Benezan Electronics TripleBeast User manual

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Triple BEAST

Bene’s Advanced Stepper Drive

3-axis high performance power amplifier

for stepper motors with integrated

Interface card for Ethernet

Installation manual

Brief product description

The "Triple BEAST" is a complete stepper motor controller for three axes. All components for the control of a small milling,

engraving or turning machine are integrated in a housing with dimensions of only 100x102x55mm. Only a power supply unit for

the power supply is still required. The effort for mounting, wiring and the possibilities for errors are thus reduced to a minimum.

The Triple BEAST offers all the advantages of the individual BEAST power amplifier at extremely low cost, such as very quiet

motor running with continuous sinusoidal commutation and complete short-circuit and overload protection. Only the maximum

current and the maximum operating voltage are limited to 5A and 55V compared to the "big brother". For applications with 4

axes, or if a more powerful motor is required, a connection option for an additional output stage is available.

The network version of the Triple BEAST is designed for operation with the Beamicon2 CNC control software. A normal

network connection with RJ45 cable is used for data transfer from the PC. No LPT port is required, and the well-known

limitations of step frequency and timing problems are a thing of the past.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Safety Instructions

The Triple-BEAST stepper motor controller may only be installed and commissioned by

qualified personnel. Please read the operating instructions carefully and follow all instructions

exactly. Improper installation or operation of the device can cause damage to the electronics

or the machine and can result in dangers to the health of the operating personnel. The system

manufacturer, who assembles the electronics and other components to form the overall

system, and the system operator are responsible for compliance with the legal regulations.

Caution: Danger to life! Operate the device exclusively with a voltage source isolated

from the mains supply and ensure that the limit values specified in the technical data are observed! Machine, motor and housing

must be grounded according to the regulations. Devices operated with mains voltage must be checked and approved by a

specialist. Make the first tests with disassembled motors or remove drive belts or couplings. This prevents injuries or damage due

to unexpected movements of the machine.

System requirements

To obtain a functional drive system, the following components are required in addition to the Triple-BEAST control:

1. One to three two-phase stepper motors with a rated current between 1.4 and 5A (up to 6A with restrictions). Three- or five-

phase motors or high-impedance motors from printers and disk drives are not suitable.

2. A power supply unit for the voltage supply. with an output voltage between 24 and 55V. Stabilization is not absolutely

necessary. More detailed selection criteria are listed in the chapter0.

3. A PC with Beamicon2 CNC software and a RJ45 network cable (patch cable). Please note that this version of the Triple

BEAST is not compatible with Mach3, Eding-CNC, LinuxCNC or similar software. Alternatively, a version with LPT

interface is available.

Recommended motors

The table below lists some recommended combinations with motors from Benezan Electronics. The applications mentioned above

only represent an approximate selection. If you wish a more precise calculation of the drives, please contact Benezan Electronics.

Motor

Type

Dimensions

Phase current

Operating voltage

Application

HS56-0818

56 x 56mm

1,8A

24..48V

Miniature machines, pick & place, cutting

and pen plotters

HS56-1442

56 x 76mm

4,2A

24..48V

Small to medium-sized milling and

engraving machines in aluminium profile

design

HS60-2150

60 x 90mm

5,0A

48..55V

HS86-3263

86 x 78mm

5,0A

48..55V

Milling machines for metal working, larger

portal machines, plasma cutting machines

The Triple BEAST control also works with many motors from other manufacturers. Please make sure, however, to use only

modern hybrid motors that are suitable for microstep operation. The best results and highest dynamics are achieved with motors

with flange sizes from 56 to 60mm and phase currents from 3 to 5A. The operation of larger motors with 86mm flange dimension

is possible, but with restrictions. For motors with 6A rated current the full torque is not reached, because the output stage only

delivers max. 5A. With large motors with 4A rated current, high speeds cannot be achieved due to the high inductance.

