Bell and Gossett 70E Guide

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual and on the

70E/70M Safety Instruction decal to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD!

INSTRUCTION MANUAL

S12228

REVISION A

Installation, Operation, & Maintenance Instructions

70E/70M Multiple Pump & Control

Pressure Booster Systems

70E

DESCRIPTION

Microprocessor controlled frame mounted multiple pump

pressure boosting system with combination pressure reducing

and non-slam check valves for maintaining system pressure.

The motors are controlled by a control panel with micro-

processor, starters, overload protection, virtual H-O-A switches,

optional short circuit protection, and control transformer.

The microprocessor control consists of an operator interface

with 2 line backlit display and membrane key pad, input/

output board with 24V power supply, and microcontrolled

kW transducer.

BELL & GOSSETT®

OPERATIONAL LIMITS

See unit nameplate for pump capacity, boost, full load current

draw, and operating voltage. The pump discharge pressure

must not exceed 125 PSI unless special piping modifications

are made.

Bell & Gossett®

2

70E/70M Pressure Booster

INSTRUCTIONS

UNIT IDENTIFICATION

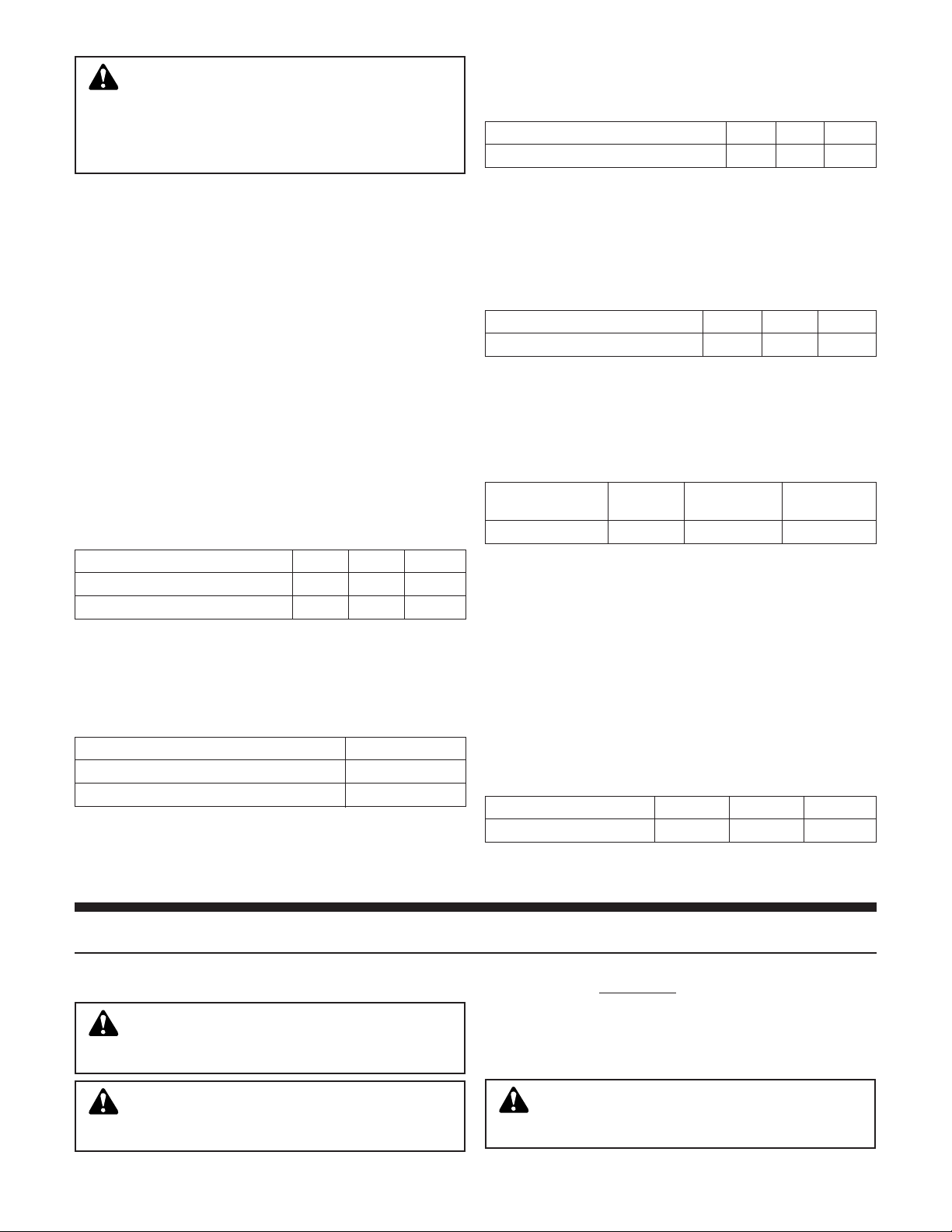

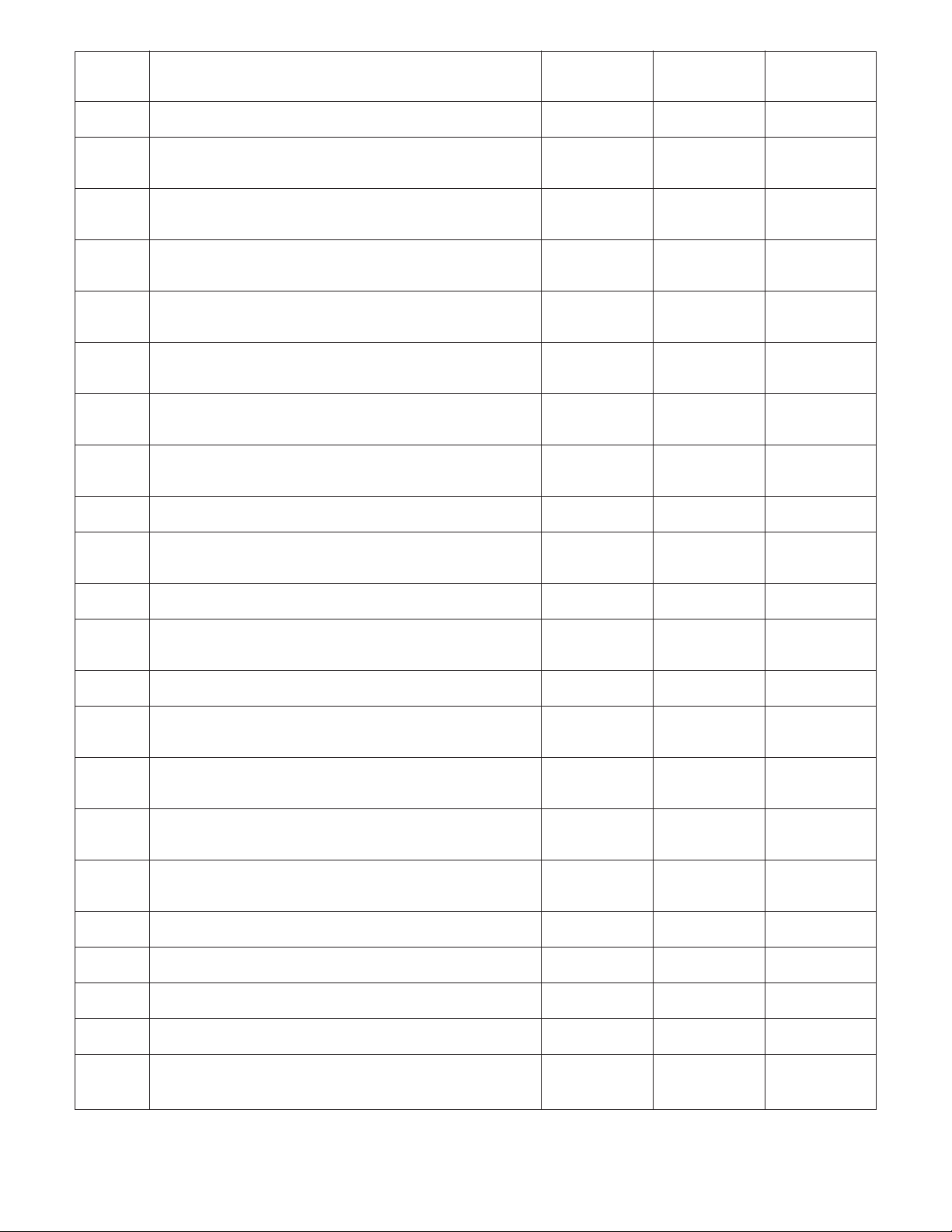

The unit nameplate gives identification and rating information as identified in Figure 1.

Permanent records for this unit are kept by the factory number and it must therefore be

used with all correspondence and spare parts orders.

Model No.

Factory No.

Wired for Volts Hz Ph

System FL Amps

Largest Motor HP

System Flow GPM

Suction Pressure PSIG

Discharge Pressure PSIG

Pump TDH Feet

FIGURE 1 - 70E/70M NAMEPLATE

3

Preface

The following manual describes the 70E/70M Pressure Boosters with emphasis on the new micropro-

cessor based Technologic Controller. This unit is in the tradition of the other members of the Technologic

Control Panels as it incorporates many original, novel, and proprietary features that may only be found on

B&G controllers. Some of these features require special emphasis here.

The controller is best described as a specific purpose programmable pump controller. This means that

the hardware and software have been created for the control and diagnostics of pumps with considera-

tion for their inherent characteristics. This results in an optimum pump controller without the cost of gen-

eral purpose control hardware. Software is dedicated and established for the unit only after extensive

testing. Changes to this software are not taken lightly and must pass rigid version control.

The controller has the unique patented analog input protection of other members of the control family.

Upon inadvertent higher than normal input voltage the analog input resistor is sacrificed. An on-board

spare is used to replace the plug-in resistor. Extreme hi-voltage is protected against by additional

components.

Unique to this new controller are virtual selector switches. Microprocessor control coupled with discrete

logic allows the pump keys to act as 3 position selector switches. The 3 positions are hand-off-auto.

Virtual selector switches surpass standard selector switches in that they can be changed from auto to

hand automatically upon a fault in order to maintain a process. It is novel that just as a standard selector

switch can change position (by human hand) with power off, so can the virtual selector switch similarly

change position.

