Beeworks B32 User manual

!

!

B32 GIMBAL CONTROLLER

USER GUIDE

!

!

!

!

!

!

!

BeeWorks LLC

www.beeworksgear.com

!

Last Modified: April 2014

Based on the “SimpleBGC Software User Manual” by BaseCam Electronics

Copyright © 2014 BeeWorks LLC. All rights reserved.

!

!

!

CHAPTER 1

OVERVIEW

This manual covers the setup, calibration, and operating modes of the BeeWorks B32

Gimbal Controller + IMU. It also covers the “SimpleBGC GUI” software application

produced by BaseCam Electronics.

The basic principle of the B32 Gimbal Controller is to input data from a stand-alone inertial

measurement unit (IMU) to control three brushless motors, each of which is responsible

for stabilizing an axis. The IMU contains electronic accelerometers and gyroscopes to sense

roll, pitch (tilt), and yaw (pan). If using the B32 Gimbal Controller to stabilize a camera,

the IMU must be mounted in the same location as the camera to sense camera movement.

PEDIGREE

The B32 Gimbal Controller is a circuit board manufactured in the USA by BeeWorks under

license to BaseCam Electronics. The BeeWorks B32 Gimbal Controller is manufactured in a

facility designed for the production of aerospace electronics and meets all standards set

forth in the Restriction of Hazardous Substances (RoHS) Directive.

The reference design from BaseCam Electronics is named “SimpleBGC” (Brushless Gimbal

Controller). Different manufacturers, such as BeeWorks, have licensed and adapted this

design into their own products. This manual covers the BeeWorks version of the 32-bit

SimpleBGC. Since the design is based on a standard architecture, most of the material in

this manual applies to other versions of the board, as well.

BaseCam Electronics also develops a multi-platform software application called SimpleBGC

GUI (Graphical User Interface), which is used to configure their gimbal controller family.

This manual includes material from BaseCam’s “SimpleBGC Software User Manual” that

BeeWorks has edited and adapted for this guide.!

!2

!

!

!

CHAPTER 2

GETTING STARTED

We recommend that you test your B32 Gimbal Controller, motors, and IMU before

installing them in your application. For this test, you will need to accomplish the following

steps, all of which are described in greater detail later in the manual but outlined here

1. Download and install the SimpleBGC GUI software application from BaseCam

Electronics: www.basecamelectronics.com/downloads/32bit/

2. Connect the B32 Gimbal Controller to your computer with a mini USB cable. If your

computer does not detect the controller automatically, you can download the latest

drivers from the following link: www.silabs.com/products/mcu/pages/

usbtouartbridgevcpdrivers.aspx

3. Connect the IMU and motors to the B32 Gimbal Controller. Reference Figure 2.1 below

for proper connections.

4. Auto-detect the number of poles for your motors or enter the number manually. For

more information, refer to the NUM.POLES description.

5. Set parameters P=0, I=0.1, D=0 for each axis. For more information, refer to the PID

description.

6. Connect your battery to the B32 Gimbal Controller. The B32 Gimbal Controller comes

with a power cable that has bare wire leads. Solder a connector to the wires that mates

with the connector on your battery. Pay careful attention to the positive and negative

terminals on your battery and ensure that you never short them or connect the battery

backwards. Doing so will damage the B32 Gimbal Controller and may cause your battery

to explode. Make sure that your battery is between 8 and 25V.

"3

Note: If you are using a Lithium Polymer (LiPo) battery, this voltage spec means you need between a

3S and 6S battery. The “S” designation is the number of cells, and each cell is 3.7V. Therefore, a 3S

LiPo is 11.1V, while a 6S battery is 22.2V.

7. Set enough POWER to get the motors to move.

8. Test the full system by rotating the IMU sensor board around each of its three axes.

Make sure each motor is moving when you do so. Motors should spin smoothly when

you move the sensor. A small amount of jitter is normal, due to the magnetic force

between rotors and stators known as “cogging” effect.!

"4

Figure 2.1 B32 Gimbal Controller Connectors

!

!

!

CHAPTER 3

STEP-BY-STEP SETUP

The following section outlines the steps required to set up and tune a gimbal using the B32

Gimbal Controller. Refer to later sections of this manual for greater details about the

software settings. This section is intended to provide a “big picture” view of the overall

process, so that you understand the purpose of more detailed sections in the manual. The

steps below assume you have completed a basic setup test, as specified in Chapter 2:

Getting Started.

