BENDIX AD-4 AIR DRYER User manual

1

®

SD-08-2407

Bendix®AD-4™Air Dryer

EXTENDED PURGE AD-4™AIR DRYER STANDARD AD-4™AIR DRYER

LOWER

BRACKET

DESCRIPTION

ThefunctionoftheAD-4™airdryeristocollectand remove

air system contaminants in solid, liquid and vapor form be-

fore they enter the brake system. It provides clean, dry air

to the components of the brake system which increases

thelife ofthe systemand reducesmaintenance costs.Daily

manualdraining of thereservoirs is eliminated.

TheAD-4™airdryer consistsof a desiccantcartridgeand a

die cast aluminum end cover secured to a cylindrical steel

outer shell with eight cap screws and nuts. The end cover

containsacheckvalveassembly,asafetyvalve, purgevalve

mechanism, a cast-in heater element with a replaceable

thermostatassembly and three threadedairconnections.

The three air connections are identified with embossed

numbersandlettering.Theidentificationandfunctionofeach

is as follows:

Port l.D. Function/Connection

CON 4................ ControlPort

(fromunloaderportongovernor).

SUP 11 .............. Supply Port (air in).

DEL 2 ................ Delivery Port(air out).

A cast-in heater element and replaceable thermostat with

anexternal terminalare provided.

The voltage and wattage requirements of the heater and

thermostatareshown with embossed numbers andletters

in the recess adjacent to the control port marked “CON.”

UPPER

BRACKET

LOWER

BRACKET

PURGE

EXHAUST

FIGURE 1 - AD-4™AIR DRYER MODELS

SUPPLY

PORT

THERMOSTAT

TERMINAL

SUPPLY

PORT

CONTROL

PORT

DELIVERY PORT PURGE

EXHAUST

UPPER

BRACKET

2

PURGE VOLUME

DESICCANT

BED

CHECK

VALVE

OIL SEPARATOR

DESICCANT

CARTRIDGE

DELIVERY

PORT

HEATER

CHECK

VALVE

PURGE

VALVE

ORIFICE

EXHAUST

PORT

SUPPLY RESERVOIR

CONTROL

GOVERNOR COMPRESSOR

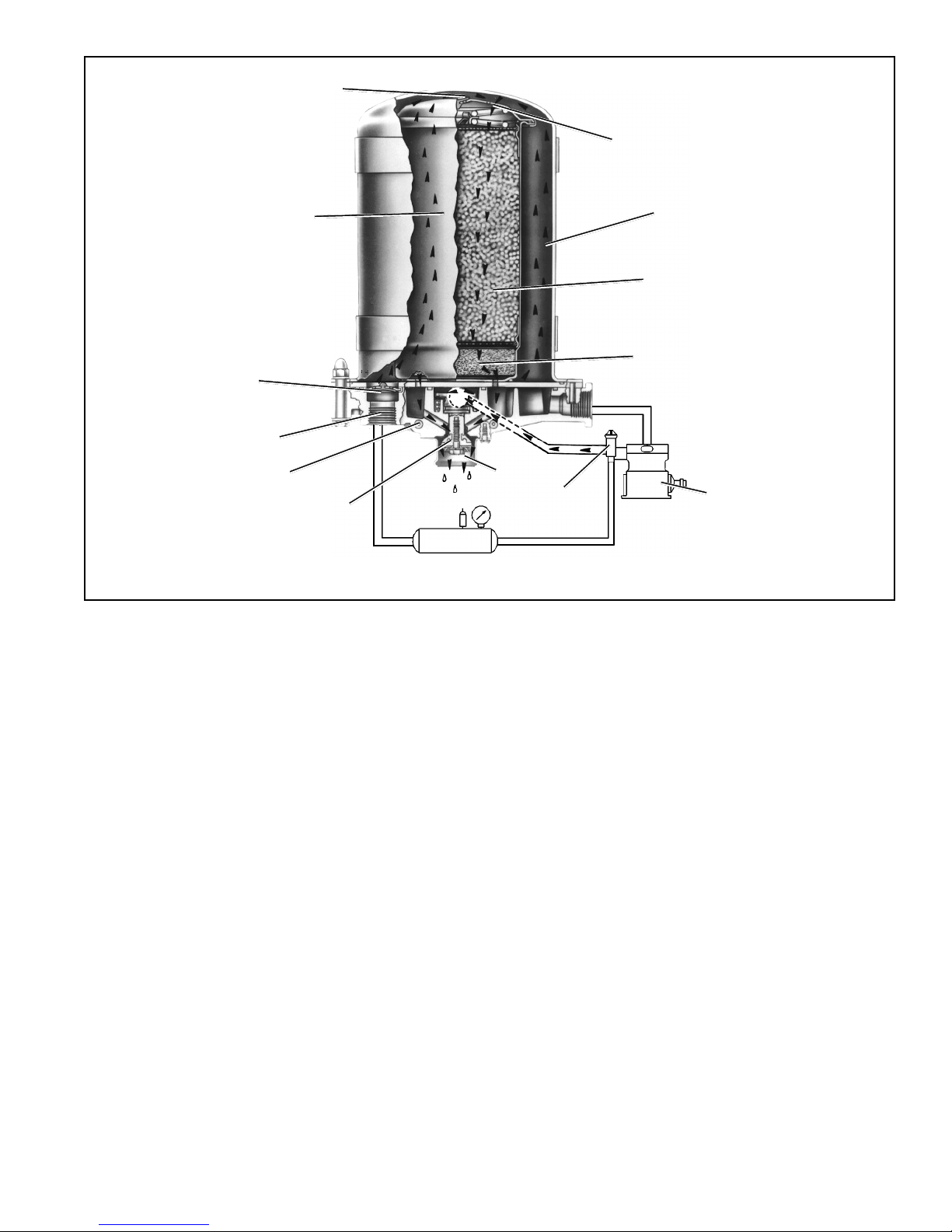

OPERATION OF THE AD-4™AIR DRYER

The AD-4™air dryer alternates between two operational

modes or “cycles” during operation: the charge cycle and

the purge cycle. The following description of operation is

separatedinto these “cycles” ofoperation.

CHARGE CYCLE (refer to Figure 2)

When the compressor is loaded (compressing air)

compressed air, along with oil, oil vapor, water and water

vapor flows through the compressor discharge line to the

supplyportof theairdryer endcover.Theflow velocityorthe

speedat whichtheair andits contaminants traveldown the

discharge line is reduced substantially as it enters the air

dryerend coverbafflesystembehind thesupply port.Asair

travelsthroughthebafflesystem,itsdirectionofflowchanges

by 180 degrees several times, reducing the temperature,

causingcontaminantstocondense and drop to the bottom

orsump of the airdryerend cover.

After exiting the end cover baffle system, the air flows into

thedesiccant cartridge. Once in thedesiccantcartridge air

first flows through an oil separator which removes water in

liquid form as well as oil, oil vapor and solid contaminants.

FIGURE 2 - AD-4™AIR DRYER CHARGE CYCLE

Air exits the oil separator and enters the desiccant drying

bed.Air flowing through the column of desiccant becomes

progressivelydryeraswatervapor adherestothe desiccant

materialin aprocessknown as“adsorption”.Thedesiccant

cartridge using the adsorption process typically removes

95%of the watervapor from thepressurizedair.

Themajority of dryairexits the desiccantcartridge through

itsintegralsinglecheckvalvetofillthepurgevolumebetween

the desiccant cartridge and outer shell. Some air will also

exitthedesiccantcartridgethroughthepurgeorificeadjacent

tothe check valve.

Dry air flows out of the purge volume through the single

check valve assembly and out the delivery port to the first

(supply)reservoir of the airsystem.

The air dryer will remain in the charge cycle until air brake

system pressure builds to the governor cutout setting.

PURGE CYCLE (refer to Figure 3)

Whenair brakesystempressure reachesthe cutoutsetting

of the governor, the compressor unloads (air compression

stopped) and the purge cycle of the air dryer begins. The

3

FIGURE 3 - AD-4™AIR DRYER PURGE CYCLE

CONTROL

GOVERNOR

SUPPLY RESERVOIR

PURGE VOLUME

DESICCANT

BED

OIL SEPARATOR

DESICCANT

CARTRIDGE

DELIVERY

PORT

HEATER

CHECK

VALVE

PURGE

VALVE

COMPRESSOR

CHECK

VALVE

ORIFICE

EXHAUST

PORT

lineconnecting the governorunloaderport to theAD-4™air

dryerendcovercontrolportispressurizedwhenthegovernor

unloadsthe compressor.Airpressure attheAD-4™airdryer

end cover control port is also present on the purge valve

piston.The purge pistonmoves in responseto air pressure

causing the purge valve to open to atmosphere.

Contaminants in the end cover sump are expelled

immediately when the purge valve opens. Also, air which

wasflowingthroughthedesiccantcartridgechangesdirection

and begins to flow toward the open purge valve. Oil, water

and solid contaminants collected by the oil separator are

removedby air flowingfrom the desiccantdrying bed tothe

openpurgevalve.

Theinitialpurgeanddesiccantcartridgedecompressionlasts

onlya few secondsandis evidenced byanaudible burst of

air at theAD-4™air dryer exhaust.

The actual reactivation of the desiccant drying bed begins

asdryair flowsfromthe purgevolumethrough thedesiccant

cartridge purge orifice and into the desiccant drying bed.

Pressurizedairfromthepurgevolumeexpandsafterpassing

through the purge orifice; its pressure is lowered and its

volumeincreased.Theflowof dryair throughthedryingbed

reactivates the desiccant material by removing the water

vaporadhering to it. Generally15-30 seconds arerequired

forthe entire purgevolumeof astandardAD-4™airdryerto

flowthrough the desiccant dryingbed.

