Bender MIP Series User manual

Isolated Power Panels

For Healthcare Facilities

NAE209501-2 / 02.2019

T M

EN Manual

Bender Inc.

USA:

420 Eagleview Blvd.

Exton, PA 19341

Toll Free: 800-356-4266

Phone: 610-383-9200

Fax: 610-466-2071

E-mail: info@bender.org

Canada:

5810 Ambler Drive, Unit 1

Mississauga, ON L4W 4J5

Toll Free: 800-243-2438

Phone: 905-602-9990

Fax: 905-602-9960

E-mail: [email protected]

Web: www.benderinc.com

NAE209501-2, 02.2019

© Bender Inc.

All rights reserved.

Content subject to change.

T M

3IP Panels © 2018 Bender Inc. All Rights Reserved

Table of Contents

1. Introduction......................................................................................... 5

1.1 Isolated Power Panels...................................................................... 5

2. Safety Instructions.............................................................................. 6

2.1 General Safety Warning .................................................................. 6

2.2 Using This Manual............................................................................. 7

3. Model Types ........................................................................................ 8

3.1 MIP / MIE Series Isolated Power Panels ..................................... 8

3.2 MIC Series Isolated Power Panels with Circuit Control........ 8

3.3 MID Series Dual Output Voltage Isolated Power Panels..... 9

3.4 MIX Series Dual System Isolated Power Panels...................... 9

4. Components ...................................................................................... 10

4.1 Backbox Package............................................................................. 10

4.2 Front Trim Package......................................................................... 11

4.3 Isolation Transformer Kit .............................................................. 11

4.4 Interior Package............................................................................... 12

4.5 Circuit Breakers ................................................................................ 13

4.6 Line Isolation Monitor (LIM) ........................................................ 14

4.7 Fault Location (EDS) Kit................................................................. 14

4.8 Receptacle Kit ................................................................................... 15

4.9 Load Monitoring.............................................................................. 15

4.10 Accessories Package....................................................................... 15

5. Receiving, Handling, and Storage................................................. 16

5.1 Receiving............................................................................................ 16

5.2 Handling............................................................................................. 16

5.3 Storage................................................................................................ 16

6. Pre-Installation Requirements ....................................................... 17

6.1 General Requirements................................................................... 17

6.2 Support Requirements.................................................................. 18

6.3 Size Requirements .......................................................................... 18

7. Installation ......................................................................................... 19

7.1 Considerations ................................................................................. 19

4 IP Panels © 2018 Bender Inc. All Rights Reserved

7.1.1 Distance From Finished Floor..................................................... 19

7.1.2 Available Conduit Areas ............................................................... 19

7.2 Mount Backbox................................................................................ 20

7.3 Install Conduit.................................................................................. 22

7.4 Install Interior ................................................................................... 23

7.5 Remove Interior Deadfront ......................................................... 24

7.6 Install Breaker Kit............................................................................. 25

7.6.1 Components..................................................................................... 25

7.6.2 Install Breaker Bracket Assembly............................................... 26

7.6.3 Install Breaker Sub-Plate............................................................... 27

7.7 Install Transformer.......................................................................... 28

7.7.1 Vibration Pads and Mounting Hardware................................ 28

7.7.2 Mounting ........................................................................................... 29

7.7.3 General Instructions....................................................................... 30

7.7.4 Transformer and Incoming Power Wiring.............................. 30

7.7.5 Branch Circuit Wiring..................................................................... 31

7.7.6 Grounding ......................................................................................... 32

