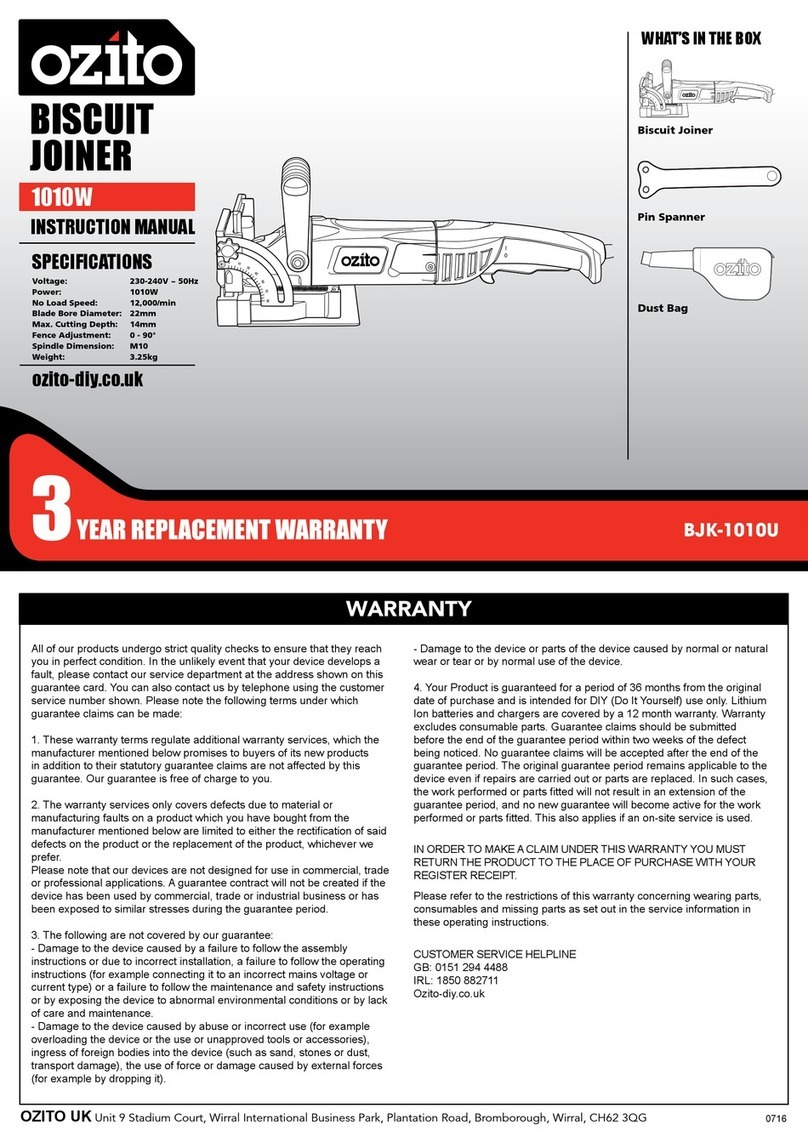

Benchmark 1261-000 User manual

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

4006849

M1K-ZK5-100

120V 60Hz 5.9Amp

5 year limited warranty on tool

BISCUIT JOINER

1

PRODUCT SPECIFICATIONS

5.9 AMP BISCUIT JOINER

Voltage 120V~ 60Hz

Rated Power 5.9A

Blade Diameter 4" (100mm)

No-load speed 11600 /min

Arbor 7/8" (22mm)

Blade diameter 4" approx. (100mm)

Fence adjustment range 0-90

Fence height adjustment range 0 - 1-9/16” (0 – 40mm)

Cutting depth: 0 - 3/4” (0 - 19mm)

Weight 5.8 lbs (2.65kg)

NEED ASSISTANCE?

Call us on our toll- free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package

1261-000

BISCUIT JOINER

2

TABLE OF CONTENTS

Product Specifications .................................................................................. 1

Table of Contents .......................................................................................... 2

General Safety Warnings ............................................................................... 3

General Power Tool Safety Warnings............................................................... 5

Work Area Safety ........................................................................................... 5

Electrical Safety............................................................................................. 5

Personal Safety ............................................................................................. 5

Specific Safety Rules for Biscuit Joiners ........................................................ 7

Safety Symbols ............................................................................................. 9

Know Your Biscuit Joiner.............................................................................. 10

Assembly .................................................................................................... 11

Operation .................................................................................................... 13

Maintenance ............................................................................................... 18

Troubleshooting........................................................................................... 20

Exploded View ............................................................................................ 21

Parts List .................................................................................................... 22

Warranty ..................................................................................................... 24

3

GENERAL SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all safety and operational instructions. Failure to follow the

safety rules listed below and other basic safety precautions may result in serious

personal injury. Keep this manual, sales receipts and applicable warranty forms

for future reference.

SAFETY SYMBOLS

The purpose of safety symbols is to alert you of the potential safety RISKS.

Recognize and understand them. Follow the instructions provided.

SYMBOL MEANING

Failure to obey a DANGER safety alert WILL result in serious personal

injury or death to you or to others. Always obey all messages following

this symbol to reduce the risk of serious personal injury or death.

Failure to obey a WARNING safety alert MAY result in serious personal

injury or death to you or to others. Always obey all messages following

this symbol to reduce the risk of potential serious personal injury or

death.

Failure to obey a CAUTION safety alert MAY result in personal injury

or property damage to you or to others. Always obey all messages

following this symbol to reduce the risk of personal injury or

property damage.

Failure to obey a NOTICE or a CAUTION (without a safety alert)

MAY result in property damage to you or to others. Always obey all

messages following this symbol to reduce the risk of property damage.

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CSA

Z94.3 or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection. The

usage of a safety standard compliant face shield placed over proper

safety glasses or goggles can reduce the risk of facial injury.

Non-compliant eyewear can cause serious injury if broken during

the operation of a power tool.

Use hearing protection, particularly during extended periods of

operation of the tool, or if the operation is noisy.