If you need high torque and high speed at the same time, it is advisable to use a BEAST single output stage, which allows

higher operating voltage and motor currents up to 10A. If only one motor with higher power is required, for example for a heavy

Z-axis, the combination with Triple-BEAST and single BEAST as 4th axis is possible.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Installation

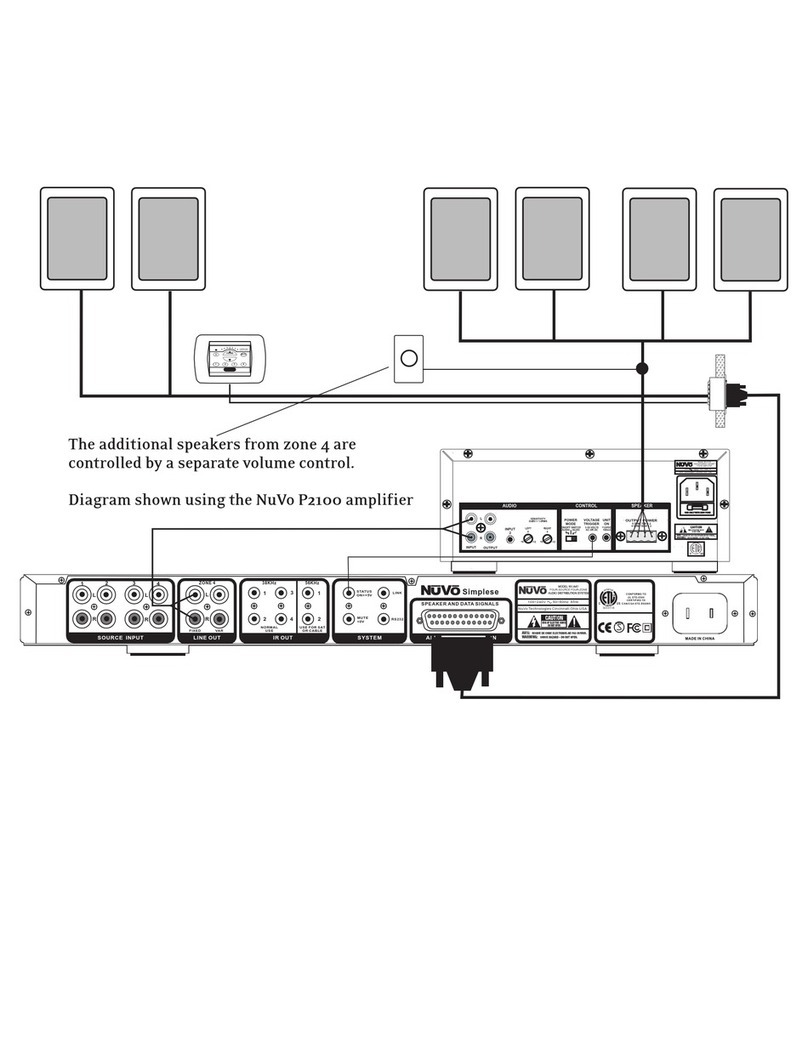

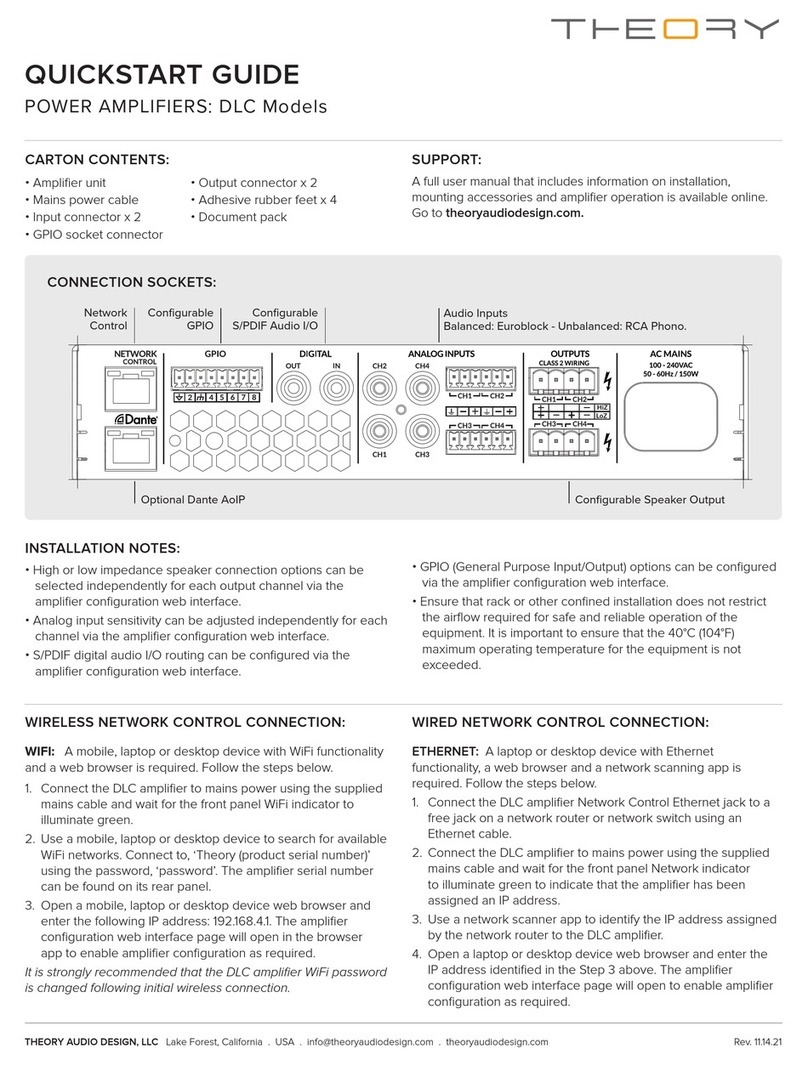

Connections Overview

All terminal numbers are numbered from top to

bottom as shown in the adjacent figure.

Reference switch inputs (8-pin terminal X3, top

left)

No.

Description

1

Reference switch X voltage output (+12 or +24V)

2

Reference switch X Signal input

3

Reference switch Y Voltage output (+12 or +24V)

4

Reference switch Y Signal input

5

Reference switch Z voltage output (+12 or +24V)

6

Reference switch Z Signal input

7

Reference switch 4th axis voltage output

(+12/24V)

8

Reference switch 4th axis Signal input

Relay outputs

(6-pin terminal X4, bottom left)

No.

Description

1

230V~ L Input

2

230V~ N Input

3

Relay 1 L Output

4

Relay 1 N Output

5

Relay 2 L output

6

Relay 2 N output

Power supply

(2-pole terminal V, right side)

No.

Description

1

Motor voltage input(+24..+55V)

2

Ground 0V

Additional functions

(6-pole terminal X2, top right)

No.

Description

1

Ground 0V for brake

2

Holding brake Output

3

Analog output ground 0V

4

Analog output 0..10V

5

Emergency stop switch Input

6

Emergency stop switch +12V

output

Power supply

(5-pole terminal X1, bottom right)

No.

Description

1

5V output (max. 150mA)

2

Ground 0V

3

12V output (max. 300mA)

4

Ground 0V

5

24V input (15..55V,max.0,3A)

Motor connections

(4-pin terminals M1 to M3, right side)

No.

Description

1

Winding 1

2

3

Winding 2

4

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Assembly

The output stage is designed for mounting on a 35mm DIN rail ("top-hat rail") in a housing. Protect the unit from flying chips,

dust and cooling water. Damage caused by metal chips or moisture will void the warranty. Hook the controller into the rail with

the motor connections facing up, then press the heat sink firmly onto the rail until it clicks into place. Alternatively, it can also be

fastened from the rear with self-tapping self-tapping self-tapping screws B3.5x10 or spacer bolts on a mounting plate. In this case

the clip for the DIN rail must be removed. Attention - never use a longer screw than the one supplied (M4x16) to screw on the

clip. Otherwise they could damage the power components mounted on the inside of the heat sink.

