Behlen WRSJ Troubleshooting guide

DOUBLE ROW

STRIP JOINING PRESS

MODEL “WRSJ”

OPERATING INSTRUCTIONS & SERVICE INFORMATION

TECHNICAL

INFORMATION

61018

F-10929-7 Rev. 9-25-07 7-1-98

NOTE: If pink sheets are included in this manual, refer to them for latest revisions.

IMPORTANT CONCERNS

WHEN MOVING YOUR SPLICE DETECTION

HOLE PUNCH FROM ONE DIE TO ANOTHER

In late 1997 we made a design change to our basic strip joining dies. This change involved making both upper and

lower die shoes thicker by approximately 11/16” (17 ½ mm). This change also eliminated the mounting plates and made

the entire unit more rigid.

This change also created a serious problem when a splice detection hole punch assembly is removed from an old style

die and placed in a new style die. The result will be considerable damage to the entire die assembly.

Do not, under any circumstances, remove a hole punch assembly from an

old style die and place it in a new style die. Any damage resulting from this

is excluded from any and all warrantees.

To best determine whether you can interchange your hole punch assembly from one die to another, measure the thick-

ness of the die shoe in both dies. If there is a thickness difference of more than 0.125” (3mm), please consult Behlen

Mfg. Co. before proceeding.

F-19853 7-18-02

SAFETY

Watch for this symbol. It points out important safety

precautions. It means “Attention - Be Alert! Your

Safety Is Involved.”

Several decals are attached to the press at various loca-

tions to call attention to your personal safety. Read and

heed the message and be alert to possible injury or fatali-

ty.

It is your responsibility as a supervisor or operator to

know what hazards exist and to make these known to all

other personnel working the area so that they too may

take any necessary safety precautions that may be

required.

If the decal(s) become damaged or detached, contact

your Behlen representative or the Behlen Mfg. Co. for

replacements.

Guards and shields are for your protection. Keep

them in place and secure while machine is in opera-

tion.

Replace safety shields that may have been dam-

aged or removed for servicing purposes and fasten

securely before operating machinery.

Enforce the use of safety blocks whenever dies are

being adjusted, repaired or replaced in the press.

Before you perform any service on the press, make

certain that the main power disconnect switch is

locked in the off position.

The design and installation of any and all safety and

guarding equipment for the passage of the metal strip

through the Strip Joining Press that may be necessary to

conform with O.S.H.A. or any applicable safety regula-

tions to meet your particular line configuration are your

responsibility, not that of Behlen Mfg. Co. Make the elec-

trical connections according to the enclosed schematic.

In the event the press fails to operate the die (even

though the pumps are running), it is possible the pump

motor is running in reverse. Check the rotation. This sit-

uation can be corrected by interchanging any 2 of the 3

phase line leads.

Before each stitching operation, check the press to make

sure the die is free of all foreign material.

BEHLEN STRIP JOINING PRESS

SERVICE AND OPERATING INSTRUCTIONS

1. Oil level should be kept to near the top of the sight

gauge. This machine was filled to the proper level at

the factory with MOBIL DTE-26 hydraulic fluid unless

otherwise specified.

2. Adjust stitch height switch for various thicknesses of

material if necessary.

3. Lubricate the guide posts on the die as required.

Keep the die area free of all foreign material.

4. Adjust the limit switch on the ram to coast to a stop at

bottom of the cylinder stroke.

5.

To perform the stitching operation, stop the trailing end

of leading material, holding about 14” (35.5cm) in the

machine. Next, insert 14” (35.5cm) of the leading end

of the next coil, either above or below the trailing end.

Push the “UP” control switch on the machine. In one

cycle, the stitch is completed. During the cycle, the die

will move up, make the stitch, reverse and stop in the

original position. Check to be sure the limit switch

shuts the press off at the finish of each stitch.

6. The Strip Joining Press can be cycled two or more

times to form additional rows of stitches that may be

required to obtain a holding stitch on lighter gauge

material. This is accomplished by cycling the

machine once, advancing the joined sheets forward

out of the die area, and then cycling the machine

again. For each additional two rows of stitches to be

formed, overlap the coils approximately 14” (35.5cm)

longer than required for two rows of stitches. Each

cycle of the machine forms two rows of stitches. A

pre-cut strip (needle) can be inserted through one row

of stitches if necessary, after two or more rows of

stitches are formed, in order to obtain a holding stich

on lighter gauge material.

7. The relief valves are pre-set at the factory and should

not be field adjusted.

8.

THE STRIPPER PLATES AND/OR COMPLETE DIE

SHOULD BE REMOVED PERIODICALLY AND THOR-

OUGHLY CLEANED OF ALL CHIPS AND FOREIGN

MATERIAL. THIS SHOULD BE DONE POSSIBLY ONCE

A MONTH UNDER SEVERE CONDITIONS.

INSTRUCTIONS FOR ORDERING

REPLACEMENT PARTS

In order to insure that the correct parts will be provided,

all orders for replacement parts must include the serial

number and model of the strip joiner. These numbers

may be found on the name plates located on the die and

on the press frame near the controls.

INSTRUCTIONS FOR SERVICING THE DIE

Reference to die teeth in the following procedure means

punch with insert assembled.