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

Refer to Page 7 of the manual for California Prop 65 warnings relating

to hazardous dust particles/

1261-000

BISCUIT JOINER

4

SYMBOL MEANING

Always wear non-slip gloves that fit properly to protect your hands

and to help you grip the tool.

Always wear sturdy clothing with long sleeves and long pants.

Never operate the tool while wearing shorts, short sleeve shirt or

while shirtless.

Always wear non-slip safety boots to prevent foot injuries

and slipping that could cause loss of control of the tool.

To avoid electrical hazards, fire hazards or damage to the tool,

use proper circuit protection.

This tool is wired at the factory for 120 V AC operations.

It must be connected to a 120 V AC, 15 A circuit that is protected by

a time-delayed fuse or circuit breaker. To avoid shock or fire, replace

power cord immediately if it is worn, cut or damaged in any way.

WARNING: Ventilation openings in batteries and chargers must

always be open to allow cooling air to circulate freely. Air vents that

are blocked, restricted or covered may result in the battery or charger

overheating. Overheating may lead to damage to the tool or cause a

fire, resulting in possible serious injury.

5

GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in

the warnings refers to your mains operated (corded) power tool or battery-operated

(cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerator. There is an increased risk of electric shock if your body

is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges and moving parts.

Damaged or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location is unavoidable,use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the o-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools

that have the switch on invites accidents.

1261-000

BISCUIT JOINER

6

• Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

• If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which

it was designed.

• Do not use the power tool if the switch does not turn it on and o. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may aect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations dierent from those intended

could result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

7

SPECIFIC SAFETY RULES FOR BISCUIT JOINERS

WARNING

Serious cuts, amputation, or death can occur from contact with rotating saw blade

during operation. Workpieces, broken blades, or flying particles thrown by blade

can blind or strike operators or bystanders with great force. To reduce the risk of

these hazards, operator and bystanders MUST completely heed the hazards and

warnings below.

PROPERLY MAINTAIN BLADE. Always ensure Biscuit Joiner blade is sharp,

undamaged, and tightly attached before each use.

AVOID TOUCHING BLADE. Never place hands or fingers between work- piece

and blade, and do not perform a cut while supporting workpiece with one hand or

balancing it on a leg or any other body part.

PROPERLY SUPPORT WORKPIECE. Properly support all workpieces to reduce

risk of workpiece and tool slipping during cutting operation. Place workpiece on

supports or workbench and clamp in place.

USE BISCUIT JOINER FOR INTENDED PURPOSE. Only use Biscuit Joiner on

wood and wood-based products. Do not attempt to use this tool for any operation

other than biscuit joining.

USE RECOMMENDED BLADES. Only use blades rated for speeds greater than

11,000 RPM. Blades not rated for this speed may fly apart. Only use blades that

meet the specifications listed in the manual. Do not use blades with dierent

diameters or arbor hole shapes/sizes. They will rotate irregularly, causing ejection of

blade fragments and tool damage.

PROPERLY INSTALL COMPONENTS. Ensure sliding base, faceplate, and fence

are in place and operating correctly before each cut.

STARTING AND STOPPING CUTS. Allow blade to reach full speed before cutting.

Always allow blade to come to a complete stop before setting tool down.

MAINTAIN CONTROL OF TOOL. Hold tool with both hands and do not allow the

Biscuit Joiner base to shift while performing plunge cuts. Always use the guard. The

guard protects the operator from broken blade fragments and unintentional contact

with the blade.

• Hold the power tool by its insulated gripping surfaces, because the blade may

contact its own cord. Cutting a “live” wire may make exposed metal parts of the

power tool “live” and could give the operator an electric shock.

• Always use correctly sized blades with the fitting mounting bore. Blades that do

not fit to the mounting components of the biscuit joiner rotate irregularly and

lead to loss of control.

• Do not use blunt or damaged blade. Blunt or damaged blades cause increased

friction, can become jammed and lead to imbalance.

• Before putting into operation, check that the guard is retracting freely.

• Always wear hearing protection when operating the biscuit joiner.

1261-000

BISCUIT JOINER

8

CAUTION:

Like all machinery there is potential danger when operating this tool. Accidents

are frequently caused by lack of familiarity or failure to pay attention. Use this tool

with respect and caution to decrease the risk of operator injury. If normal safety

precautions are overlooked or ignored, serious personal injury may occur.

SAVE THIS USER MANUAL

WARNING

MISUSE or failure to follow the safety rules stated in this instruction manual may

cause serious personal injury.

MINIMUM GAUGE (AWG) EXTENSION CORD (120 V use only)

Amperage rate Total length

More than Not more than 25' (7.5 m) 50' (15 m) 100' (30 m) 150' (45m)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

9

SAFETY SYMBOLS

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

WARNING: Please read all of the safety and operating instructions

carefully before using this tool. Please pay particular attention to all

sections of this User Guide that carry warning symbols and notices. Some

of the following symbols may be used on this tool.

Observe caution and safety notes.

To reduce the risk of injury, user must read and understand User Guide

before using this tool.

Wear ear protection.

Wear protective helmet and eye protection.

Switch o and remove plug from power source before cleaning or

maintenance.

Do not use in the rain or leave outdoors while it is raining.

Keep bystanders away.

Don’t touch the inlet and outlet when the vacuum cover is opened or the

tube is removed.

Double insulation.

Remove plug from the power source immediately if the power cord is

damaged or cut.

This symbol designates that this tool is listed with Canadian and U.S.

requirements by ETL Testing Laboratories, Inc.