7.7.7 Accessories / Add-On Kit Wiring................................................ 32

7.8 Wiring Diagrams.............................................................................. 33

7.8.1 MIP, MIE, and MIX Series............................................................... 33

7.8.2 MIC Series........................................................................................... 34

7.8.3 MID Series .......................................................................................... 35

7.9 Reinstall Interior Deadfront......................................................... 36

7.10 Install Front Trim ............................................................................. 37

7.10.1 Install U-Type Retaining Nuts ..................................................... 37

7.10.2 Mount Front Trim............................................................................ 38

7.10.3 Install Line Isolation Monitor ...................................................... 39

7.10.4 Install Transformer Heat Shield (MIX Series Only)............... 40

7.10.5 Install Lower Front Trim (MIX Series Only)............................. 41

7.10.6 Install Restraining Lanyard (MIX series only)......................... 41

7.10.7 Connect Line Isolation Monitor Harness ................................ 42

7.10.8 Close Front Trim .............................................................................. 42

Introduction

5IP Panels © 2018 Bender Inc. All Rights Reserved

1. Introduction

1. 1 Isolated Power Panels

Bender isolated power panels provide isolated, ungrounded power to electri-

cal systems in operating rooms and other critical areas in healthcare facilities.

Isolated power systems allow for early detection of hazardous current while

keeping the system online. The system gives a visual indication of the level of

current in milliamperes (mA). When the threshold is reached, a visual and audi-

ble alarm is activated.

An isolation transformer serves a single operating room, except when supply-

ing power to equipment requiring 150 VAC or higher. A line isolation monitor

(LIM) indicates possible leakage current from all isolated conductors to

ground.

This manual provides instructions on installing and operating isolated power

panels. Refer to all relevant national and local codes and standards before pro-

ceeding with installation.

6 IP Panels © 2018 Bender Inc. All Rights Reserved

Safety Instructions

2. Safety Instructions

2. 1 General Safety Warning

Hazard of Electric Shock, Burn, or Explosion

Only qualified maintenance personnel should operate or service this equip-

ment. These instructions should not be viewed as sufficient for those who are

not otherwise qualified to operate or service this equipment. No responsibility

is assumed by BENDER for any consequences arising from use of this docu-

ment.

Turn OFF all sources of electric power before performing any inspections, tests,

or service on this equipment. Assume all circuits are live until they have been

properly de-energized, tested, grounded, and tagged. Failure to observe these

precautions will result in equipment damage, severe personal injury, or death.

Proper operation of this equipment depends on proper installation. Refer to

NFPA 70, NFPA 70E, CSA Z462, and other relevant standards and codes for

installation standards. Neglecting fundamental installation techniques will

result in equipment damage, severe personal injury, or death.

Do not make any modifications to the equipment. Failure to observe this pre-

caution will result in equipment damage or personal injury.

Use only manufacturer’s and manufacturer recommended accessories with

this equipment. Failure to do so may damage the equipment beyond repair.

!

DANGER

Safety Instructions

7IP Panels © 2018 Bender Inc. All Rights Reserved

2. 2 Using This Manual

Read these instructions carefully and become familiar with the equipment

before attempting to install, operate, or service it. Throughout this manual,

special messages may appear to warn of potential safety hazards or to call

attention to information which clarifies instructions or procedures. Observe all

safety messages that appear throughout this manual to avoid possible injury

or death. An explanation of these symbols is given below.

DANGER: Indicates a hazardous situation which, if

not avoided, will result in death or severe injury.

WARNING: Indicates a potentially hazardous situa-

tion which, if not avoided, may result in death or injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in injury or equipment

damage.

NOTE: Provides additional information to clarify in-

structions for a product or procedure.

D

AN

G

ER

WARNIN

G

C

A

U

TI

O

N

8 IP Panels © 2018 Bender Inc. All Rights Reserved

Model Types

3. Model Types

3. 1 MIP / MIE Series Isolated Power Panels

Single-system, single-output-voltage isolated

power panel. MIP designation is used for pan-

els rated 10 kVA or below. MIE designation is

used for panels rated 15 kVA or above.

3. 2 MIC Series Isolated Power Panels with Circuit Control

Single-system, single-output-voltage (of

at least 150 V) isolated power panel. Pro-

vides programmable control of up to

twelve (12) individual circuits. Commonly

used with 208 VAC or 240 VAC portable

medical equipment, such as lasers. Circuit

control logic is configured at the factory.

