Benassi RT 80 Manual

S.p.A.

USE AND MAINTENANCE HANDBOOK

MOTORISED HOE

RT 80

06/07/01

S.p.A. RT 80

2

CONTENTS

1) Introduction

2) After-sales service and Warranty

3) Technical details

4) Packing and transport

5) Accessories

6) Safety rules and limits on use

7) Starting and stopping

8) Operating and regulating the machine

9) Mill assembling

10) Maintenance and lubrication

11) End-of season servicing

12) Possible problems and solutions

13) Instructions for a good operation of the

machine

1 -INTRODUCTION

We are pleased that you chose a machine built byBENASSI SPA.

This booklet provides the information and data needed to preserve and use the machine properly.

Themoreyougettoknowyour farming machine,thebetter youwill work. Thereforewestronglysuggestthatbeforestarting work, you carefullyread and

understand this "USER AND MAINTENANCE" booklet.

Youwill findimportantinformationonusing themachinewhichwill allowyoutogetthemostofits technical capacities. You will alsofindprecious

information on howto care for it and service it, in terms of safety, and a guide on running and servicing it in the best possible wayduring the lifetime of your

machine.

For reasons of technical progress, BENASSI SPA reserves the right to modify the mechanical parts, the finishes and the accessories. The data

regarding measures, weights and performance are specified within DIN tolerance. The figures, the descriptions and the technical data are not binding.

2 - AFTER-SALES SERVICE AND WARRANTY

BENASSI SPA provides its customers with an after-sales service for solving anyprobleminvolving the use and the maintenance of its machinery. All the

machines are guaranteed for defective material for 12 months (one year) from purchase. For anyneed, refer to your dealer.

N.B. IMPORTANT WARNING FOR YOUR SAFETY

Always use original BENASSI SPA products, spare parts and accessories; anymodification or application using non-original parts exempts BENASSI

SPAfrom anyresponsibility

BENASSI SPA disclaims all responsibilityin case of application of accessories made byother firms to its machines: Anywarrantywill begivenfor said

applications even when such modifications have been tested byboards of control or certified bypublic bodies as tests on single machines are not valid.

BENASSI SPAW ISHES YOU A PLEASANT W ORK W ITH OUR MACHINES

N.B. PAY SPECIAL ATTENTION TO THE INSTRUCTIONS MARKED OUT BY THE

FOLLOWING SIGN

THIS SYMBOL INDICATES DANGER: FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAYCAUSE INSIDIOUS OR EVEN FATAL INJURY.