Conforms to UL Std. 62841-1:2015 and 62841-2-14:2016

Certified to the CAN/CSA Std. C22.2 No. 60745-1 and 60745-2-19

4006849

M1K-ZK5-100

1261-000

BISCUIT JOINER

10

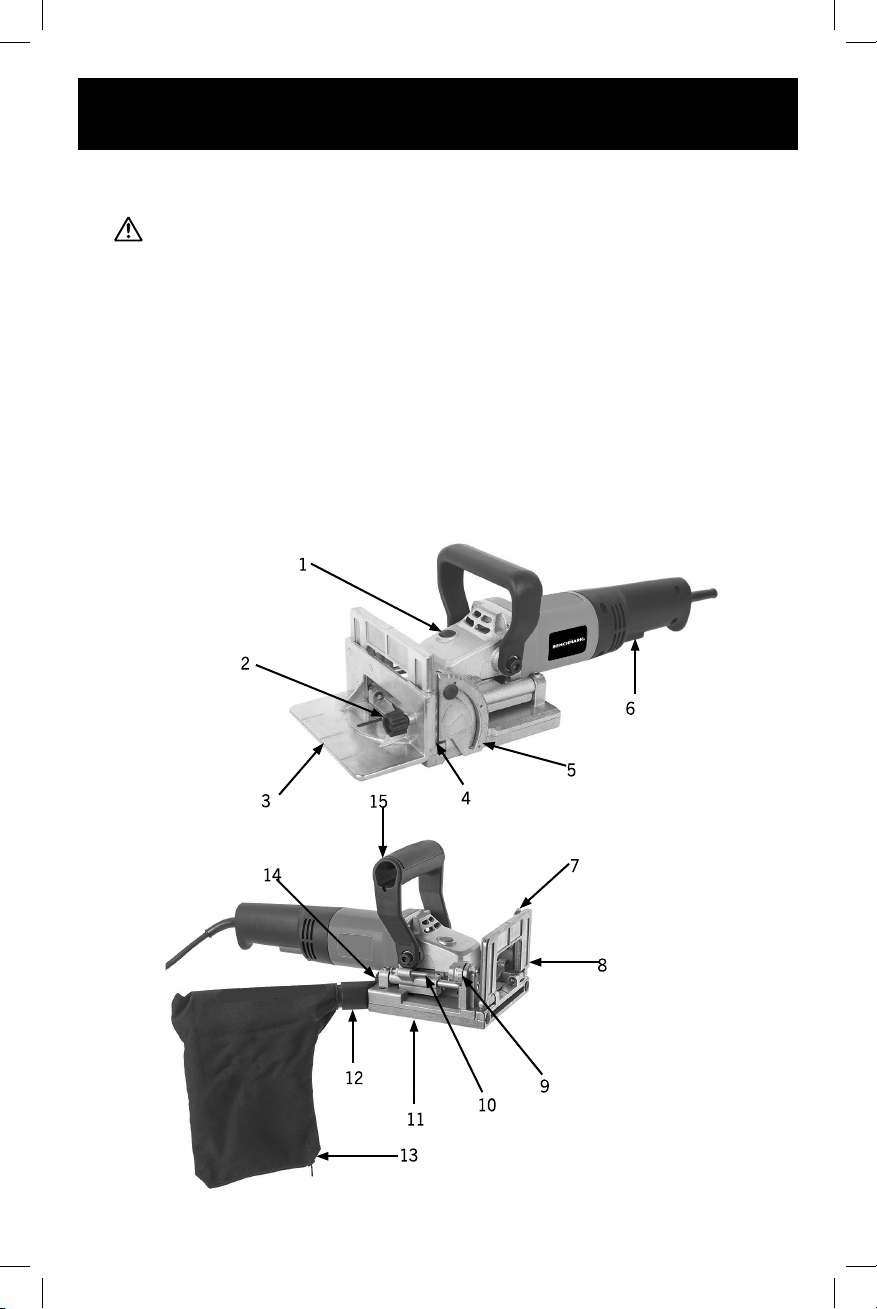

KNOW YOUR BISCUIT JOINER

ATTENTION

Always be sure that the tool is switched o and unplugged before making

any adjustments to the tool.