Since the output stage becomes more or less hot during operation depending on the motor current, the following rules must be

observed during installation:

Make sure that there is free air circulation. The distance to other devices, housing wall, cable ducts, etc. should be at least 2 cm

on all sides.

If possible, the heat sink should be mounted vertically with vertical fins.

For motor currents up to a maximum of 3 x 4.2A, natural convection is sufficient, i.e. a fan is not required if the air circulation

is not obstructed by a housing that is too small.

For motor currents from 3 x 5A or >13A in total, supported cooling with a fan is advisable. A small processor fan for PCs, for

example, can be used for this purpose. A 12V connection is provided for the power supply of the fan (X1 terminals 2+3), which

can supply up to 300mA.

Overheating cannot lead to the destruction of the controller, because an integrated overtemperature protection switches off the

motor current when the maximum temperature is exceeded. Nevertheless, it is advisable not to operate the output stage

permanently at the upper temperature limit, as this will reduce its service life.

Power supply connection

The supply voltage must be between 24 and 55V. For most applications a 48V switch mode power supply is ideal because

these power supplies are small, light, relatively inexpensive and easy to connect. They are also overload-proof and usually have

inrush current limiting and mains filter already integrated.

However, a stabilized power supply is not necessarily required; an unregulated power supply consisting of transformer, rectifier

and filter capacitor is also suitable. Please note, however, that the voltage range must be maintained even with mains and load

fluctuations (usually ±10%). Also make sure you have suitable fuse protection. If necessary, inrush current limitation and an

interference filter may be necessary.

The maximum current with which the power supply unit is loaded is approx. 2/3 of the motor current. However, the continuous

load load is lower in most applications. For the operation of 3 motors with 4A each, for example, a power supply unit with 3 x 4A

x 2/3 = 8A peak current and about 5A continuous load capacity is sufficient. An electrolytic capacitor with about 4700μF at the

power supply output is recommended to keep voltage fluctuations small due to fast load changes.

Connect the positive pole of the power supply unit to terminal "V" connection 1 (on the side, labelled +24..55V) and the

negative pole to connection 2 (labelled GND). Attention, wrong polarity can damage the power amplifier, especially if the

power supply has no fast fuse or current limiter. Never connect or disconnect the supply connection under load. Do not switch

the secondary side of the power supply (DC voltage) with switches or fuses. The resulting arc can cause damage. Only switch

the power supply unit on and off on the primary side (mains AC voltage). The protection should also be provided on the primary

side. Please note that the negative connection (Power Ground) is connected to the heat sink and thus automatically to the housing

(potential earth).

For most applications, the power supply unit that supplies the motor voltage can also be used to supply the PC interface

(terminal X1). Connect the positive pole to X1 terminal 5 and the negative pole to terminal 4. Only if you use inductive proximity

switches with 24V and the motor supply voltage is higher than 24V, an extra 24V power supply unit is required. For details please

refer to the chapter "Limit switches".

Motor connection

When using prefabricated cables for stepper motors from Benezan Electronics the connection of the motors is very easy. Connect

the wires numbered 1..4 in sequence to terminals M1, M2 or M3. Connect the cable lug of the shield connection to the flat plug

next to the terminal. Plug the XLR connector of the motor into the female connector on the other side of the cable - ready.

For motors from other manufacturers you must consult the relevant data sheet to identify the wire colours of the coil

connections. For motors with 4 connections you can also use a continuity tester. Connected terminals belong to the same coil.

Connect the terminals of one coil to terminals 1 and 2 of the terminal, the terminals of the other coil to terminals 3 and 4.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Interchanging the coils or the terminals of the same coil with each other only changes the direction of rotation, but does not affect

the function. Only with crossed connections (e.g. one coil at 1-3 or 1-4) the motor does not work.