Model Types

9IP Panels © 2018 Bender Inc. All Rights Reserved

3. 3 MID Series Dual Output Voltage Isolated Power Panels

Isolated power panel for a single-input-

voltage and dual-output-voltage system.

Commonly used to simultaneously supply

power to both normal line powered

equipment and equipment operating at a

voltage greater than 150 VAC (such as por-

table medical lasers).

3. 4 MIX Series Dual System Isolated Power Panels

Two MIP series interiors installed side-by-

side in a common enclosure. In figure

below, the transformer access front trim is

translucent for illustration purposes.

Wire is provided with the front trim

assembly for ground bus interconnection

and transformer terminal block connec-

tions to panel board lugs (or sub-feed

lugs, if applicable).

10 IP Panels © 2018 Bender Inc. All Rights Reserved

Components

4. Components

The following sections describe key components of isolated power panels.

These components are standard for the United States unless otherwise noted.

Ensure equipment conforms to all national and local codes and standards

prior to purchasing.

4. 1 Backbox Package

The backbox meet the requirements of NEMA

Type 1 according to UL 50. It is fabricated from a

minimum 14 GA galvanized steel and is

designed for flush (recessed) or surface mount-

ing. Flush mounting is standard. Surface

mounted backboxes must be requested during

the purchasing process.

Surface mounted backboxes are finished with a

coat of hospital grade ivory baked enamel or

equivalent.

All backboxes include an easy-lift-off hinge

assembly to ease front trim installation and sys-

tem maintenance.

Components

11IP Panels © 2018 Bender Inc. All Rights Reserved

4. 2 Front Trim Package

The front trim is manufactured from a minimum

14 GA, type 304 stainless steel. It contains a door

with hidden hinges and flush mounted key lock.

The door provides access to circuit breakers and

optional fault location (EDS) accessories if

equipped. Most front trims are provided with

provisions for future field installation of recepta-

cle and/or fault location assembly kits.

Front trims may be used with flush-mounted or

surface-mounted backboxes. For flush mounted

panels, the front trim extends 1”(25.4 mm) on

all sides of the backbox. For surface-mounted

panels, the front trim has the same height and

width as the backbox.

4. 3 Isolation Transformer Kit

The isolation transformer kit contains the fol-

lowing:

• Transformer and mounting hardware

• Primary main circuit breaker and bracket

assembly

• Secondary main circuit breakers (where

applicable)

• Breaker sub-plate and mounting hardware

Isolation transformers used in isolated power

systems are special-purpose, low-voltage, dry-

type transformers. They are application-specifi-

cally designed and fulfill the requirements of UL

5085 and UL 1047.

The primary main breaker, mounting hardware,

and sub-plate are included in the isolation trans-

former kit. For MID series panels (and custom

configurations where applicable), the isolation

transformer kit will also include secondary main

circuit breakers.

12 IP Panels © 2018 Bender Inc. All Rights Reserved

Components

4. 4 Interior Package

The interior assembly is a single, factory-wired

sub-panel containing one or more of the follow-

ing (varies by configuration):

• Distribution panel with branch circuit

breaker load center

• Equipment ground bus

• LIM2010 line isolation monitor and connec-

tor plate

• Accessory kits per project documents

Per project specifications, interior packages may

also include any of the following accessories /

accessory kits:

• Transformer load monitoring (STW kit)

• Branch circuit fault location (EDS kit)

• Receptacle and ground jack kit (GPMP)

• Communication gateway (COM465IP)

Components

13IP Panels © 2018 Bender Inc. All Rights Reserved

4. 5 Circuit Breakers

All panels utilize two-pole, thermal magnetic cir-

cuit breakers. Panels ordered with selective

coordination may include an electronic trip ele-

ment added to the primary and/or secondary

main circuit breakers to achieve 0.1 second sys-

tem coordination.