FUNCTIONS

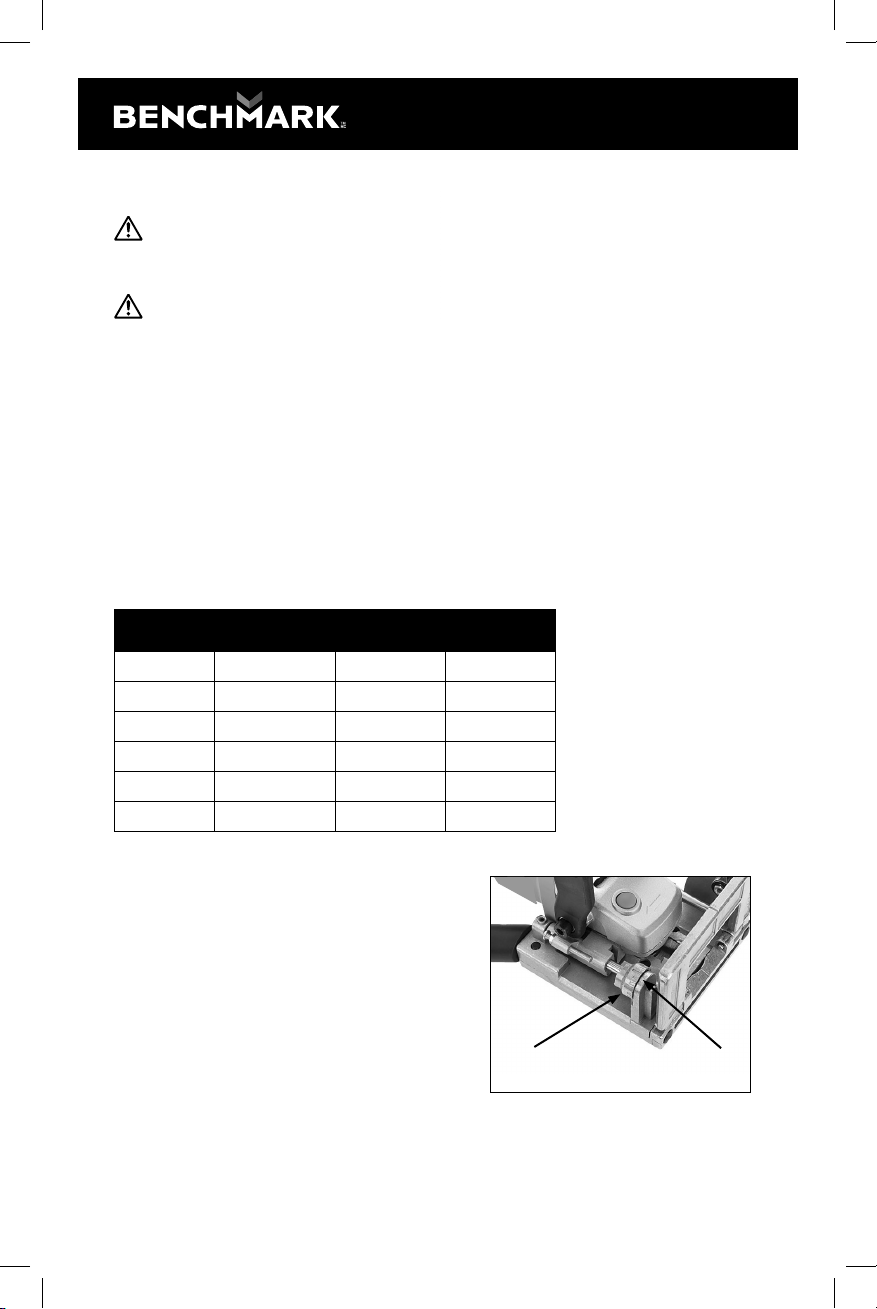

1. Spindle Lock Button 2. Fence Lock Knob

3. Fence 4. Fence Height Scale

5. Angle 6. ON/OFF Switch

7. Fence Angle Lock 8. Faceplate

9. Depth Indicator 10. Depth Stop

11. Sliding Base 12. Dust Port

13. Dust Bag 14. Blade Access Knob

15. Auxiliary Handle

ASSEMBLY

ATTENTION: Read the entire important safety information section at the

beginning of this manual Including all text under subheadings therein before set up

or use of this product.

CONTROLS & COMPONENTS

ATTENTION:

Refer to Figures 1 & 2 and the following

descriptions to become familiar with the basic

controls of this tool.

A. Spindle Lock Button: When pressed, locks

spindle for removing/replacing blade.

B. Fence Lock Knob: Locks fence at desired

height of cut.

C. Fence: Orients tool to workpiece at specified angle.

D. Fence Height Scale: Indicates distance between center of blade and bottom of

fence.

E. Angle Scale: Indicates angle of cut.

F. ON/OFF Switch: Starts and stops motor. Tool

will remain running while switch is held until

released.

G. Dust Port: Connects dust extraction system

to blade housing and prevents dust build up

during cutting operations.

H. Sliding Base: Houses blade. Spring action

retracts blade after cut.

I. Depth Stop: Contacts turret stop during

operation, limiting depth of cut.

J. Depth Indicator: Six-position turret for selecting biscuit cut depth

(0, 10, 20, S, D, and MAX).

K. Faceplate: Contacts edge of workpiece at desired location of biscuit groove.

L. Angle Lock: Locks faceplate to desired angle of cut.

WARNING

Always disconnect this tool from the power supply

before attaching or removing accessories, or making

any adjustments.

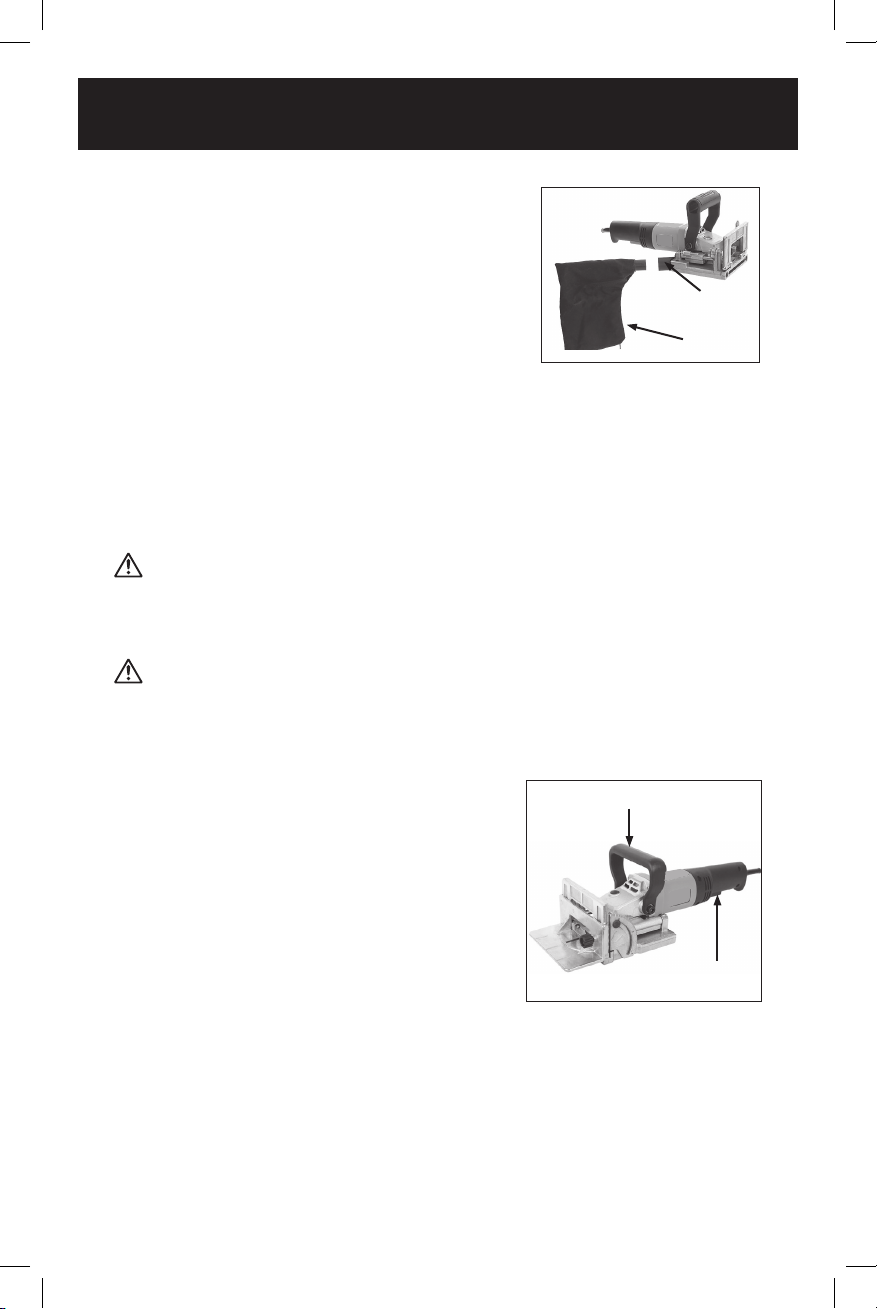

TO ASSEMBLE TOOL:

1. Loosen fence lock knob, and slide fence onto

faceplate (see Figure 6).