Combined with the virtual selector switches is redundant control with discrete logic which is activated

upon a microprocessor fault. This is explained in detail in Section 5.4.

In addition to this unique hardware the controller has provision for three 4-20mA analog signals and two

RTD temperature inputs. Bell & Gossett is able to offer suction, system, and temperature inputs as stan-

dard. The third 4-20mA is used for an optional flow transmitter.

Bell & Gossett is thereby able to offer staging of pumps by any one of 4 methods, i.e.: watts, amps, PSI

and GPM (flow). The main changes occur in the menu entries.

Staging by watts is standard. A power transducer of Bell & Gossett design is included. This transducer is

factory calibrated, single conductor sensing, wide current and voltage range, and automatic adaptability

to Wye or Delta systems either grounded or ungrounded. At the customer’s discretion it may be used for

amp staging with the watt feature used to display total system power.

4

TABLE OF CONTENTS

SECTION 1 –GENERAL

Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Safety Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Temperature and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Field Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 2 –INSTALLATION

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unit Support and Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pressure Transmitter Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Temperature Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Sensor/Transmitter Wiring and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Differential Pressure Switch Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Alarm Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pump On/Off Remote Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 3 –START UP

Putting Unit into Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 4 –SETUP AND FEATURES

Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setup and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Normal Operating Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 5 –OPERATION

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Auto Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Manual Operation (CPU OK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Operation (CPU Fails) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5

SECTION 6 –MAINTENANCE

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Diagnostics (Service Test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Read Only –Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Read Only –Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Manual Control –Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pre-Determined Fault and Fault Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fault Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Instruments and Their Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Field Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Serial No. and Firmware Version No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance (Physical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

APPENDIX A

System Piping and Unit Installation –Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

APPENDIX B

Electrical Wiring and Control Settings –Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

APPENDIX C

Procedure for Field Balancing 70E/70M PRV’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

APPENDIX D

Troubleshooting Combination Pressure Reducing and Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . 24

PRV Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

APPENDIX E

Service Test Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

APPENDIX F

Power Transducer Board (PTB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

NOTE:

The information contained in this manual is intended to assist operating personnel by providing information

on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of

accepted practices in the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your 70E/70M Pressure

Boosting System can be found in the I.O.M.s for the associated equipment provided:

A. ITT Bell & Gossett 1510 (IOM Part #P81673)

B. ITT Bell & Gossett 1531 (IOM Part #P81567)

C. Pressure Reducing Valve –CLA-VAL Co. Manual #TM90-01

D. Flow Sensor/Transmitter Manufacturers IOM

1.1 PURPOSE OF MANUAL

1.1.1 This manual is furnished to acquaint you with some

of the practical ways to install, operate, and maintain

this unit. Read it carefully before doing any work on

your unit and keep it handy for future reference.

1.1.2 Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recom-

mended installation and servicing procedures out-

lined in this manual.

1.1.3 SAFETY INSTRUCTION

This safety alert symbol will be used in this manual

and on the unit safety instruction to draw attention to

safety related instructions. When used the safety alert

symbol means ATTENTION BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOL-

LOW THIS INSTRUCTION MAY RESULT IN A

SAFETY HAZARD.

1.1.4 Your Technologic 70E/70M Series Pump Controller

should have a safety instruction decal (Part #S11550).

If the decal is missing or illegible contact your local

B&G representative for a replacement.

1.2 ADDITIONAL SAFETY REQUIREMENTS

1.2.1 Motor must have a properly sized starter with properly

sized overload block to provide overload and under-

voltage protection. Ground fault protection should be

sized properly.

1.2.2 Refer to the motor manufacturer’s I.O.M. for specific

installation information.

1.2.3 Even when the motor is stopped, it should be consid-

ered “alive”as long as its controller is energized.

Keep hands away from the output shaft until the

motor has completely stopped and power is discon-

nected from the pump controller.

1.2.4 Motor control equipment and electronic controls are

connected to hazardous line voltages. When servic-

ing electronic controls, there will be exposed compo-

nents at or above line potential. Extreme care should

be taken to protect against shock. Stand on an insu-

lating pad and make it a habit to use only one hand

when checking components. Always use accurate

test meters when checking electrical components.

Always work with another person in case of an emer-

gency. Disconnect power when performing mainte-

nance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic

control or rotating equipment.

1.3 STORAGE

For long periods of storage, the unit should be cov-

ered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between -20 and +75˚C. The relative humidity should

not exceed 85%. The unit should be checked period-

ically to ensure that no condensation has formed.

After storage, again check that it is dry before apply-

ing power.

1.4 HANDLING

1.4.1 Care should be taken to prevent damage due to

dropping or jolting when moving the unit. Inspect the

unit thoroughly for damage upon receipt.

Transportation damage should be brought to the car-

rier’s attention immediately. Ensure that sensing lines

are free of crimps and kinks.

1.4.2 The units should be unloaded and handled by quali-

fied personnel. The unit is top heavy due to the posi-

tion of the motors. Use the motor eyebolts to stabilize

the unit while lifting to prevent overturning. Do not

use the motor eyebolts to lift.

1.5 TEMPERATURE AND VENTILATION

All electrical equipment is susceptible to failure if

operated in ambient temperatures outside of its rat-

ing. The OPERATING temperature range for this unit

is 0 to 40˚C. The relative humidity should not exceed

95% non-condensing. The unit should not be oper-

ated outside these extremes.

1.6 GROUND CONNECTIONS

A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the National

Electrical Code and local codes must be followed.

1.7 POWER WIRING

Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire rated for 75˚C (minimum) may be

used for the power connections. Refer to the input

current as listed on the nameplate on the enclosure

door when sizing wire.

6

SECTION 1 –GENERAL

WARNING: Motor can start automatically. Keeps

hands away from output shaft until motor is com-

pletely stopped and input power is removed from the

motor control panel. Lockout main power switch while

working near the motor shaft. Failure to follow these

instructions could result in serious personal injury,

death, and/or property damage.

DANGER: Troubleshooting live control panels ex-

poses personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electri-

cian. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

Failure to follow these instructions could result

in serious personal injury, death, and/or property

damage.

WARNING: Falling Objects Hazard. Eyebolts or lift-

ing lugs, if provided, are for lifting only the compo-

nents to which they are attached. Failure to follow these

instructions could result in serious personal injury,

death, and/or property damage.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the

ground lug provided in the enclosure to avoid potential

safety hazards. Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

2.0 LOCATION

2.1 Locate the pumping unit for ease of inspection, main-

tenance and service.

2.2 INSTALLATION

This unit is built to give you years of service; install it

properly and provide a suitable foundation. A base of

concrete weighing 21/2times the weight of the unit is

recommended. (Check the shipping ticket for the unit

weight.) Tie the concrete pad in with the finished

floor. Use foundation bolts and larger pipe sleeves to

give room for final bolt location.

2.3 LEVELING

Place the unit on its concrete foundation, supporting

it with steel wedges or shims totaling 1" in thickness.

These wedges or shims should be put on both sides

of each anchor-bolt to provide a means of leveling

the base.

2.4 UNIT SUPPORT AND LOCATION

The Bell & Gossett Series 70E/70M Pressure Booster

should be installed where there will be sufficient room

for future inspection and service. If the unit is to be

located near a noise sensitive area, consult a sound

specialist. Special precautions should be taken to

avoid sound and vibration transmission.

2.5 PIPING

2.5.1 Important. Do not install and operate ITT Bell &

Gossett 70E/70M Pressure Booster in a closed sys-

tem unless the system is constructed with properly

sized devices and control devices. Such devices

include the use of properly sized and located pres-

sure relief valves, compression tanks, pressure con-

trols, temperature controls and flow controls as

appropriate. If the system does not include these

devices, consult the responsible engineer or architect

before making pumps operational.

2.5.2 Make all necessay system piping connections. Be

aware that connecting dissimilar metals to the headers

can lead to corrosion damage due to galvanic corro-

sion. The rate of corrosion is dependant on various

factors some of which are: the potential between the

dissimilar metals, electrolyte conductivity, geometry

and areas of the metals. Dielectric connections are

recommended between dissimilar metals at the

header connection. Be sure to eliminate any pipe

strain on the unit. Support all pipes independently by

use of pipe hangers near the unit. DO NOT ATTEMPT

TO FORCE THE SUCTION OR DISCHARGE LINES

INTO POSITION. Refer to assembly drawing for cus-

tomer piping connections.

2.5.3 Eccentric increasers can be used in the suction lines

when increasing the pipe size, with straight sides of

increaser on top to eliminate air pockets.

2.5.4 As a rule, ordinary wire or band hangers are not ade-

quate to maintain alignment. It is very important to

provide a strong, rigid support for the suction line. A

saddle hanger is recommended.

2.5.5 For critical installations, equipment for absorbing

expansion and vibration should be installed in the

inlet and outlet connections of the unit.

2.5.6 After hydrotesting, drain plugs are removed, to facili-

tate system drainage, placed in a cloth bag and

secured to the unit. Drain plugs shall be reinstalled

prior to filling the system with fluid. Inspect all unit

piping connections. Joints may also become loose

during transit due to vibration and shock. All joints

are to be checked for tightness. Flanged joints should

be checked for proper torque of all flange bolts prior

to filling the system with fluid.

2.5.7 On an open system with a suction lift, use a foot

valve of equal or greater area than the pump suction

piping. Prevent clogging by using a strainer at the

suction inlet next to the foot valve. The strainer

should have an area three times that of the suction

pipe. Provisions must be made to prime the pump

suction piping on start up. Do not start the pump

unless all suction piping is full of water.

2.5.8 A thermal relief valve (B&G Part #S51260) is installed

on the discharge header to prevent potentially dan-

gerous thermal buildup in the package. This valve

acts as a safety device and it should never be re-

moved or tampered with. It is factory set to open and

discharge when the water temperature in the dis-

charge header exceeds 125˚F. The 3/8" NPT opening

of this valve must be piped to a floor drain.

2.6 LUBRICATION

Before starting, all pumps and motors should be

checked for proper lubrication.

7

SECTION 2 –INSTALLATION

DANGER: Heavy load, may drop if not lifted prop-

erly. Do not lift the entire unit by the motor eyebolts.