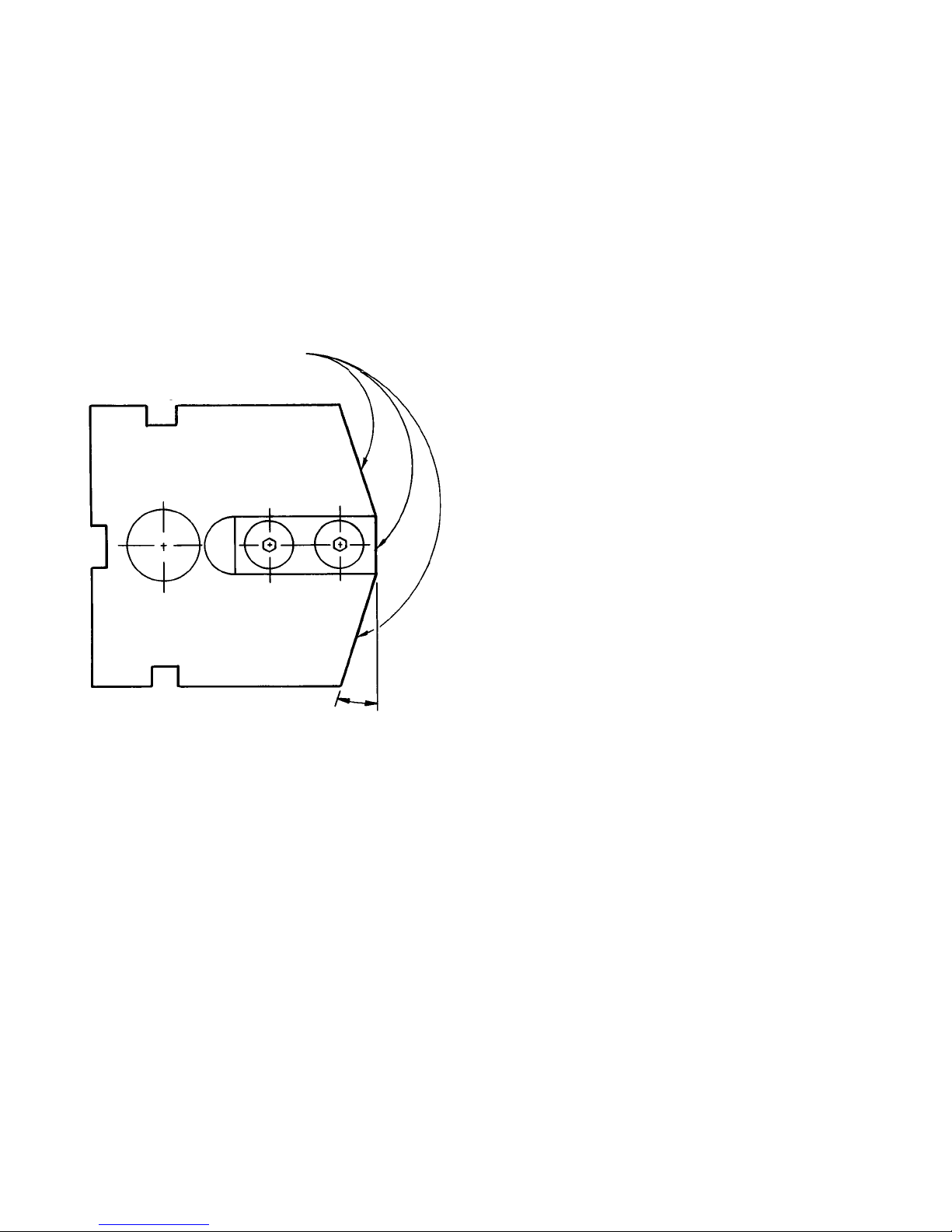

For 18° angle on punch - part no. 615 061, assembly

includes punch 616 116 with insert 616 117.

For 9° angle on punch - part no. 615 067, assembly

includes punch 616 131 with insert 616 117.

DIE REMOVAL INSTRUCTIONS

1. Lock out machine.

2. Place wooden block (2 places) into die opening.

NOTE: Blocks need to be 3-3/8” (86mm) to 3-1/2”

(89mm) in height.

3. Loosen bottom bolts and remove from die.

4. Using a bottle jack each end of die, jack bottom die

until wooden blocks contact upper die.

5.

Place 1/2” (13mm) dia. round rods under raised die.

6. Loosen and remove top bolts from die.

7. Lower die set onto rods and remove bottle jacks.

!!

!!

!!

!!

!!

PRE-OPERATIONAL PROCEDURE

F-19282-2 Rev. 7-5-05 7-1-98

1

!!

8. Push die out onto die cart.

9. Reverse procedure to install die.

INSTRUCTIONS FOR SHARPENING TEETH

Remove the entire die from the press as a unit and sepa-

rate it into a top and bottom die set. Keep all teeth

attached to the die plates, however, the die shoes may be

removed from the die plates for ease in grinding teeth.

The stripper plates and urethane stripper plugs must be

removed before the teeth are ground. Grind teeth of the

top and bottom as a unit. Teeth shall be ground on tops

and both adjoining angled sides. The sides are ground

at an angle of 9° or 18°, depending on machine model.

This angle is not critical, however, both sides should be

the same. The die may now be reassembled and placed

back into the machine. The die and press each have a

marking labeled “Front”. The die is symmetrical, but it

should be placed back in the press as originally assem-

bled. If grinding equipment is not available to sharpen

teeth as a unit, they may be ground individually. Read

the instructions for the procedure to remove and replace

teeth.

PROCEDURE FOR REPLACING TEETH

OR OTHER PARTS OF THE DIE

Remove the die from the press as a unit and separate it

into the top and bottom die sets. Next, remove the strip-

per plates and and urethane stripper plugs, tooth clamps

and rod. Teeth that need replacing may now be lifted off

the die plate. In replacing new teeth, it is very important

that all parts be cleaned thoroughly, making certain that

no lint from wiping rags or other foreign material gets

between the teeth. A spare tooth should be used for indi-

vidually checking clearance between all teeth. This clear-

ance should be .002” (0.05mm) minimum to .007”

(0.18mm) maximum around all parts of mating teeth.

After the clearance is determined to be correct, the teeth

in the bottom die set should be securely fastened by

means of the clamps and rod. The nuts on the rod

should be tightened with a torque wrench to 120 foot

pounds (163 N-M).

The two sets of set screws in each end keeper should

also be tightened at this time. These are locked in

placed with a second set of socket head set screws. The

teeth in the top die set should be tightened securely with

the rod, but only tight enough with the clamps to hold

them in place so they are allowed to move for adjustment

after the top and bottom die sections have been slipped

together. The top and bottom die sections should be

slipped together without the urethane stripper plugs and

stripper plates. At this time, clearance between top and

bottom mating teeth should be checked and adjusted if

necessary. This adjustment can be accomplished by

means of the set screws in the keepers on both ends of

the top die section. After it is determined that the die

meshes properly, the clamps of the top die should be

tightened and the urethane stripper plugs and stripper

plates replaced in the die. The entire die may now be

returned to the press.