2. Tighten fence lock knob (see Figure 6) The

machine is equipped with a 1" dust port that can

attach to a dust collection system (not included)

or the included dust bag.

11

D

A

B

CE

F

Fig.1: Fence adjustment and power controls

Fig.2: Depth adjustment, angle lock,

and dust port.

Fence

Lock

Knob

Fig.6: Fence attached to faceplate.

Fence

Faceplate

TO INSTALL DUST BAG:

1. Push plastic end of dust bag into dust port, as

shown in Figure 7.

2. Verify dust bag is closed before operating tool.

Note: If using the dust bag, remove and clean out

on a regular basis. Ideally, empty the dust bag

when it is half full.

TEST RUN

Once assembly is complete, test run the tool to ensure it is properly connected

to power and safety components are working properly.

If you find an unusual problem during the test run, immediately stop the tool,

disconnect it from power, and fix the problem BEFORE operating the tool again.

The Troubleshooting table in the SERVICE section of this manual can help.

The test run consists of verifying the following:

1) The motor powers up and runs correctly.

ATTENTION

Serious injury or death can result from using tool BEFORE understanding its

controls and related safety information. DO NOT operate, or allow others to operate,

tool until information is understood.

ATTENTION

DO NOT start tool until all preceding setup instructions have been performed.

Operating an improperly set up tool may result in malfunction or unexpected results

that can lead to serious injury, death, or tool/ property damage.

TO TEST RUN TOOL

1. Clear away all setup/adjustment tools.

2. Verify blade is properly installed

(see Changing Blade on Page 17).

3. Connect tool to power supply.

4. While firmly holding auxiliary handle (see Figure

8) in one hand, squeeze ON/OFF switch with

opposite hand. Motor should run smoothly and

without unusual problems or noises.

5. Release ON/OFF switch. Motor should

immediately stop running.

1261-000

BISCUIT JOINER

12

Fig. 8: Location of auxiliary handle and

ON/OFF switch

Auxiliary handle

ON/OFF switch

Fig.7: Installing dust bag into dust port

Dust Port

Dust Bag

OPERATION

ATTENTION

To reduce risk of eye injury from flying chips or lung damage from breathing dust,

always wear safety glasses and a respirator when operating this tool.

ATTENTION

If you are not experienced with this type of tool, we strongly recommend that you

seek additional training outside of this manual. Read books/magazines or get formal

training before beginning any projects. Regardless of the content in this section,

Benchmark tool will not be held liable for accidents caused by lack of training.

TURNING TOOL ON/OFF

• To start the tool squeeze the On/O Trigger Switch

• Release the On/O Trigger Switch to turn o

ADJUSTING DEPTH OF CUT

The biscuit joiner can be adjusted to cut slots for standard #0, #10 and #20

biscuits, simplex fittings, and duplex hinges. Refer to the table in Figure 9 to

determine biscuit size and cutting depth.

Biscuit # Material

Thickness (mm)

Cut Depth

(mm)