Lift the unit with slings placed under the unit base rails.

Failure to follow these instructions could result

in serious personal injury, death, and/or property

damage.

DANGER: The heating of water and other fluids

causes volumetric expansion. The associated forces

may cause failure of system components and releases of

high temperature fluids. This will by prevented by install-

ing properly sized and located pressure relief valves and

compression tanks. Failure to follow these instructions

could result in serious property damage and serious

personal injury or death.

1.8 FIELD CONNECTION DIAGRAMS

1.8.1 Refer to the pump Installation, Operation, and Main-

tenance Manual for specific details unique to the

pump.

1.8.2 Refer to the flow sensor/transmitter Installation,

Operation, and Maintenance Manual for specific

details unique to the flow sensor/transmitter.

1.8.3 The following field connection diagrams should be

reviewed prior to unit installation and operation.

Drawing # Description

Job Specific Print(s) Wiring Diagram(s)

Job Specific Print Dimensional Drawings

CAUTION: Failure to reinstall drain plugs, check all

joints for tighteness and flange bolts for proper

torque could result in leaks and/or flooding. Failure to

follow these instructions could result in property

damage and or moderate personal injury.

8

2.7 WIRING

2.7.1 POWER WIRING

The 70E/70M Pump Control Panel can be set up to

operate across a broad range of voltages. It was fac-

tory set to operate on the voltage shown on the

nameplate. Verify proper transformer primary wiring

per the job-specific wiring diagram. Check power

leads in accordance with wiring diagram enclosed in

control cabinet. The voltage tolerance is +10%/-10%.

2.7.2 ANALOG SIGNAL WIRING

If installing the panel on an existing system, shielded

cable (#22 AWG, Belden type 8762, Alpha #2411 or

equal) should be installed for the DC control wiring.

The shield must be terminated in the 70E/70M con-

trol panel. Do not connect the shield at the other end

of the cable! Insulate the shield so that no electrical

connection is made at the other end of the cable. A

twisted pair of #22 AWG conductors (Belden 8442 or

equal) can be used in place of shielded cable. The

cable length must be limited to 3000 feet for #22

AWG wire.

2.7.2.1 PRESSURE TRANSMITTER WIRING

(4-20 mA Analog Signals)

2.7.2.2 TEMPERATURE SENSOR WIRING

(Analog Resistance Input)

The 70E/70M uses resistance temperature detectors

(RTDs) to sense the suction and discharge water

temperatures. These devices change their resistance

as the water temperature changes.

2.7.2.3 FLOW SENSOR/TRANSMITTER WIRING AND

INSTALLATION (4-20 mA Analog Signal) (Optional)

The flow sensor should be installed at an angle no

greater than 45 degrees from top dead center in a

horizontal installation (see manufacturer’s IOM). See

the Bell & Gossett drawing for installation instruc-

tions. The signal wiring should be terminated in the

70E/70M panel at the terminals below.

2.7.3 DIGITAL SIGNAL WIRING

2.7.3.1 DIFFERENTIAL PRESSURE SWITCH PIPING

AND WIRING (Digital Signal) (Optional)

Differential pressure switches installed to sense the

increase in pressure between the pump suction and

discharge gauge taps are used to determine whether

a pump is running. Each switch should be wired from

the normally closed contact to the terminals below.

2.7.3.2 LOW LEVEL CONTROL WIRING

(Digital Signal) (Optional)

The low water level control option is utilized when

drawing water from a tank. In this control circuit, two

electrodes sense the water level inside of a water

tank. When the water level drops below its minimum

level, the pressure booster will shut down.

2.7.3.3 REMOTE START-STOP (Digital)

Install a non-powered dry contact digital input to ter-

minals J4-1 and J4-2. With the LOCAL-REMOTE-

OFF switch in the REMOTE position this contact

closure will provide the start signal.

2.7.3.4 REMOTE ALARM INDICATION (Digital Signal)

A digital output dry contact rated 2 Amps at 115V is

supplied on terminals J5-7 and J5-8. This output

closes to indicate that an alarm condition exists.

2.7.3.5 PUMP ON/OFF REMOTE SIGNAL (Digital Signal)

A digital output dry contact (one per pump) rated 2

Amps at 115V is provided for remote monitoring of

pump On/Off status. This contact closes when a

pump is running.

Terminals (J3) + - Shield

Suction Pressure 3 2 4

System (discharge) Pressure 3 6 4

Temperature Sensor (RTD) Wiring Terminals (J3)

Low Temperature Sensor (suction) 13, 14

High Temperature Sensor (discharge) 16, 17

Optional Flow Sensor/Transmitter + - Shield

Terminals (J3) 9 8 10

Pump # 1 2 3

Terminals (J4) 9, 8 10, 11 11, 12

Pump On Pump Off

Ground Electrode Electrode

Terminals (J4) 66 67 68

Pump On/Off Signal Pump #1 Pump #2 Pump #3

Terminals (J5) 9, 10 11, 12 13, 14

3.0 PUTTING THE UNIT INTO SERVICE

3.1 PUMP ROTATION, 3 PHASE MOTORS ONLY

With the disconnect switch engaged to the “ON”

position, momentarily start and stop each motor with

the pump motor key on the key pad. See Paragraph

5.3 on page 16. Observe the pump shaft rotation.

3.2 If incorrect, turn the main disconnect off and inter-

change any two wire leads leaving the starter over-

load block and going to the motor.

3.3 Unit is now ready for operation (factory assembled

tested units only).

SECTION 3 –START UP

WARNING: Rotating shafts can catch loose cloth-

ing. Do not operate the pump without all guards in

place. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

CAUTION: Seal Damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation. Failure to follow these instructions could re-

sult in property damage and/or moderate personal injury.

DANGER: High Voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing

unit. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

DANGER: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices. Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

9

4.1 GENERAL NOTES

4.1.1 The HELP key can be pressed at any time without

disrupting system operation. The HELP key will give

details on alarm conditions or if used in conjunction

with any function key will give a detailed explanation

of the function key application.

4.1.2 The key names are shown in CAPITAL LETTERS and

the operator interface responses are shown in bold

CAPITAL LETTERS.

4.2 POWER-UP

4.2.1 Put LOCAL-REMOTE-OFF (LRO) switch in the

LOCAL position.

4.2.2 Turn main disconnect on.

4.2.3 The operator interface will display the ITT Bell &

Gossett corporation signature.

4.2.4 The operator interface will perform a lamp test and

display test.

4.2.5 Press CLEAR to stop the test.

4.2.6 The START-STOP led will be red.

4.2.7 If the START-STOP led is not illuminated as des-

cribed above, press the START-STOP button once to

obtain the red LED.

4.2.8 The Auto-Hand led should be green for auto opera-

tion. If not green, press the AUTO-HAND key to

obtain green led.

4.2.9 Press the PUMP 1 ON/OFF key to obtain a flashing

green light. On two pump systems, press the PUMP

2 ON/OFF key to obtain a flashing green LED and

press PUMP 3 ON/OFF key, for 3 pump systems, to

obtain a flashing green LED. Refer to Section 5 for

operation.

4.3 SETUP & SYSTEM CONFIGURATION

4.3.1 Press the SETUP key. Enter the serial number of the

assembly by pressing the appropriate numeric keys.

Press the ENTER key. The serial number may always

be found by reading the 4th message after power up

and the word “booting”disappears.

4.3.2 Confirm the system setup values per the following

table. Use the UP or DOWN ARROW keys to move

through the menu. To change values, press ENTER,

modify the value using the numeric key pad or UP and

DOWN ARROW keys, press ENTER to accept the

modification.

SECTION 4 –SETUP AND FEATURES

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices. Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

WARNING: Electrical shock hazard. Multiple power

sources. The off position of the LOCAL-REMOTE-

OFF switch does not disconnect all of the power sources

in the technologic panel. All power sources must be dis-

connected prior to entering the control panel. Failure to

follow these instructions could result in serious per-

sonal injury, death, and/or property damage.