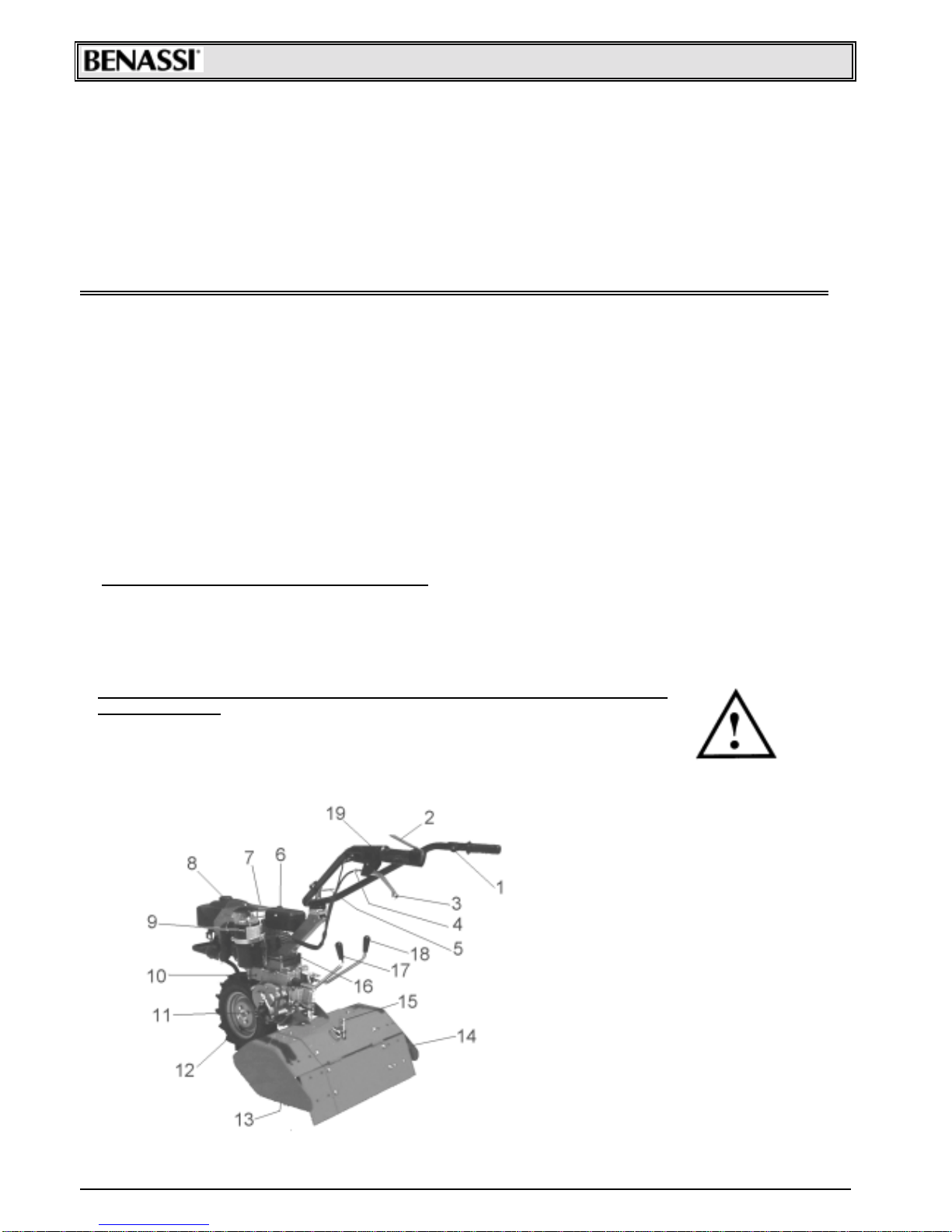

3 – TECHNICAL DETAILS LIST OF MACHINE PARTS

1. Accelerator

2. Stop engine

3. Clutch lever

4. Clutch adjuster

5. Handle-bar adjuster

6. Tool-case

7. Start engine

8. Fuel inserting

9. Air filter

10. Oil level

11. Power take-off

12. Driving wheel

13. Mill

14. Mills bonnet

15. Bonnet adjustment

16. Oil inlet

17. Mills lever

18. Gearbox lever

19. Blocking push button

SpA RT 80

3

ENGINE MINSEL COMPACT 7 HP

CYCLE 8

STROKE 2

FUEL TYPE Gasoline-oil mixture 4%

DISPLACEMENT 148 cc.

NET W EIGHT Kg. 100 complete with accessories

RPM 4500

MAX. POW ER OF THE DRIVING SHAFT 6 HP (Kw. 4,4) whit a consumption of 2,0 Kg/H

CLUTCH Oil bath cone clutch

GEARBOX Oil bath gearbox, four forward speeds and 1 reverse speed.

HANDLE-BAR Height and side adjustment

W HEELS 3.50.8 rubber or metal wheels

MOVING SPEED with:

•tyres 3.50.8

•the engine at 5.000 RPM

GEAR FORW ARD SPEED : Km/h REVERSE SPEED : Km/h

1° 1.5 2.6

2° 3.2

3° 4.5

4° 9.4

The engine fitted on this cultivator has following features:

• Exhaust guard

• Recoil starter

• Oil bath air filter

• Safety device for both forward and backward gear stopping the tiller.

• Standard handlebar with vertical and side adjustment. MACHINE IDENTIFICATION

The machine can be identified through its gearbox unit model and serial

number. The motor serial number is printed on the motor plate or on the motor

carburetor manifold by the manufacturer.

The machine identification data are reproduced on a plate located on the handle-

bar support (right-hand side looking from the operating position), and the serial

number is reproduced both on the motor flange and on the unit (see picture

sideways)

Copy the plate data and the complete serial number on this manual in order to

have them at hand when necessary.