The end cover single check valve assembly prevents air

pressurein the brakesystemfrom returning totheair dryer

during the purge cycle.After the 30 second purge cycle is

complete,the air dryer is readyfor the next charge cycleto

begin.

The purge valve will remain open after the purge cycle is

completeandwill not close untilairbrake system pressure

is reduced and the governor signals the compressor to

charge.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

anyintrusivemaintenanceprocedures.Anextendedwarranty

maybe voidedif intrusivemaintenanceis performedduring

thisperiod.

Becausenotwo vehiclesoperateunderidenticalconditions,

maintenanceandmaintenanceintervalswillvary.Experience

is a valuable guide in determining the best maintenance

intervalfor anyone particularoperation.

4

FIGURE 4 - AD-4™AIR DRYER SECTIONAL VIEW

DESICCANT

BED

OIL SEPARATOR

DESICCANT

CARTRIDGE

CHECK

VALVE PURGE

ORIFICE

EXHAUST

COVER

NUT

CHECK VALVE

ASSEMBLY

END COVER

HEX HEAD

SCREW

SPECIAL

WASHER DELIVERY

PORT PURGE

VALVE EXHAUST

DIAPHRAGM

O-RING

PURGE PISTON

SPRING

SEALING RING

SEALING RING

SEALING RING

SEALING RING

SUPPLY

PORT

PERFORATED PLATE

PURGE VOLUME

WASHER

Every900operating hours or 25,000milesor every three

(3)months:

1. Check for moisture in the air brake system by opening

reservoirs, drain cocks, or valves and checking for

presenceofwater. If moisture is present,thedesiccant

may require replacement; however, the following

conditions can also cause water accumulation and

shouldbe considered beforereplacingthe desiccant:

A. An outside air source has been used to charge the

system. This air did not pass through the drying bed.

B. Airusage is exceptionallyhighand not normal fora

highway vehicle. This may be due to accessory air

demandsorsome unusualairrequirementthatdoes

not allow the compressor to load and unload

(compressing and non-compressing cycle) in a

normal fashion. Check for high air system leakage.

If the vehicle vocation has changed it may be

necessaryto upgradethe compressorsize. Referto

AppendixA,TableAand thecolumnentitled Vehicle

Vocation.

C. The air dryer has been installed in a system that

has been previously used without an air dryer. This

type system will be saturated with moisture and

severalweeks ofoperationmay berequiredto dryit

out.

D. Location of the air dryer is too close to the air

compressor. Refer to LocatingAD-4™Air Dryer On

Vehicle section and AppendixA, TableA, column 2

fordischarge line length.

E. In areas where more than a 30 degree range of

temperature occurs in one day, small amounts of

water can accumulate in the air brake system due

to condensation. Under these conditions, the

presence of small amounts of moisture is normal

and should not be considered as an indication that

thedryer is notperformingproperly.

Note:Asmallamount ofoilinthesystem maybe normal

and should not, in itself, be considered a reason to

replacethe desiccant;oil staineddesiccant canfunction

adequately.

5

2. Check mounting bolts for tightness. Retorque to 270-

385inch pounds.

3. Perform the Operation & Leakage Tests listed in this

publication.

Every 10,800 hours or 300,000 miles or 36 months:

1. Rebuildthe air dryer includingthedesiccant cartridge.

Note:The desiccantchange intervalmayvary fromvehicle

to vehicle.Although typical desiccant cartridge life is three

years, many will perform adequately for a longer period of

time.In order to takemaximumadvantage of desiccant life

andassure that replacement occurs onlywhennecessary,

itisimportantthatOperation&LeakageTestsbeperformed.

WARNING!

This air dryer is intended to remove moisture and other

contaminants normally found in the air brake system.

Do not inject alcohol, anti-freeze, or other de-icing

substances into or upstream of the air dryer. Alcohol

is removed by the dryer, but reduces the effectiveness

of the device to dry air. Use of other substances can

damage the air dryer and may void the warranty.

OPERATION & LEAKAGE TESTS

1. Test the outlet port check valve assembly by building

the air system to governor cut-out and observing a test

airgauge installedinthe supplyreservoir.Arapid lossof

pressurecould indicate a failedoutlet port check valve.

(Note: Purgevalve will be openwhengovernor cut-out

pressure is reached. Allow 45 seconds after governor

cut-outoccurstocompletethepurgecyclebeforetesting

thecheck valve.)Coat theexhaustwith asoap solution.

Leakage should not exceed a 1" bubble in 1 second.

2. Check for excessive leakage around the purge valve.

Withthe compressorin loadedmode (compressingair),

apply a soap solution to the purge valve housing

assembly exhaust port and observe that leakage does

not exceed a 1" bubble in 1 second. If the leakage

exceedsthemaximumspecified, servicethepurgevalve

housingassembly.

3. Closeallreservoirdraincocks.Build upsystempressure

togovernorcut-outandnotethatAD-4™air dryerpurges

with an audible escape of air. “Fan” the service brakes

to reduce system air pressure to governor cut-in. Note

thatthe systemonceagain buildstofull pressureand is

followedby anAD-4™air dryerpurge.

4. Check the operation of the safety valve by pulling the

exposed stem while the compressor is loaded

(compressingair).Theremustbe anexhaustofairwhile

the stem is held and the valve should reseat when the

stem is released.

5. Check all lines and fittings leading to and from the air

dryerfor leakage andintegrity.

6. Check the operation of the end cover heater and

thermostat assembly during cold weather operation as

follows:

A. Electric Power to the Dryer

With the ignition or engine kill switch in the ON

position, check for power at the dryer’s electrical

terminal using a voltmeter or test light. On a single

terminalAD-4™air dryer’s disconnect the lead wire

at the end cover terminal post. Place the test leads

on the lead wire and a GOOD vehicle ground. On

dualterminalAD-4™airdryer’sdisconnect bothlead

wires at the end cover terminal posts. If there is no

voltageindicated,lookforablownfuse,brokenwires,

orcorrosion in the vehicle wiringharness.Check to

see if a good ground path exists.

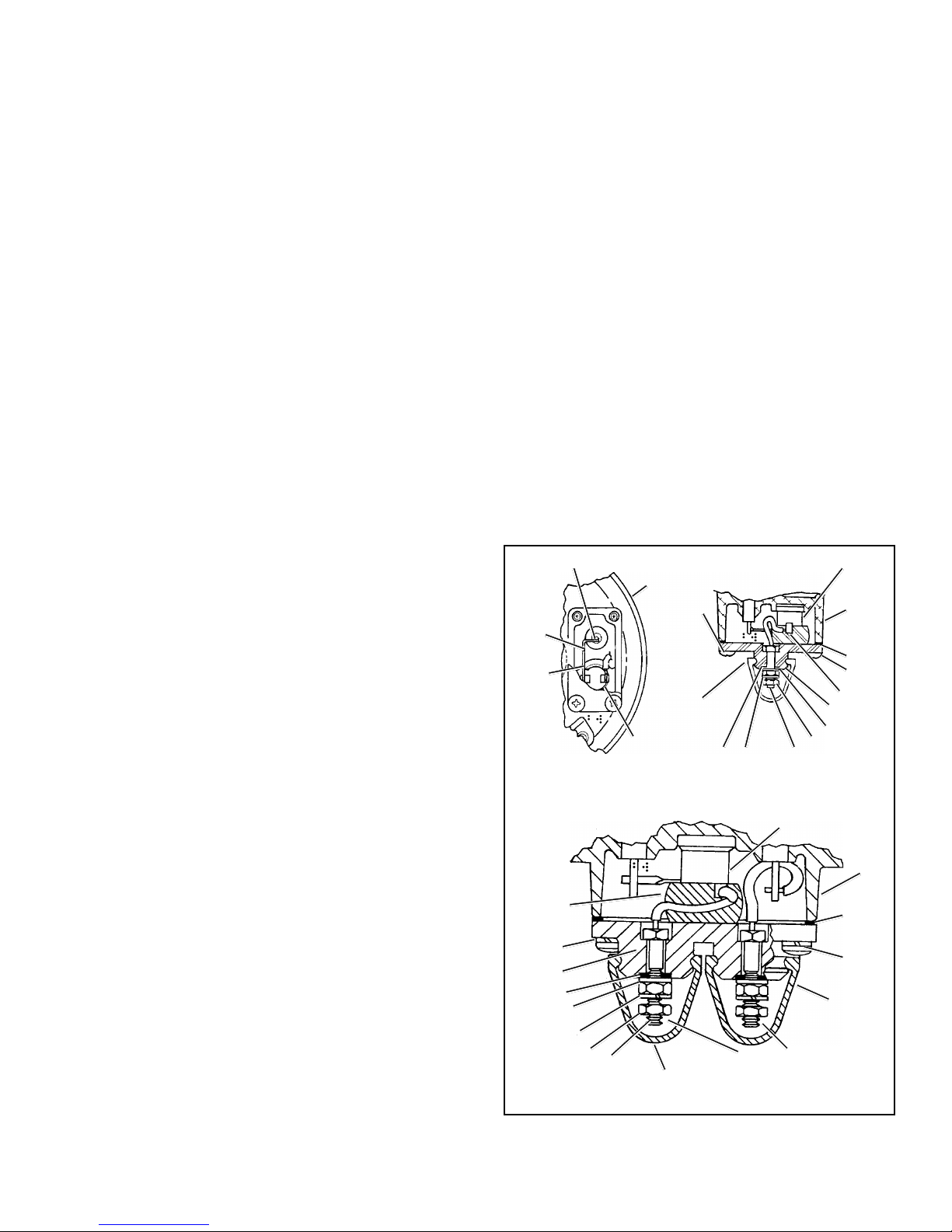

B. ThermostatandHeaterOperation

Turn off the ignition switch and cool the end cover

assemblytobelow40degreesFahrenheit.Using an

ohmmeter, check the resistance between the

electricalterminalandthemetalendcover(seeFigure

5).(Note:Onthe dualterminal endcover,check the

resistance between the two terminals.) The

FIGURE 5 - AD-4™AIR DRYER SINGLE AND DUAL

TERMINAL THERMOSTAT ASSEMBLIES

DUAL WIRE SYSTEM

BOOT

7

10

9

1

11

8

6

1CONNECTIONS FOR POWER

AND INSULATED RETURN

BOOT

32

4

5

BOLD NUMBERS ARE ITEMS IN MAINTENANCE KITS

SINGLE WIRE SYSTEM

1

9

8

1

9

2

1

46117

10

THERMOSTAT

COVER

53

A

B

HEATER POST

6

resistanceshould be 2.0to 4.0 ohmsfor the 12volt,

60watt end coverand 4.0 -7.0 ohms forthe 24 volt,

120 watt end cover. These resistance values apply

toeither singleor dualterminalair dryerend covers.