The primary and secondary (where applicable)

main circuit breakers are sized to protect the

transformer coil. The primary main circuit

breaker is sized at 125% of rated current. Any

supplied secondary main circuit breakers are

sized at rated coil ampacity.

The quantity and rating of branch circuit breakers varies by panel:

• MIP and MIE series: Provided with sixteen (16) factory-installed 20 A

branch circuit breakers (unless otherwise stated).

• MIC series: Quantity and ampacity of branch circuit breakers is provided

according to project documents. The maximum allowed is twelve (12).

The logic for simultaneously energized branch circuits is configured at the

factory per project specifications.

• MID series: Output voltage 1 (designated as the “low side”) is provided

with sixteen (16) factory-installed branch circuit breakers. Output voltage

2 (designated as the “high side”) is provided with either one (1) or two (2)

factory-installed branch circuit breakers. Ampacity is per project specifica-

tions

NOTE: To maintain compliance with UL 1047, branch

breakers must not exceed 60 A.

14 IP Panels © 2018 Bender Inc. All Rights Reserved

Components

4. 6 Line Isolation Monitor (LIM)

All panels are supplied with one or more line

isolation monitor (LIM). The LIM monitors the

system impedance to ground of the entire iso-

lated power system. The impedance to ground

is used to calculate the total hazard current

(THC), given in units of milliamperes (mA).

The factory default THC alarm is set to 5 mA. The

value may be changed to 2 mA to meet applica-

ble certification requirements.

The LIM is installed on the front trim in a conspicuously visible location. Refer

to LIM user manual for more information on operation and use.

4. 7 Fault Location (EDS) Kit

Panels may include branch circuit fault location

as part of an optional accessory kit (EDS kit). The

system works together with the LIM2010 to

assist in identifying the specific circuit contribut-

ing to the total hazard current alarm. Fault loca-

tion is automated (unless otherwise configured)

once the total hazard current alarm is activated.

The EDS kit is installed in the interior assembly

and may be installed at the factory or on site.

Refer to panel add-on user manual for more

information on installation, operation, and use.

Components

15IP Panels © 2018 Bender Inc. All Rights Reserved

4. 8 Receptacle Kit

Panels may include on-board receptacles and

ground jacks as part of an optional accessory kit

(receptacle kit). The receptacle kit provides

NEMA type receptacles and/or hospital grade

ground jacks accessible directly from the front

trim. Type and quantity is per project specifica-

tions.

The receptacle kit is installed in the interior

assembly and may be installed at the factory or

on site. Refer to panel add-on user manual for

more information on installation, operation, and

use.

4. 9 Load Monitoring

Panels may include one or both of the following

load monitoring systems:

• Full system monitoring: The STW3 connects

to the line isolation monitor and monitors

the current draw of the full system. The LIM

can alarm once a set threshold is reached.

• Branch monitoring: Two CMS460 series

devices monitor the load current for each

individual circuit branch.

4. 10 Accessories Package

Refer to applicable documentation for any additional accessories included

with the panel.

16 IP Panels © 2018 Bender Inc. All Rights Reserved

Receiving, Handling, and Storage

5. Receiving, Handling, and Storage

5. 1 Receiving

Inspect all equipment immediately upon delivery. If any damage or mishan-

dling has occurred, file a damage claim with Bender and/or the carrier. Verify

packing slip details before filing a shortage claim.

Isolated power panels are typically packaged and shipped as four (4) separate

components:

• Backbox

• Interior assembly

• Transformer kit

• Front trim

These system components may be shipped at different times to accommodate

the installer project schedule. In many cases, the backbox and interior assem-

bly arrive first to allow sufficient time for preliminary installation.

5. 2 Handling

5. 3 Storage

• Do not store equipment in dusty or damp locations.

• Do not stack panels or equipment.

• Do not rest or lean front trims against walls.

NOTE: Do not separate the contents of the isolation

transformer kit until ready for installation.