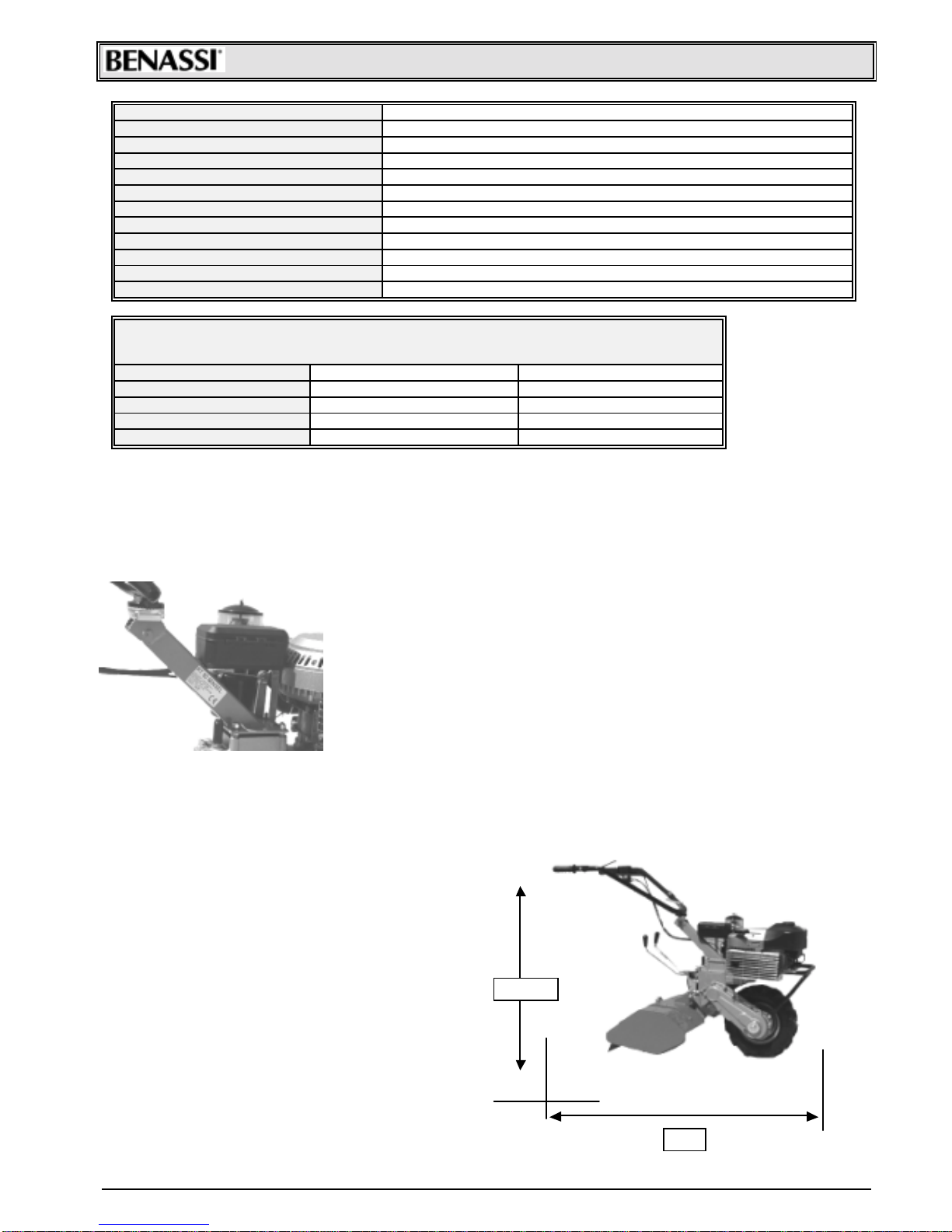

4 - PACKING AND TRANSPORT

The machine is generally supplied without its accessories, in carton boxes having the following overall dimensions:

• WIDTH : cm. 95

• HEIGHT: cm. 42

• LENGTH : cm. 85

• NET WEIGHT : Kg. 75 (without rotary tiller)