PROCEDURE FOR REPLACING CYLINDER SEAL

1. Remove the urethane roller (615059) from one side of

the press.

2. Remove the top and bottom bolts holding the com-

plete die in place, and remove the complete die unit

from the press.

3. Remove the screws that secure the ram plate to the

pistons and then remove both ram plate skirts

(616113) and the ram plate (616112).

4.

Bolt a long bar or pipe to the piston (616002) - there is

one threaded hole in the top of each piston. Remove the

piston upward from the cylinder (616099).

5. Replace the defective seal (3308009) in the cylinder,

with the lips of the seal pointing downwards.

Lubricate the seal for easier assembly.

6. Also, check the “O”ring #331 (2748014), under the

cylinder, for leakage and replace as required.

7. Reverse steps 1, 2, 3 and 4 to assemble. When

replacing pistons, apply pressure downwards as

evenly as possible so that lips of the seals will not be

cut or damaged.

HOLE PUNCH FOR SPLICE DETECTION

For strip joining dies equipped with a hole punch assem-

bly, 1½” or 2” (38mm or 51mm) diameter on the exit side

of the die, you can sharpen the round punch portion and

the die plate one or more times until a total of 0.075” to

0.100” (1.9mm to 2.5mm) maximum has been removed,

depending upon the thickness of the material being

joined. The following spare parts can be ordered by

complete description and you must indicate the diameter

of the hole punch, press model number and serial num-

ber.

1. Spare hole punch and die plate. (You will need to

locate and drill dowel pin holes to properly match up

the new mating punch and die plate.)

2. Urethane stripper ring (616270) over the hole punch

for splice detection assembly.

Original Length 2.500” (63.5mm)

Sharpen these three surfaces.

Do not grind off more than .060” (1.5mm)

total during successive sharpenings.

F-13569-5 Rev. 7-5-05 5-15-80

2

9° or 18° depending on machine model.

OPERATION FOR BEHLEN STRIP JOINER PRESS

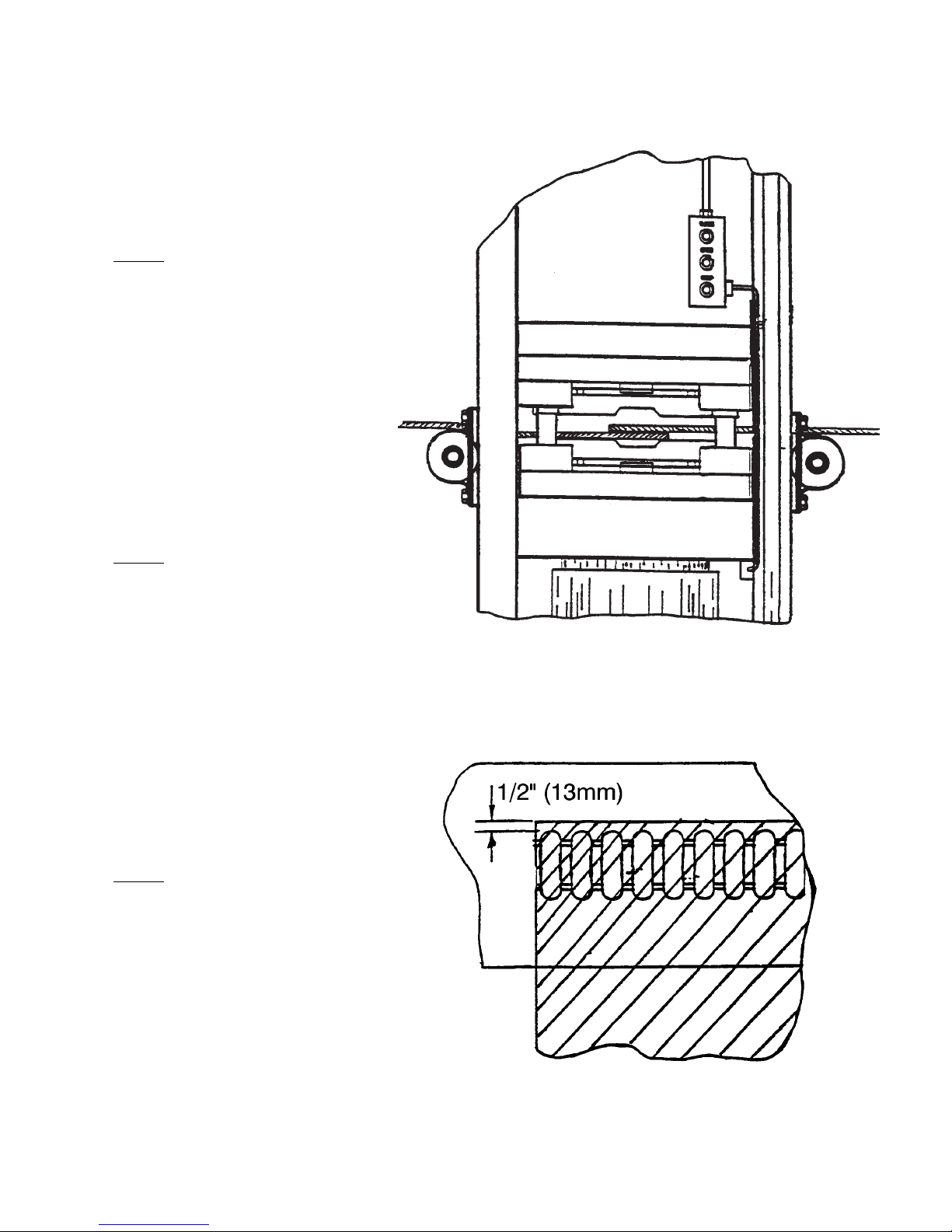

STEP 1

FEED INCOMING EDGE OF COIL

INTO DIE AREA AS SHOWN IN

ILL. 1.1 OVERLAP MAY VARY

DUE TO THE NEED FOR MORE

ROWS OF STITCHES. STRIP

EDGES SHOULD BE NO CLOSER

THAN 1/2” (13MM) TO

STRIPPER PLATE POCKETS AS

SHOWN IN ILL. 1.2.