Settings and displays

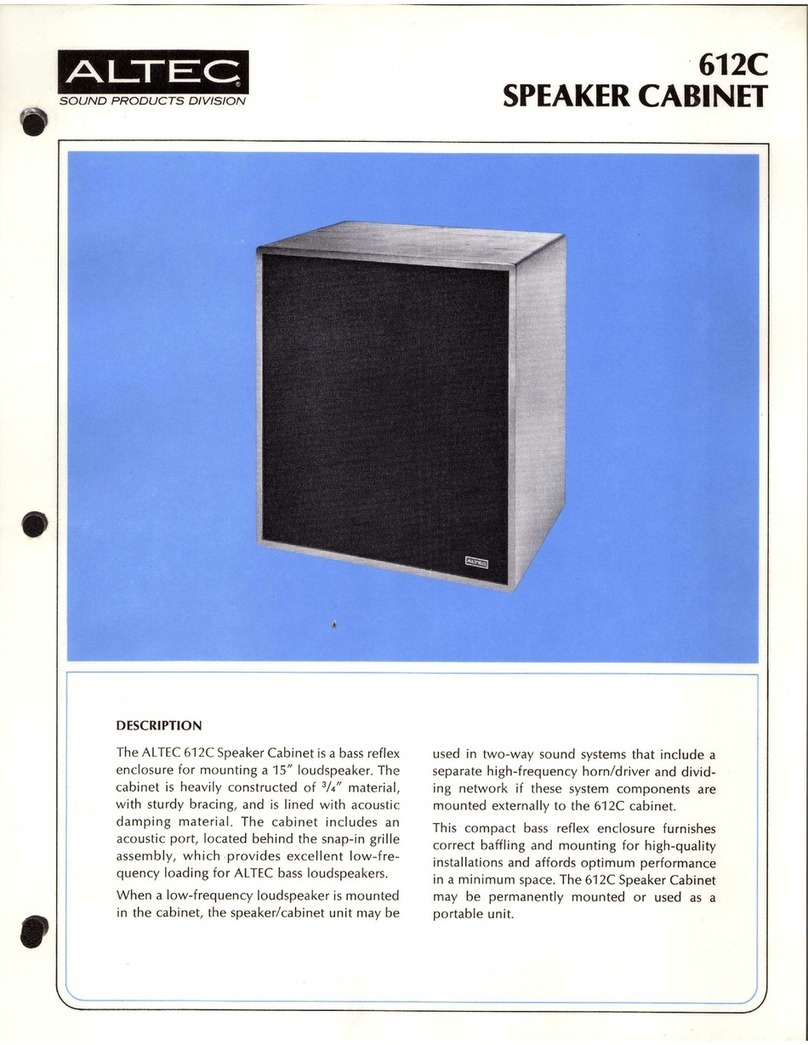

The Triple-BEAST control has ten so-called piano switches on the left side to select the

operating mode of the power amplifiers and the phase current of the motors. A pressed

switch is switched on (1 = ON, in the picture to the left), in the upper position (in the

picture to the right) it is switched off (0 = OFF).

No.

Description

1

Polarity of the current reduction signal (0=high-active, 1=low-active)

2

Waveform: 0 = pure sine, 1 = sine with harmonics

3

Selection of motor current for axis no. 1 (X)(fine adjustment, see small table

below)

4

5

Selection of motor current for axis no. 2 (Y)(fine adjustment)

6

7

Selection of motor current for axis no. 3 (Z)(fine adjustment)

8

9

Microstep resolution: 0 = 1/10 (2000/rev), 1 = 1/5 (1000/rev)

10

Motor current range (rough adjustment): 0 = 1.4..3.2A, 1 = 2.5..5A

Switch No. 10 is used for rough selection of the motor current range for all axes

simultaneously. Simultaneous operation of very small and very large motors is therefore

not possible. Depending on the selected range, the fine adjustment can then be carried

out separately for each motor with the switches 2...8.

