Belfort AWOS User manual

BELFORT

INSTRUMENT Co.

800-937-2353 www.Belfortinstrument.com

Belfort ®

Automated Weather

Observing System

AWOS

Maintenance Manual

Proprietary

Prepared in Response

to the

FAA, Automated Weather Observing System (AWOS)

Requirements

Aug. 2014

-i-

BELFORT INSTRUMENT Proprietary Information

Table of Contents

Maintenance Manual

Paragraph Description Page

1.0 Introduction....................................................................................................... 1

1.1 Purpose.............................................................................................................. 1

1.2 Scope................................................................................................................. 1

1.3 Level of Maintenance ....................................................................................... 1

1.4 Periodic Maintenance........................................................................................ 1

1.5 Warranty ........................................................................................................... 1

1.6 Warranty Support.............................................................................................. 2

2.0 Applicable Documents & List of Acronyms .................................................... 3

2.1 Applicable Documents...................................................................................... 3

2.2 List of Acronyms .............................................................................................. 3

3.0 Maintenance Program Overview ...................................................................... 5

4.0 Qualification Requirements for Maintenance Personnel.................................. 5

5.0 Preventative Maintenance and Calibration Procedures .................................... 6

5.1 DATU –Data Acquisition Terminal Unit Maintenance.................................... 7

5.1.1 DATU Tri-Annual Maintenance....................................................................... 7

5.1.2 DATU Annual Maintenance............................................................................. 9

5.2 DCP Annual Barometric Pressure Sensor Maintenance & Calibration ........... 11

5.3 Temperature, Humidity and Dew Point –Annual Maintenance & Verification

Procedures......................................................................................................... 17

5.4 6000 Visibility Sensor –Tri-Annual Maintenance Verification and Calibration

Procedure .......................................................................................................... 18

5.5 Wind Speed Sensor Annual Verification Procedure......................................... 22

5.6 Wind Direction Sensor Annual Maintenance Verification............................... 23

5.7 Lightning Protection System, Battery & Tower Tri-Annual Maintenance....... 26

5.8 The UHF Transceiver Annual Maintenance..................................................... 27

5.9 The VHF Unicom Radio Annual Maintenance ................................................ 27

5.10 Belfort AWOS System Component Failure...................................................... 28

6.0 Troubleshooting the System ............................................................................. 29

6.1 System Built–In Diagnostics and Troubleshooting ......................................... 29

6.2 Interpreting Diagnostic Messages .................................................................... 31

6.2.1 System Status Indicators ................................................................................... 31

6.2.2 Interpreting Sensor Status And Data Quality Indicators .................................. 34

7.0 Tools and Test Equipment Required ................................................................. 41

8.0 Key System Performance Parameters and Expected Sensor Outputs............... 42

9.0 Maintenance Data Recording and Forms.......................................................... 42

9.1 Belfort AWOS Comprehensive Facility Performance Adjustment Data Form 42

9.2 Belfort AWOS Technical Performance Record................................................ 42

9.3 FAA Form 6030-1............................................................................................. 42

10.0 Component Removal and Replacement Procedures......................................... 43

10.1 DCP Removal Procedures................................................................................. 43

10.2 Temperature, Humidity/Dew Point Sensor Removal Procedures..................... 45

-ii-

BELFORT INSTRUMENT Proprietary Information

10.3 6000 Visibility Sensor Removal Procedures..................................................... 47

10.4 Wind Speed Sensor and Wind Cups Removal Instructions............................... 49

10.5 Wind Direction Sensor and Vane Removal Instructions.................................... 51

10.6 Power Supply Replacement Instructions............................................................ 53

10.7 Surge Suppressor Replacement Instructions...................................................... 54

11.0 Recommended Spare Parts................................................................................. 56

12.0 Customer Product Support and Website Assistance .......................................... 56

Tables

Table 1 Belfort AWOS Alert Messages........................................................................ 11

Table 2 Recommended Spare Components................................................................... 56

Table 3 Recommended Spare Hardware ....................................................................... 56

Figures & Illustrations

Figure 1 Typical Display Acquisition Terminal Unit Setup ........................................... 5

Figure 1a Advisor Main Screen ........................................................................................ 6

Figure 1b System Status Page........................................................................................... 7

Figure 2 Typical Belfort AWOS Tower Equipment Mounting Locations...................... 13