Depth Indicator

Marking

#10 4 8 0

#10 4 10 10

#20 4 12.5 20

Simplex 4 13 S

Dimplex 4 15 D

N/A N/A 18 Max

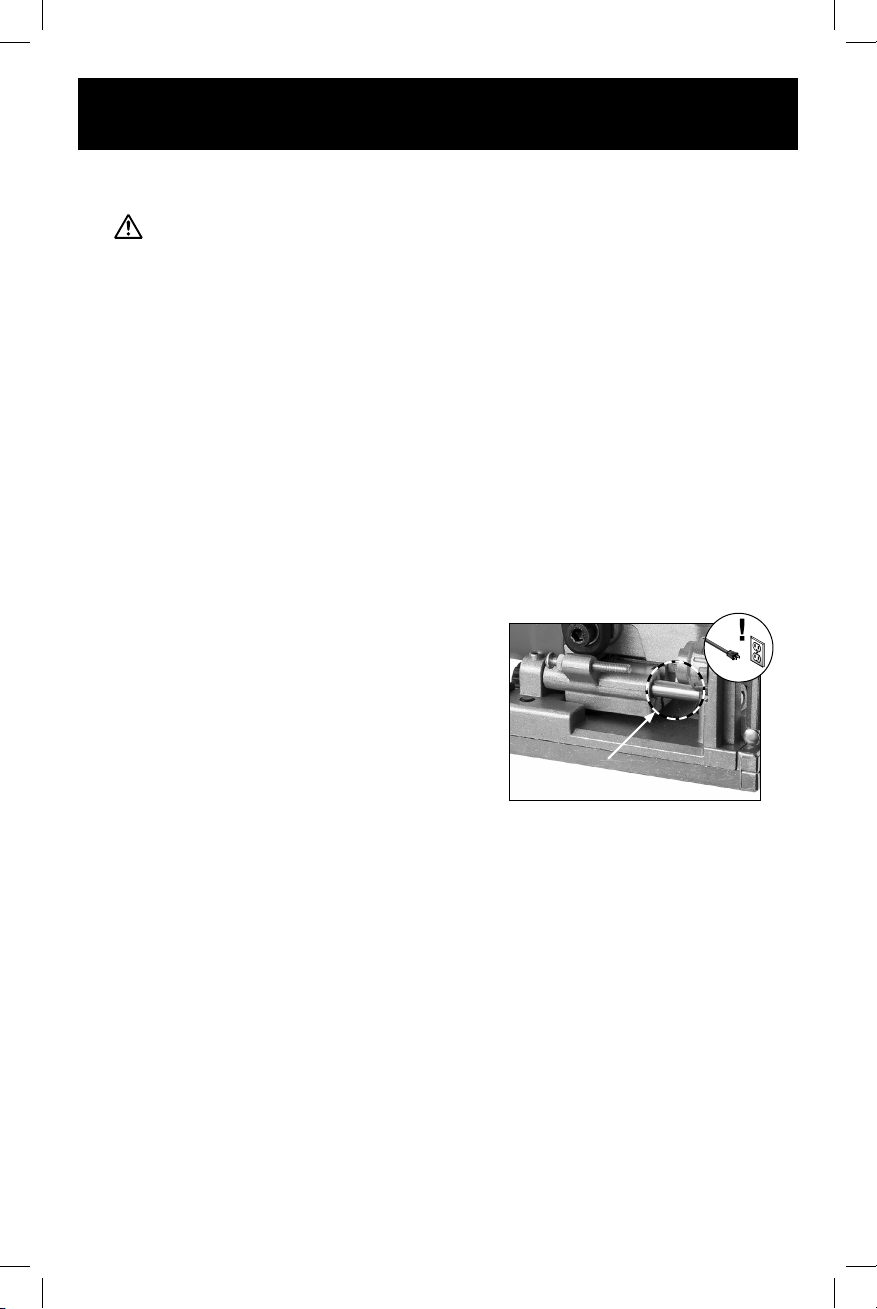

SETTING CUTTING DEPTH

1. Rotate depth indicator (see Figure 10) until

desired depth marking on indicator aligns

with arrow mark.

13

Fig 10. Depth indicator aligned with arrow mark

Depth indicator Arrow mark

Fig 9. Buiscut cut depth and depth scale marking table

ADJUSTING CUTTING DEPTH

1. DISCONNECT TOOL FROM POWER!

2. Rotate depth indicator until position "10"

is aligned with arrow mark.

3. Push forward on auxiliary handle until depth

stop contacts depth indicator and measure

length of exposed blade from blade tooth tip

to sliding base.

Note: Rotate saw blade until blade tooth tip is

centered at the maximum distance from the

sliding base.

4. Verify depth measurement as follows:

• If measurement equals 10mm, the cutting depth is properly calibrated.

• If measurement does not equal 10mm, loosen depth stop lock nut

(see Figure 11).

WARNING:

Failure to correctly adjust the cutting depth could cause damage to the workpiece.

Note: Always make a trial cut on scrap material to confirm the settings and reduce

or extend depth stop until measurement equals 10mm. Tighten depth stop lock nut

once depth is reached.

ADJUSTING CUTTING ANGLE

The faceplate can be adjusted between 0° and 90°,

though 90° is the most common angle of cut for

biscuit joining. Certain applications, such as joining

beveled edges, require the biscuit to be inserted at

Note: Ball and groove detents on the angle scale

are provided to set the angle at 0°, 45°, and 90°.

To adjust cutting angle:

1. Release angle lock (see Figure 12).

2. Tilt faceplate until desired angle on scale lines

up with arrow mark.

3. Tighten angle lock.

ADJUSTING CUTTING HEIGHT

The fence can be adjusted to a height of 0-40mm.

Cutting height depends on your workpiece

thickness. Set the cutting height to half the

thickness of your workpiece for the strongest joint.

To adjust cutting height.

1. Set faceplate angle to 90°

(see Adjusting Cutting Angle above).

1261-000

BISCUIT JOINER

14

Fig 11. Location of cutting depth

adjustment components.

Lock Nut

Depth Stop Depth

Indicator

Fig 12. Location of cutting angle

adjustment components.

Angle Lock

Angle Scale

Fence

Lock

Knob

Arrow Mark

Fence Height Scale

Fig 13. Location of cutting height

adjustment components.

2. Loosen fence lock knob and move fence up or down on faceplate until arrow

mark on angle scale aligns with desired height on fence height scale

(see Figure 13).

3. Tighten fence lock knob once desired height is reached.

WORKPIECE PREPARATION

Properly mark your workpieces to avoid incorrect biscuit placement

and wasted material.

The following example illustrates a typical biscuit joining layout.