Switch No. 2 can be used to adjust the waveform of the motor current. Some motor

types do not have an exact sine wave but a waveform slightly distorted in the direction of

a triangle. The optimal waveform can be determined experimentally, and leads to a

reduction of vibrations in certain speed ranges.

Switch No. 9 is used to select the resolution. In normal position this is 1/10

microstep (corresponds to 2000 steps/revolution for the standard motor with 200 full

steps/revolution). When the switch is held down, it switches to 1/5 microstep

(corresponds to 1000 steps/revolution).

While other stepper motor power stages often offer a confusingly large number of

possible resolutions, this is not necessary with the Triple-BEAST. Higher resolutions

are usually only used to reduce disturbing jerking caused by single steps, while the

step size is then out of reasonable proportion to the accuracy of the mechanics, is

basically useless and only unnecessarily increases the required clock frequency. The

Triple-BEAST power amplifier, on the other hand, does not need a finer subdivision

of the steps, because it is pleasantly quiet even with only 1/5 or 1/10 microstep. No

single steps are noticeable because the motor is driven with a continuous sine wave instead of a staircase function.

Ar

ea

■□

= 1

Ar

ea

□■

= 0

□■

□■

2,5

A

□■

□■

1,4

A

□■

■□

3,2

A

□■

■□

2,0

A

■□

□■

4,2

A

■□

□■

2,5

A

■□

■□

5,0

A

■□

■□

3,2

A

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Status LEDs

The status displays of the power amplifiers are located on the left side (see picture below). The different colours or combinations

thereof indicate the following operating states:

LEDs

Lettering

Description

(green)

Running

Motor(s) running, no current reduction

(yellow)

Standby

Motors stand still, current reduction

(red blinking)

Fault Axis...

A single red flashing LED indicates a short circuit, overload or faulty

wiring on the corresponding motor. The other motors and the yellow or

green LED remain active.

(red blinking)

Fault Axis...

If all red LEDs flash simultaneously when the green and yellow LEDs

are switched off, the output stage is overheated. All motors are switched

off.

(yellow/red

alternating)

Fault Axis...

If the yellow and all red LEDs flash alternately, the power stage has been

deactivated due to overvoltage. The cause can be braking energy from the

motors or an incorrectly dimensioned power supply unit.

On the left below the middle of the housing, between

the RJ45 socket for the 4th axis and the relays, there is a

pin header with five contacts and two jumpers. These are

numbered from right to left with no. 12 to 16 and are

described further below.

The LEDs on the upper side indicate the status of the PC interface.

LEDs

Lettering

Description

1 (green)

Power

Power supply ok

2 (green)

Batch pump

Watchdog (charge pump) active

3 (red)

Drive fault

One or more output stages report an error

4 (red)

E-Stop

Emergency stop switch activated or line interrupted

5 (yellow)

Relay 1

Relay 1 switched on (spindle motor)

6 (yellow)

Relay 2

Relay 2 switched on (coolant or suction)

7 (green)

-

Network connection established (Network carrier)

8 (yellow)

-

Network data transmission (network traffic)

PC / network connection

The data transfer from the PC software to the Triple BEAST takes place via an Ethernet network connection (IEEE802.3

10BASE-T). The connection can be made with standard patch cables at the RJ45 socket "N". Please note that the other RJ45

socket "A4" (without LEDs, see figure page 4) is not a network connection, but is intended for the step/direction signals of the

external 4th axis.

In contrast to similar products from competitors (e.g. Smoothstepper or Eding-CNC) no exclusive interface has to be reserved

on the PC, but the infrastructure of an existing network with switches can be used. There is also no need to change IP addresses or

otherwise interfere with the Windows Control Panel. The Beamicon2 software automatically recognizes the Triple BEAST, even

if it is connected "somewhere" in the network. To ensure reliable operation, however, the following rules must be observed:

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

The Triple BEAST must be connected either directly to the PC or to the first switch after the PC. A further switch may

only be added if only devices of the machine are connected to the second switch, e.g. within the control cabinet of the

machine. All devices not involved in machine control (Internet router, printer, NAS, etc.) must be connected to the first

switch or to additional switches behind the first.