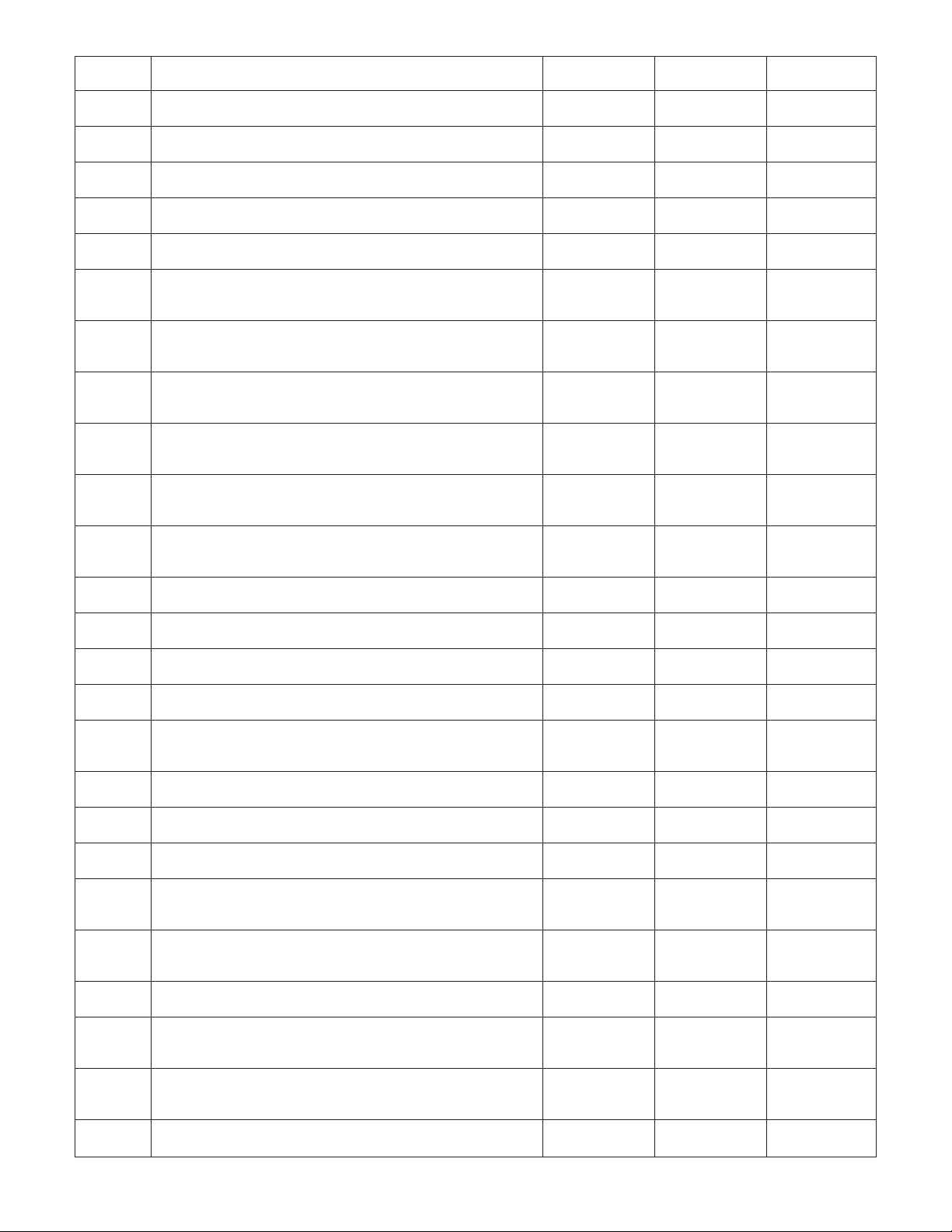

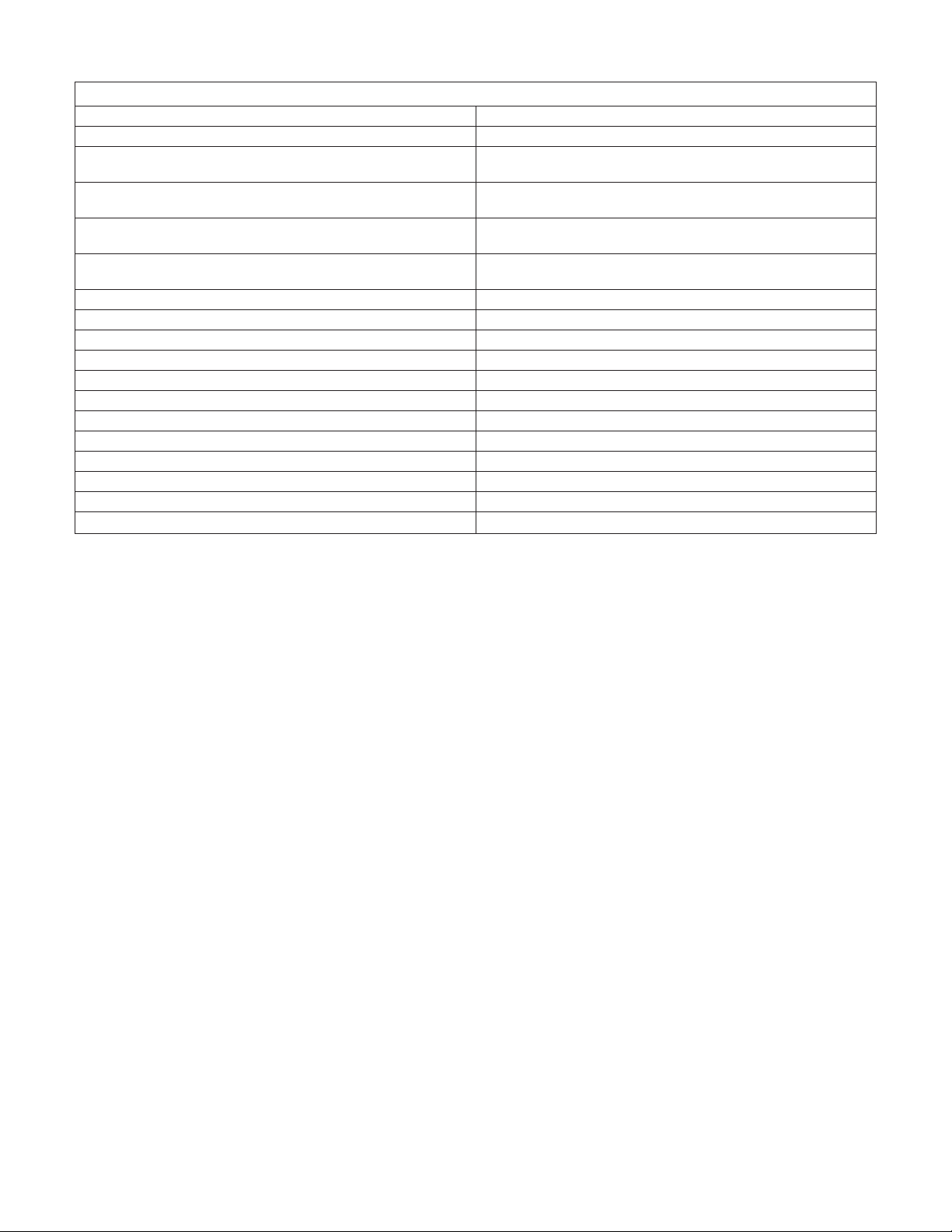

Default Allowable Field

Line # DISPLAY ➀Value Range Values

1 Number of Pumps 1

Number of Pumps on the System (1-2-3) 1 1 - 3

2 Alternation Sequence None

Use up/down keys to select: None, Duplex, Triplex - all, None As Listed

Triplex - 132A

3 Auto Alt. Period 0

O = Manual only, for Auto Enter 0 0 - 6553

Alternation period in hours

4 Reset Pump 1 Time No

Yes = arrow key to reset No Y/N

5 Reset Pump 2 Time No

Yes = arrow key to reset No Y/N

6 Reset Pump 3 Time No

Yes = arrow key to reset No Y/N

7 Staging Type Watts

Use up/down keys to select the primary method of Watts As Listed

pump staging: Watts, AMPs, PSI, GPM, TEMP

8 Pump #1 HP 0

Enter Motor #1 nameplate horsepower 0 0 - 99.9

9 Pump #2 HP 0

Enter Motor #2 nameplate horsepower 0 0 - 99.9

10 Pump #3 HP 0

Enter Motor #3 nameplate horsepower 0 0 - 99.9

11 Pump 1 AMPs 0

Enter Motor #1 nameplate FLA 0 0 - 175

10

Default Allowable Field

Line # DISPLAY ➀Value Range Values

12 Pump 2 AMPs 0

Enter Motor #2 nameplate FLA 0 0 - 175

13 Pump 3 AMPs 0

Enter Motor #3 nameplate FLA 0 0 - 175

14 Pump #1 GPM 0

Enter Staging GPM of Pump #1 0 0 - 30,000

15 Pump #2 GPM 0

Enter Staging GPM of Pump #2 0 0 - 30,000

16 Pump #3 GPM 0

Enter Staging GPM of Pump #3 0 0 - 30,000

17 1 - 2 Stage % 80

Enter percent of NPHP, NPFLA, or GPM to stage 2nd

pump in sequence 80 0 - 100

18 2 - 3 Stage % 80

Enter percent of NPHP, NPFLA or GPM to stage 3rd

pump in sequence 80 0 - 100

19 Destage % 90

Enter percent of stage percent for destaging with HP,

AMPs, or GPM only 90 0 - 99

20 Staging PSI 0

Enter pressure to stage in PSI mode after entering system 0 0 - System Span

pressure span (see Line 38)

21 Destaging PSI

Enter pressure to destage in PSI mode after entering system 0 0 - System Span

pressure span (see Line 38)