STEP #1:

CONNECT THE B32 GIMBAL CONTROLLER TO YOUR COMPUTER

Connect the board to your computer with a mini USB cable. The first time you connect the

board to your computer, it may install the drivers automatically. If not, you can download

the latest drivers from the following link: www.silabs.com/products/mcu/pages/

usbtouartbridgevcpdrivers.aspx

After you install the driver, a new virtual COM port will be created. You need to choose this

COM port in the SimpleBGC GUI software application to initiate the connection.

Caution: It is safe to connect both USB and the battery simultaneously, but be very careful not to reverse

the polarity of the battery, because it will burn out the controller and may damage your PC!

!

"5

STEP #2:

UPDATE THE FIRMWARE

Your BeeWorks B32 Gimbal Controller comes preloaded with the latest firmware at the

time it is shipped. You can verify that you have the latest firmware by connecting the board

to a computer with a mini USB cable. This connection also will enable you to adjust

settings on the board itself.

STEP #3:

ADJUST GIMBAL MECHANICS

Mount the camera on the camera tray and balance the gimbal in all three axes. Stabilization

quality depends on balance quality. To check the balance, ensure the gimbal is turned off,

hold the gimbal in your hands and make fast motions along all three axes. If the camera

remains still, then the gimbal is balanced correctly. Proper balance and low friction will

reduce power consumption and improve stabilization quality.

If you rewound the motors yourself, we recommend checking the winding. Remove the

motors from the gimbal, connect them to the controller and set parameters P=0, I=0.1,

D=0 for each axis. Set enough POWER to get the motor to move, and connect your battery.

Motors should spin smoothly when you move the sensor. A small amount of jitter is normal

due to the magnetic force between rotors and stators (“cogging” effect).

Pay great attention to the IMU sensor installation. The IMU axes must be parallel to the

motor axes, and the IMU must be configured properly (i.e. mounting orientation set). Pay

close attention to mechanical linkages. They must be extremely rigid and backlash-free. The

IMU sensor provides feedback data for stabilization, and small amounts of freedom or

flexibility will cause feedback delays and low-frequency resonances. In such cases, it will be

more challenging to find acceptable PID settings and ultimately will result in unstable

performance in real-world conditions (multi-rotor frame vibrations, wind, etc).

STEP #4:

CALIBRATE THE SENSOR

CALIBRATING THE GYROS

Each time you turn the controller on, it takes about 7 seconds to power-up and calibrate the

gyro. Try to immobilize the sensor (camera platform) as much as possible in the first few

seconds after power-up, while the green LED is blinking.

"6

If you activated the option to “Skip gyro calibration at startup,” the gyro is not calibrated

every time, and the controller will start working immediately after power-up. Recalibrate

the gyro manually if you notice degradation in the stabilization quality.

CALIBRATING THE ACCELEROMETERS

It is necessary to calibrate the IMU prior to installation, and it is recommended to re-

calibrate it occasionally, particularly when the temperature changes significantly.

Simple calibration mode – Set the IMU sensor flat on the table and press CALIB.ACC in the

software (or the menu button on the controller, if it is assigned). The LED will blink for 3

seconds. Do not move the sensor during calibration. The sensor does not need to be

connected to the camera platform for this step, as you are calibrating the sensor, not the

camera.

Advanced calibration mode – Perform calibration in simple mode first, as described above.

Then, rotate the sensor board so that each side of the sensor faces up (6 positions total).

Fix the sensor in each position, press the CALIB.ACC button in the software and wait about

3-4 seconds while the LED is flashing. The order of the other sides does not matter, as long

as the base position used in the Simple calibration mode is first. You do not need to press

the WRITE button —calibration data is written automatically after each step.

NOTE: Precise accelerometer calibration is extremely important for holding the horizon during dynamic

movements or yaw rotation.

STEP #5:

TUNE BASIC SETTINGS

Prior to tuning the gimbal, ensure that the IMU is configured and calibrated and that Follow

Mode is not enabled (ensure “Estimate frame angles from motors” is offand Follow YAW is

off). “+” should be set to zero. PWM frequency should be set correctly for your application

prior to tuning.

1. Connect the battery.

2. Set POWER such that the motors have enough torque to hold the camera in place but

do not overheat. Wait at least five minutes to ensure the motors do not get too hot at

that setting. Find the lowest power setting that still provides adequate holding torque,

even when the camera is disturbed.

3. Set PID values for all axes to zero.

"7

4. Auto-detect the number of poles and the motors’ direction. If you know the number of

poles for your motors, it is best to enter the value manually. Do not proceed to the next

step until proper direction is detected.