STEP 2

AFTER ALL CLEAR HAS BEEN

ANNOUNCED FOR SAFETY

PURPOSES, PRESS THE CLOSE

BUTTON(S) FOR CYCLE

ACTIVATION. THE MACHINE

WILL RUN THROUGH COMPLETE

CYCLE AND TURN OFF

AUTOMATICALLY.

STEP 3

JOG THE JOINED MATERIAL COIL

FOR LOCKING THE STITCHES.

F-18221-1 37-1-98

ILLUS. 1.2

ILLUS. 1.1

F-19587 44-15-00

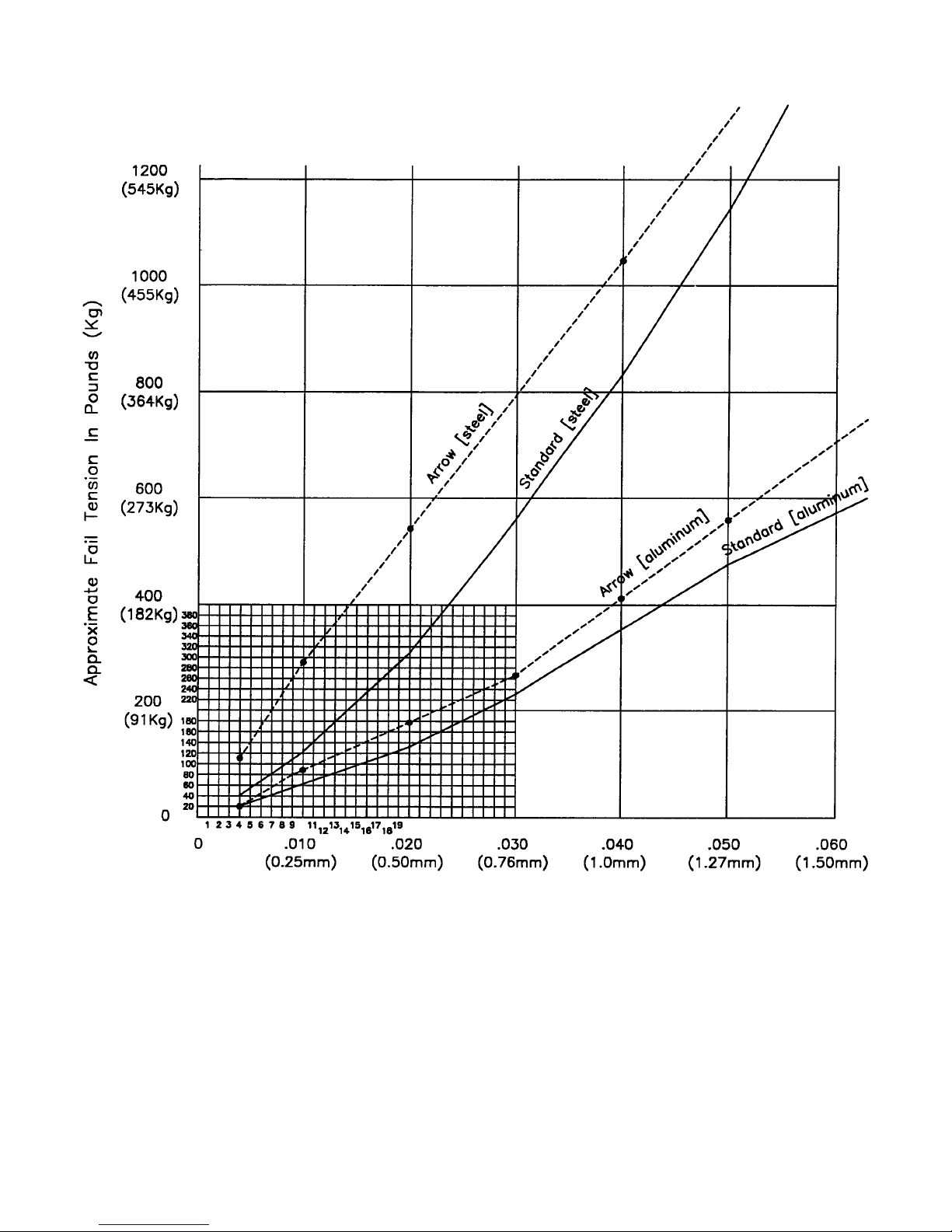

FAIL TENSION DIAGRAM FOR TYPICAL STEEL & ALUMINUM

Thickness of Each Coil End - In Inches (mm)

MILD STEEL 45,000 PSI (32 Kg/mm2)YIELD

ALUMINUM 5052 H-32 23,000 PSI (16 Kg/mm2) YIELD

Single Row Die - Read as pounds (Kg) per 1½” (38mm) of coil width.

Double Row Die - Multiply by 2 and read as pounds (Kg) per 1½” (38mm) of coil width.

Single Row Die with “W15T” as part of model number - Read as pounds (Kg) per 3” (76.2mm) of coil width.

Shift force is 25% of fail for steel and 60% for aluminum.