Figure 2a Securing the Tower for Maintenance................................................................ 14

Figure 3a Scatter Plate Attachment Detail........................................................................ 19

Figure 3b Tower with Visibility Scatter Plate Attached ................................................... 19

Figure 3c Installation of Opaque Filters on Transmitter Hood......................................... 20

Figure 4 Wind Direction Vane Alignment...................................................................... 24

Figure 5 Typical Battery Terminal Bruch....................................................................... 26

Figure 6 Belfort AWOS Alert Messages ........................................................................ 30

Figure 7 Advisor Current Status Page ............................................................................ 30

Figure 8 DCP Removal ................................................................................................... 44

Figure 9 Temperature/Humidity Sensor Removal .......................................................... 46

Figure 10 Visibility Sensor Removal................................................................................ 48

Figure 11 Wind Speed Sensor Removal............................................................................ 50

Figure 12 Wind Direction Sensor Removal...................................................................... 52

Figure 13 Power Supply and Surge Suppressor Mounting ............................................... 54

Appendix A Belfort AWOS Maintenance Forms

Appendix B Belfort AWOS Tri-Annual, Annual and Five-Year Maintenance Plan

Appendix C UHF Transceiver Specifications

Appendix D Standard Unicom Radio-ICOM A110 VHF Radio Specifications

Appendix E Belfort AWOS Commissioning / Annual Inspection Procedure & Data Record

Appendix F DCP Site Configuration Procedure

Appendix G Belfort AWOS Atomic Clock Verification Procedure

-1-

BELFORT INSTRUMENT Proprietary Information

1.0 Introduction

1.1 PURPOSE –This manual has been prepared to thoroughly describe the maintenance

requirements to be followed by the owner and factory qualified technician to assure a long-term

successful usage of a Belfort AWOS system.

1.2 SCOPE –This manual has been developed in accordance with the guidance and

requirements described in FAA Advisory Circular, AC No: 150/5220-16D and other referenced

documents. This manual is intended to provide the owner and maintenance technician with proper

maintenance procedures applicable to all FAA approved Belfort AWOS configurations. Owners

and maintenance technicians are encouraged to contact the Belfort product support group at 1-800-

937-2353 regarding questions concerning the applicability of any specific maintenance procedure.

1.3 LEVEL OF MAINTENANCE –All levels of maintenance must be performed by a technician

that meets the requirements indicated in section 4.0 of this manual. Site/user maintenance is

characterized by routine preventive periodic maintenance, calibration adjustments and quick

turnaround replacement of defective or unreliable Lowest Replaceable Unit (LRU) assemblies.

Examples include completion of tri-annual performance, annual performance

validation/maintenance checks and removal and replacement of a failed sensor component. This

manual provides site maintenance personnel with instructions for completion and documentation

of routine performance and maintenance checks and tasks, instructions for adjustment of out of

tolerance sensors, troubleshooting procedures to identify defective components, and instructions

for the removal and replacement of defective system components.

1.4 PERIODIC MAINTENANCE –Equipment/system components that require periodic

maintenance and maintenance frequencies are identified in this manual. Forms to be used to

document completion of maintenance tasks, system calibration and adjustments are provided in

Appendix A of this manual. These forms can also be downloaded from the Belfort Instrument Co.

website, http://www.belfortinstrument.com. In addition to providing documentation of

maintenance actions completed, the Facility Performances and Adjustment Data Forms provided

are intended to be used as checklists to assure that all required routine maintenance tasks are

completed. Tri-annual preventive maintenance tasks must be completed in a timely manner to

assure system accuracy, optimum performance and reliability of the system.

1.5 WARRANTY –The entire Belfort AWOS TM system is provided with a one-year warranty.

The warranty period starts with the date of delivery from the factory. The entire system has been

manufactured and will perform in accordance with the requirements of the FAA AC 150/5220-

16D. The dual-pressure sensor and visibility sensor will perform as a certified instruments in

accordance with requirements of the FAA AC 150/5220-16D. Any defect in design, materials, or

workmanship which may occur during proper and normal use during a period of 1 year from date

of installation or a maximum of 2 years from date of shipment will be corrected by repair or

replacement by the manufacturer FOB Belfort. An extended warranty or and service contract may

have been purchased. Maintenance personnel should check with the system owner to determine if

an extended warranty or service contract is applicable to the system installed at their site.