During start-up the total exclusion of kinematic motions

through blocking push button on clutch is scheduled

Accessories are generally supplied separately from the

machine, with or without packing

Free the machine from its packing in order to prepare it to

operate in the following way:

a) Open the packing and free the machine from it, with the

help of another person lift the machine: one taking it from

the wheels, the other from the handle-bars;

b) Adjust handle-bars as desired;

c) Apply the accessories

1410

98+-15

SpA RT 80

4

5 -ACCESSORIES

Spacer with pin for 2^ wheel

application

Cod. 94904400

Front ballast Kg. 21,5

Cod. 98000402

Second rubber wheel 3.50.8

Cod. 97004400

Wheel ballast Kg. 9,5

Cod. 98060100

1^iron wheel

Cod. 97004300

Adjustable furrow-opener with

connection

Cod. 91002511

2^iron wheel

Cod. 97004500

(it is necessary to apply a

spacer cod.94904400)

6 - SAFETY RULES AND LIMITS ON USE

IMPORTANT:

Before using the machine read carefully this operation and

maintenance manual; It will allow you to get from your machine the

best performance of use and duration.

• The use of the machine is forbidden to persons younger than 16 years.

• The operator is responsible of any possible damage and he should always drive the machine carefully and safely.

• Before carrying the machine always empty the fuel tank.

• Before leaving the machine be sure that it is fully stopped.

• Never use the machine without heavy shoes and long transfers. Always inspect the area where you want to work

taking off stones, branches, cables and any other thing which can be dangerous.

• Before starting working, make sure that a radius of minimum 5 m. is completely free.

• Clean any possible leakage of fuel.

• Fill up when the engine is off and not hot, always in an open space far from fires or any heating source and refrain

from smoking during this operation.

• Before starting the machine make sure that you can quickly stop the engine and that you are familiar with the control

levers.

• Never allow the engine to run in enclosed spaces where the highly toxic carbon monoxide could not evacuate.

• Never start or use the machine not completely assembled especially concerning the safety devices and the tiller

protection guards which should always be completely assembled with all its extensions.

• Never fix or clean the tiller blades or any other tools when the engine is running.

• Never work in over 50% sloping ground.

• We are not responsible for accidents due to the wrong use of the machine neglecting the above basic instructions.

• The elimination of the lubricants used must be carried out according to the norms existing in the country of use.

7 – STARTING AND STOPPING

Whenever you set about starting a cold engine, make sure :

• That the gasoline cock “A” is always open. The lever must be

placed towards the outlet pipe.

• That the gasoline has reached the carburetor. If so, by pumping

piston “B”, the gasoline will drop down from the hole on the

upper section of carburetor.

• Then, turn the accelerator control lever placed on the handle-bar

of about ¼.

• Check that the gear-lever and the mill-control lever are idle.

SpA RT 80

5

Check that stop lever and clutch lever are blocked through the

blocking push button (Ref. ”F”)

• Seize the starting-handle “C” by one only hand, pull it gently until the ratchet

gear is engaged. Then give a pull. The cord must never be left free quite

suddenly with the engine running, but followed till when it’s completely

winded-up.

8 - OPERATING AND REGULATING THE MACHINE

The refuelling must be always performed before starting the work, with cold and

stopped engine, using a funnel, and in the open air.

If fuel comes out from the tank, move the machine at once before starting the engine

and dry well the parts wet of gasoline.

We recommend to use always a funnel with a net-filter in order to keep back the

possible impurities.

FUEL-TYPE: gasoline-oil mixture 4%

SAFETY LEVER : The motor hoe is provided with a red safety stop lever connected

to the clutch lever (Ref. G)through side blocking push button (Ref. “F”).

The main function of this lever consists in stopping the engine in the moment in which

the hands are removed from the driving-beams.

It’s recommended not to bind the stop-engine lever “E” to the handle-bar hand-grip.

CLUTCH LEVER : To assure a regular clutch working it is a good rule to check from

time to time the play that the clutch-lever must have: (as shown in the picture) the

lever idle-stroke must be from 8 to 10 mm. In the opposite, act on the adjuster (G)

increasing or decreasing the play according to the need.