5. It is best to configure the PID settings for each axis individually, starting with PITCH. To

check stabilization quality, use the peak indicator (shown by the blue traces and blue

numbers) in the control panel on the right of the software. Incline the frame by small

angles, and try to minimize the peak values by increasing P, I and D according to the

following algorithm:

i. Set “I” to a small value of 0.05 or less.

ii. Slowly increase “P” until the motor starts to oscillate.

iii. Increase “D” in small increments until the oscillations stop.

iv. Repeat steps ii and iii until high-frequency vibration occurs. You may feel the

vibration by hand and see a noisy line on the gyro graph. At this point, you have

identified the maximum values for “P” and “D” for PITCH for your setup. Decrease

each slightly and proceed to step v.

v. Repeat steps i through iv for ROLL. Stabilization of ROLL may cause instability in

PITCH. If so, reduce P and D slightly for PITCH. Cross-axis interference is most

pronounced when the gimbal construction is less rigid.

vi. Repeat steps i through v for YAW.

vii. Increase “I” for PITCH until low-frequency oscillation appears. Then, decrease “I”

slightly to keep the gimbal stable. You can reduce “I” as much as 20%, if needed.

viii. Repeat step vii for ROLL and YAW.

ix. When all axes are tuned, test the gimbal. You may find it helpful to use the gyro

data from the Realtime Data tab to estimate stabilization quality. Turn offall data

except GYRO and gently tap the camera in the direction of the axis you are

configuring. This impulse will display on the graph as a fading wave as shown in

Figure 3.1 below. The oscillation should damp within two to four cycles. If the

oscillation continues beyond that point, further adjustment of the rig is required.

Reduce the gain factors (P, I) or increase the damping factor D to reduce these

oscillations.

The result of good tuning is that stabilization error will be less than one degree when you

gently rock the gimbal’s frame.!

"8

STEP #6:

CONNECT AND CONFIGURE REMOTE CONTROL (RC)

Connecting a RC system to the gimbal is optional. A configuration that includes a RC

system will allow control and aiming of the gimbal independently from the direct physical

movements of the gimbal unit.

1. Connect one of the RC receiver’s free channels to the RC_PITCH input, making certain

to preserve the correct polarity in the RC Settings tab.

2. Set SOURCE=PWM.

3. Assign RC_PITCH input to the PITCH axis.

4. Leave all other axes and CMD as “no input.”

5. For the PITCH axis, set MIN.ANGLE=-90, MAX.ANGLE=90, ANGLE MODE=checked,

LPF=5, SPEED=10 (not used in angle mode).

"9

Figure 3.1 Turning PID in the SimpleBGC software application

6. Connect the battery to the main controller and receiver, and check that RC_PITCH input

receives data in the “Realtime Data” tab (slider should be filled blue and reflect stick

movement).

Now you can control camera PITCH from your RC transmitter from -90 to 90 degrees.

If you are not satisfied with the speed of movement, adjust the “I” setting for PITCH in

the “Basic” tab.

Experiment with SPEED mode to determine if SPEED or ANGLE mode is best for your

application.

7. Connect and tune the ROLL and YAW axes the same way, as required.

STEP #7:

TEST THE GIMBAL IN REAL-WORLD CONDITIONS

If your gimbal is attached to a multi-rotor aircraft, connect the controller to the SimpleBGC

GUI software application and turn on the multi-rotor motors. Check the vibrations on the

camera by using the Realtime Data tab / ACC raw data. Try to decrease the level of

vibrations using soft dampers.

NOTE: Brushless motors provide faster reaction than traditional servos but less torque. Depending on

your installation, it may be difficult for the motors to fight against wind and prop-wash. If you are

developing the multi-rotor aircraft frame yourself, try to avoid this influence by lengthening the motor

arms, tilting the motors away from center, or placing the camera above the props. Also, keep in mind that

deflected airflow, when moving at high speeds, can affect the gimbal.!

"10

!

!

!

CHAPTER 4

“SimpleBGC GUI” SOFTWARE

OVERVIEW

The SimpleBGC GUI software application enables you to do the following:

•Update the firmware on your controller

•Define settings for your specific installation of the controller

•Tune settings to get the optimal performance for your installation

•Adjust settings for various modes of operation

USING SimpleBGC GUI

After you start the software and select the correct COM port from the list, click “Connect."

When the connection is established, all board settings and profiles will be loaded into the

software. You can re-load the current board parameters anytime by clicking the “READ”

button.

