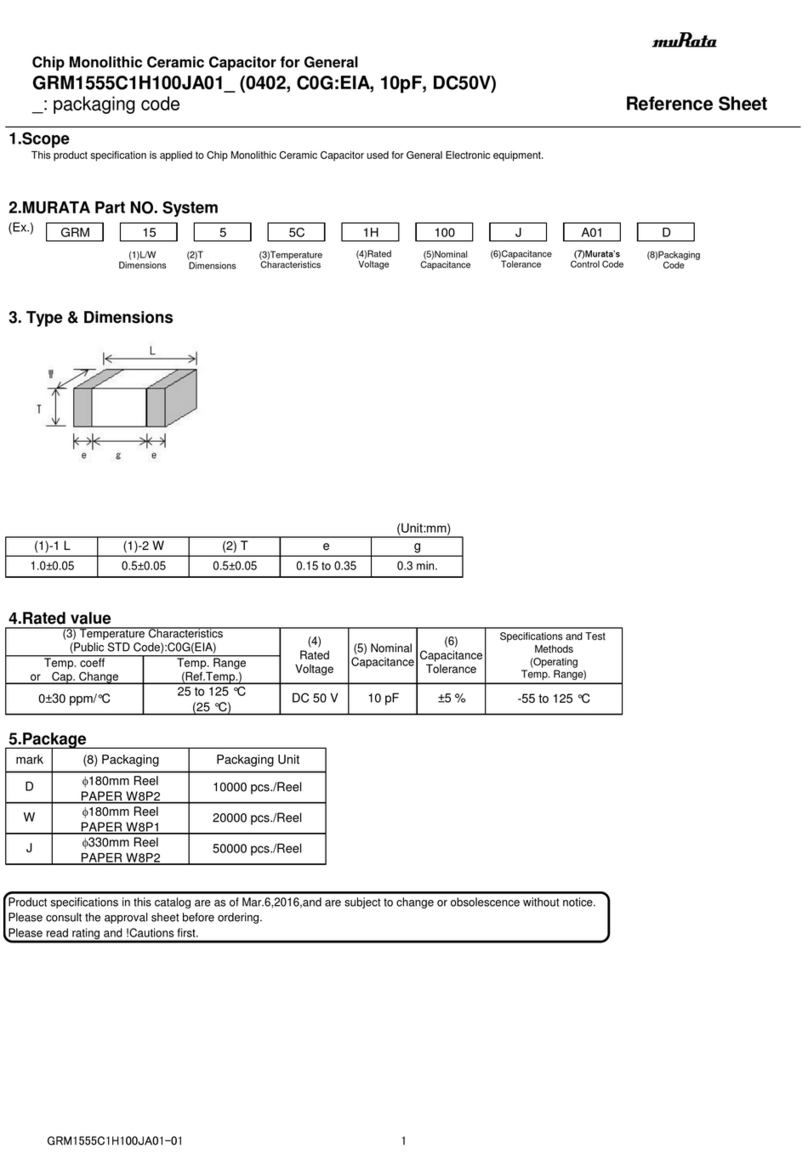

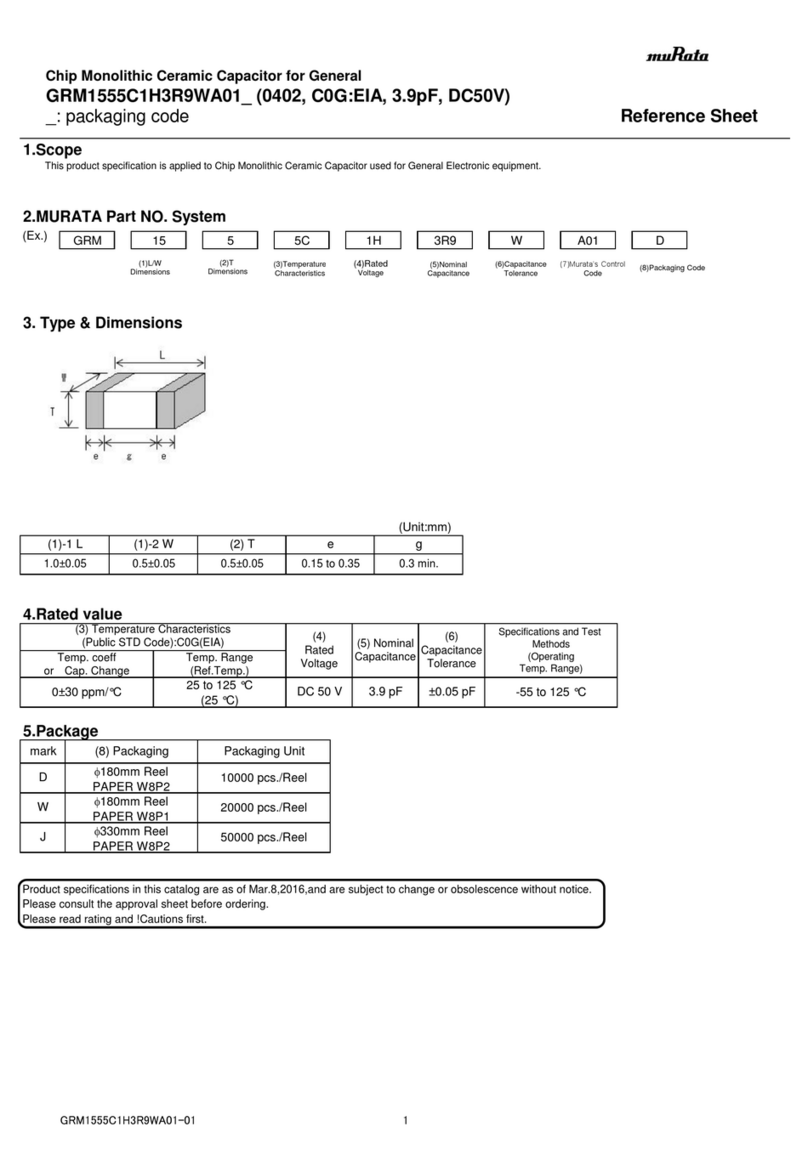

Murata GRM1555C1H100JA01 Series Reference sheet

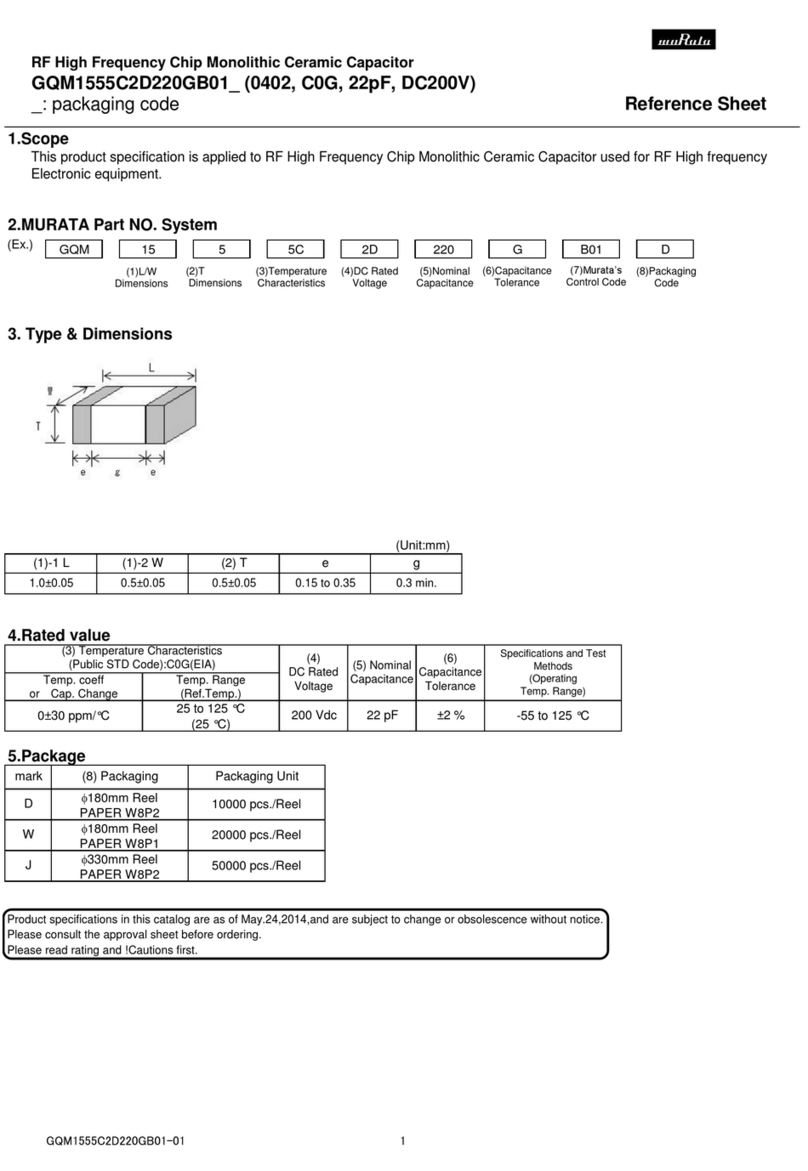

Murata

Murata GRM1555C1H3R9WA01 Series Reference sheet

Murata

Murata GQM1555C2D220GB01 Series Reference sheet

Superior

Superior SD23 Operator's manual

Eaton

Eaton M22-I Series Instruction leaflet