22 Forced Destg Tmr. 60

Enter in minutes (0 - 99) value of a timer after which the 60 0 - 99

pump will be forced to de-stage; ‘0’disables this function

23 GPM Xmiter Span

Enter value equal to GPM transmitter calibration 0 0 - 30,000

24 2nd Stage Proof 2

2nd pump stage proof time in seconds 5 1 - 180

25 3rd Stage Proof 2

3rd pump stage proof time in seconds 5 1 - 180

26 Display Watts YES

Use up/down keys to enter yes or no Yes Y/N

27 Three phase Watts YES

Use up/down keys to enter yes or no, YES = three phase, Yes Y/N

NO = single phase

28 Display AMPs YES

Use up/down keys to enter yes or no Yes Y/N

29 Display GPM No

Use up/down keys to enter yes or no No Y/N

30 Suction Press. Span 100

Enter value equal to suction pressure span 100 0 - 999

31 High Suct. Press. 0

Enter value of the high suction pressure above which an 0 0 - 100

alarm will be set

32 High Suct. Pr. TMR. 0

Enter in seconds (0 - 999) value of high suction cutout 0 0 - 999

proof timer, ‘0’disables this function

33 High Suct. Reset 0

Enter value of the high suction reset pressure 0 0 - 100

34 Low Suct. Press. 5

Enter value of the low suction pressure below which an 5 0 - 100

alarm will be set

35 Low Suct. Pr. TMR. 20

Enter in seconds (0 - 999) value of low suction proof timer; 20 0 - 999

‘0’disables this function

36 Low Suct. Reset 10

Enter value of the low suction reset pressure 10 0 - 100

11

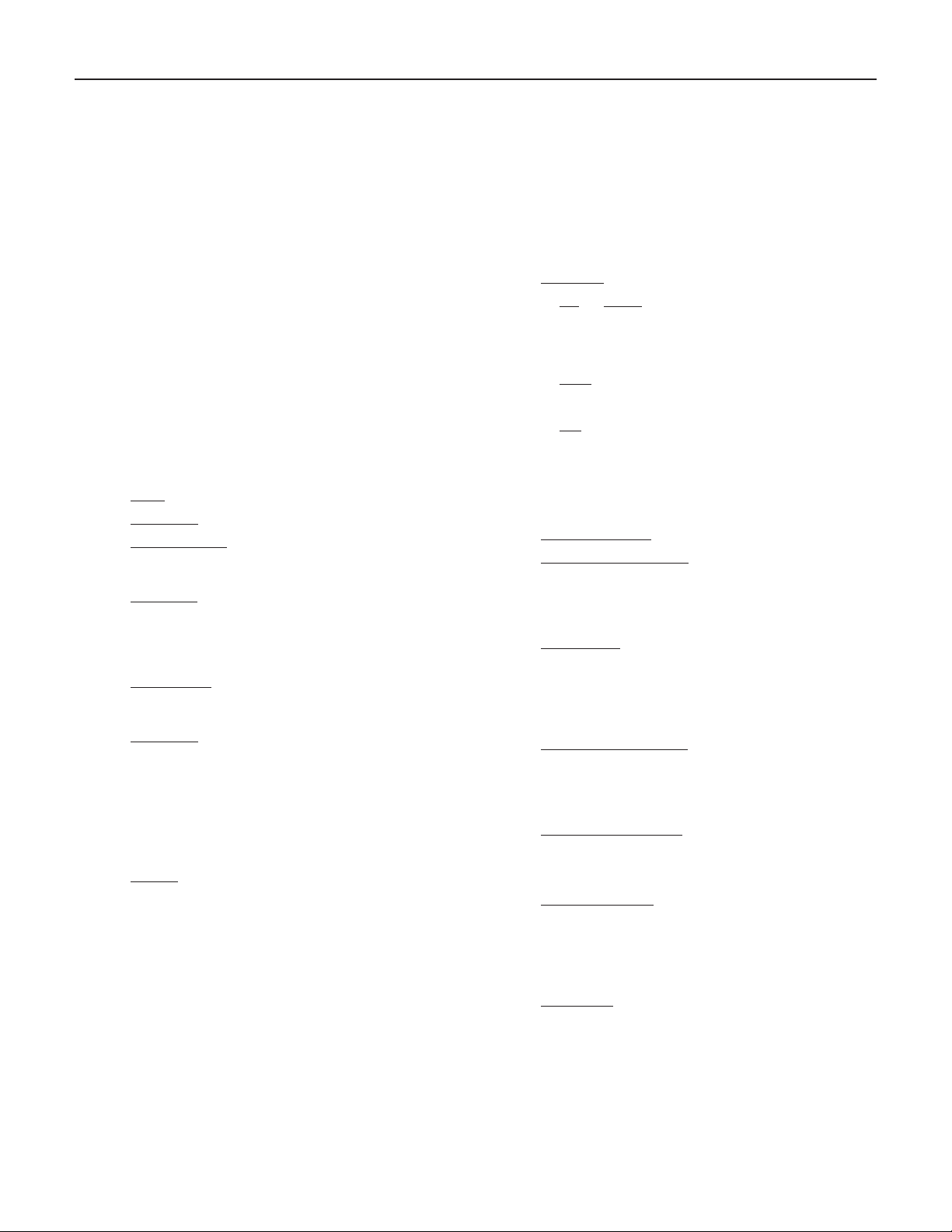

37 Low Suct. Auto RST Yes

To change the Low Suction reset, use UP/DOWN key Yes Y/N

to enter yes or no

38 System Press. Span 300

Enter value equal to system pressure span 300 0 - 999

39 High Sys. Press. 125

Enter value of the high system pressure above 125 0 - SPAN

which an alarm will be set

40 High Sys. PR. TMR. 20

Enter in seconds (0 - 60) value of proof timer, 20 0 - 60

‘0’disables this function

41 Audible Alarm 0

Enter 1 for low suction only, 2 for high system only, 3 for 0 0 - 3

low suction and high system, 0 to disable audible alarm

42 Low Sys. Press. 0

Enter value of low system pressure below 0 0 - Span

which an alarm will be set

43 Low Sys. Pr. Tmr. 0

Enter in seconds (0 - 60) value of proof timer, 0 0 - 60

‘0’disables this function

44 High Temp Cut Out 125

Enter value of the high temp cut-out in deg. F above 125 0 - 200

which an alarm will be set

45 High Temp PR. TMR. 20

Enter in seconds (0 - 60) value of proof timer, 20 0 - 60

‘0’disables this function

46 High Temp. Reset 100

Enter value of the high temp. Reset in deg. F 100 0 - 199

47 FS NFSD PR TMR

Enter in seconds (5 - 60) value of the 0 5-60

no flow condition proof timer, ‘0’disables the function

48 NFSD Temp. Cut Out 0

Enter NFSD temp differential, ‘0’disables this function 5 0-10

49 NFSD Min. Run TMR. 10

Time period (minutes) to ignore no flow sequence 10 0 - 999

after restart from no flow shut down

50 NFSD Restart PSI 0

Enter value of system pressure to restart 0 0 - SPAN

51 NFSD Test Pr. TMR. 0

Enter in seconds (0 - 999), value of the no flow condition 0 0 - 999

proof timer ‘0’disables this function

52 DP 1 Start Time 30

Time period in seconds to allow pump 1 to start prior 30 15-60

to detecting pump failure

53 DP2 Start Time 30

Time period in seconds to allow pump 2 to start prior 30 15-60

to detecting pump failure

54 DP3 Start Time 30

Time period in seconds to allow pump 3 to start prior to 30 15-60

detecting pump failure

55 DP 1 Proof Time 3

Pump #1 failure proof time in seconds 3 0-30

56 DP 2 Proof Time 3

Pump #2 failure proof time in seconds 3 0-30

57 DP 3 Proof Time 3

Pump #3 failure proof time in seconds 3 0-30

58 Minimum Run Timer 5

Minimum time a pump will run after auto start in minutes 5 0-25

59 Backup Staging WATTS, AMPS,

Select method of backup staging in the event WATTS PSI, GPM,

the primary method fails TEMP

60 TEMP Xmitr Span

Enter value equal to remote temperate transmitter span.

Note this input is used for temperature staging requiring 0 999

a 4-20mA temperature transmitter.

61 Stage TEMP Rise

Select yes to stage pumps on temperature rise Yes Y/N

based on setpoint.

62 Temp Staging H

Enter the high temperature for staging/destaging. 75 999

63 Temp Staging L

Enter the low temperature for staging/destaging. 50 999

64 Standby

When yes is selected disables the staging of the N Y/N

last pump in sequence.

65 DI SUC ALARM

0 = Low Level 0 0-1

1 = Low Pressure

66 DI SA PT (DI ALARM TMR)

Enter in seconds proof timer for alarm. 1 0-99

“0”disables this function.

67 Default All ? N

Set all parameters to factory default N Y/N

In every case above the message scrolls right to left twice and blanks out. Press CLEAR twice to exit.

NOTE: Keys from Line 2 through Line 12 (except clear) also have numbers for numerical entry within a menu.

NOTES: ➀One pump must be enabled to obtain start function. Has green - run and red - stop LED.

➁To change selection the START-STOP key must be in stop. Green LED-AUTO, red LED-HAND.

➂The alternation sequence will be according to the user menu selection and will be displayed according to the message of 4.5 below

to match that selection.

12

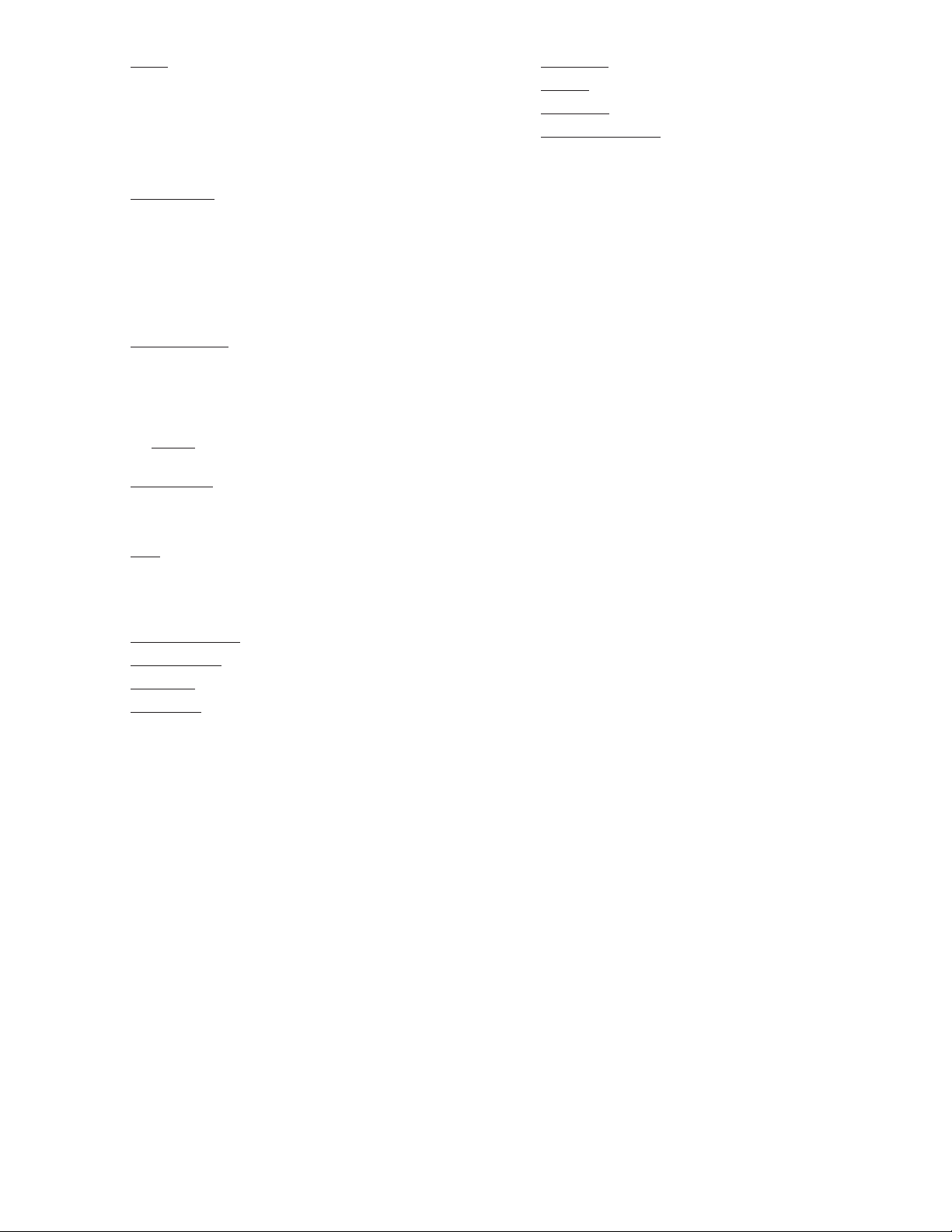

4.4 KEY FUNCTIONS

4.3.3 Press the CLEAR key. You will return to the standard

operating display.