After adjusting parameters in the software, you should write them to the controller board

by clicking the “WRITE” button. Only the current profile parameters will be saved to the

board. To return to the default settings, select the “USE DEFAULTS” button.

To choose a different profile, select it from the list of profiles located in the upper right

corner of the window. You can store different settings as five different profiles onto the

controller board. You can switch profiles saved on the board by choosing the profile in the

software or by pressing the MENU button, if configured on your controller board.

"11

Remember that some settings are common for all profiles and can not be saved on a per-

profile basis. Parameters such as sensor orientation, hardware configuration, RC inputs, and

motor outs are the same across all profiles.

The software starts in English. To change the interface language, choose one in the

“language” menu and restart the program.

SimpleBGC GUI LAYOUT

SimpleBGC GUI contains seven main sections, as illustrated below in Figure 4.1.

1. Connection – COM-port selection and connection status.

2. Profile – Select, rename, load, and save different profiles.

3. Configuration – Central part of the window, organized into seven tabs:

"12

Figure 4.1 SimpleBGC GUI Layout

i. Basic – Basic gimbal stabilization settings. Adjusting these settings is usually

adequate to achieve good camera stabilization.

ii. Advanced – More precise tuning options.

iii. RC Settings – Settings to control the gimbal roll/pitch/yaw orientation with RC

inputs.

iv. Service – Specify the behavior of the MENU button (located on the controller board

or mounted externally) and tune the battery monitoring service.

v. Follow Mode – Settings related to this special mode of camera control.

vi. Realtime Data – Realtime sensor data monitoring. This screen is helpful in tuning

your gimbal performance.

vii. Firmware Upgrade – Firmware and SimpleBGC GUI software versions and update

options.

4. Control Panel – Graphic visualization of gimbal orientation angles for all three axes.

• Black arrows display the angles.

• Blue arrows are a 10x time magnification to provide higher precision.

• Red marks show target angles that the gimbal should hold.

• Thin blue lines show the peak deflection from the central, neutral point.

• Blue digits show peak deflection amplitude, which provides an estimation of

stabilization quality.

• Vertical red bars to the right of the scales show actual power level from 0 to 100%.

5. READ, WRITE, USE DEFAULTS buttons are used to transfer settings to/from the

controller board.

6. MOTORS ON/OFF button – Toggle motor state.

7. Tips, status or error messages (in red color) are displayed at the bottom of the screen.

Overall cycle time and I²C error count is also displayed.

8. Battery voltage indicator with warning sector.!

"13

!

!

!

CHAPTER 5

“SimpleBGC GUI” REFERENCE

BASIC SETTINGS

Before tuning your controller, install the camera into the gimbal firmly, and ensure the

gimbal is balanced. Refer to your gimbal manufacturer’s balancing procedures for the best

way to balance your gimbal. In general, you want to ensure that your camera is positioned

such that each axis of the gimbal is balanced as precisely as possible.

"14

Figure 5.1 SimpleBGC GUI –$Basic Settings

PID (PROPORTIONAL-INTEGRAL-DERIVATIVE)

The primary tuning parameters are PID. For a technical explanation of PID parameters in

control loops, refer to the following Wikipedia article: en.wikipedia.org/wiki/PID_controller

“P” – Defines the strength of response to a disturbance. Higher values mean a stronger

response to external disturbance. Raise this value until the stabilization quality is

adequate. However, if the “P” value is too high, oscillations of the axis will occur. These

oscillations will get worse if there are vibrations that reach the IMU sensor board. If

oscillations occur, raise the “D” parameter by one or two units, then try to raise the “P”

value again.

“I” – The “I” value changes the speed at which the gimbal moves to incoming RC

commands and moves back to neutral. Low values result in a slow and smooth reaction to

RC commands and returning to neutral position. Increase this value to speed up the

movement.

“D” – The “D” value reduces the reaction speed of the gimbal. This value helps to remove

low-frequency oscillations. A “D” value that is too high can cause high-frequency

oscillations, particularly when the IMU sensor is exposed to vibrations.

Limit Accelerations – Check this option to limit angular accelerations with RC or serial

control. Setting this limit prevents rapid movement and results in smoother camera control.

If your gimbal is mounted on a multi-rotor frame, setting this limit will result in less impact

to the frame in flight from quick movements of the camera. The lower the limit, the

smoother the camera movement but the longer it takes for the camera to move to the

desired point.