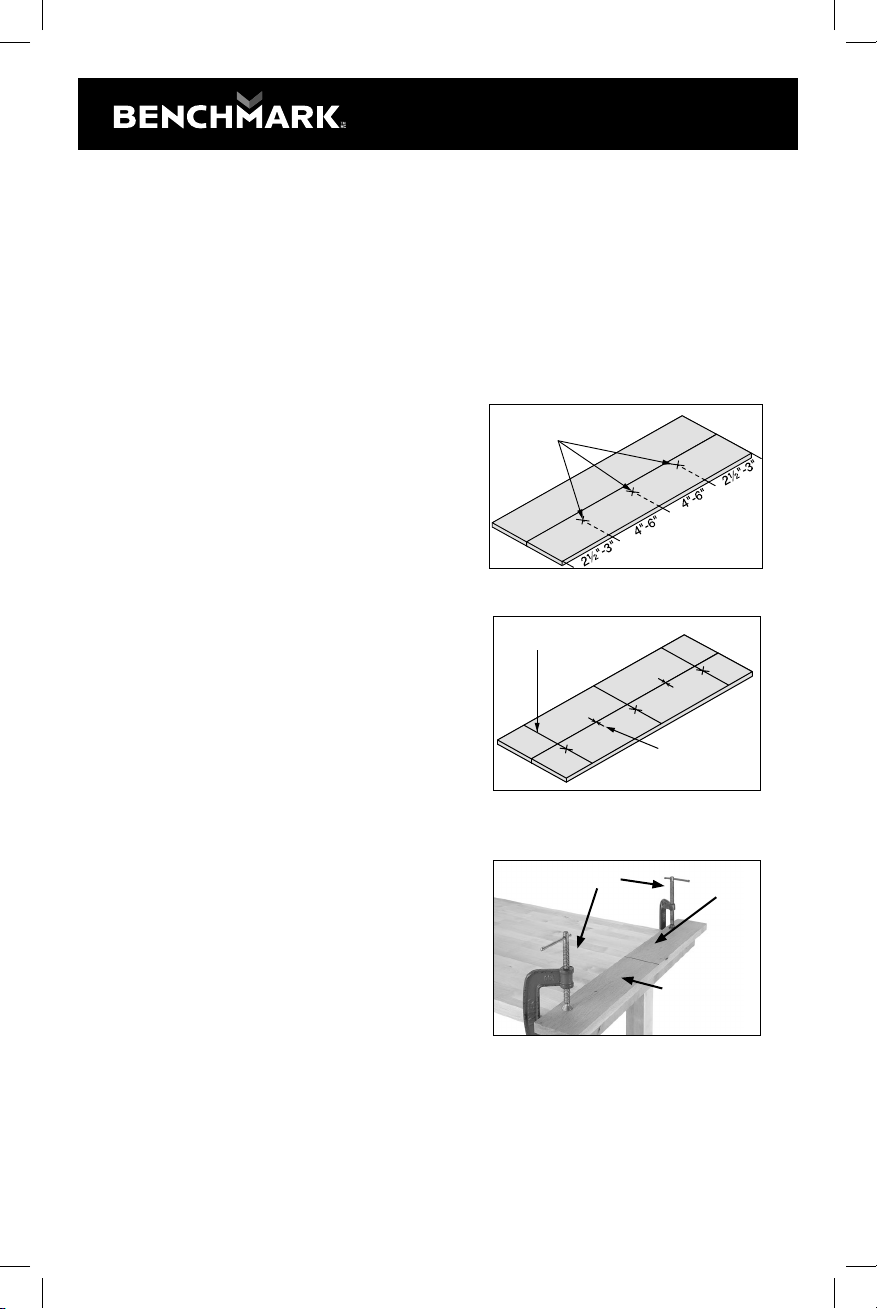

LAYING OUT CUTS

1. Place edges of (2) workpieces flush against

each other on a smooth, flat surface. Verify

board ends line up.

2. Place marks 2 1/2”- 3” from each end of one

board. Note: If distance between marks is

greater than 6", place additional marks at

4"-6" intervals (see Figure 14).

3. Use a square to draw layout lines across

boards through marks, then make

registration marks on edge of each boar

to ensure correct edge is cut

(see Figure 15).

SECURING WORKPIECE

Your workpiece must be properly secured

before making cuts. Cutting biscuit grooves with

a biscuit joiner places pressure on the edge of

the workpiece, which can cause an improperly

secured workpiece to shift on the workbench,

resulting in personal injury or damage to the

tool or workpiece.

Use clamps to secure workpiece on work-

bench. Edge of workpiece should hang slightly

over edge of workbench (see Figure 16).

Note: Clamps should be placed at least 3"

from any cut marks to prevent interference with

joiner.

15

Fig 15. Layout lines and registration marks.

Layout lines

Registration marks.

Fig 14. Biscuit location marks

Marks

Fig 16. Example of workpiece setup.

Workpiece

Center Line

Clamps

TO CUT BISCUIT GROOVES

1. Place fence on workpiece so front groove and

rear groove line up with layout line, as shown

in Figure 17. Make sure faceplate contacts

edge of workpiece.

2. Turn biscuit joiner ON and allow motor to

reach full speed.

3. With both hands holding tool, slowly push

blade into workpiece, as shown in Figure 18,

making sure joiner grooves remain aligned

with layout line on workpiece, as described

in Step 1.

4. Once blade reaches full depth, slide joiner

body backward, allowing blade to retract

into base plate.

5. Turn joiner OFF and wait for motor to come

to a complete stop before setting tool down.

GLUING BISCUITS

Once all biscuit grooves have been cut, test-fit biscuits with a "dry fit" prior to

the glue-up. Place a biscuit in each groove, and fit the pieces together to check

for proper alignment.

Once a proper fit is verified, apply glue to workpiece edges and grooves, insert

biscuits into grooves, then clamp according to the needs of the material and

the glue manufacturer's instructions.

CHANGING BLADE

This tool accepts 4" blades with either a 20mm or 22mm bore, depending

on the position of the inner flange.

ATTENTION

To reduce risk of injury, always disconnect power from joiner before changing

blades. Since blade is sharp, use extra care and wear gloves when installing it.

1261-000

BISCUIT JOINER

16

Fig 17. Biscuit joiner aligned with workpiece.

Front Groove

Layout Lines

Rear Groove

Fig 18. Biscuit joiner operation

TO CHANGE BLADE:

1. DISCONNECT TOOL FROM POWER!

2. Loosen fence lock knob and then slide fence up

to remove it from faceplate (see Figure 19).

3. Turn tool over so bottom of sliding base is

facing upward.

4. Loosen blade access knob (see Figure 20) until

the sliding base lid can be raised.

5. Press spindle lock button (see Controls &

Components on Page 10) and use spanner

wrench to turn outer flange until spindle lock

engages spindle (see Figure 21).

6. Continue to press spindle lock button, and use

spanner wrench to loosen outer flange.

7. Remove blade and outer flange from spindle.

Note: If switching between blades with 20mm and

22mm bores, flip inner flange over before installing

new blade to accommodate change in bore size

(see Figure 22).

8. Install new blade, verify teeth face correct direction for rotation of spindle, as

shown in Figure 23

9. Place outer flange on spindle, press spindle

lock button, and tighten outer flange with

spanner wrench.

10. Close sliding base lid and tighten blade

access knob.

11. Install fence to desired height, as shown in

Adjusting Cutting Height on Page 13.

17

Fence

Faceplate

Fig. 19. Fence removed from faceplate

Fig. 20. Loosening blade access knob.

Sliding Base

Blade

Access

Knob

Out

Flange

Fig. 21. Removing blade with spanner wrench

Fig. 23. Blade installed with teeth

correct direction.

Inner

Flange

Blade

Spindle

Outer

Flange

Fig. 22. Proper orientation

of blade components for assembly.