-2-

BELFORT INSTRUMENT Proprietary Information

1.6 WARRANTY SUPPORT –For warranty support, contact Belfort Instrument Co. customer

support at 1-800-937-2353. When calling, please have the Belfort AWOS TM location and serial

number available.

Table of contents

Popular Weather Station manuals by other brands

ADE

ADE WS 1711 operating instructions

WAREMA

WAREMA EWFS Weather station eco Operating and installation instructions

Auriol

Auriol z29592 Operation and safety notes

Auriol

Auriol 296289 Operation and safety notes

Hyundai

Hyundai WS 2266 instruction manual

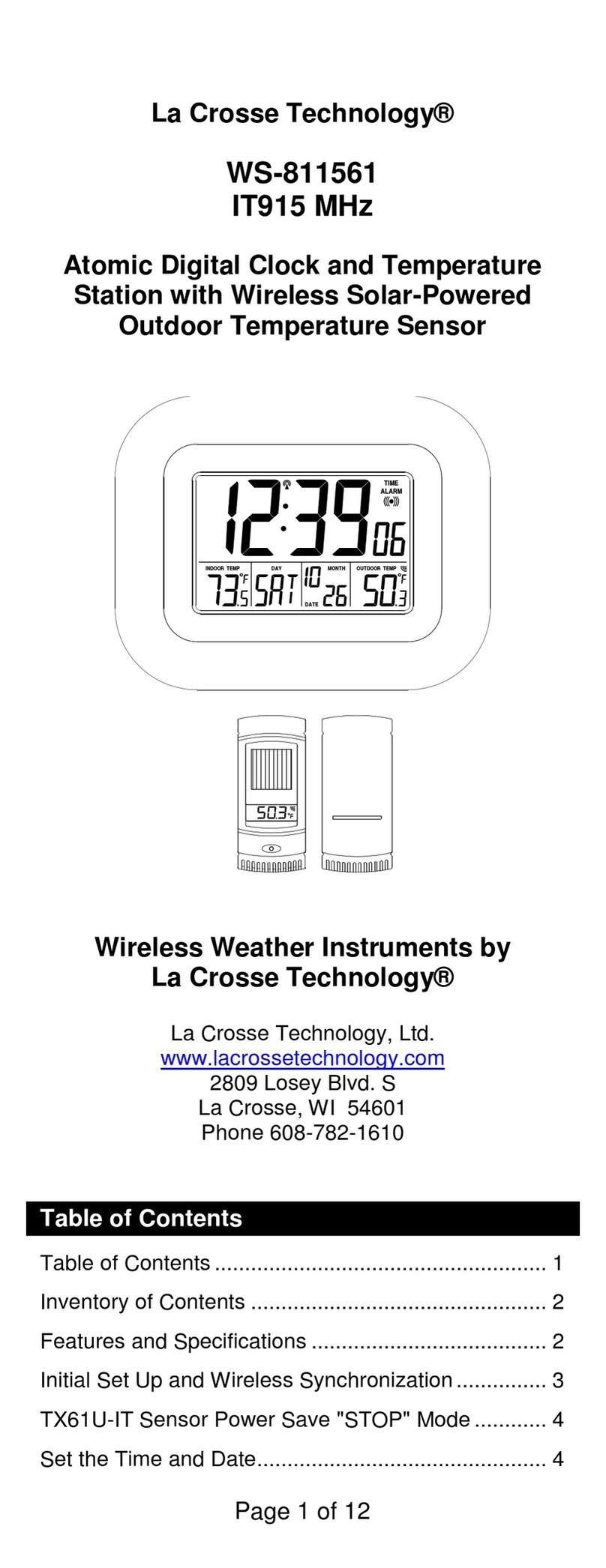

La Crosse Technology

La Crosse Technology WS-2210 Operation manual

La Crosse Technology

La Crosse Technology WS-811561 manual

Ventus

Ventus W177 owner's manual

National Geographic

National Geographic VA Colour RC instruction manual

Instant Transmission

Instant Transmission MA 10410 instruction manual

Lutron Electronics

Lutron Electronics PHB-318 Operation manual

Oregon Scientific

Oregon Scientific Alizé BAR266 user manual