Power – The power setting defines the maximum voltage supplied to the motors (0-255,

where 255 means full battery voltage). Choose this parameter according to your motor

characteristics. Find the lowest power setting that still provides good stabilization and

adequate holding torque. A Power value that is too low will not provide enough force for

the motor to stabilize the camera, particularly in windy conditions, when the gimbal is not

well balanced, or if the gimbal suffers from mechanical friction. Slowly lower the Power

parameter to find its optimal value.

Caution: Avoid high power settings that cause your motors to get too hot. Motor temperatures over 80 °C

(176 °F) will cause permanent damage to motor magnets.

Raising the power is equivalent to raising the “P” value in the PID settings. If you raise the

POWER value, you should re-tune your PID values as well.

“+” – Additional power that will be added to the main power in case of a large error caused

by missed steps. This additional power helps to return the camera to the normal position. If

main power plus additional power (+) is greater than 255, the result is limited to 255.

"15

INVERT – Reverse motor rotation direction. It’s extremely important to choose the correct

motor rotation direction to not damage your gimbal. To determine the correct direction, set

the P, I, and D values to 0 and the POWER values to 80 (or higher if your motors don’t

produce enough force to hold/move the camera). Level the camera tray horizontally and

click the AUTO button in the “Motor configuration” settings. The gimbal will make small

movements to determine correct motor rotation direction. Wait for the calibration

procedure to complete. Then, re-set your PID values and tune your Power values.

NUM.POLES – Number of motor poles. This value needs to be equal to the number of

magnets in your motor’s bell. During the “auto” calibration process described above, this

value is automatically detected. However, sometimes the auto calibration process is unable

to determine the correct number. Most brushless gimbal motors are built with 14 poles

(magnets) and utilize a DLRK winding scheme. Count your motor magnets and enter this

value if the “auto” value is not correct.

SENSOR – Configure your IMU by specifying the IMU sensor board’s orientation and

position on the gimbal. For a standard IMU sensor installation, look at the gimbal from

behind, like the camera view out from the gimbal. From this perspective, the up and right

direction will match the Z and X axis, respectively. You can place the IMU sensor in any

direction, as long as its sides are parallel to each motor axis. Take extra care in this step. It

is important to align the sensor precisely and mount it firmly. The correct configuration of

the IMU should result in the following:

1. Camera pitches forward – the PITCH arrow spins clockwise in the software.

2. Camera rolls right – ROLL arrow spins clockwise in the software.

3. Camera yaws clockwise – YAW arrow spins clockwise in the software.

SKIP GYRO CALIBRATION AT STARTUP – With this option, the board starts working

immediately after powering on, using the saved calibration data from the last gyroscope

calibration. Stored calibration data may become inaccurate over time or during temperature

changes, however. We recommend that you recalibrate your IMU on a regular basis to

ensure the best performance.

"16

ADVANCED TAB

Attitude, Heading, and Reference System (AHRS)

The following options influence the accuracy of the camera stabilization.

Gyro trust (0-255) – The higher the value, the more trust is given to the gyro data

compared with the accelerometer data when estimating angles. High values can reduce

errors caused by accelerations but also decreases gyro drift compensation, resulting in

horizon drift over time. For smooth operation, we recommend low values (40-80), which

will result in a more stable horizon for a longer period of time. For more aggressive

movements, higher values (100-150) are better.

Acceleration compensation (FC input only) – Enable this option to use a physical model of the

multi-rotor to compensate for accelerations during flight. This option works only when an

external FC is connected and calibrated.

"17

Figure 5.2 SimpleBGC GUI –$Advanced Tab

Timings

SERIAL PORT SPEED – Changes the baud rate used for serial communication. Decrease it

when using over-the-air serial adapters that do not work at maximum speed. The software

can auto-detect the baud rate configured in the board.

PWM FREQUENCY – Sets the PWM frequency used to drive the motors in the POWER

stage. Two modes are available: Low Frequency (within audible range) and High

Frequency (outside audible range). In the high-frequency mode, it is necessary to increase

the POWER setting slightly.

Motor Outputs

You can assign hardware motor outputs for any of the stabilization axes. For example, you

can use a second controller for YAW stabilization and set it up with the following settings:

ROLL=disabled, PITCH=disabled, YAW=ROLL_OUT. Then connect a YAW motor to

hardware ROLL_OUT.

RC Sub-Trim

RC Sub-Trim allows correction of transmitter inaccuracy.