F-19180MA 57-1-98

Rev. 3-1-99

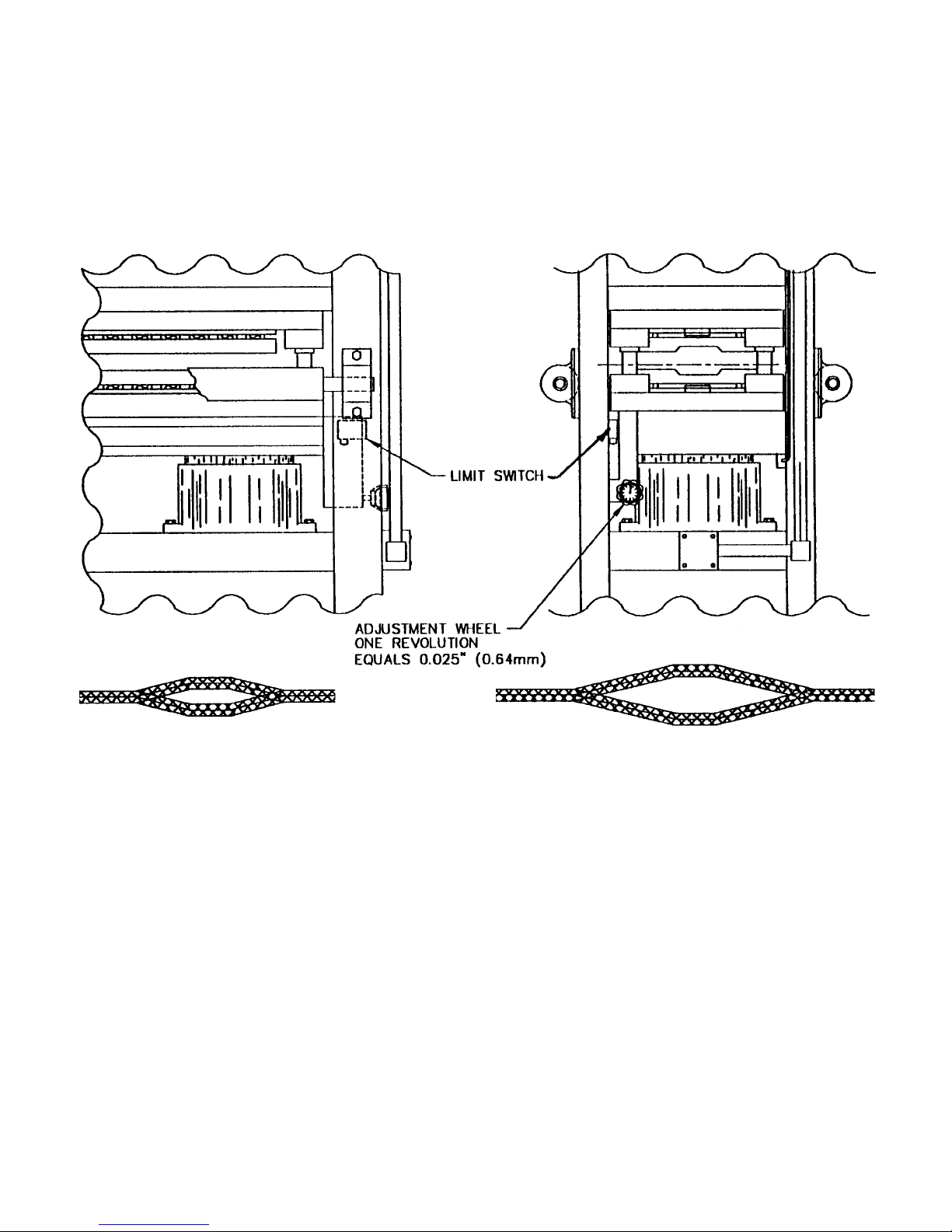

STITCH HEIGHT ADJUSTMENT

Adjust the depth switch as required to produce a good joint. The switch has been preset at the factory for

the maximum material thickness you will run and, in most cases, will work for you. If adjustment of stitch

height has been deemed necessary, each full turn will move the stitch height 0.025” (0.64mm). Adjust until

satisfactory results are met. For a deeper stitch, turn adjustment wheel counter-clockwise. For a shallower-

stitch, turn adjustment wheel clockwise.

In this case, the stitch is incomplete.

Turn the adjustment wheel counter-

clockwise to make a deeper stitch.

In this case, the stitch is too deep causing

the material to fracture. Turn the adjustment

wheel clockwise to make a shallower stitch.

NUMBERED PARTS

Ref. Part No. Description

1 1328-092 Bolt, Rd. Hd. Stove ¼” x ½”

2 1588-028 Connector, ¾” St. Liquid Tight

3 1588-029 Connector, ¾” x 90° Liquid Tight

5 1588-065 Connector, 1½” x 90° Liquid Tight

6 1508-003 Clamp, ½” Conduit

7 1508-013 Clamp, 1” Conduit

8 1749-150 Conduit, ¾” Liquid Tight

9 1749-110 Conduit, ½” Liquid Tight

10 1749-160 Conduit, 1½ Liquid Tight

11 2688-022 Nut, Hex 5/8” NC

12 3188-039 Screw, Hex Hd. Cap ½” NC x 3”

13 2688-010 Nut, Hex 5/16” NC

14 3188-004 Screw, Hex Hd. Cap ½” NC x 1”

15 3248-037 Screw, Socket Hd. Cap 7/16”

16 3188-042 Screw, Hex Hd. Cap 5/16” NC x ¾”

17 3188-066 Screw, Hex Hd. Cap ¼” NC x ¾”

18 3188-036 Screw, Hex Hd. Cap ½” NC x ½”

19 3188-037 Screw, Hex Hd. Cap 7/16” NC x 3”

20 1328-099 Bolt, Rd. Hd. Stove 3/16” NC x 1”

21 3208-055 Screw, Slot Rd. Hd. 3/16” NC x 2”

22 3248-002 Screw, Socket Hd. Cap 5/8” NC x 2”

23 3188-037 Screw, Socket Hd. Cap 7/16” NC x 3”

24 3248-012 Screw, Socket Hd. Cap 5/8” NC x 3”

25 1588-015 Connector, 1/2” x 90° Liquid Tight

27 3248-026 Screw, Socket Hd. Cap 1” NC x 2”

28 3248-009 Screw, Scoket Hd. Cap 1/2” NC x 1/2’

29 3948-001 Washer, Wrought 5/16”

30 3948-002 Washer, Wrought ½”

31 3948-016 Washer, Wrought 1/4”

32 1788-030 Elbow, 1/2” x 90° Pulling

33 3948-028 Washer, Lock ½”

34 3948-019 Washer, Lock 5/8”

F-8550-5 6Rev. 9-25-07 7-1-98

DOUBLE ROW

WRSJ STITCHING DIE

PARTS IDENTIFICATION

U.S. Patent No. 3,728,779

Foreign patents and Foreign patents pending.