Warm the end cover assembly to over 90 degrees

Fahrenheitandagainchecktheresistanceasabove.

The resistance should exceed 1000 ohms for both

singleand dual terminal air dryers.Ifthe resistance

values obtained are within the stated limits, the

thermostatandheaterassemblyisoperatingproperly.

If the resistance values obtained are outside the

stated limits, proceed to Step C to determine the

cause.

C. HeaterElementInspection

Withtheignitionorenginecontrolswitch“off”, remove

the thermostat cover (see Figure 5). Using an

ohmmeter, checkthe resistance betweenthe metal

endcoverandtheheaterpost(see Figure5). (Note:

Onthedual terminalend cover,checkthe resistance

between the two terminals.) For a 12 volt, 60 watt

end cover, the resistance should be 2.0 - 2.8 ohms

andfor a24 volt,120 wattend cover,4.0 -5.6ohms.

Theseresistancevaluesapplyto eithersingleordual

terminalairdryer endcovers.If theheaterresistance

value obtained is outside the stated limits, a new or

remanufacturedendcover shouldbe installed,since

the heater element cannot be serviced. Check that

agood groundpath existsbetween theair dryerend

cover casting and the vehicle chassis. Correct if

needed. If the heater resistance value obtained is

within the stated limits the thermostat should be

replaced (Kit Number 102657) or a new or

remanufacturedend coverinstalled. Note: The dual

terminalair dryercoverrequires kitnumber 103982.

D. Reassembly

Reinstallthethermostat coverasillustratedinFigure

5. Take special care to assure the rubber spacer

and the gasket are correctly installed, to assure

properoperation.

REBUILDING THE AD-4™AIR DRYER

GENERAL

If,after completing theroutine operationandleakage tests,

ithas beendetermined that oneor morecomponents ofthe

airdryer requires replacement ormaintenance, refer tothe

followinglistto find the appropriatekit(s).

When rebuilding or replacing components of the air dryer

use only genuine Bendix parts. For ease in servicing the

AD-4™air dryer desiccant cartridge assembly, it is

recommendedthattheairdryerberemovedfromthevehicle.

MAINTENANCE KITSAVAILABLE:

103817 MajorMaintenance Kit

Thiskit contains theparts necessary tocompletely

rebuild the AD-4™air dryer (desiccant cartridge

included)and includes kit 103980.

103818 AD-4™AirDryerPurge Valve MaintenanceKit

Thiskit contains the partsnecessaryto rebuild the

AD-4™airdryerend coverpurge valveonly.

103879 AD-4™Air Dryer Seal Kit

Thiskit containsthe outletport checkvalve andthe

o-ringsand seals requiredwhenremoving the end

coverassembly.Thiskit isincludedwithkits103980

and103981.

103980 EndCover MaintenanceKit

Thiskit contains the partsnecessaryto rebuild the

end cover of the AD-4™air dryer and includes kit

103818.

103981 DesiccantCartridge Replacement Kit

This kit contains the parts necessary to change

the desiccant cartridge only.

102657 ThermostatMaintenance Kit (singleterminal

models)

This kit contains the parts necessary to rebuild a

single terminal thermostat assembly in theAD-4™

airdryer.

103982 ThermostatMaintenance Kit(dual terminal

models)

This kit contains the parts necessary to rebuild a

two terminal thermostat assembly (insulated

ground).

288918 ThermostatCover ReplacementKit (single

terminalmodels)

This kit contains the necessary components for

replacingthe non-metallicthermostatcover.

104964 ThermostatCover ReplacementKit (dualterminal

models)

This kit contains the necessary components for

replacingthe non-metallicthermostatcover.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebe in operation, EXTREME CAUTIONshould

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

7

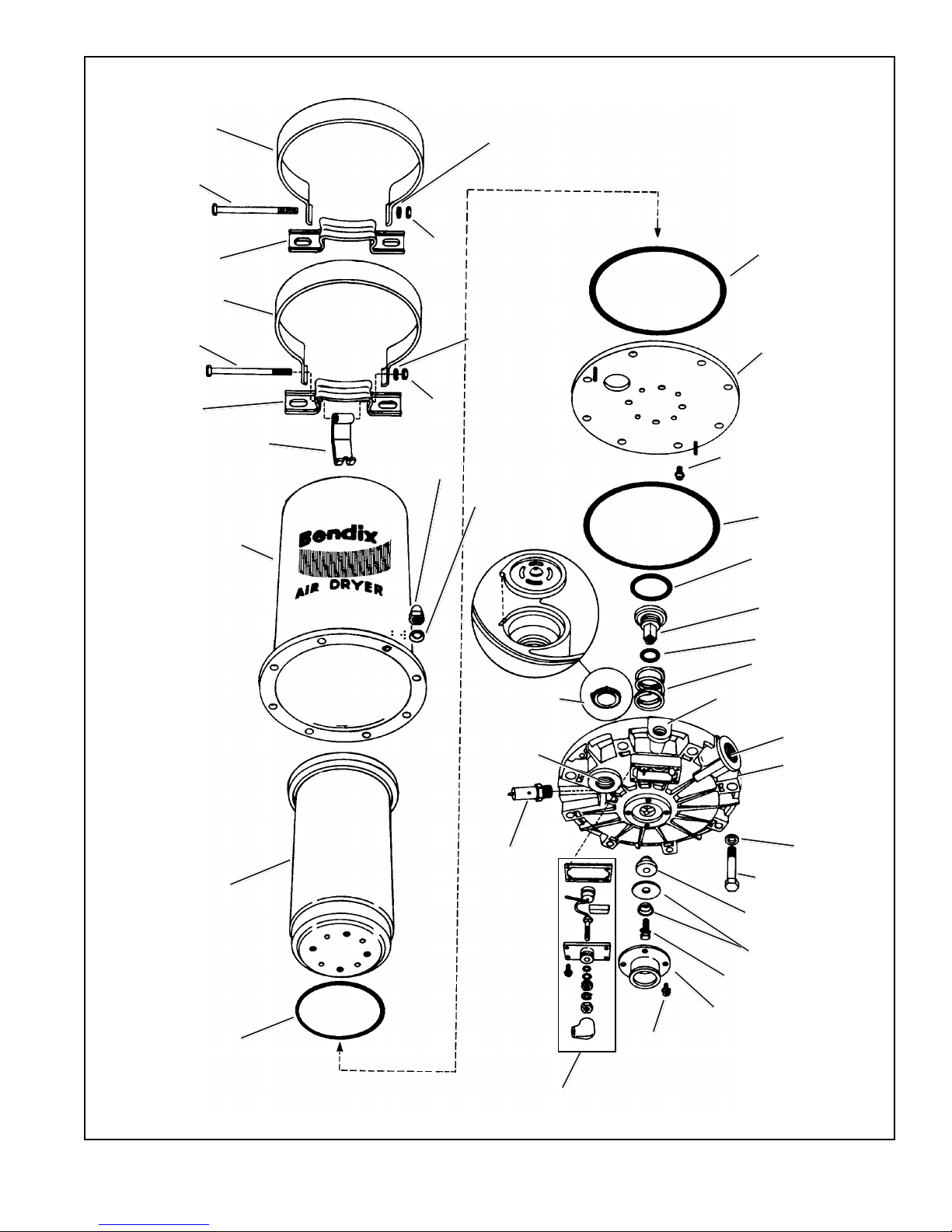

FIGURE 6 - AD-4™AIR DRYER ASSEMBLY

AIR DRYER

HOUSING

THERMOSTAT

ASSEMBLY

SAFETY

VALVE

CHECK VALVE

ASSEMBLY

SCREW

EXHAUST COVER

1/2” CAP SCREW

PURGE VALVE

(8) CAP SCREW 3/8”

SEALING RING

SEALING PLATE

(4) DESICCANT CARTRIDGE

CAP SCREW

& LOCKWASHER

SEALING RING

SEALING RING

END COVER

HEATER

VOLTAGE

SHOWN

SUPPLY PORT

CONTROL

PORT

SPRING

O-RING

PURGE PISTON

SPECIAL

WASHER

EXHAUST

DIAPHRAGM

DELIVERY

PORT

BRACKET

MOUNTING STRAP

CAP SCREW

5/16” X 4-1/2”

BRACKET

MOUNTING STRAP

CAP SCREW

5/16” X 4-1/2”

LOCKWASHER

NUT

LOCKWASHER

NUT

MOUNTING BRACKET HOOK (8) LOCK NUT

(8) SPECIAL

WASHER

DESICCANT

CARTRIDGE

SEALING RING

8

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonly theproper toolsand observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems,makecertain to draintheair pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommendedprocedures, deactivate theelectrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix®replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certainallcomponentsandsystemsarerestoredto

their proper operating condition.