ROLL, PITCH, YAW trim – Enables trimming of the center point. The central point is PWM

1500. It is better to trim the center point with the transmitter, but if it is not possible to

do so (when using a joystick, for example), you can use the AUTO function in the

software. Place the stick in the center and press the AUTO button. Actual data becomes

the new center point. Press the WRITE button to apply these settings.

Dead band – Adjusts a dead band around the neutral point. With this setting, there is no

control while the RC transmitter signal is inside the dead band range. This feature works

only in SPEED mode and helps to achieve better control by eliminating jitter around the

stick neutral point.

Expo curve – Adjusts the curvature of an exponential function allowing precise control from

a RC transmitter for small stick movements but more aggressive control near the stick

endpoints. This option works only in SPEED mode.

SENSOR

Gyro LPF – Adjusts gyro data filtering. It is not recommended to set values other than 0,

because it will make adjusting the PID controller harder, but you can experiment with this

option if you desire.

"18

Gyro high sensitivity – Doubles gyro sensitivity. Use this option for large DSLR cameras if

your PID settings are close to the upper limits and stabilization still is not good.

Increasing gyro sensitivity is equivalent to multiplying P and D values by 2.

I²C Pull-ups Enable – Turns on built-in I²C pull-up resistors for SDA and SCL lines. Enable

this function only if the sensor does not appear to be working properly.

Frame IMU – Set the location of the frame IMU above or below the YAW motor. See the

Second IMU Sensor section of this manual.

SERVICE TAB

MENU BUTTON – If you connected a menu button to the BTN connector on the controller,

you can assign different actions to it. Note that many of these button functions are the

same as options in the software.

!

"19

Figure 5.3 SimpleBGC GUI –$Service Tab

Available actions include:

i. Use profile (1, 2, 3, 4 or 5) – Loads selected profile

ii. Calibrate ACC – Accelerometer calibration

iii. Calibrate Gyro – Gyroscope calibration

iv. Swap RC PITCH-ROLL – Temporarily swap RC inputs from PITCH to ROLL. In most

cases only one PITCH channel is enough to control a camera on 2-axis systems. Before

a flight, you can swap control from the pitch channel to the roll channel to keep the

camera level in flight. Activating this function again swaps channels back and saves the

roll position in static memory.

v. Swap RC YAW-ROLL – Similar to the Swap RC PITCH-ROLL options, this option

switches RC inputs from YAW to ROLL.

vi. Set tilt angles by hand – Selecting this option will turn offthe motors for a few seconds

and enable you to fix the camera position by hand. After a few seconds, the Controller

will save and hold the new position. This function may be useful to correct camera

position before flight if there is no RC control connected.

vii. Reset controller

viii. Motors toggle, Motors ON, Motors OFF – Turn motors on or off.

ix. Inverse Yaw Motor – Reverse YAW motor direction.

BATTERY MONITORING – The 32-bit board has a voltage sensor installed to monitor the

main battery voltage to avoid damaging the battery. Battery monitoring is used to apply

voltage drop compensation so that PID remains stable throughout the battery lifecycle. The

battery monitor also triggers low-voltage alarms and cuts offpower to the motors when the

battery becomes discharged.

i. Calibrate – Adjusts the rate of the internal multiplier to make the measured voltage

more precise. Use a multimeter to measure the actual voltage, than enter this value in

the calibration dialog.

ii. Low voltage - alarm – Set the voltage threshold at which the alarm will sound.

iii. Low voltage - stop motors – Set the voltage threshold at which the controller stops the

motors, to avoid damaging the battery.

iv. Compensate voltage drop – Set this option to increase POWER automatically as the battery

loses voltage.