F-10931-4 77-1-98

Rev. 7-5-05

HYDRAULIC SCHEMATIC

(1) RESERVOIR

(2) PUMPS

(4) RELIEF VALVE

(6) CYLINDER 2, 4, 6, or 8 of Each

(7) PISTON Used Depending On

(8) SEAL Machine Model

(9) MOTOR

F-13571-1 87-1-98

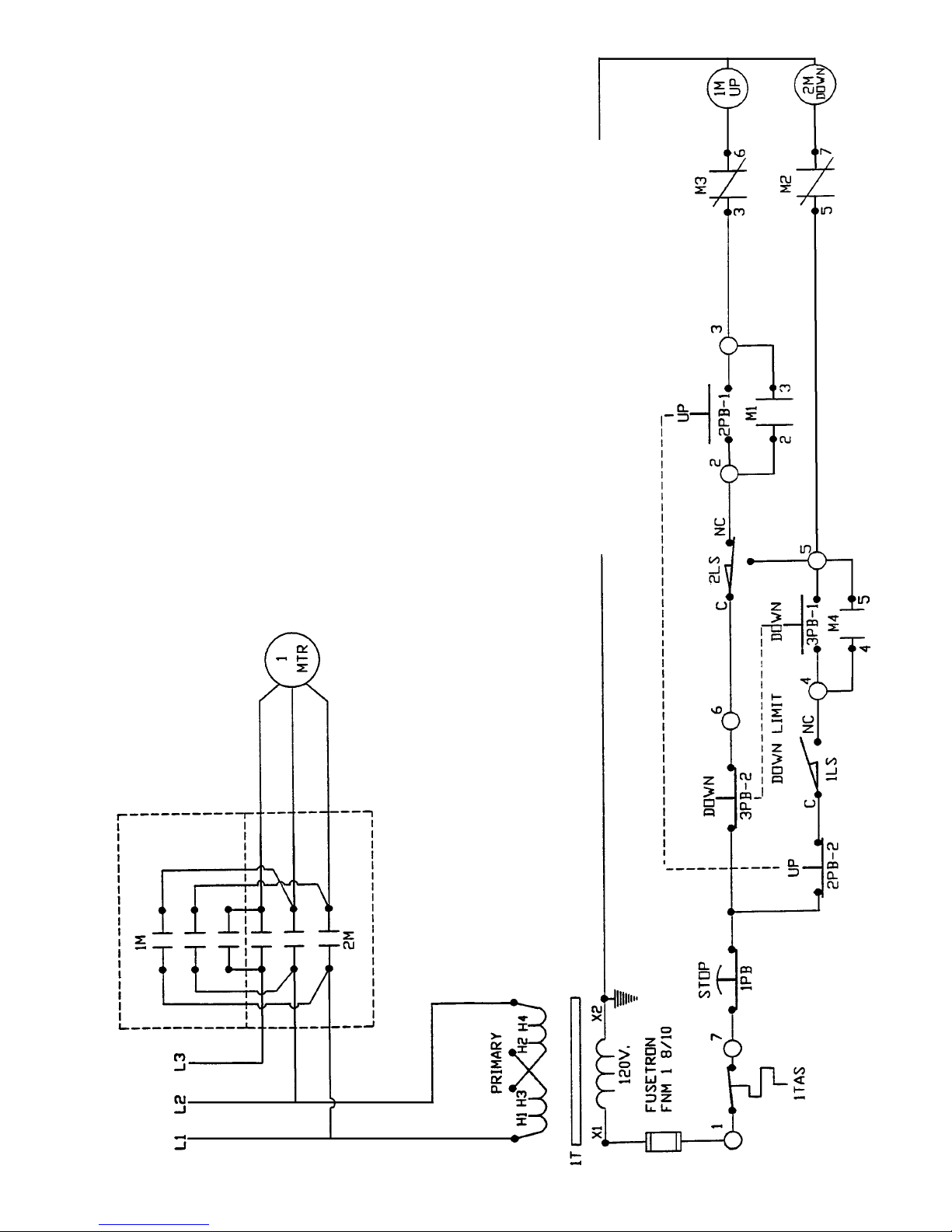

ELECTRICAL CIRCUIT

1 LS LIMIT SWITCH (DOWN)

2 LS LIMIT SWITCH (DEPTH SWITCH)

1 M, 2 M MOTOR STARTER (REVERSING)

M1 INTERLOCK ON 1 M (NO-UP)

M2 INTERLOCK ON 1 M (NC-UP)

M3 INTERLOCK ON 2 M (NC-DOWN)

M4 INTERLOCK ON 2 M (NO-DOWN)