HELP MESSAGES. PRESS HELP AFTER

CLEARING ANY ALARMS

LINE KEY MESSAGE

➀1 Start/Stop Used to start and stop pumps.

➁2 Auto/Hand Used to select auto or manual operation.

3 Pump 1 Used to start/stop pump 1; green = run, flashing green = enable,

Enable flashing red = failure.

4 Pump 2 Used to start/stop Pump 2; green = run, flashing green = enable,

Enable flashing red = failure.

5 Pump 3 Used to start/stop Pump 3; green = run, flashing green = enable,

Enable flashing red = failure.

➂6 Alternation Used to alternate pump sequence.

7 Service Test Used to perform service test.

8 Reset/Silence Used to reset alarm after its correction and to silence audible alarm.

9 Used for selection in a menu.

10 Set Up Used to define system parameters - security.

11 Clear Clears latest entry (operation and data).

12 Help User assistance; press: Help + Key/Item.

13 Enter Used to accept data and operation input.

➔

➔

NOTES:

➀The top line of each display is stationary while the changeable value, if any, is flashing. The bottom line scrolls from right to left continuously. To scroll from

display to display continuously press either arrows. At any display the data may be changed by pressing enter, pressing the key or keys to change data, and

pressing ENTER again. If a value to be entered is out of range the following is displayed:

Top Line - value out of range Bottom Line - X1 < = Value < = X2 With X1 being the minimum value and X2 the maximum value of the range

➁Note: For software version 3.28 or greater.

13

4.5 NORMAL OPERATING MESSAGES

4.5.1

NORMAL SCROLL AUTO OR HAND

LOCAL OR REMOTE ➀➁

MESSAGE CONDITION

Alternation ➂“None”According to menu entry for simplex,

or duplex or triplex.

“1-2, 2-1”

or

“1-2-3

2-3-1”

3-1-2

or

“1-2-3

1-3-2”

Elapsed Time P1 Hours XXX

Elapsed Time P2 Hours XXX If 2 pumps selected

Elapsed Time P3 Hours XXX If 3 pumps selected

High suction cutout ➂Bottom Line Only

No flow shut down ➂Bottom Line Only

Suction Pressure PSI XX If span is entered

System Pressure PSI XX If span is entered

Suction Temperature XX F˚If high temperature cut-out is entered

System Temperature XX F˚If high temperature cut-out is entered

Total AMPS XXX If selected in menu

Total KW XXXX If selected in menu

Flow = XXXXX ➃GPM If span entered

* Alarm (flashing) When an alarm occurs

Startup —Standby Bottom Line Only

Alternation Engaged Standby Bottom Line Only

Pump Not Available Bottom Line Only

Please Enable a Pump Bottom Line Only

Not Allowed Bottom Line Only

User Setup Lost Top Line

Call Factory For Assistance Bottom Line Only

NOTES:

➀Press ENTER and ARROW keys for scroll lock.

➁Display is blank if CPU fails.

➂Not scrolled in hand operation.

➃XXXX reverts to ??? if span is entered and signal is less than 4mA.

*See 4.5.2 for alarm messages.

4.5.2 ALARMS

ALARMS

CONDITION HELP MESSAGE

Overload X Failure Check AMP draw, use manual reset if OK

High Suction PSI High suction pressure –check suction

pressure and trip point

Low Suction PSI Low suction detected –check suction

pressure and trip point

High System PSI High pressure detected in the system –

check trip point

Low System PSI Low pressure detected in the system –

check PRV and set point

Water Level Low Check water level in holding tank

Water Temp High Check water temperature

Pump X Off Need pump in system –if OK enable pump

Suction Trans Fail Check wiring, piping, polarity, and continuity

System Trans Fail Check wiring, piping, polarity, and continuity

Flow Trans Fail Check wiring, piping, polarity, and continuity

Suction RTD1 Fail Check wiring, continuity

System RTD2 Fail Check wiring, continuity

Power Fail Check cable connections and plug insertions

Pump X Failure Check DP switch, impeller, coupler, motor

Remote Contact Open ➀

7 Day Timer Off ➀

NOTES:

➀Bottom line only. No help message.

14

15

5.1 POWER UP

5.1.1 Initial –turn selector switch to local or remote with

power on.

5.1.2 Message Scroll

A. “Booting”

B. “ITT Bell & Gossett”

“Pressure Booster”

C. “Technologic 70E”

“Pump Controller”

D. “Copyright 1995”

“Fluid Handling Division”

E. “FW Release VX.XX”

“Serial # XXXXX”

F. Normal Scroll per 4.5 commences

5.1.3 Set Up and System Configuration. User Menu.

A. Press the SETUP key. Enter the serial number fol-

lowed by the ENTER key.

B. Press the UP or DOWN arrow key to step through

user menu of paragraph 4.3.2. To change any

value press ENTER, modify the default value using

the numeric key pad, and then press ENTER to

load. Press CLEAR to exit menu.

5.2 AUTO OPERATION

5.2.1 Local (turn selector switch to local or remote).

5.2.2 Auto/Hand –select Auto.

5.2.3 Enable/Pump/s by pressing 1, 2, or 3 PUMP ENABLE

keys according to number of pumps in menu. Green

LED’s flash.

5.2.4 Start/Stop –Press START/STOP key momentarily.

Green LED is on. Note: Only if selector switch is

turned to local or remote and at least 1 pump is

enabled. Message: Top Line –see below. Bottom

Line –“start up standby”.

5.2.5 Pump Start –The first pump in the alternation

sequence starts and LED turns to solid green. Only 1

pump is on.

5.2.6 Alternation –If the alternation key is pressed the next

pump in sequence starts and both pumps then run

for 5 seconds at which time the first pump stops.

During alternation: Top Line –normal scroll. Bottom

Line –“Alt. Engaged standby”.

If Alternation Timer picks up the action is the same as

above provided an entry other than 0 is made in the

user menu.

5.2.7 Staging –According to the method of staging selected

in the user menu, i.e., HP, AMPs, PSI, GPM the 2nd

pump in the alternation sequence will turn on when:

1. HP matches % stage value

or 2. AMP value matches % stage value

or 3. GPM value matches % stage value

or 4. Pressure matches PSI stage value

The third pump in the alternation sequence turns on

similarly.

Staging will not occur if:

1. No flow condition is on.

2. High suction is on.

3. Low suction is on.

4. High temperature is on.

5. High system in on.

6. Timed de-stage is on.

7. Starter feedback is not on.

The 3rd pump stages in the same manner as the sec-

ond pump according to the menu entry for that pump.

5.2.8 Destaging occurs when:

1. HP or AMPs (selected method of stating) of the

last pump staged, plus the cumulative value of all

other running pumps, reaches the destage percent

value entered in the user menu, and a proof timer

and the minimum run timer time out.

2. GPM decreased to the value of the destage GPM

in the menu. The pump stops after a proof timer

and then a minimum run timer.

3. PSI setting of the destage PSI value in the menu

is reached. The destage PSI is higher than stage

PSI and a proof timer and the minimum run timer

time out.

All of these methods of destaging are exclusive and

may not be mixed.

5.2.9 Pump Shut Down occurs when:

5.2.9.1 High Suction Pressure analog signal triggers when

“High Suction Pressure”of the menu is reached and

the “High Suction Pressure Timer”of the menu ex-

pires. All pumps stop. Alarm message is set. Pumps

start when “High Suction Reset”is reached.

5.2.9.2 Low Suction analog signal reaches the level of “Low

Suction Pressure”in the menu and “Low Suction

Pressure Timer”in menu times out. All pumps stop.

Alarm message is set. Audio visual alarm is set.

Pumps restart when “Low Suction Reset”setting in

the menu is reached. Auto reset.

5.2.9.3 High System Pressure analog signal triggers when

“High System Pressure”of the menu is reached and

“High System Pressure Timer”of menu setting ex-

pires. All pumps stop. Alarm message is set. A-V

alarm turns on. Manual reset to start pumps.

5.2.9.4 Low System Pressure analog reaches menu setting

“Low System Pressure”and after “Low System

Pressure Timer”menu setting times out the alarm

message is set. Does not stop pumps. Auto reset.

5.2.9.5 High Temperature analog reaches “High Temperature

Cut Out”value of the menu. The “High Temperature

Pressure Timer”times out. Alarm message set.

Pump/s stop. Auto reset occurs when “High Temp-

erature Reset”of the menu is reached. NOTE: A value

must be entered for temperature display.

5.2.9.6 Low Level probes detect low level. After non-

accessible proof timer of 5 seconds the pumps stop.

Alarm message is set. When level returns to normal

and another non-accessible proof timer of 5 seconds

times out the pumps start. Auto reset.

SECTION 5 –OPERATION

16

5.2.9.7 NFSD analog RTD inputs reach a temperature within

“NFSD Cut Out”in the menu and after “NFSD Test

Pressure Timer”the pump stops. Pump will start

when “NFSD Restart Pressure”analog input reaches

this point in the menu setting. Auto reset. NFSD can-

not occur again until “NFSD Minimum Run Timer”

setting in the menu elapses. NOTE: NFSD will only

occur while one pump is running.

5.2.9.8 O.L.X. Failure from digital inputs from starters 1M, 2M

and 3M from pumps 1, 2 and 3, respectively trip and

shut down the associated pump. The next pump in

the sequence will start. “Alarm”message flashes.

Manual reset. Upon manually resetting the tripped

starter and pushing the reset key the previously

tripped starter starts it pump and the pumps run

together for 5 seconds and then return to normal

operation.