The transmission speed between the PC and the first switch must be higher than the maximum data rate of any existing

Internet routers (DSL modem etc.). For home networks with few PCs 100MBit is recommended, for larger networks

Gigabit-Ethernet.

Since no TCP/IP is used but a separate protocol, this cannot be forwarded by routers, external firewalls, proxies, etc.

Therefore only so-called "unmanaged switches" may be used between the control PC and the CNC pod.

Switches must support Fast Forward and Store-and-Forward (virtually all modern switches meet this criterion)

Hubs are also allowed for test purposes (listening with diagnostic tools on taps), but are not recommended.

The data traffic of the machine controller must not be routed via slow (DSL modem) or unreliable (wireless) connections

(WLAN). All wireless interfaces are therefore intentionally hidden.

If the Triple BEAST is connected directly to the PC and the PC interface does not support automatic crossover, a crossover

cable must be used (usually marked with a red plug or "X"). The network interface is galvanically isolated from the PC. Power-

over-Ethernet (PoE) is not supported.

Reference switch inputs

Up to 4 switches or inductive sensors can be connected. If the 4th axis is not used or does not require a reference switch, a tool

length sensor can also be connected here, for example.

Mechanical switches or inductive proximity switches of the PNP type can be used. With the jumpers 12-13 or 13-14 the supply

voltage for the switches can be selected (see picture on page 6).

Jumper setting

Voltage

Description

▪ ▪ ▬ ▪ 13-14

12V

(internal

regulator)

recommended for mechanical switches

also for inductive switches, if they are specified for 12V

Input voltage at X1.5 any (15..55V)

▪ ▪ ▪ ▬ 12-13

24V

(connected

with X1.5)

recommended for inductive switches (industry standard)

also possible for mechanical switches (mixed types)

separate 24V power supply unit required at X1 if motor voltage >24V

Inductive proximity switches or other sensors should be connected as follows: brown (+24V) to terminal 1, 3, 5 or 7, blue to

the ground connection of the power supply, black (signal) to terminal 2, 4, 6 or 8.

The inputs are high-active, i.e. the signal is logic 1 when the connected switch is closed, or when a voltage >8V is present at the

input. The signal is logic 0 when the input is de-energized or the switch is open. If required, all input signals can be inverted in the

software.

The switch inputs have a Schmitt trigger function and are interference suppressed with a low-pass filter, so that there is usually

no need to fear interference even with unshielded cables. The inputs are overvoltage tolerant up to +80V. Please note that the

switch inputs are not suitable for fast signals (>1kHz) with 5V level, for example TTL encoder signals.

If more than four inputs are required for additional functions, an additional IO expansion module can be installed.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Emergency stop

The Triple BEAST has several independent functions that are used to stop the machine in case of problems:

1. An emergency stop button (mushroom/panic button) must be connected to terminals X2.5 and X2.6. If the contact is

opened, relays 1 and 2 are forcibly switched off. A push-button emergency stop is indicated by the right LED (red,

LED4). Additionally, an emergency stop is reported to the PC

2. If the status output of one or more output stages reports an error or if the line of the step/direction signal is interrupted, an

error signal (drive fault) is sent to the PC. The output stage error is indicated by the second LED from the right (red,

LED3).

3. In case of missing or insufficient supply voltage, an emergency stop signal is sent to the PC, so that the software does not

continue to run uncontrolled.

4. Relay outputs and step signals are only enabled if there is a valid connection with the PC software and the software

regularly sends ready messages. If the connection is interrupted, all outputs are deactivated after a few seconds for safety

reasons.