1 MTR PRESS MOTOR

1 PB PUSHBUTTON STOP (NC)

2 PB-1 PUSHBUTTON UP (NO)

2 PB-2 PUSHBUTTON UP (NC)

3 PB-1 PUSHBUTTON DOWN (NO)

3 PB-2 PUSHBUTTON DOWN (NC)

1T TRANSFORMER CONTROL

1 TAS OVERLOAD SWITCH WOUND IN 1 MTR

NOTE: 1 LS HAS ADDITIONAL CONTACTS (2 NO &

1 NC) THAT MAY BE USED FOR INTERLOCKING.

F-7891-3 9Rev. 3-1-99 7-1-98

F-19181 10 7-1-98

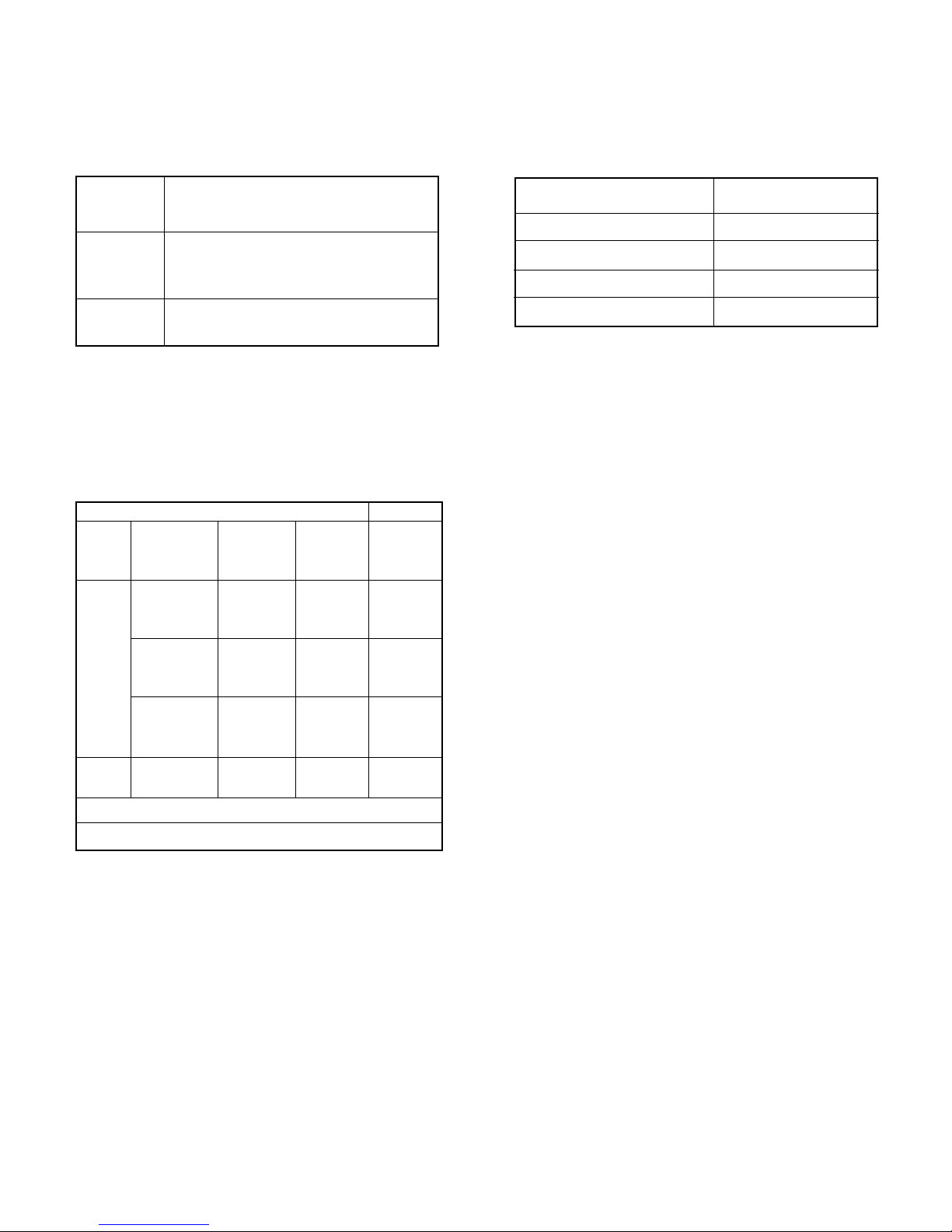

SERVICE CONDITIONS

Table 1

Standard Eight hours per day, normal or light

Conditions loading, clean @ 40°C (100°F) max-

imum ambient.

Severe Twenty-four hour per day operation

Conditions or shock loading, vibration, or in dirt

or dust @ 40-50°C (100-120°F)

Extreme Heavy shock or vibration, or dust.

Conditions

LUBRICATION VOLUME

Table 3

NEMA (IEC) Volume in Cubic

Frame Size Inches (cm3)

182 Thru 215 (112 - 132) 0.5 (8)

254 Thru 286 (160 - 180) 1.0 (16)

324 Thru 365 (200 -225) 1.5 (24)

404 Thru 449 (250 - 280) 2.5 (40)

LUBRICATION FREQUENCY

Table 2

BALL BEARINGS

NEMA Standard Severe Extreme

Speed (IEC) Condi- Condi- Condi

Frame tions tions tions

182 (112) 6

Thru 3 Years 1 Year Months

215 (132)

1800 254 (160)

RPM & Thru 2 Years 6 to 12 3

Slower 365 (200) Months Months

404 (225)

Thru 1 Year 6 1 to 3

449 (280) Months Months

3600 3

RPM ALL 6 Months Months 1 Month

ROLLER BEARINGS

For Roller Bearings divide the time periods above by 2.

REPLACEMENT BEARINGS

Your maintenance program will not be complete without

including spare bearings. It must be remembered that

the bearing is a wearable component and therefore

must eventually be replaced. To insure that you are

able to maintain original operation, we recommend the

purchase of spares directly from Reliance Electric.

All bearings used in Reliance motors are subject to

exact specifications and tests necessary to satisfy per-

formance requirements. In this manner, it is possible to

duplicate your present bearing. Markings on the bear-

ings do not indicate complete specifications.

Motors covered by this Instruction Manual are

equipped with several types of bearings. This descrip-

tion covers regreasable anti-friction bearings only.

Non-regreasable ball bearings require no periodic main-

tenance. See I/M B-3654 for oil mist lubricated anti-

friction bearings procedures.

GREASE LUBRICATED BEARINGS

This motor has been properly lubricated at the time of

manufacture and it is not necessary to lubricate at

time of installation unless the motor has been in stor-

age for a period of six months or more.

Lubrication of anti-friction bearings should be done as

a part of a planned maintenance schedule. The

Recommended Lubrication interval should be used as a

guide to establish this schedule.

Cleanliness is important in lubrication. Any grease

used to lubricate anti-friction bearings should be fresh

and free from contamination. Similarly, care should be

taken to properly clean the grease inlet area of the

motor to prevent grease contamination.

RECOMMENDED LUBRICANT

For motors operating in ambient temperatures shown

below, use the following lubricant or its equal.

BALL BEARING MOTORS

OPERATING TEMP. -25°C (-15°F) to 50°C (120°)

CHEVRON OIL SRI NO.2

EXXON UNIREX N2

SHELL OIL CO. DOLIUM BRB

TEXACO, INC. PREMIUM RB

MINIMUM STARTING TEMPERATURE -60°C (-76°F)

SHELL OIL CO. AEROSHELL 7

ROLLER BEARING MOTORS

OPERATING TEMP. -25°C (-15°F) to 50°C (120°F)

CHEVRON OIL BLACK PEARL EP NO.