DRIVING-BEAMS :

Adjustable in height and transversally, with possibility of locking in the wished

position. This operation must be carried out by means of the screw-handle (“A”) placed

on the lowest section of driving-beams.

SPEED AND MILL CONTROL LEVERS :

The shifting of speed-lever (Ref. “I”)must always happen under the following

conditions:

• With engine idling

• With the hand-clutch-lever (Ref. G) pulled towards the hand-grip.

Anyhow, never force the lever in its shifting.

ATTENTION: The mills rotation must never occur, when the machine is in reverse speed, an

inner lever-system disengages the mill or the reverse-speed.

FUEL INLET

FOR

REPLENISHING

SpA RT 80

6

If this should not occur, apply to a skilled workshop by our concessionary agents.

In the picture, turning lever “A” left the rotary tiller is activated, on the contrary turning it right it is stopped.

POWER TAKE-OFF :

The motor hoe is equipped with a lateral power take off, which may be

employed both with stopped and running machine.

The power take off and its own couplings are unified with most of commercial

fittings.

POWER TAKE-OFF OUTLINE:

Splined 16 UNI 221X120 mm. Working

Turning direction: left.

Max. rev. 440 at 5,000 engine/RPM.

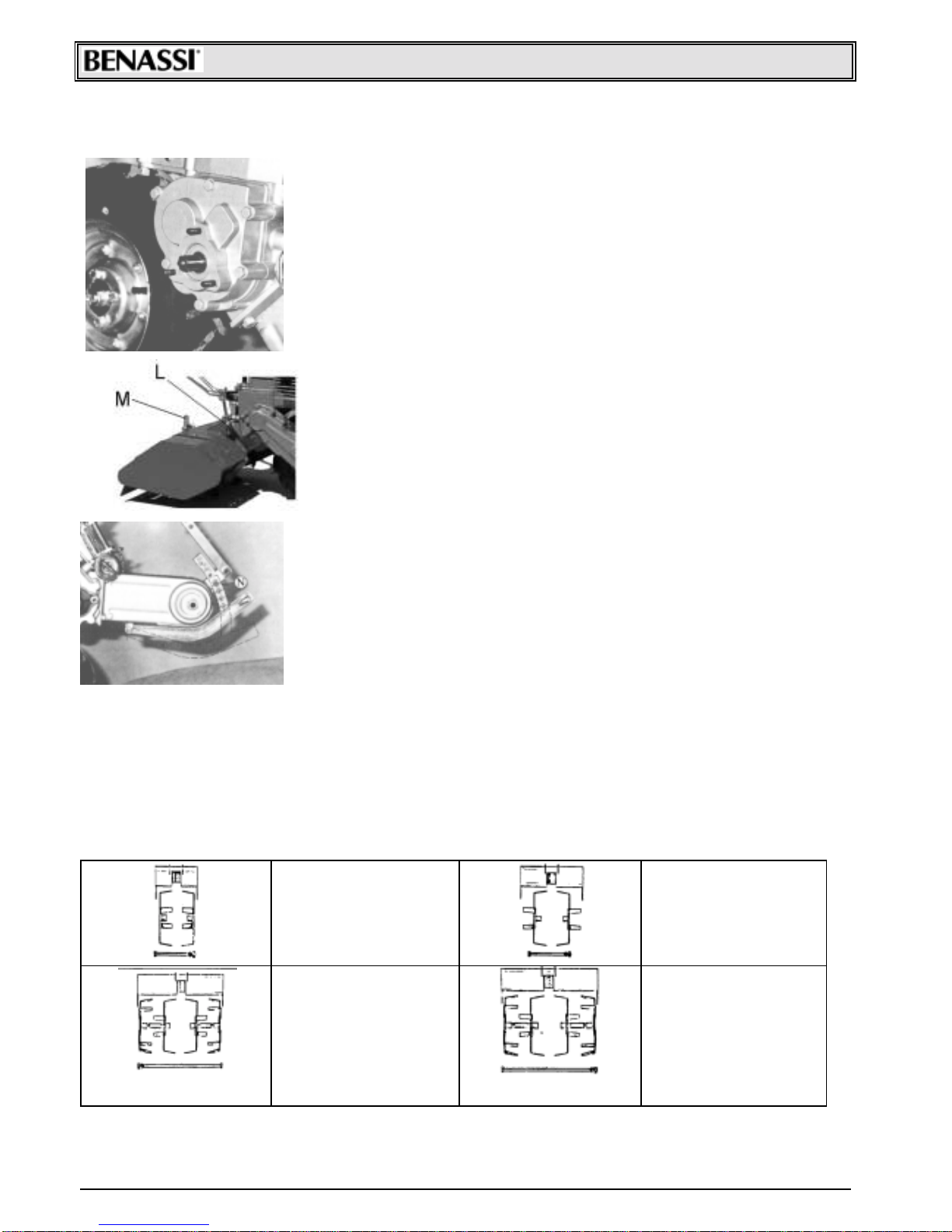

MILL BONNET :

The milling-depth may be adjusted as follows: for working on the surface,

it’s recommended to keep the safety-mill-bonnet lowered.

For a deep working, to sink more in the ground.

For these operations it’s sufficient to act on the pin fixing the bonnet “L” and on

adjusting pin “M”.

DIRECTION - JOINTER :

For getting a more regular machine advancement it is sufficient to operate the

adjustable direction-jointer.

When working on soft ground, it is required to keep the spur up, to help the

machine advancement.

On solid ground it’s right to keep the jointer down, so that sinking in the earth it

prevents a too quick machine advancement.

For this adjustment, act on the pin “N” fixing the jointer.

The machine presented in this manual has been designed to be used only in

agriculture and especially for ground milling.

Any different use is considered contrary to its proper use.

The builder does not assume responsibility for damages or injuries due to improper