WARNING: Due to the heavy load of isolated power

equipment, use suitable equipment for lifting and

transporting. Failure to do so may result in severe per-

sonal injury and damage to equipment.

WARNIN

G

Pre-Installation Requirements

17IP Panels © 2018 Bender Inc. All Rights Reserved

6. Pre-Installation Requirements

6. 1 General Requirements

Review all code, standards, and project requirements thoroughly before pro-

ceeding with installation.

Of particular importance is minimizing the cumulative system leakage current

in an isolated power system. NFPA 99 mandates an isolated power system’s

total line-to-ground insulation impedance shall exceed 200 kΩ. Excessive leak-

age current may result in non-conformance with this requirement.

NOTE: In addition to adhering to all national, local,

and project-specific requirements, the installer shall

thoroughly review and understand all information

within this manual and relevant reference material.

Applicable material includes, but is not limited to:

• NFPA 99 - 2012: Healthcare Facilities Code Chapter 6

• NFPA 70: National Electric Code (NEC), Article 517

• (Canada) CSA C22.1: Canadian Electrical Code (CEC,

CE-Code), Section 24

• (Canada) CSA Z32: Applications of Electricity in

Healthcare

18 IP Panels © 2018 Bender Inc. All Rights Reserved

Pre-Installation Requirements

6. 2 Support Requirements

Prior to installation, ensure the proper structural support will be used. Mini-

mum load bearing requirements are listed in the table below. For panels

weighing in excess of 500 lb (230 kg), install both horizontal (bottom) and ver-

tical (side) supports.

6. 3 Size Requirements

Verify backbox dimensions on label. Ensure the wall space required is available

before proceeding with backbox installation. Ensure the mounting style (sur-

face or flush) is correct for the application. For reference, standard backbox

sizes are listed in the table below. Dimensions are given in inches (cm).

NOTE: Custom configurations may have special

weight and load bearing requirements.

Type Weight (lb) Weight (kg)

MIP series 370 168

MIE series 650 295

MIC series 650 295

MID series 675 306

MIX series 700 317

Model Height Width Depth

B662406(S) 66” (167.6 cm) 24” (61 cm) 6” (15.2 cm)

B662408(S) 66” (167.6 cm) 24” (61 cm) 8” (20.3 cm)

B723012(S) 72” (182.9 cm) 30” (76.2 cm) 12” (30.5 cm)

B723014(S) 72” (182.9 cm) 30” (76.2 cm) 14” (35.6 cm)

B803608(S) 80” (203.2 cm) 36” (91.4 cm) 8” (20.3 cm)

Installation

19IP Panels © 2018 Bender Inc. All Rights Reserved

7. Installation

7. 1 Considerations

7.1.1 Distance From Finished Floor

Refer to table below for allowable distances between bottom of isolated

power panel and finished floor.

7.1.2 Available Conduit Areas

Refer to figures below. Shaded areas are allowable conduit locations.

Models Allowable Distance

MIP, MIC, MIE, MID Minimum 2’ (61 cm), maximum 20’ (610 cm)

MIX Minimum 2’ (61 cm), maximum 9’ (275 cm)

A 5” (127 mm)

B 2” (51 mm)

C 16” (405 mm)

20 IP Panels © 2018 Bender Inc. All Rights Reserved

Installation

7. 2 Mount Backbox

The manufacturer recommended mounting method is to secure the backbox

to a rigid support structure (strut channel, etc.) using minimum 5/16”commer-

cial grade hardware (not included). Mounting locations are near the four cor-

ners of the enclosure sidewalls. Refer to figure on the following page for

example location in the top left corner. Note the following requirements for

each corner:

• Use two (2) 5/16”fasteners per corner on the side wall of the backbox

• Must be 2” (51 mm) from the top of the backbox

• Must be 2” (51 mm) from the front of the backbox

• Screws must be 2”(51 mm) apart

For flush-mounted enclosures, install flush with finished wall or recessed no

more than 1/8”(3 mm).