2

TEXACO, INC. PREMIUM RB

LUBRICATION PROCEDURE

Reliance regreasable anti-friction bearings may be lubri-

cated with the motor running or stationary. Stationary

with the motor warm is preferred.

1. Locate the grease inlet, clean the area and replace

the pipe plug with a grease fitting, if the motor is

not equipped with grease fittings.

2.If motor is equipped with grease drain plug, remove

plug and loosen any hardened grease that may

block drain.

3. Add the recommended volume of the appropriate

lubricant using a hand operated grease gun.

4. Run the motor for two hours.

5. Replace the pipe plug in grease drain.

6. Grease may not relieve from drain. Use only vol-

ume shown in Table 3.

LUBRICATION INSTRUCTIONS

1. Select Service Condition from Table 1.

2. Select Lubrication Frequency from Table 2.

3. Select Lubrication Volume from Table 3.

4. Lubricate the motor at the required frequency with

the required lubricant volume in accordance with

LUBRICATION PROCEDURE.

NOTE: Mixing lubricants is not recommended due to

possible incompatibility. If it is desired to change

lubricant, follow instructions for lubrication and repeat

lubrication a second time after 100 hours of service.

Care must be taken to look for signs of lubricant

incompatibility, such as extreme soupiness visible from

the grease relief drain area, or from the shaft opening.

LUBRICATION OF BEARINGS

F-19182-1 11 Rev. 7-5-05 7-1-98

F-19183 12 7-1-98

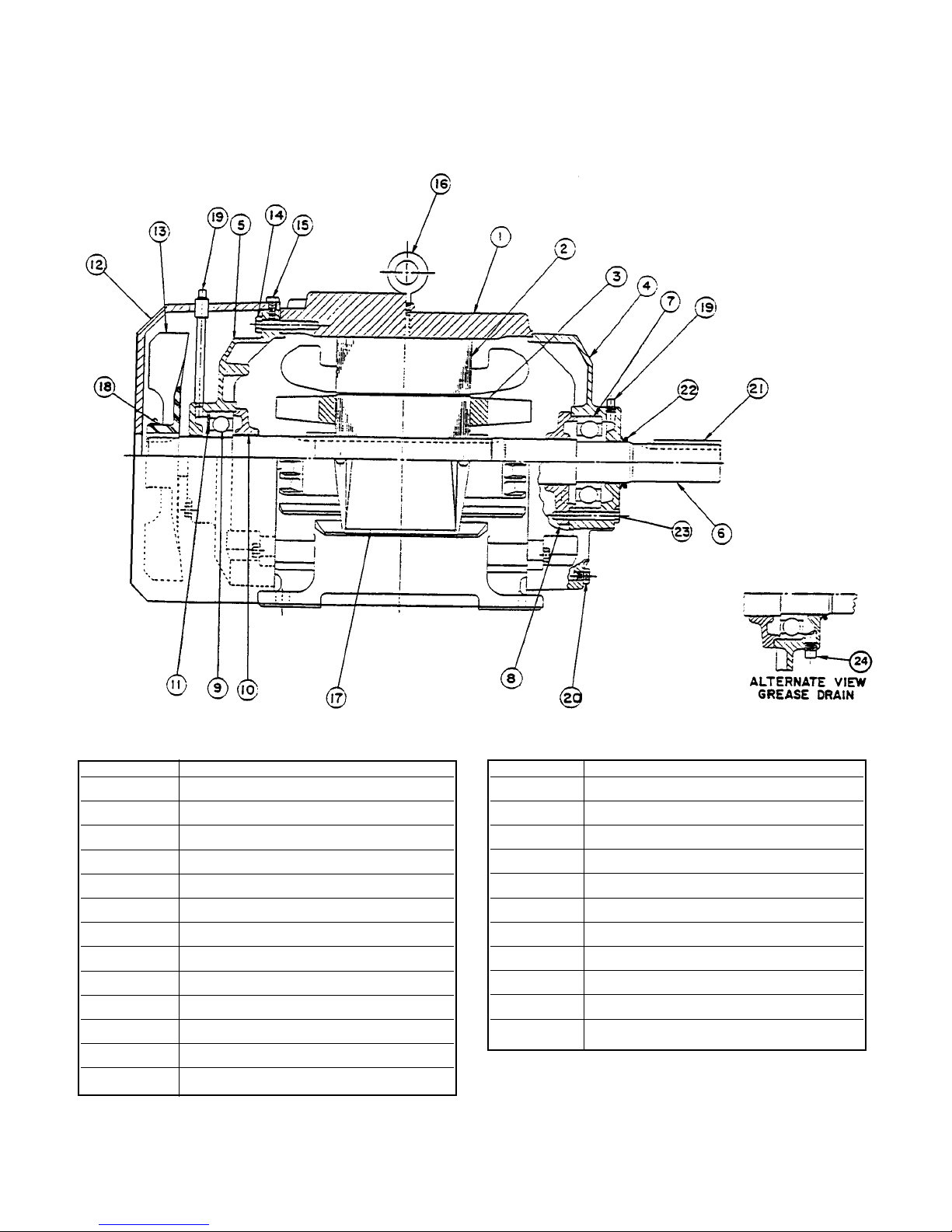

CROSS SECTIONAL AND PARTS IDENTIFICATION SECTION AND DRAWINGS.

REF. NO. PARTS DESCRIPTION

1 FRAME

2 STATOR

3 ROTOR/INTERNAL COOLING FAN

4 BACKEND BRACKET

5 FRONTEND BRACKET

6 SHAFT

7 BACKEND BALL BEARINGS

8 BACKEND INNER BERARINS

9 FRONTEND BALL BEARINGS

10 FRONTEND INNER CAP

11 WAVE WASHER, FRONTEND

12 FAN COVER

13 OUTER COOLING FAN

REF. NO. PARTS DESCRIPTION

14 FRONT END BRACKET BOLTS

15 FAN COVER BOLTS

16 EYEBOLT

17 TERMINAL BOX

18 FAN CLAMP

19 GREASE ENTRY

20 CONDENSATION DRAIN

21 KEY

22 SLINGER

23 BACKEND CAP BOLTS

24 GREASE DRAIN

Table of contents