use of the machine.

According to the norms, even the respect of the operation, maintenance, and repairing conditions fixed by the Firm

BENASSI SPAis part of a correct use

The machine can be operated, maintained and repaired only by those operators who have read this manual and are

informed of possible dangers.

Any arbitrary modification on the machine exempts the Firm BENASSI SPAfrom any responsibility in case of

damages. 9 – MILL ASSEMBLING

WORKINGWIDTH :18cm.

2 one-side joiners

1 pin cm.17

1 bonnet cm.18

WORKINGWIDTH :26cm.

2 two-side joiners

1 pin cm.17

1 bonnet cm.26

WORKINGWIDTH :32cm.

2 two-side joiners

2 one-side joiners

2 spacers

1 pin cm.31

1 bonnet cm.33

WORKINGWIDTH :38cm.

2 two-side joiners

2 one-side joiners

2 spacers

1 pin cm.36

1 bonnet cm.38

SpA RT 80

7

WORKINGWIDTH :45cm.

4 two-side joiners

2 spacers

1 pin cm.36

1 bonnet cm.45

WORKINGWIDTH :58cm.

4 two-side joiners

2 one-side joiners

4 spacers

1 pin cm.55

1 bonnet cm.58

WORKING WIDTH : 65 cm.

6 two-side joiners

4 spacers

1 pin cm.55

1 bonnet cm.65

10 - MAINTENANCE AND LUBRICATION

PLUG-CONTROL :

From time to time it’s necessary to check the plug wear-level and the

electrodes-distance, which must be of 0.5 mm , as shown in the near drawing.

AIR FILTER CLEANING :

This operation must be performed regularly in the following way:

• clean the filter externally, so to avoid that some earth falls inside during the

disassembling.

• Loose the clips “P”, remove the oil-cup “Q”, take away the filter-element “R”

and wash carefully the different parts with gasoline oil.

• Fill the cup with new oil till reaching the level, as pointed out in the picture.

OIL INLET BLEED :

Every component of the gear-box and transmission is in oil-bath. It’s

necessary to check from time to time the oil-level through screw “S” and fill it up

again, if required, through the vent plug “T”.

USE ONLY OIL FOR TRANSMISSION SAE 30

FRONT-WHEEL OIL LEVEL PLUG :

Check from time to time the oil level on the front wheel through plug “U”, placed

on one side, as shown in the picture. For a perfect machine efficiency, a good

maintenance and a perfect lubrication are necessary.