"20

Table of contents

Popular Toy manuals by other brands

LeapFrog

LeapFrog Learn & Groove Music Wand Parent guide & instructions

JMB-Jets

JMB-Jets Boeing TX/ T7A instructions

Eduard

Eduard Stirling Mk.IV exterior quick start guide

Maison Battat

Maison Battat Bbaby Mini Woofer BX1986 quick start guide

Mattel

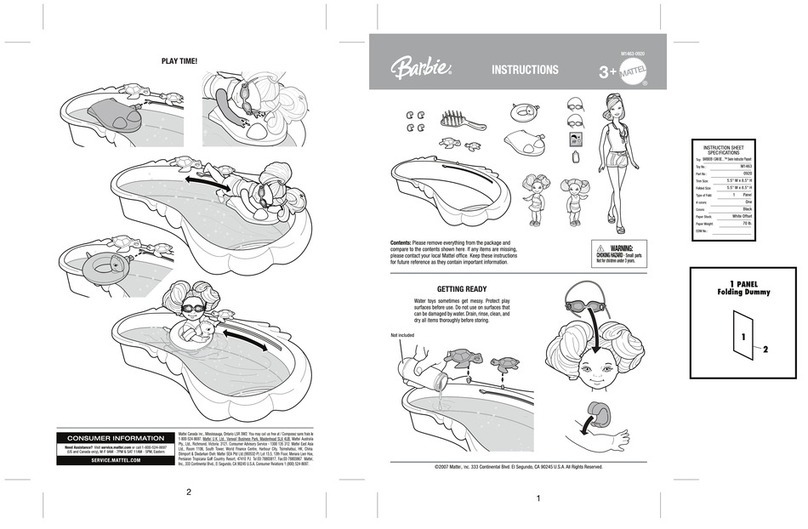

Mattel Barbie M1463 instructions

CYmodel

CYmodel f4u corsair Assembly instruction

LGB