11. Forvehicles with AntilockTraction Control (ATC),

the ATC function must be disabled (ATC indicator

lampshouldbeON)priortoperforminganyvehicle

maintenance where one or more wheels on a

drive axle are lifted off the ground and moving.

AD-4™AIR DRYER REMOVAL

1. Parkthevehicleonalevelsurfaceandpreventmovement

by means other than the brakes.

2. Drain all reservoirs to 0 p.s.i. (0 kPa).— Caution:

Compressor discharge line may still contain residual

pressure.

3. Identify and disconnect the three air lines from the end

coverand notethe positionofendcoverportsrelativeto

thevehicle.

4. Pullboot fromthe thermostatandheatercoverand slide

it onto the wire to expose the connection. Remove nut

and disconnect electrical wire from the terminal. Note:

Vehicleswithinsulatedground (2wire) systemwill have

two boots and two terminals to be disconnected. (See

Figures 5 & 8.)

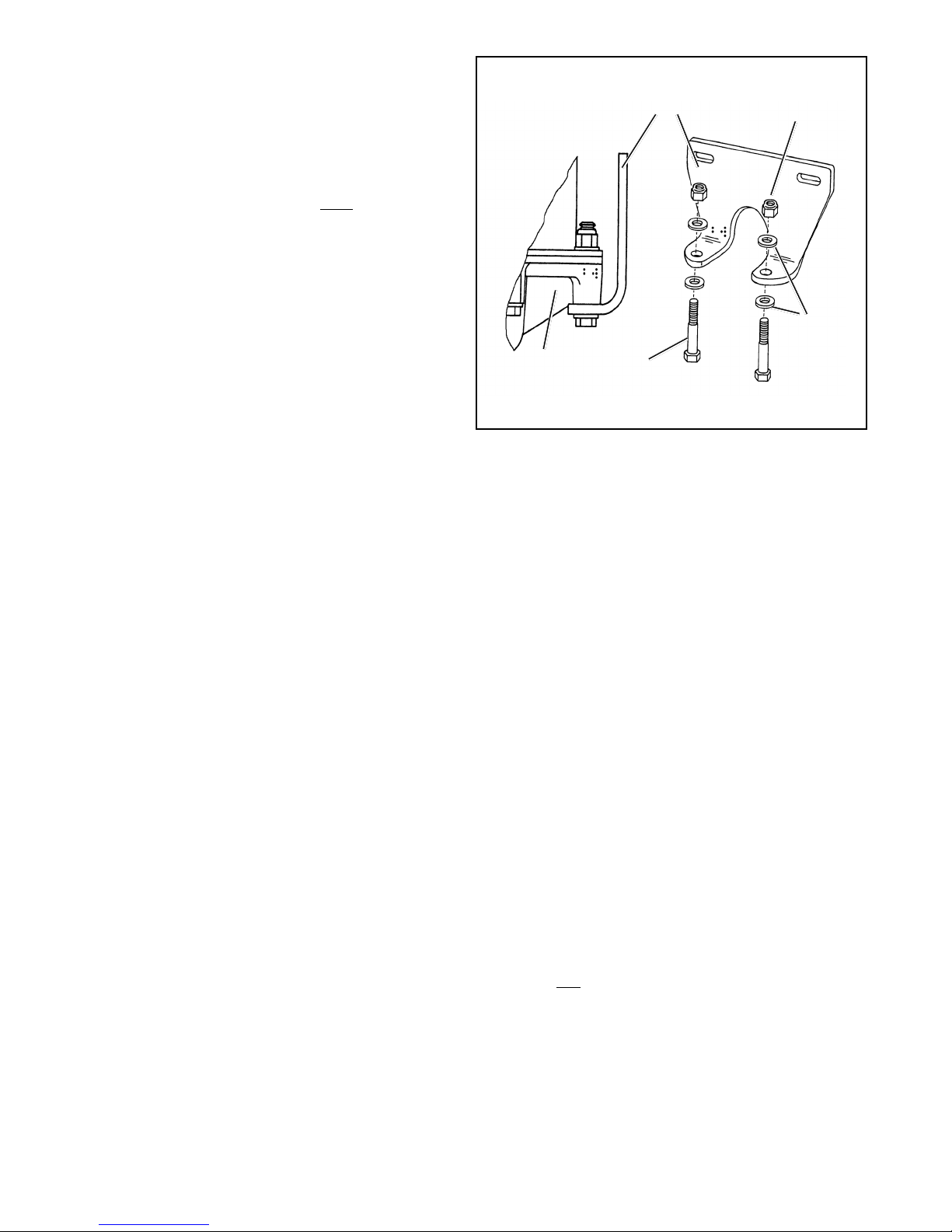

5. Loosen the 5/16" X 4-1/2" hex bolt securing the upper

and lower mounting straps. Disengage the mounting

END

COVER

SPECIAL

WASHER

LOCK NUT

LOWER RIGHT ANGLE

BRACKET

EXTRA

LONG

CAP SCREW

bracket hook from the end cover (Refer to Figure 6.)

Note: If theAD-4™air dryer being serviced has a right

angle bracket instead of a lower mounting strap and

safety hook, proceed to step 6, otherwise proceed to

step 7.

6. Remove, retain and mark the two 3/8" end cover cap

screws, lock nuts and four special washers that retain

thelower mounting bracket to theend cover, also mark

thesetwoholes oftheend cover.(Theseboltsarelonger

than the other 6 bolts.)

7. RemovetheAD-4™airdryer fromitsmounting brackets

onthe vehicle.

DISASSEMBLY

The following disassembly and assembly procedure is

presented for reference purposes and presupposes that a

major rebuild of the AD-4™air dryer is being undertaken.

Severalreplacementpartsandmaintenancekitsareavailable

which do not require full disassembly. The instructions

providedwith thesepartsand kitsshould befollowedin lieu

ofthe instructions presented here.Refer to Figure 6during

disassembly.

Caution: While performing service on the AD-4™air

dryer, it is not recommended that a clamping device

(vise, C-clamp, etc.) be used to hold any die cast

aluminum component as damage may result. To hold

the end cover, install a pipe nipple in the supply port

and clamp the nipple into a vise.

1. Remove the remaining 3/8" lock nuts, special washers

and cap screws from the flange of the air dryer and

separatethe endcover fromthe airdryer outerhousing.

Separatethe desiccantcartridge andsealingplate from

FIGURE 7 - LOWER BRACKET INSTALLATION

9

the end cover. Remove and discard the three sealing

rings. One sealing ring is located in the groove on the

sealingplate andthe othertwo arein groovesin theend

cover.

2. Remove 1/4" cap screw from the bottom of the purge

valve and remove the diaphragm washer, exhaust

diaphragm and purge valve. Discard the exhaust

diaphragmandpurgevalve.Removepurgepiston.Note:

Holdpistondownwhenremovingcapscrewduetospring

tension.

3. Remove and discard the check valve assembly in the

recessat the delivery port ofthe end cover.

4. Removethesafetyvalvefromtheend cover(onlyifithas

beendeterminedthatitneedsreplacementduringservice

checks).

5. To removethe thermostatseethe appropriatesection in

thismanual (only ifithas been determinedthat it needs

replacementduring servicechecks).

6. Removepurge pistonand springfromthetopside ofthe

cover.

7. Remove o-ring from the purge piston and discard the

o-ring.

8. Removethe four 1/4"capscrews and lockwashersthat

secure the sealing plate to the desiccant cartridge.

Separatethe sealing plate fromthe desiccantcartridge

anddiscard thesealingring atthe baseofthe cartridge.

CLEANING & INSPECTION

1. Usingmineral spiritsor anequivalent solvent,clean and

thoroughly dry all metal parts.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superficialcorrosionandorpittingontheexteriorportion

ofthe upper and lowerbody halves is acceptable.

3. Inspectthe boresofboththeend coverfor deepscuffing

orgouges.

4. Makecertain thatall purgevalve housingand endcover

passagesare open andfreeof obstructions.

5. Inspectthe pipe threads intheend cover. Make certain

theyare clean and freeofthread sealant.

6. Inspect the purge valve housing bore and seat for

excessivewear andscuffing.

7. Inspectthe purge valvepiston seat forexcessive wear.

8. Inspect all air line fittings for corrosion. Clean all old

threadsealant from thepipethreads.

9. All o-rings removed should be discarded and replaced

withnew o-ringsprovidedin appropriatekit(s).

Any component exhibiting a condition described in step 1

to 8 should be replaced.

ASSEMBLY

Priortoassembly,coatall o-rings,o-ringgrooves, andbores

witha generous amount ofbarium base lubricant.

Important Note: The single exception to prelubrication

is the sealing ring between the desiccant cartridge and

sealing plate. Refer to step number 8 for proper

installation of this sealing ring. Refer to Figure 6 during

assembly unless otherwise advised.

1. Placereturn springinto cavityin thecenter oftopside of

endcover.

2. Install the purge piston o-ring on the purge piston and

placethe purge piston inside thereturn spring installed

in Step 2.

3. Turnend coveroveron aflat cleansurface(making sure

purgepistonandreturnspringremaininproper position.)

Compressthereturnspringby pushingdownontheend

coverandalign squareshankofpurgepistonintomating

holein the endcover.

4. Placethediaphragmwasher,diaphragm,andpurgevalve

onto the 1/4" cap screw.