MAINTENANCE

ATTENTION

Always DISCONNECT POWER before servicing, adjusting, or doing maintenance

to reduce risk of accidental injury or electrocution.

For optimum performance from this tool, routinely check the condition of the

following items and repair or replace as necessary.

• Loose bolts

• Damaged bits

• Worn or damaged wires

• Any other unsafe condition

CLEANING

Use a brush and a shop vacuum to remove wood chips and other debris from the

tool, particularly from around the blade slot on the sliding base. Never blow o

the tool with compressed air, as this could force wood chips deeper into the motor

vents. Use a clean cloth to wipe away any dust remaining after each operation.

Note: DO NOT use caustic cleaners on plastic parts. If dry cleaning is insucient,

a mild detergent on a damp cloth is recommended.

Keep water away from tool at all times.

LUBRICATION

Periodically lubricate all moving parts with a light

machine oil as needed. Place a drop of oil on the

guide rails on both sides of the sliding base (see

Figure 27), then slide the base back and forth,

working the oil across the rails. Use a clean rag to

wipe o any excess oil, which can collect sawdust

or stain the workpiece.

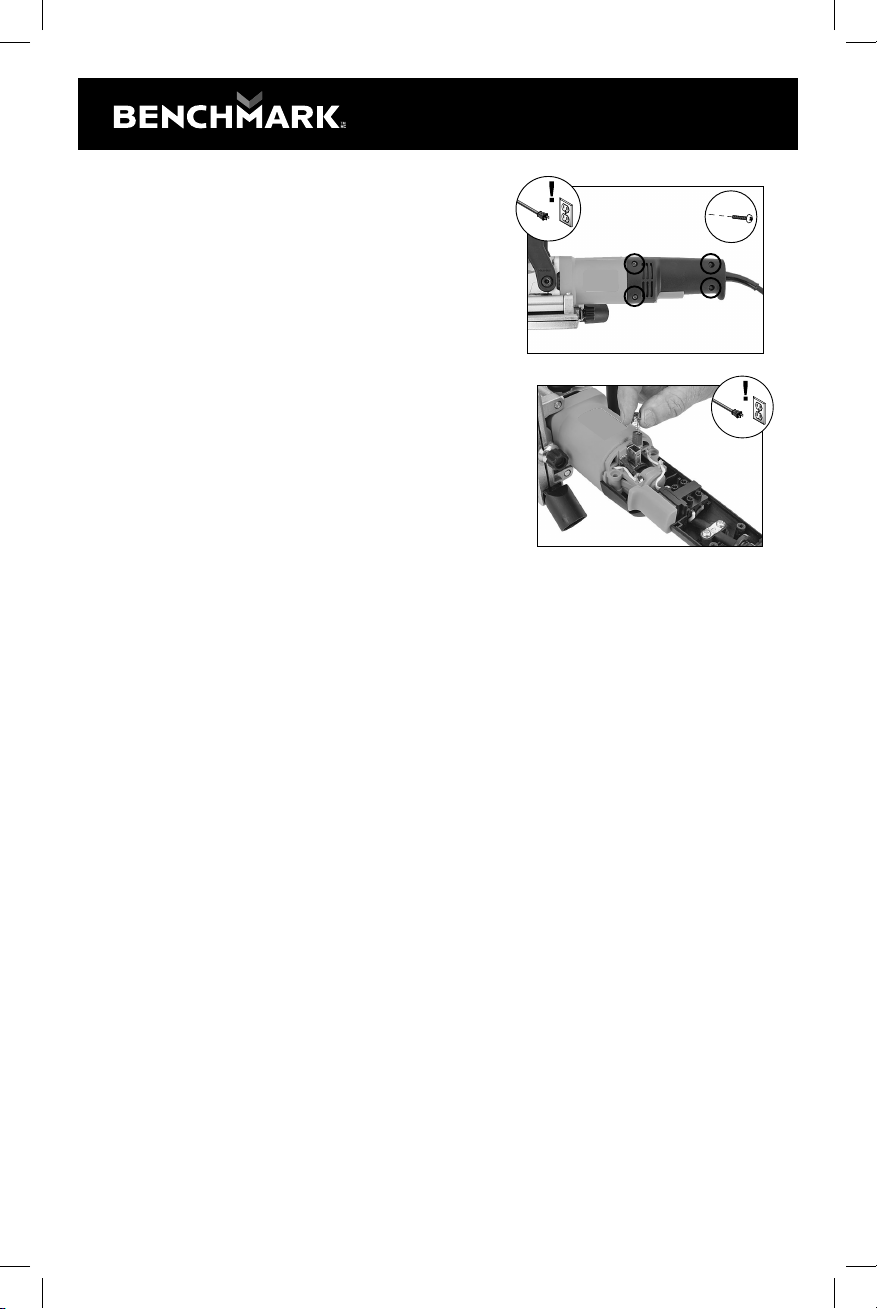

REPLACING BRUSHES

This tool is equipped with a universal motor that uses two carbon brushes to

transmit electrical current inside the motor. These brushes are considered to be

regular "wear items" or "consumables" that will need to be replaced during the life

of the motor. The frequency of required replacement is related to how much the

motor is used and how hard it is pushed. Replace both carbon brushes at the same

time when the motor no longer reaches full power, or when the brushes measure

less than 1/4" long (new brushes are 5/8" long).

1261-000

BISCUIT JOINER

18

Fig. 27. Location of sliding base

guide rail (1 of 2).

TO REPLACE MOTOR BRUSHES:

1. DISCONNECT TOOL FROM POWER!

2. Remove (4) tap screws from left side of main

joiner handle (see Figure 28), and separate

both sides of handle.

Note: Make sure not to pull on or damage

the wires located in main handle during

disassembly.

3. Locate and remove (2) motor brushes

(see Figure 29).

Note: If removing the brushes by hand is

too dicult, carefully use a small screwdriver

to push down on the brush holder tabs to

release them.

4. Replace motor brushes and install main handle

19

x4

Fig. 28. Location of main handle fasteners

Fig. 29. Replacing motor brush (1 of 2)

Table of contents