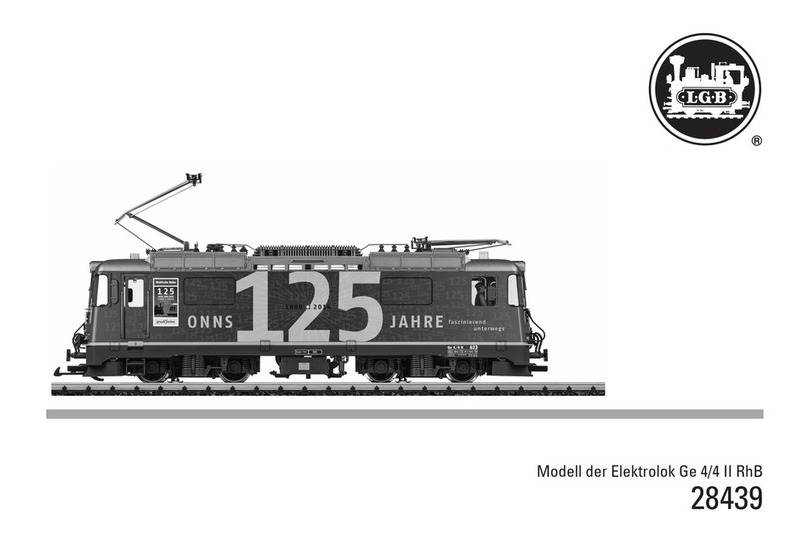

LGB Ge 4/4 II RhB operating instructions

Costway

Costway TQ10023 user manual

REVELL

REVELL SnapTite IMPERIAL STAR DESTROYER 1638 manual

Black Horse Model

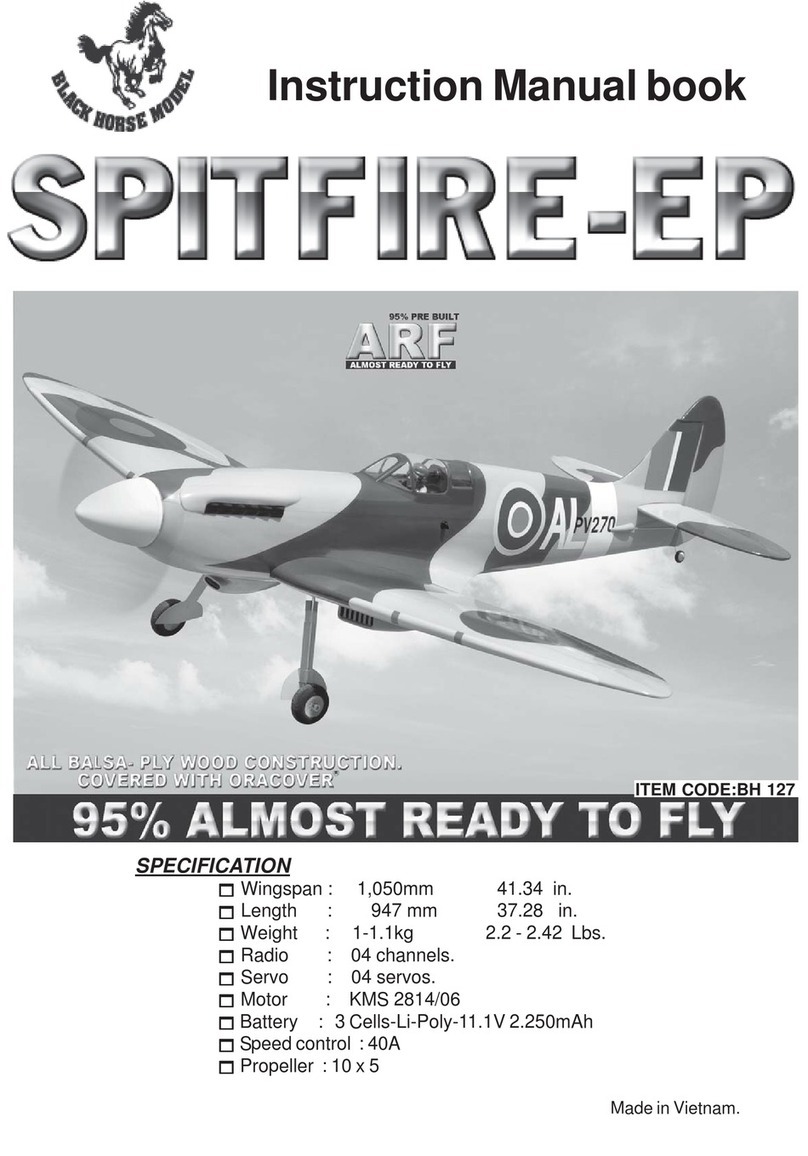

Black Horse Model Spitfire-EP BH 127 Instruction manual book

Horizon Hobby

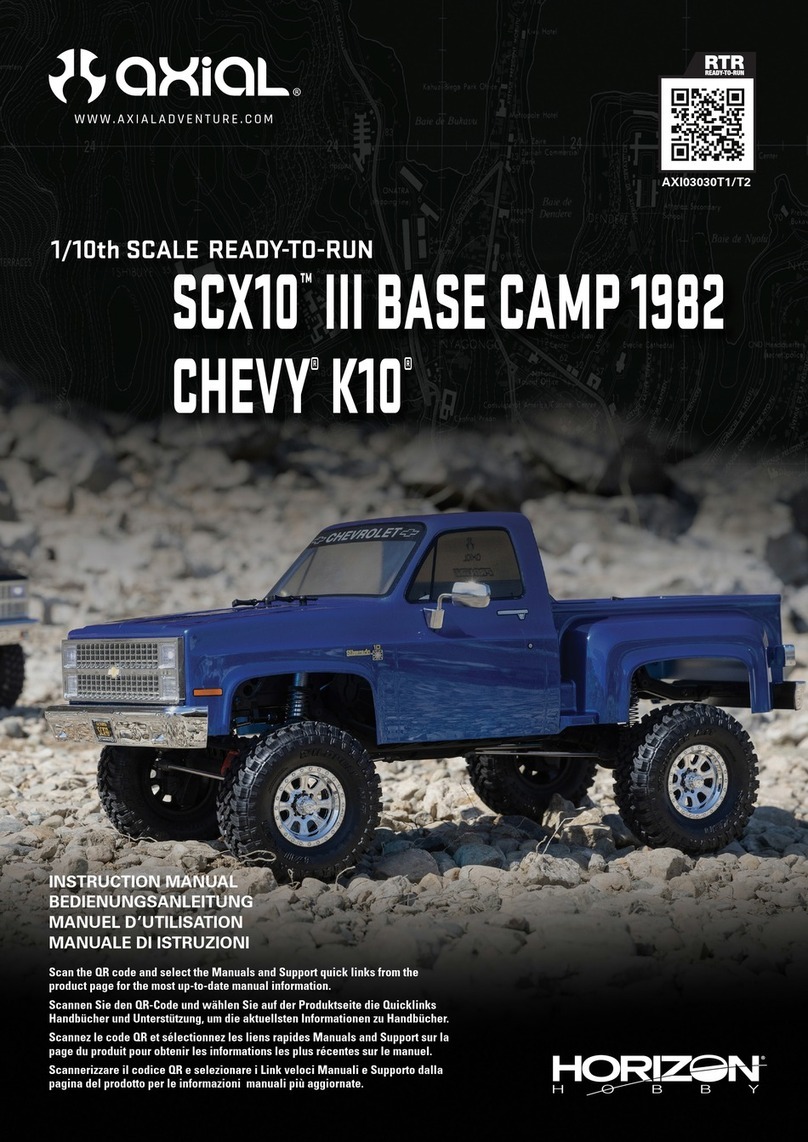

Horizon Hobby axial SCX10 III BASE CAMP 1982 CHEVY K10 instruction manual

Viessmann

Viessmann 4129 Operation manual