5. Install the 1/4" cap screw with parts on it into exhaust

coverand torque to60-80 inch pounds.

6. Install safety valve (if removed) and torque to 120-400

inch pounds, making sure that the exhaust hole is

pointeddownward when thedryeris installed.

7. Install thermostat (if removed). Refer to instructions

pertaining to thermostat installation under section

ThermostatAssembly.

8. Placesealing ringon bottomof desiccantcartridge. The

desiccantcartridge,sealingring andsealingplateshould

be wiped and free of lubricant prior to this assembly

procedure.Attachcartridgeto plate(smoothside ofplate

oppositecartridge)withfour1/4"socketheadcapscrews

andlockwashers.Torqueto 80-100inchpounds.

9. Install the two sealing rings in the recesses of the end

cover.

10. Install the check valve assembly into the end cover

making sure the tang on the check valve assembly fits

into the mating recess in the end cover.

11. Place desiccant cartridge and sealing plate assembly

ontoendcover.(Takingcarenottodisplacesealingrings.)

Thelargehole in the sealingplatemust line up withthe

check valve and spiral pins in the sealing plate must

entercorresponding holesinthe end cover.

12.Installthe outer sealing ring onthesealing plate. Place

theouter housingover thedesiccantcartridge (liningup

marksmadeontheouterhousingand endcover priorto

disassembly) and retain with eight 3/8" hex head bolts,

special washers, and lock nuts. Refer to Figure 8 for

torquepattern.Torque to270-385 inch pounds.Note:If

10

3/8" bolts require replacement, insure that the

replacement bolts are grade 5 minimum and the same

length as the original bolts. Use of inferior bolts can

compromise the integrity of the air dryer and lead to

prematurefailure.Where a lower,rightangle mounting

bracket(instead of alower mounting strap)is used; line

upthemarksmadeontheouterhousingand endcover.

Installthe six (standard) 3/8"cap screws, locknuts and

twelvespecial washers.The twolonger3/8"cap screws

will be used to secure the AD-4™air dryer to the right

anglemounting bracket.

Note: If during the Operation & Leakage Tests it was

determinedthatthethermostatwasinoperative,usethe

following procedure for repair or replacement. It is not

necessary to replace this unit each time the end cover

is rebuilt. Use thermostat maintenance kit 102657 for

singleterminalapplication. Fordualterminal application,

usekit#103982.(See Figure 5.)

THERMOSTAT DISASSEMBLY (Refer to Figures 5

and 8)

1. Remove nut (2), then lockwasher (3), plain washer (4),

nut (2) and o-rings (5). Discard o-ring and retain other

parts.

2. Remove and retain four Phillips head screws (7) and

cover(6).

3. Removeand discardgasket (10).

4. Removeand retainspacer(11).

5. Cutuninsulated thermostatwireat PointB, remove and

discardthermostatand terminal assembly (1).

6. Cleanremaining wire attachedto heater terminal.

7. Cleanthermostat “pocket” inendcover (9).

THERMOSTAT ASSEMBLY (Refer to Figure 5)

1. Cut uninsulated lead of new thermostat (1) at PointA.

2. Install thermostat in end cover pocket and position

uninsulated leads next to each other.

3. Usinga soldering heatsink,clamp uninsulatedleadsat

PointB and solder leadswithstraight rosin core solder.

Do not use acid core solder as corrosion can result.

Cleanexcess solder offend cover.

4. Installthermostat terminal (1) incover (6).

5. Install o-ring (5), washer (4), and nut (2).Torque nut to

20-30inch pounds. Then installlockwasher (3) and nut

(2)finger tightto allowfor reconnectionofelectricalwire

whenreinstalled onvehicle.

6. Installspacer(11) over thermostat(1).

7. Install gasket (7) and thermostat cover (6) and secure

thermostatcoverto end cover (9) usingscrews(7) and

lockwashers(8).

8. Torque to 20-30inch pounds.

9. Test thermostat as follows:

A. At a temperature above 90 degrees Fahrenheit,

check resistance between thermostat terminal (1)

andendcover(9). Resistanceshouldbe1,000ohms

or greater; if not, check for solder “path” short.

B. Chill entire end cover assembly to 40 degrees

Fahrenheit or below and check resistance again.

Resistanceshould be2-4 ohmsfor a12 volt,60 watt

end cover and 4-7 ohms for a 24 volt, 120 watt end

cover.

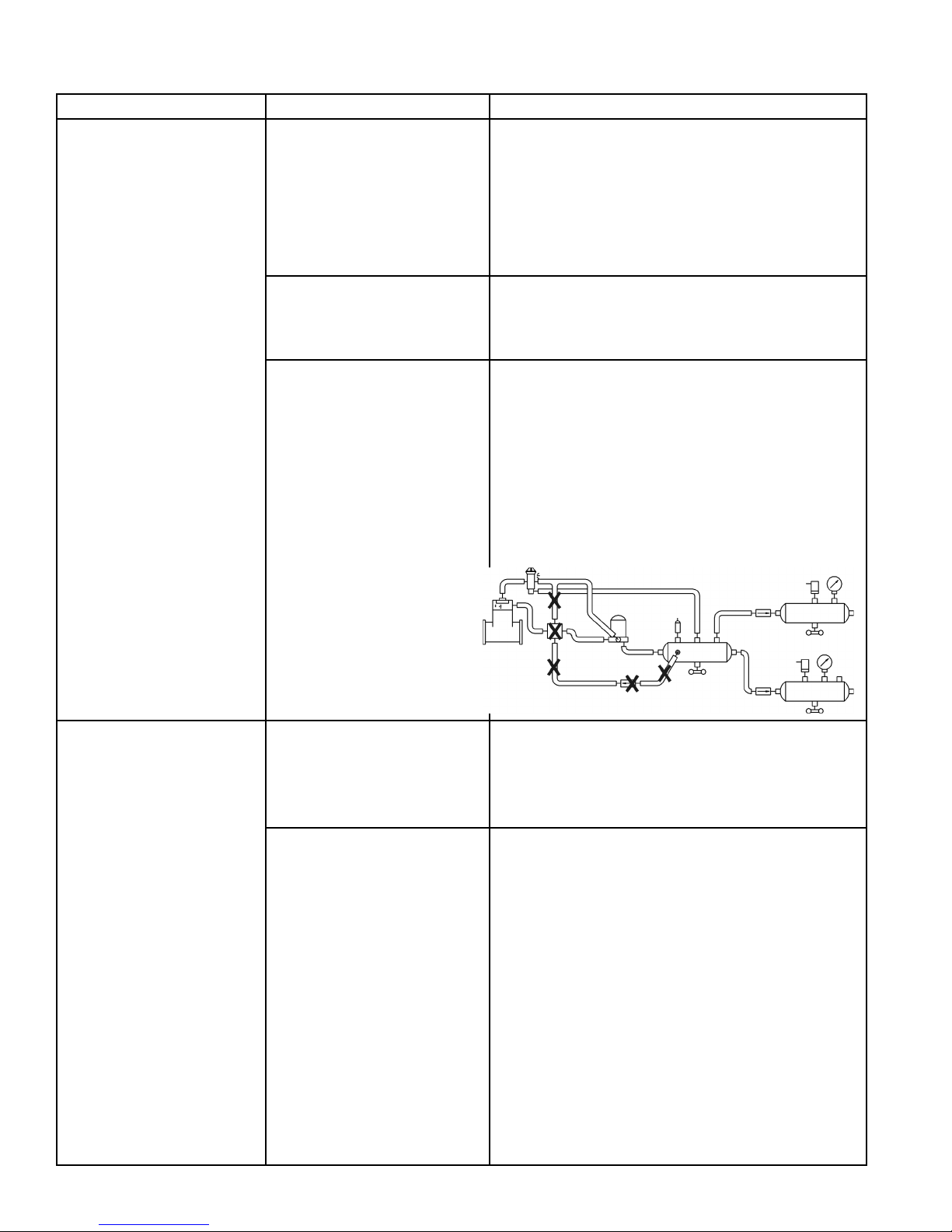

FIGURE 9 - AD-4™AIR DRYER INSTALLATION SCHEMATIC

COMPRESSOR

UNLOADER

“UNL”

PORT

AD-4™

AIR

DRYER

SUP

SUPPLY

RESERVOIR

8-10 AMP FUSE

TO IGNITION

RESERVOIR

“RES”

PORT

DEL

CON

GOVERNOR

1&9

7

5

6

DELIVERY

PORT

MOUNTING

BRACKET HOOK

SAFETY

VALVE

2

CONTROL

PORT

HEATER

VOLTS/WATTS

EMBOSSED

HERE

8

3

SUPPLY

PORT

4

FIGURE 8 - AD-4™AIR DRYER END COVER WITH TORQUE

PATTERN

11

Bendix parts outlet or sales representative for additional

information.

1. ChargeCycleTime-TheAD-4™airdryeris designedto

provide clean, dry air for the brake system. When a

vehicle’s air system is used to operate non-brake air

accessories it is necessary to determine that during

normal,daily operation the compressorshouldrecover

fromgovernor “cut-in”to governor“cut-out” (usually100

psi to 120 psi) in 90 seconds or less at engine RPMs

commensuratewith thevehicle vocation.If therecovery

time consistently exceeds this limit, it may be

necessaryto “bypass”theair accessoryresponsible for

thehigh airusage. Consultyour localauthorized Bendix

parts outlet or sales representative for additional

information.

2. PurgeCycleTime -During normalvehicleoperation, the

aircompressormustremain unloaded fora minimum

of 20 seconds for the standard AD-4™air dryer or 30

seconds for the extended purge model. These

minimum purge times are required to ensure complete

regenerationof thedesiccantmaterial. Ifthe purge time

is occasionally shorter than the times specified, no

permanentill effectshould beexpected,however, ifthe

purge time is consistently less than the minimum, an

accessory by-pass system must be installed.