NOTE: Before installing, check the part number to ver-

ify the backbox to be installed matches with the appro-

priate interior, transformer kit, and front trim. Most

backboxes are identical in appearance.

CAUTION: Do not over-tighten the mounting hard-

ware. Over-tightening will cause distortion, misalign-

ment of the front trim, and improper hinge

functionality. Use shims to mitigate distortion as need-

ed.

NOTE: Recessing enclosure more than 1/8” (3 mm) will

impede hinge functionality.

C

A

U

TI

O

N

This manual suits for next models

14

Table of contents

Other Bender Portable Generator manuals

Popular Portable Generator manuals by other brands

Kodiak

Kodiak SGB12000HX Operating instructions and parts manual

Fortin

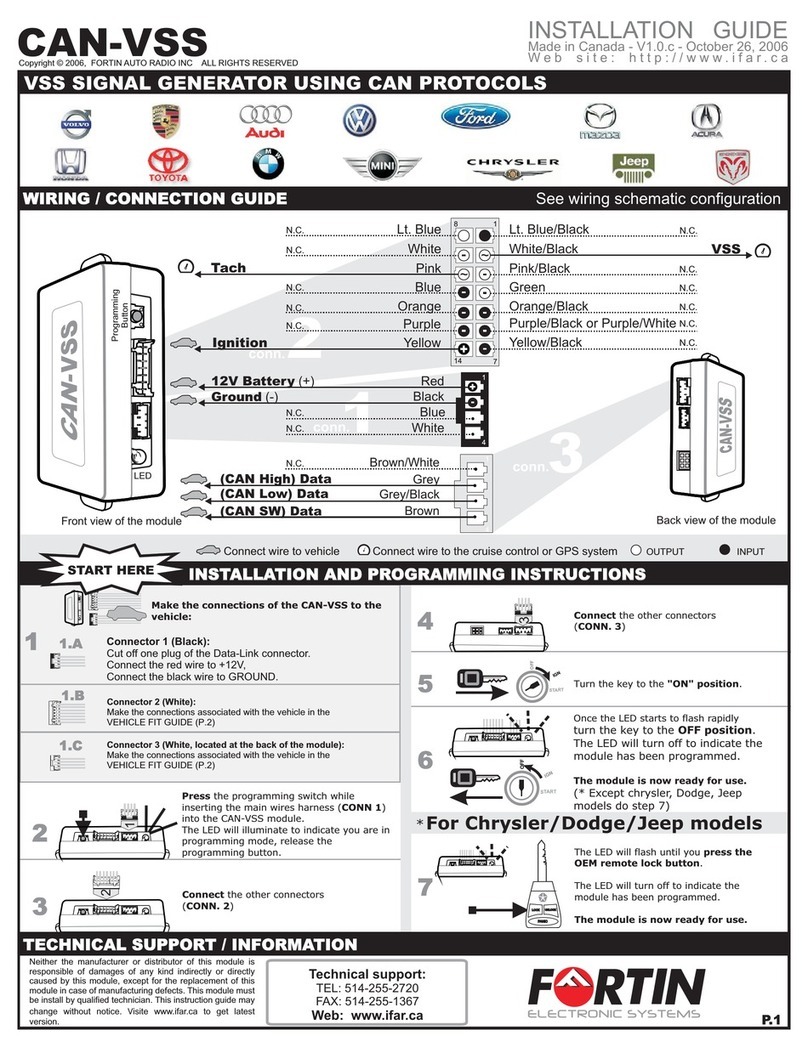

Fortin CAN-VSS installation guide

AtmosAir

AtmosAir Matterhorn 1000 Series Installation, operation, maintenance guide

Homelite

Homelite UT903655DA Operator's manual

Fischer Panda

Fischer Panda 12000x PMS manual

Onan

Onan MEP-003A Technical manual