5.2.9.9 Pump X Failure from digital inputs from DP switches

1 through 3, respectively trip and shut down the

associated pump 1, 2, or 3 respectively. The next

pump in sequence then starts. Pump fail message

set. Manual reset. Shut off pump now restarts with 2

seconds delay.

5.2.9.10 (B) Alarms –are listed in Table 4.5.2. Most alarms are

discussed with the balance self-explanatory.

5.2.9.11 Normal Stop –with power on press start/stop key.

Enabled pumps have flashing green LEDs. All faults

are in memory and do not reset. Status of the 3 pump

keys is written to memory.

5.2.9.12 Stop –with power failure, alarms are reset but status

of start-stop key and 3 pump keys is held in memory.

5.3 MANUAL OPERATION (Watchdog LED Off)

5.3.1 Choose local or remote operation.

5.3.2 AUTO/HAND Key –select HAND.

5.3.3 Enable Pumps by pressing 1, 2 or 3 PUMP keys.

5.3.4 Start/Stop as 5.2.4 above.

5.3.5 Pump Start as 5.2.5 above.

5.3.6 Alternation –none.

5.3.7 Staging –none.

5.3.8 De-staging –none.

5.3.9 Pump Shut Down –none. However, all alarms of

Table 4 are active but do not shut the pumps down.

Some items are not in normal scroll. See foot note of

Table 3. Note that motors are still protected with O.L.

relays as part of the respective starter.

5.4 MANUAL OPERATION

(CPU Fails, Watchdog LED On)

The 70E/70M has a redundant feature allowing criti-

cal operation even though the microprocessor and its

support I.C.’s may have failed. Although this is a rare

occurrence, B&G has planned for this possibility.

When the Watchdog LED is “on”a separate section

of LOGIC is used to bypass the problem area. This

LOGIC has its own memory which is held with power

off by a small clock battery (B1). This memory must

be pre-set for operation as desired upon CPU failure.

To set this memory perform the following (assuming

unit is running in auto):

1. Press STOP Key –Red stop LED is on.

2. Press AUTO/HAND Key –Red HAND LED is on.

3. Press PUMP ENABLE Keys in any order for pumps

to run upon a CPU failure. Associated green LED’s

will flash.

4. Press AUTO/HAND Key –green AUTO LED is on.

5. ENABLE PUMPS as required and press

START/STOP key –green LED on.

The unit is now running in auto. If the CPU fails the

system reverts to the manual operation that was pre-

set in steps above. Pumps do not stop except for

overload trip. Press the PUMP ENABLE key to stop a

specific pump or press START/STOP key to stop all

pumps.

Press PUMP ENABLE key to re-start a pump. Only

the hand and pump LED’s are active. All other LED’s

and the display are off.

17

6.0 Preface: The following is a description of the hard-

ware, diagnostics, and corrective action to maintain

a process being controlled by the Technologic

70E/70M.

NOTE: The following should not be interpreted as the

maximum configuration of this controller, rather this

describes its application as a technologic 70E/70M

only.

6.1 TECHNICAL OVERVIEW

The Technologic 70E/70M is a micro-processor

based dedicated pump controller unique to and

exclusively manufactured by ITT Bell & Gossett. All

aspects of this unit are strictly proprietary to ITT Bell

& Gossett.

It consists of 3 electronic assemblies. The first

assembly consists of 3 circuit boards, i.e., display,

keyboard, and central processor unit (CPU) and is

referred to as the operator interface panel (OIP).

This operator interface is connected (with ribbon

cable) to a large board assembly known as the input/

output (I/O) board. This board contains a 24 volt DC

power supply to power the unit, all I/O, and a limited

number of sensors. It also has the terminals to con-

nect to external devices. All hard wire interface to the

outside world resides on this board and is protected

from the external environment.

The third electronic assembly is the power board

which connects to the OIP with a special cable. This

board senses amps, voltage, and calculates the total

power for staging and display on the OIP.

6.2 DIGITAL INPUTS

The controller has provision for digital inputs with a

voltage operating range of 22 to 26.4 VDC. This sig-

nal voltage must be obtained from the on-board 24

VDC power supply. Eighteen terminals are provided

with 6 of these terminals used to connect to the 24

VDC power supply.

It is not recommended that other power sources

be used without factory approval.

The terminal will accommodate (2) No. 18 AWG wires.

6.3 DIGITAL OUTPUTS

The controller has provision for relay outputs to con-

trol 120V 50/60 HZ devices.

Sixteen terminals are provided. All terminals will

accept up to (2) No. 14 AWG wires.

The relays are not removable. If defective the I/O

board must be returned to the factory for repair.

All relays operate as single pole single throw. Com-

ponents are provided to reduce contact arc and ex-

tend electrical life.

6.4 ANALOG INPUTS

Analog inputs are provided on the I/O board for

process variables and for flow readout. All analog

inputs operate at 4-20mA. They may be powered

from 24 VDC on board or self powered, in any mix,

without isolators.

Each analog input has 4 terminals associated with it,

i.e., 2 for signal input, 1 for 24 VDC, and 1 for shield

chassis ground.

Each analog input terminal will accommodate (2) No.

18 AWG conductors.

6.5 MEMORY

6.5.1 The EPROM is the only removable chip. However, it

is not recommended that it be changed by other than

the factory.

The EPROM is programmed by ITT Bell & Gossett

and its code is copyrighted. On power up the soft-

ware version is displayed as FW RELEASE VX.XX on

the top line and unit assembly serial No. on the bot-

tom line.

6.5.2 The EEPROM holds all data entered by the operator.

It is not removable. Old data is erased with new. All

data may be erased by the factory at which time all

data reverts back to default values published else-

where in this manual.

6.5.3 The RAM chip is not replaceable and requires no

maintenance.

6.6 CPU

The CPU does not require any maintenance, and

cannot be replaced as a field repair.

6.7 POWER SUPPLY

The power supply provides 24 VDC for all digital and

analog signals. It is specifically rated only for the con-

troller and other loads should not be applied without

factory approval.

The power supply also supplies 5 VDC for all TTL

devices.

The power supply is protected with Fuse F1 located

near the 120 VAC line terminals.

6.8 DIAGNOSTICS (Service Test)

The Technologic 70E/70M has built in I/O diagnostic

capabilities activated with a SERVICE TEST key while

in normal message scroll. It consists of 2 menus, i.e.,

read only and read/write. Read/write overrides the

program and requires a security code.

NOTE: Service test cannot be used if any of the fol-

lowing occur:

1. Power is off.

2. Display and or the start/stop LED is off (red or

green).

3. Watch dog LED (CR6) on the I/O board on.

6.9 READ ONLY –Digital Inputs

6.9.1 To Enter –press CLEAR key twice and then press

SERVICE TEST key once while in normal scroll.

6.9.2 Display –numbers 1 through 12 (implied) on the top

line and status on the second line. Status is displayed

as a “1”for signal on and “0”for signal off.

SECTION 6 –MAINTENANCE

18

6.9.3 Interpretation –compare the status shown to the

following terminals and the wiring diagram. For

example, starter 1M “on”signal at J4 4 and 8 is dis-

play No. 3 and should be a “1”if the 1M starter is

energized.

Input J4 Input No.

Signal Terminals On Display

Local ** 1 to 2 1

Remote 3 to 2 2

1M 4 to 5 3

2M 6 to 5 4

3M 7 to 8 5

* DP1 9 to 8 6

* DP2 10 to 11 7

* DP3 12 to 11 8

* Low Level 18 to 17 12

* 7 Day Timer 19 to 20 13

* Optional

** This input is also used for remote start when the selector switch

is in the REMOTE position.

NOTE: Terminal No.’s on the right, e.g., 2, 5, 8, etc. are all in common.

6.9.4 Corrective Action –compare the inputs on to the

device/s connected to the digital inputs and trigger

same. If a “1”is not received check the associated

wiring or the particular device and correct or replace

the cause of the fault.

6.9.5 Controller Operation –the keyboard (except the

CLEAR key) and all LED’s cannot change state. The

display is dedicated to the digital input display. The

program is otherwise active.

6.9.6 Exit –press CLEAR twice and then press ENTER

twice.

6.10 READ ONLY ANALOG INPUTS

6.10.1 To enter (from normal scroll) –press CLEAR key

twice and press SERVICE TEST key once. Then

press CLEAR key once.

6.10.2 Display –ANALOG INPUT TEST on top line and input

type and measurement on bottom line. Press key 1,

2, 3 or 4 to read channels 1, 2, 3 or 4 in % with 4mA

@ 20% and 20mA at 100%. Six other items may be

accessed with the up arrow key. These items are:

RTD 1(˚F), RTD 2(˚F), Dc supply (DCV), and power

board readings. “Power Board Readings”is now dis-

played on top line. These readings are: voltage in

volts, current in amps, and power in watts.

6.10.3 Interruption –read channel values from connected

devices with channel 1 as suction pressure, channel

2 as system pressure, channel 3 as flow input

(optional) and channel 4 is unused at this time.

If there is a problem replace the analog source with a

known source such as a 20mA signal generator.

Connections to terminal block J3 are as follows:

Source 2 Wire

*Step Signal Input Terms Terms

1 Suction 1 1-, 2+ 2-, 3+

2 System 2 5-, 6+ 6-, 3+

3 Flow 3 7-, 8+ 8-, 9+

Polarity shown is that of the signal analyzer

and not the markings on the I/O board.

4 not used 4 ——

5 RTD1 RTD in 1 —13, 14

6 RTD2 RTD in 2 —16, 17

A substitute 100 OHM resistor @ terms.

13 & 14, or 16 & 17 will result in a temperature

reading of 32˚F.

7 DC Supply = 24.00 VDC ± 10% satisfactory.

8 Display top line changes to: Power Board

Readings.

8 Voltage = XXX VAC equal to system line

voltage.

9 Current = XXX amps equal to actual load.

10 Power = XXX watts actual power.

* Step = each momentary step of up arrow key.

6.10.4 Corrective Action –correct the wiring or a faulty

device. If a signal is good with a signal generator then

the inter-connection wires are good and the sensor is

bad. In the case of RTD’s a substitute 100 OHM

resistor will isolate a problem to the sensor.

Power board readings may be confirmed by a sepa-

rate clamp-on line current readings, line voltage read-

ing, and calculations for watts.