3. European Air Brake Systems - Brake systems that

incorporate compressors without integral unloading

mechanismsand/or utilizeacompressor dischargeline

unloadervalve have specialAD-4™air dryer installation

requirements.ConsultyourlocalauthorizedBendixparts

outletor salesrepresentativefor additionalinformation.

4. AirCompressor Size -AlthoughtheAD-4™air dryer can

be used in conjunction with larger compressors, it was

designedprimarilyfor units rated forupto 17 CFM. Itis

recommendedthat when usingtheAD-4™air dryer with

acompressorwhichhasarateddisplacementexceeding

17CFMthatanauthorized Bendixparts outletorBendix

marketingrepresentative be contactedfor assistance.

5. Holset“E orQE”TypeAir Compressors- Inorder forthe

AD-4™airdryerto function properly wheninstalled with

the Holset Type “E or QE” compressor, several

specialized Holset components are required. Consult

your local authorized Holset parts outlet or sales

representativeforadditional information.

6. Use of Standard or Extended PurgeAD-4™Air Dryer -

Usethe followingguidelines:

Total Vehicle Reservoir

Volume Requirement

Less than 9,000 cu. in. ...................StandardAD-4™Air Dryer

9,000-12,500 cu.in. ............................Extended PurgeAD-4™

Air Dryer

Greater than 12,500 cu. in. .............Contact Bendix Rep. or

Bendix Engineering

RE-INSTALLATION

1. Install the assembled AD-4™air dryer (if an AD-4™air

dryerwith alowerright angle bracketinsteadof a lower

mountingstrap isbeing serviced proceedto step#2) on

the vehicle by sliding it into mounting brackets until

mountingbrackethookcatchesunderthelipofthecover.

Proceed to step #3.

2. Install the assembled AD-4™air dryer back onto the

vehicle by slipping it into the upper mounting bracket.

Align the two unused holes in the end cover with the

bottom mounting bracket such that the bottom bracket

supportsairdryer.TheAD-4™airdryer endcovershould

rest on the bracket. Using the remaining two 3/8" cap

screws,four special washers,and two locknuts,secure

the air dryer to the lower bracket. Tighten, then torque

the two remaining cap screws to 270-385 in. Ibs.

3. Tighten the 5/16" x 4-1/2" bolt and nut on the upper

mountingbracket. Torque to 80-120in Ibs.

4. Reconnect the three airlines to the proper ports on the

endcover (identifiedduring disassembly).

5. Reconnect the thermostat and heater wire and place

boot in position to protect connection by forcing it over

knobon plastic cover.

6. Before placing vehicle back into service, perform the

Operation and Leakage Tests stated elsewhere in this

manual.

RETROFITTING THE AD-4™AIR DRYER

GENERAL

Thefollowingretrofitinstructionsarepresentedfor reference

purposes only since Bendix aftermarket retrofit and

replacement air dryers are packaged with the most up-to-

dateinstallationinstructions. Theinstructionspackagedwith

the AD-4™air dryer should be followed in lieu of those

presentedhere.

Thepreceding portionof this manualdeals with“in-service”

repairand orreplacementof theAD-4™airdryer.Theportion

of the manual that follows is concerned with installing an

AD-4™air dryer on a vehicle not previously equipped with

one.

VEHICLE APPLICATION REQUIREMENTS

Thebasic applicationrequirementspresentedhereapplyto

a standard air dryer installation. The majority of highway

vehicles in use today will meet these basic requirements

however,some maynot. Examplesofvehiclesthatmay not

meet the requirements include bulk trailer unloading

operationsand other highair consumption/continuous flow

systems. While the AD-4™air dryer can be used on these

vehicles the standard installation procedure presented in

this manual may require modification to assure proper

operation and service life. Consult your local authorized

12

VEHICLE PREPARATION

1. Parkthevehicleonalevelsurfaceandpreventmovement

by means other than the brakes.

2. Drain all reservoirs to 0 p.s.i. (0 kPa).

LOCATING AD-4™AIR DRYER ON VEHICLE

1. TheAD-4™air dryer must be mounted vertically (purge

exhaust toward road surface) outside the engine

compartmentin anarea of airflow whilethe vehicleisin

motion. The AD-4™air dryer must not be exposed to

direct wheel splash (located behind axle mud flap is

acceptable).

2. Locate theAD-4™air dryer as close to the first (supply)

reservoiras possible.

3. Do not locate the AD-4™air dryer near heat producing

components such as the vehicle exhaust and make

certain adequate clearance from moving components

(e.g. drive shaft, suspension, pitman arm, etc.) is

provided.

4. LocatetheAD-4™airdryeron vehicleso thata minimum

of 11 inches (28 cm) clearance below the end cover is

availabletoallow servicing.Alternatively,provideaccess

to the bracket bolts so the unit may be removed for

servicing.

5. Whenchoosing the mounting locationfortheAD-4™air

dryer,notethedischargelinelength requirementsstated

underthe heading ConnectingtheAir Lines, elsewhere

in this instruction sheet.

ImportantNote: Under normaloperatingconditions,the

maximuminlet airtemperature for theAD-4™airdryeris

160degreesFahrenheit.

MOUNTING THE AD-4™AIR DRYER

1. Assemble the mountingstrap and mountingbracket as

illustrated in Figures5 & 6using the 5/16"screws, nuts

and lock washers. Make certain the mounting bracket

hookisinstalledonthe5/16"screwofthelowermounting

bracketandthatitengagestheAD-4™airdryerendcover.

Makecertain thattheinside surfaceof thetop mounting

strapbearsentirely onthecylindrical surfaceofthe dryer

shell and that it does not overlap the domed top. The

bracketsshouldbe a minimumof 5.5inches apart.After

positioning the mounting straps according to the

installationrequirements, torqueboth 5/16" screws to

80-120inch pounds.

Note:Themountingbracket atthe baseof theAD-4™air

dryercanbeoftwo types.The onedescribed aboveora

singlepieceright anglebracket.(See Figure7.)Toinstall

the single piece lower mounting bracket, remove and

discard two of the bolts and nuts that retain the end

cover. Install the lower mounting bracket as shown in

Figure 7. Utilizing the bolts and lock nuts provided with

thebracket and placingthe washersremovedin proper

sequence,torqueto 270-330inch pounds.To determine

which end cover bolts to utilize to attach the bracket,

takeinto consideration the pipingconnections required

toinstall theAD-4™airdryer and usethose that willbest

position the unit for ease of installation.

2. Auniversal mountingplate (Pc.No.248478)isavailable

tofacilitatethe mounting of theAD-4™air dryer. It is not

includedinkitsbutcanbeobtainedthroughanauthorized

Bendix parts outlet.

3. Use3/8"bolts(grade5min.)andwashers(notfurnished)

tomount theAD-4™airdryertothevehicle.Torque to25

ft.Ibs.(300inch pounds).

CONNECTING THE AIR LINES

PURGE CONTROL LINE

1. Install a purge control air line having a minimum inside

diameter of 3/16 inches between the AD-4™air dryer

end cover control port and an unused unloader port on

thegovernor.The controlline mustbe plumbeddirectto

thegovernorandnotinserieswithautomaticdrainvalves,

lubrication systems, etc.

2. Thecontrol lineshouldslope downwardtotheendcover

withoutforming potential watertraps.

DISCHARGE LINE

General:

Refer to Appendix A, TableA for recommended discharge

line lengths and sizes for various vehicle applications and

vocations.

PURGE EXHAUST LINE

1. If it is necessary to direct AD-4™air dryer discharge

contaminantsaway fromvehicle componentsa 1.5inch

(38.1 mm) I.D. hose can be clamped on theAD-4™air

dryerexhaust cover.

WIRING THE HEATER/THERMOSTAT

1. Notethe required voltageandwattage fortheAD-4™air

dryer heater by checking the end cover as shown in

Figure8.

2. Remove the rubber boot covering the single electrical

terminalofthestandardAD-4™airdryerendcover.Install

a16 gaugewire betweenthe “on”position ofthevehicle

ignitionor engine“kill” switch andthe heater/thermostat

electrical terminal.An 8-10 amp fuse is required in this

lineregardless ofvoltage.

13

3. ForAD-4™airdryerendcoverswith adual terminal(See

Figure 6) heater connections, the power and insulated

return wires may be connected to either terminal. An

8-10amp fuse shouldbe installed inthe power carrying

wire.Use 16 gaugewire for bothpower and return.

4. Allelectrical connections must bewaterproofed.

5. Tie wrap or support all electrical wire leading to the

AD-4™airdryerat6-8inchintervals.Note:Wiresshould

have sufficient slack and not be completely taught.

TESTING THE AD-4™AIR DRYER

Beforeplacing the vehicle in service,performthe following

tests:

1. Closeall reservoir drain cocks.

2. Build up system pressure to governor cut-out and note

that theAD-4™air dryer purges with an audible escape

ofair.

3. “Fan”the service brakes toreduce system air pressure

togovernorcut-in.Notethatthesystemonceagainbuilds

to full pressure and is followed by a purge at theAD-4™

airdryer exhaust.

4. Itis recommended thatthe following itemsbe tested for

leakageto assure that theAD-4™airdryer will not cycle

excessively.

(A) Total air system leakage (See Bendix publication

BW-5057“Air BrakeHandbook”).

(B) Compressorunloadermechanism.

(C) Governor.

(D) Draincockandsafetyvalveinfirst(supply)reservoir.

(E) All air connections leading to and from the first

(supply)reservoir.