Check that air filter is clean, in case of oil bath filter check level every 8-10

operating hours or even more frequently when working in dusty grounds. Use motor

oil to restore oil level and clean the cup before filling it.

GEARBOX Check oil level every 50 operating hours removing the cap on the

gearbox sump keeping the machine in horizontal position.

If necessary add SAE 30 oil. It is advisable to replace oil at least every 100

hours.

MILLS Before starting to work check that all screws are tight, check especially

rotary tiller hoe fastening screws.

SpA RT 80

8

11 - END-OF-SEASON MAINTENANCE

OIL DRAG PLUG :

For whatever mechanical repair in the ear-box or in the mill-descent, it’s

necessary to remove the oil.

To make the transmission empty, unscrew the plug “V” placed in the lowest

section of the gear-box.

Before parking the machine:

• wash it accurately with gas oil,

• empty the carburetor tank and clean or replace air filter,

• lubricate and grease all articulated joints and gears,

• replace or repair possible worn parts,

• lubricate cylinder with motor oil through the spark plug hole, pull the start-up

cord so that the piston makes some strokes

• Park the machine in a dry place with wheels on wood tables or even better with wheels up from the floor.

12 - POSSIBLE PROBLEMS AND SOLUTIONS

Possible problems that can be solved by the machine operator:

MOTOR - The motor does not start; check that:

• the gasoline in the tank is more then half.

• the gasoline cock is open

• if the motor is cold , the starter lever is pulled

• the gasoline reaches the carburetor

• the bleed on the tank cap is not clogged

• carburetor jets are not clogged, if necessary, clean

them with air jet

• the spark plug sparks, in order to carry out this check

operation unscrew the spark plug; connect it to the power

supply cable, place the spark plug earthed metal part

(motor cylinder) and make the motor pulley turn as in the

start-up phase. If electrodes do not spark, check the

supply cable junctions, and if this does not solve your

problems, replace the spark plug with one of the same

type. If even this time you should not obtain positive

results, the defect concerns the electric plant (points,

condenser, coil etc.)In this case it is advisable to contact

the nearest service (according to the motor assembled on

the machine).

13 - INSTRUCTIONS FOR A GOOD OPERATIONOF THE MACHINE

• Carry out a good breaking-in of the motor and of the

machine (for at least 10 hours do not exceed 70%of motor

power)

• always use the clutch before using any lever

• do not keep the clutch disengaged for long periods of

time

• never force gear levers, if you cannot engage them,

jerkily release the clutch

• never force the motor.

• do not work at full speed for long periods, in particular

during hot days

• periodically check tyres pressure ( Atm. 1.3)

• when assembling the different tools, do not damage

shaft spigot and spline, check that tool screws and lockpin

are tight, in particular the rotary tiller hoe screws and the

screws fastening the mowing bar

• do not leave the machine in the rain.

IMPORTANT: using the machine for a

long time you should use ear

protection system.

SpA RT 80

9

TESTS FOR CE CERTIFICATION

EC Certificate of conformity conforming to EEC directions 89/392

40010 SanMatteo della Decima BO Italy Via Lampedusa n°1 Tel. (051) 682.46.56

Declare in sole responsibility, that the product CULTIVATOR RT 80 to which this certificate applies, conforms

to the basic safety and health requirements to EEC directions 89/392 and to the other relevant EEC directions : PREN

709/94 - N67 CEN TC 144/WG4 - PREN 836/92 - EN 294.

THE PRESIDENT

S.Matteo della Decima li 20 -12 - 1994

TEST AND RESULT

TYPE: CULTIVATOR MODEL RT 80

Noise level at operator’s ear : LAeq = 87,1 dB (A)

Test condition: 1,6 Mt at the center of the handlebar

Handlebar vibration according to ISO.5349 : 5,7 m/sec2

SpA RT 80

10

S.p.A.

Via Lampedusa,1 - 40010 S. MATTEODELLADECIMA (BO) - ITALY

TEL. 0039/051/82.05.34 TELEFAX 0039/051/682.61.64

Table of contents

Other Benassi Lawn And Garden Equipment manuals