6.10.5 Controller Operation –keyboard (except arrows,

clear, 1, 2, 3, 4) and all LED’s cannot change state.

The display is dedicated to the analog input display.

The program is otherwise active.

6.10.6 Exit –press CLEAR once and then press ENTER

twice.

6.11 MANUAL CONTROL –OUTPUTS

To enter this section a user code (serial no.) is

required. Since the program is being overridden cau-

tion must be exercised.

IF NOT SURE CALL THE FACTORY. IF “USER

CODE”IS DISPLAYED PRESS THE ENTER KEY

TWICE TO RETURN TO NORMAL SCROLL.

DO NOT LEAVE UNIT IN SERVICE TEST.

6.12 DIGITAL OUTPUTS

6.12.1 To enter:

A. Normal scroll on display

B. Press CLEAR twice

C. Press SERVICE TEST

D. Press CLEAR twice

E. Enter user code (serial no.)

F. Press ENTER key

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

DANGER: Troubleshooting live control panels ex-

poses personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electri-

cian. Failure to follow these instructions could result

in serious personal injury, death, and/or property

damage.

19

6.12.2 Display = output #1 through 8 on top line and state,

either 0 or 1, on bottom line. A “1”= output “on”

(relay coil energized) and a “0”= off. Toggle output

with a numerical key to match the output #.

6.12.3 Interpretation –this is an output forcing operation to

allow checking of wiring and the connected device.

Since some outputs are normally closed the following

must be observed.

Relay

Contact

Output Relay with a Output

# Function # State of 1" Terminals

1 1M control K5 Closed J5 1-2

2 2M control K6 Closed J5 3-4

3 3M control K7 Closed J5 5-6

4 Alarm K8 Open J5 7-8

5 Pump 1 on K1 Closed J5 9-10

6 Pump 2 on K2 Closed J5 11-12

7 Pump 3 on K3 Closed J5 13-14

8 not used K4 Closed J5 15-16

Correlate output terminals to the wiring diagram for

actual practice.

NOTE: It is important to view status on the display

before any state is changed. This shows the actual

output state of the program as it was presently

running.

6.12.4 Corrective Action –if a fault is suspected trigger the

associated output to confirm that either connections

to the connected device is the problem.

6.12.5 Controller Operation –all outputs are static and con-

trolled by the numerical keys. The program is static.

Confine operation to numerical keys. LEDs are static.

6.12.6 Exit –press CLEAR and ENTER. All forced outputs

are cleared.

6.13 PRE-DETERMINED FAULT AND FAULT CONTROL

6.13.1 Pre-determined Fault –a software timer known as a

watch dog times out upon a software or CPU failure

and shuts down in a predicable manner. LED CR6 on

the I/O board turns on and all outputs are turned off.

OIP board components are now used to determine

the state of all relays according to LOGIC installed by

the factory.

6.13.2 Fault Control –operates as follows:

A. Press START-STOP key for stop.

B. Press AUTO-HAND key for HAND.

C. Enable pump/s as desired. (Press PUMP keys) to

run upon control failure.

D. Press AUTO-HAND key for auto.

Press START-STOP key to start.

E. Upon a CPU or software fault the unit will revert to

pumps selected in C above.

If power is momentarily interrupted the unit will return

to the same “hand”operation as before provided

pump keys were not pressed while the power was off.

6.14 PROTECTION

6.14.1 Analog inputs –the analog inputs provided on the

Technologic 70E/70M must be wired according to the

wiring diagram that shipped with the unit.

6.14.2 Protection –all analog inputs are protected from high

voltage, crossed wiring, etc. A 1 AMP fuse (F1) fast

acting 3AG located just above relays K6, K7 and K8

protects all analog inputs up to 600V (in error only). A

sustained fault may blow this fuse and burn out the

input resistors. They are located just below terminals

J3 and are numbered R3, R4, R1 and R2 for chan-

nels, 1, 2, 3 and 4 respectively.

6.14.3 Field Repair –resistors R1, R2, R3 and R4 plug in

and are easily replaced.

Unplug a bad resistor by pulling it from the socket

and replace with a 124 OHM, 1/4watt, 1%, metal film

(no substitute). Cut leads and bend to fit sockets.

Resistors are also available from the factory.

NOTE: It is not always clear that a resistor is bad by

observation. It may be brown or black. The best way

to check is unplug the resistor and check with an

ohm-meter. DO NOT check resistors on board. It may

cause other problems and will not give a true reading.

6.14.4 Digital Inputs –as long as input power is derived from

the integral 24VDC power supply they are protected.

6.14.5 Digital Outputs –each output shall not exceed 1 AMP

@ 115 VAC (6 AMP inrush).

6.14.6 Power Supply –the power supply has inherent short

circuit protection, thermal overload shutdown, tran-

sient protection, and line noise filtering. To reset the

power supply cycle input power off and on.

6.14.7 Protection –fuse F1 located near terminal J4 (power

in) protects the power supply. It is rated 1 AMP fast

acting #3 AG.

6.14.8 Operator Interface –it is protected by the I/O board.

6.15 FAULT ISOLATION

Certain messages, common sense, observation, and

diagnostics allow fault isolation of an on-board fault.

6.15.1 CONDITION: RAM Error on the display and

auto/hand red LED on. Watch dog LED CR6 is on.

Corrective Action:

Pumps will run in manual operation according to

paragraph 5.4 above. Replace the operator interface.

6.15.2 CONDITION: Comm Error in the display and pump 1

red LED is on. Watch dog LED CR6 is on.

Corrective Action:

Pumps will run in manual operation according to

paragraph 5.4 above. Replace the operator interface.

CAUTION: Do not trigger outputs unless the resul-

tant action is known. Do not trigger all outputs on at

one time or trigger at random. Failure to follow these

instructions could result in property damage and/or

personal injury.

WARNING: Electrical shock hazard. Multiple power

sources. The off position of the HAND-OFF-AUTO

switch does not disconnect all of the power sources in

the Technologic panel. All power sources must be dis-

connected prior to entering the control panel. Failure to

follow these instructions could result in serious per-

sonal injury, death, and/or property damage.

20

6.15.3 CONDITION: I/O Error on the display and pump 2

red LED is on. Watch dog LED CR6 is on.

Corrective Action:

Pumps will run in manual operation according to

paragraph 5.4 above. Replace the operator interface

and the I/O board.

6.15.4 CONDITION: E2 Bad. System Halted. Call factory

for assistance. Watch dog LED CR6 is on.

Corrective Action:

Pumps will run in manual operation according to

paragraph 5.4 above. Replace the operator interface.

6.15.5 CONDITION: No Program Found on the display and

pump 3 red LED is on. Watch dog LED CR6 is on.

Corrective Action:

Pumps will run in manual operation according to

paragraph 5.4 above. Replace the operator interface.

6.15.6 CONDITION: E2 Defaults Set on the display. Watch

dog LED CR6 is not on.

Corrective Action:

Remove EPROM. Watch dog LED CR6 will turn on.

Pumps will run in manual operation to paragraph 5.4

above. Replace the operator interface.

6.15.7 Display Blank

A. Watch dog LED CR6 is off.

Corrective Action:

Confirm power to OIP with at least 1 LED on or

measure 120 volt. A. C. at J6 L1 and N. If power

present reboot and if display stays off, replace OIP.

B. Watch dog LED CR6 is on.

Corrective Action:

None. No display. This condition except back light

is on. Unit will run in manual per paragraph 5.4.

6.15.8 Key Board Inoperative

A. Watch dog LED CR6 is off.

Corrective Action:

Be sure power is on by checking or observing dis-

play or at least one LED. Press RESET and HELP

keys. If condition prevails replace OIP.

B. Watch dog LED CR6 is on.

Corrective Action:

Only 4 keys are active: START/STOP, PUMP 1,

PUMP 2, and PUMP 3. If these keys are inopera-

tive replace the OIP. Unit will run in manual per

paragraph 5.4.

6.15.9 LEDs Malfunction

A. Observe that all LEDs turn on during the booting

process. Watch dog LED CR6 is off.

Corrective Action:

If any fail to operate replace the OIP.

B. Watch dog LED CR6 is on. Only the red HAND

LED and the 3 green LEDs with one for each

pump key will turn on, or off. Unit will run in manual

per paragraph 5.4.

Corrective Action:

Replace OIP.

C. Watch dog LED CR6 is off but all LEDs or some

LEDs are off.

Corrective Action:

1. Check that the ribbon cable is plugged in.

2. Check for ribbon cable damage.

3. If all LEDs off check incoming power and

fuse F1.

4. Reboot.

5. Replace OIP unit.

6.15.10 Selector Switch Malfunctions

Press SERVICE TEST –

A. In local, input 1 should be “1”(J4).

B. In remote, input 1 = 0 with remote contact open

and input 2 = “1”(J4).

Corrective Action:

A and B are not present; correct wiring or replace

the switch. See wiring diagram for correct wiring.

A new switch may be obtained from the factory.

6.15.11 Suction Transducer Fault

A. Alarm per 4.5.2 indicates this fault.

B. Confirm with analog input test of CHNL 1 per 6.10.3.

Corrective Action:

1. Disable transducer by entering user menu per

4.3 and changing suction pressure span (item

11) to “0”. Alarm message turns off. Low and

high suction is disabled.

2. Replace this transducer.

6.15.12 System Transducer Fault

A. Alarm per 4.5.2 indicates this fault.

B. Confirm with analog input test of CHNL 2 per 6.10.3.

Corrective Action:

1. Disable transducer by entering user menu per

4.3 and changing system pressure span (item

37) to “0”. Alarm message will turn off. Low and

high system PSI and PSI staging is inoperative.

2. Replace this transducer.

DANGER: Troubleshooting live control panels ex-

poses personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electri-

cian. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

WARNING: Electrical shock hazard. Multiple power

sources. The off position of the HAND-OFF-AUTO

switch does not disconnect all of the power sources in

the Technologic panel. All power sources must be dis-

connected prior to entering the control panel. Failure to

follow these instructions could result in serious per-

sonal injury, death, and/or property damage.

This manual suits for next models

1

Table of contents