14

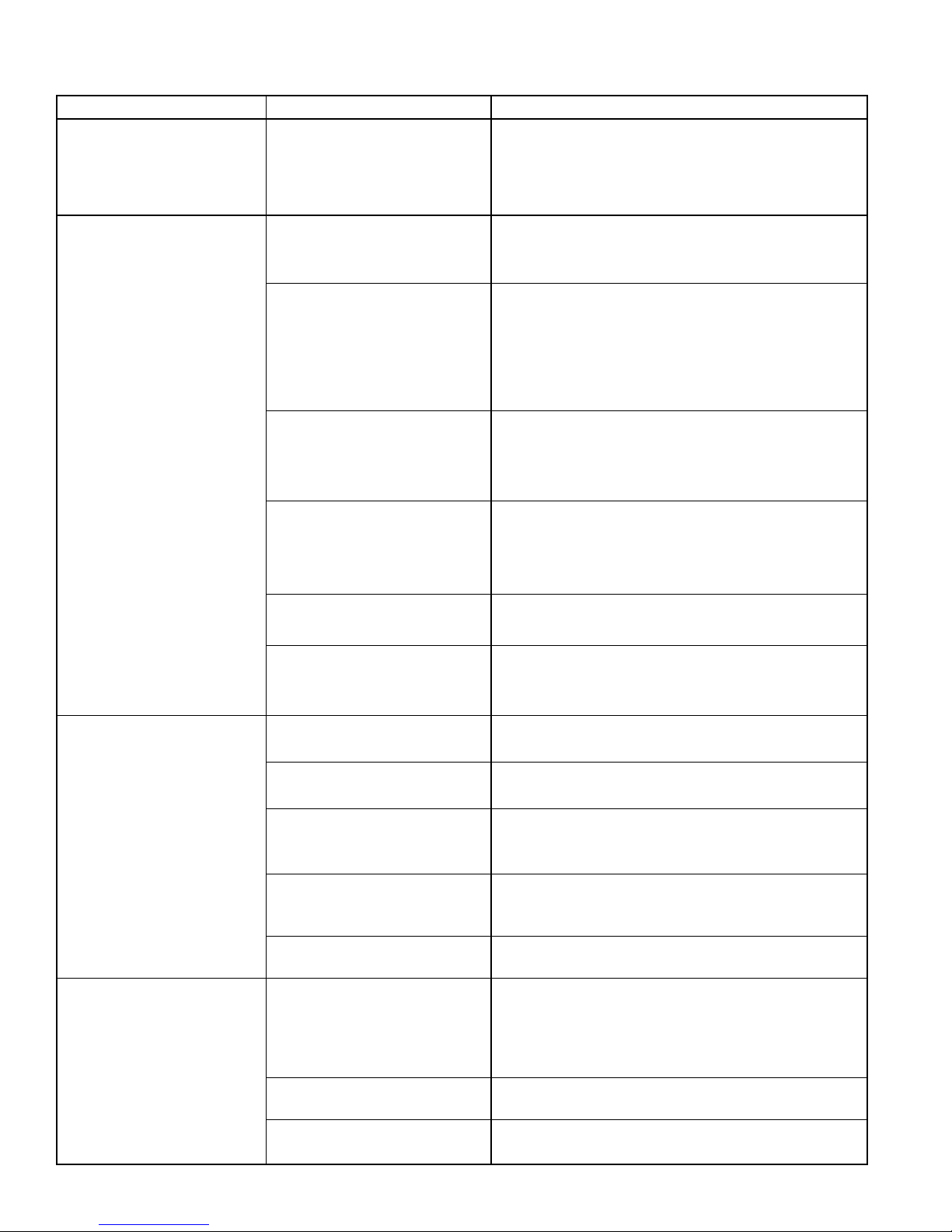

SYMPTOMS

1. Dryer is constantly

“cycling”or purging.

Dryerpurges frequently

(every 4 minutes or less

whilevehicleisidling).

A. If leakage IS SHOWN on gauges test for

excessiveservicebrake system leakage.

Allowableleakage:

Singlevehicle-1 psi/minute either service

reservoir.

Tractortrailer-3 psi/minute either service

reservoir.Repair andretest as required.

A. Excessive system

leakage.

IMPORTANT:Note whether

air pressure loss is shown

ondashgauge(s). Pressure

loss shown on gauges is

causedbyservice brake

system or component

leakage.PressurelossNOT

SHOWN on gauges is

caused by supply system or

componentleakage.

CAUSE REMEDY

B. If leakage is NOT SHOWN on gauges test for

excessive supply system leakage.

Removedrain cock orvalve in supplyreservoir(wet

tank) and install air gauge. Build system pressure,

allowairdryer to purge and observeairgauge in

supplyreservoir.Pressuredrop should not exceed 1

psi per minute. Perform tests 1 to 6 in the order

presented.

AD-4™AIR DRYER TROUBLESHOOTING CHART

15

1. Test fittings, hoses, lines and connections.

Apply soap solution to detect excessive

leakage.Tightenor replace as needed then

repeattheair dryer charge-purge cycle and

observethegaugeinstalled in the supply

reservoir. Ifleakage is within limitsremove gauge

fromreservoir and replacedrain cock orvalve. If

excessive leakage is detected, continue testing.

2. Test accessories connected tosupplyreservoir.

Drain all air pressure from system, disconnect

all air lines leading to accessories (fan clutch,

wipers, air seats, etc.) and plug the reservoir at

disconnection point. Build air system pressure

untilairdryer purges and observe supply

reservoirgauge. If leakage isnolonger

excessive,repairor replace leaking accessory. If

excessive leakage is detected, continue testing.

3. Test governor leakage. Buildsystempressureto

governorcut-out, turn off engineand apply soap

solutionto governor exhaust portandaround

cap. Leakage should not exceed a 1" bubble in

5 seconds. Reduce system pressure to 80 psi

or less, and re-apply soap solution. Leakage

should not exceed a 1" bubble in 5 seconds. If

excessive leakage is detected in either test,

repairorreplace governor.

4. Test compressor unloaderleakage.Drain all air

pressurefrom system andremove the governor

fromthecompressor.Temporarily plug the

governorunloaderport or air line thatmated with,

or connected to, the compressor. Build air

system pressure until air dryer purges then

IMMEDIATELYSHUTOFFTHE ENGINE.

Observethe air gauge inthesupply reservoir. If

leakage is within limits, replace the compressor

unloaders.Re-connect the governor tothe

compressor(after removing plug installedin

governor)and retestwhileobserving supply

reservoirgauge. If excessive leakageis

detected, continue testing.

5. Test airdryer purge valveand outlet (delivery)

checkvalve.Drainallair pressure from system,

remove the control line connection at the air

dryer and plug the end of the air line leading to

thegovernor(not the air dryer control port). Build

systempressure to governor cut-outandobserve

airgauge.If little or no pressure drop is observed

replacetheair dryer check valve. Ifpressure

drop continues apply soap solution to air dryer

purgeexhaustand purge control port (wherethe

controllinewas removed). Leakage shouldnot

exceed a 1" bubble in 5 seconds. If leakage is

excessiverepair orreplace purgevalve

assembly.

REMEDY

CAUSE

SYMPTOMS

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

16

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE REMEDY

6. Withgauge installed atRESportof governor,

pressureshould not dropbelow”Cut-In” pressure

attheonsetof the compressor “Unloaded”

cycle. If pressure drops, check for “kinks” or

restrictions in line connected to RES port. Line

connected to RES port on governor must be

samediameter,orpreferably larger than, lines

connectedto UNLport(s)on governor.

B. Remove end cover.Apply120psi at control port.

Soapbothsides around purge valve to testfor

control piston leakage. Leakage should not

exceed a 1" bubble in less than 5 seconds.

C. Test the Holset E Compressor unloader system

withfeedback line and checkvalve for proper

operation. Make certain Holset ECON is not

usedwiththedrop-in version of the air dryer, if

so,removeand retest.

B. Leakingpurge valvein air

dryerend cover(control

side).

C. Holset “E” type

compressor.

When installing a Bendix Drop-In air dryer in a

system equipped with a Holset E or QE

compressor,remove theHolsetECON valvealong

withitsfeedback and governor control line.

2. Water and/or Oil in

Supplyor Service

Reservoir.

A. Improperdischarge line

lengthor improper line

material.Maximumair

dryerinlettemperatureis

exceeded.

B. Air system charged from

outsideairsource

(outsideairnotpassing

throughair dryer).

A. Refer to section entitled Connecting the Air Lines

as well asAppendixA, Table A columns 1 & 2

then and check line size and length.

B. If system must have outside air fill provision,

outside air should pass through air dryer. This

practice should be minimized.

17

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

2. Water and/or Oil in

Supplyor Service

Reservoir(continued).

CAUSE REMEDY

E. Excessive air usage,

duty cycle too high - Air

dryernotcompatible

with vehicle air system

requirement(Improper air

dryer/vehicle

application).

NOTE: Duty Cycle is the

ratio of time the compressor

spends building air to total

enginerunningtime.Air

compressorsare designed

tobuildair (run “loaded”) up

to 25% of the time. Higher

duty cycles cause

conditions that affect air

brakechargingsystem

performancewhich may

requireadditional

maintenance. Factors that

add to the duty cycle are: air

suspension,additionalair

accessories, use of an

undersizedcompressor,

frequentstops,excessive

leakagefrom fittings,

connections, lines,

chambersor valves, etc.

D. Check causes and remedies for Symptom #1.

E. SeeAppendixA, TableA, column 1, for

recommendedcompressorsizes. If the

compressoris“too small” for the vehicle vocation

(forexample, where a vehicle’svocationhas

changedorservice conditions exceed the original

vehicleorengine OE spec’s) then upgrade the

compressor. Note: The costs incurred (e.g.

installing a larger capacity compressor, etc.) are

notcovered under originalcompressor warranty.

Charge Cycle Time -TheAD-4™air dryer is

designedtoprovide clean, dry air for the brake

system. When a vehicle’s air system is used to

operate non-brake air accessories it is necessary

todeterminethat; during normal, daily operation

thecompressor shouldrecover fromgovernor

“cut-in”togovernor “cut-out” (usually 100 psi to

120 psi) in 90 seconds or less at engine RPM’s

commensuratewiththe vehicle vocation. If the

recovery time consistently exceeds this limit, it

may be necessary to “bypass” the air accessory

responsible for the high air usage.An example of

where a by-pass system would be required is

when the compressor is used to pressurize a

tanktrailer for purposes ofoff-loading product.

Consult your local authorized Bendix parts outlet

orsales representative foradditional information.

PurgeCycle Time - Duringnormal vehicle

operation, the air compressor must remain

unloaded for a minimum of 30 seconds. This

minimum purge time is required to ensure

completeregenerationof the desiccant material.

If the purge time is consistently less than the

minimum, an accessory by-pass system must be

installed. Consult your local authorized Bendix

partsoutletor sales representative foradditional

information.

Air Compressor Size -Although theAD-4™air

dryer can be used in conjunction with larger

compressors, it was designed primarily for units

rated for up to 30 CFM. It is recommended that

when using theAD-4™air dryer with a

compressor which has a rated displacement

exceeding 30 CFM that an authorized Bendix

partsoutletor Bendix marketing representative

be contacted for assistance.

D. Purge (air exhaust) time

insufficientdueto

excessive system

leakage(seecauses for

Symptom #1).

C. See Symptom #5.C. Airdryer not purging

(see Symptom #5).

18

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

2. Water and/or Oil in

Supplyor Service

Reservoir(continued).

DischargeLineFreeze-UpThedischargelinemust

maintainaconstantslopedownfromthe

compressortothe air dryer inletfittingto avoid low

pointswhere ice may form and block the flow. If,

instead, ice blockages occur at the air dryer inlet,

insulation may be added here, or if the inlet fitting is

a typical 90 degree fitting, it may be changed to a

straightor45degreefitting.Formore informationon

howtohelppreventdischargelinefreeze-ups,see

BendixBulletinsTCH-08-21andTCH-08-22.Shorter

dischargelinelengthsorinsulationmaybe required

in cold climates.

Insufficientcoolant flowthroughcompressor.

Inspect coolant line. Replace as necessary (I.D.

is 1/2" min.). Inspect the coolant lines for kinks

and restrictions and fittings for restrictions.

Replace as necessary. Verify coolant lines go

from engine block to compressor and back to the

waterpump.Repairasnecessary.

Restricted air inlet (not enough air to

compressor). Check compressor air inletline for

restrictions, brittleness, soft or sagging hose

conditions etc. Repair as necessary. Inlet line

size is 3/4 ID. Maximum restriction requirement

for compressors is 25 inches of water. Check the

engineairfilterand service if necessary (if

possible, check the air filter usage indicator).

Poorly filtered inlet air (poor air quality to

compressor).Checkfor leaking, damaged or

malfunctioningcompressorair inlet components

(e.g. induction line, fittings, gaskets, filter bodies,

etc.). Repair inlet components as needed. Note:

Dirt ingestion will damage compressor and is not

coveredunderwarranty.

Ifyoufoundexcessive oil present in the service

reservoirandyou did not find any issues above,

the compressor may be passing oil.

Replacecompressor.Ifstill under warranty, follow

normalwarranty process.

G. Ifyoufoundexcessive oil present in the service

reservoirandyou did not find any issues above,

the compressor may be passing oil. Test the

compressor using the BASIC cup method as

describedintheBendix compressor service

manual and referred to inAppendixA,TableA,

column 5.

Replacecompressor.Ifstill under warranty, follow

normalwarranty process.

CAUSE REMEDY

G. Compressormalfunction.

F. Restricted discharge line. SeeAppendixA,

TableA, column 1 & 2 for recommended sizes.

If discharge line is restricted or more than 1/16"

carbonbuildupis found, replace the discharge

line. Replace as necessary.

F. Air compressor

dischargeand/or air

dryerinlet temperature

too high.

19

I. Desiccantrequires

replacement.

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE REMEDY

H. If vehicle uses Holset compressor, inspect

feedbackcheck valve forproperinstallation and

operation.

When replacing the desiccant cartridge, make

sure desiccant cartridge assembly is properly

installed and sealing rings are in place on

mountingsurfaceof desiccant cartridge.

H. Air by-passes desiccant

cartridgeassembly.

I. Replace desiccant cartridge assembly. Refer to

AppendixA, TableAcolumns 3 & 4 for

recommendedintervals.

A. Air dryers remove water and oil from the air

brake charging system.Asmall amount of oil is

normal. Check that regular maintenance is

being performed and that the amount of oil in the

air tanks (reservoirs) is within the acceptable

range shown on the BASIC cup (see also

column 5 ofAppendixA, TableA). Replace the

airdryercartridge as needed and return the

vehicleto service.

A. Airbrake charging

system is functioning

normally.

3. Oil present at air dryer

purgeexhaust or

cartridgeduring

maintenance.

A. Check to determine if air is reaching supply

reservoir. Inspect for kinked tubing orhose.

Checkforundrilledor restricted hose or tubing

fittingsandrepairor replace as needed.

B. Verify relief pressure is at vehicle orcomponent

manufacturerspecifications. Replace if

malfunctioning.

C. Refer toAppendixATableAand column 3.

Check compressor for excessive oil passing

and/orcorrectcompressor installation. Repair or

replace as necessary. Replace desiccant

cartridge.

D. Test to determine if air is passing through check

valve.Repair orreplace.

E. Increasevolume in discharge linebyincreasing

length or diameter.Add a ping tank (small

reservoir).

A. Restrictionbetween air

dryerandsupply (first)

reservoir.

B. Airdryer safetyvalve

malfunction.

C. Desiccantcartridge

maintenancerequired.

D. Malfunctioningdischarge

checkvalve inend cover

of theAD-4™air dryer.

E. Excessivepressure

pulsationsfrom

compressor. (Typical

single cylinder type).

4. Safetyvalve on airdryer

“poppingoff”or

exhaustingair.

20

AD-4™AIR DRYER TROUBLESHOOTING CHART (Continued)

D. Excessivebends in

dischargeline(water

collectsandfreezes).

E. RefertoSymptom4,

causes E & F.

SYMPTOMS CAUSE REMEDY

F. Governormalfunction.

Missing or restricted

governorcontrolline

installation.

F. Testgovernor operation and/orinspectthe

controlline leading fromthegovernor UNL

(unloader)porttotheair dryer control port.

5. Constantexhaust of air

atair dryerpurge valve

exhaust.(Charge

mode.)

A. Airdryerpurgevalve

leakingexcessively.

B. Compressorfails to

unload(stop

compressingair) and air

dryerpurge exhaust

makes“sputtering”or

“popping”sound.

C. Purge control line

connectedto reservoir or

exhaustport ofgovernor.

D. Purgevalvefrozen open-

malfunctioningheater

andthermostat,wiring,

blownfuse.

A. With compressor loaded, apply soap solution

onpurgevalve exhaust, to test for excessive

leakage.Repairpurgevalve as necessary.

B. Confirm failure to unload by increasing &

decreasingengineRPM and noting change in

the rate of leakage and intensity of

accompanyingleakage sound. Repair/replace

compressorunloaders.

C. Purge control line must be connected to

unloaderportofgovernor.

D. Test heater and thermostat as described in

PreventativeMaintenance Section.

E. See Symptom #1.

E. Excessive system

leakage.

F. Purgevalve stays open-

supply air leaks to

control side.

F. Repair purgevalve andhousing.

6. Can not build system air

pressure. A. Inlet and outlet air

connectionsreversed.

B. Checkvalvebetweenair

dryerand first reservoir.

C. Kinkedorblocked

(plugged)dischargeline.

A. Connect compressor discharge to air dryer

supplyport.Reconnectlines properly.

B. Test checkvalvefor proper operation.Repair or

replace as necessary.

C. Check to determine if air passes through

discharge line. Check for kinks, bends,

excessive carbon deposits, or ice blockage.

D. Discharge line should be constantly sloping from

compressor to air dryer with as few bends as

possible.

E. Refer to Symptom #4, Remedies E & F.

7. Airdryer does not purge

or exhaust air. A. Missing, broken, kinked,

frozen,plugged or

disconnectedpurge

control line.

A. Inspectcontrol linefrom governorUNL(unloader)

port to control port of air dryer. Test to determine

airflowsthrough purge control line when

compressorunloaded. Check for undrilled

fittings. (See Symptom #4, Remedy C.)

B. Afterdetermining airreaches purge valve

(RemedyAabove),repairpurgevalve.

C. Refer to Remedies B, E, G for Symptom #4.

B. Faultyair dryer purge

valve.

C. See Causes, B, E, G for

Symptom #4.

This manual suits for next models

1

Table of contents

Other BENDIX Dryer manuals

Popular Dryer manuals by other brands

Bosch

Bosch WTG8620XCL Installation and operating instructions

Beko

Beko DPS7405 XW3 user manual

Kenmore

Kenmore 796.8077 series Use & care guide and installation instructions

Amana

Amana NDE8805AZW Use & care guide

Oliver

Oliver DVX Operation manual

American Dryer Corp.

American Dryer Corp. AD-75 parts manual