Speed control (analog output)

In order to be able to specify the speed for a frequency inverter, the Triple BEAST has an analog output 0..10V. A voltage

proportional to the duty cycle of the PWM signal is output. Here 0% (low) corresponds to a voltage of 0V, 10% corresponds to

1V, 20% corresponds to 2V etc. up to 100% and 10V. The frequency of the PWM signal should be at least 1kHz so that the ripple

of the analog signal is not too high.

The analog output is not galvanically isolated, but referred to the power supply ground. However, this is not a problem with all

modern frequency inverters because they have an isolated speed input. Care should be taken with old thyristor controllers whose

speed input is partially connected to the mains voltage. These must not be used. If in doubt, please refer to the data sheet of the

frequency inverter or speed controller.

Please note that a frequency inverter should not be controlled exclusively with the analog signal. Be sure to connect the digital

start/stop input to one of the relays as well. Otherwise it is possible that the motor does not stop completely at 0V, or that it starts

unexpectedly in case of malfunctions. Please note that mixed use of mains voltage (230V~) and low voltage (<=24V) at the relay

outputs is not permitted (see chapter "Relay outputs", above).

Holding brake

When using ball screws, smooth-running servomotors or very heavy Z-axes, an electromechanical holding brake must be provided

to prevent the vertical axis from moving down by itself when the drive is switched off. Such brakes are usually operated with 24V.

They are blocked when no voltage is applied and open when the voltage is switched on.

The Triple BEAST has a relay output for such a holding brake. The relay is controlled as a normal output via the software. If

no brake is required, the relay can also be used for other purposes, e.g. as a start/stop signal for a frequency converter. This has the

advantage that the signal is applied to the same terminal (X2), and the relay outputs 1 and 2 at terminal X4 then remain free for

other consumers with possibly different voltages.

The output has an integrated free-wheeling diode and is suitable for switching inductive loads. The output voltage is always

equal to the power supply voltage at terminal X1.5, i.e. for a 24V brake the board must then be supplied with a 24V power supply.

If the brake is to be operated pneumatically, hydraulically or with a voltage other than the power supply voltage, an external

contactor or solenoid valve is required.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Connection for 4th axis

An external power amplifier for a 4th axis can be connected to the RJ45 socket on the upper side. This can be a single BEAST, a

UHU or stepper motor output stage or a servo controller from another manufacturer. For BEAST or UHU a simple patch cable can

be used. When connecting external power amplifiers, the following pin assignment applies (numbered from left to right in the

picture on page 6):

No.

Description

1

Current reduction

2

Signal ground

3

Clock

4

+5V

5

Direction

6

+5V

7

Status (0=ok, 1=error)

8

Signal ground

If the output stage does not provide a status signal, pins 7-8 must be bridged or jumper 15-16 must remain plugged in. For BEAST

or UHU with status signal it should be disconnected.

External LEDs

Between terminals X3 and X4 there is a socket under the housing cover to which external status LEDs can be connected via a

ribbon cable. This is useful if the Triple BEAST is installed in a switch cabinet where the internal LEDs are not easily visible or

accessible. A small circuit board with six LEDs and ribbon cable is available ready to use from Benezan Electronics. The

instructions for disassembling the housing are included with the board.

Configuration

The assignment of the inputs and outputs is done in the Beamicon2 software. Only the selection of the supply voltage for the

switch inputs and the (de)activation of the 4th axis is realized with jumpers.

If jumper 12-13 is inserted, the connections X3.1, X3.3, X3.5 and X3.7 are connected to the supply voltage of the power supply

(X1.5). This is useful if a 24V power supply unit is connected there and the switches used are inductive proximity switches or

similar industrial sensors with 24V. If the power supply has a higher voltage than 30V, this jumper setting must not be used,

otherwise you risk damaging the sensors.

Mechanical switches are best supplied with 12V from the internal voltage regulator. In this case the jumper 13-14 must be

inserted. If you are using sensors that already work with 12V, you can also use this position.

Pin No.

Description

12

Sensor supply 24V or voltage at X1.5

13

Supply voltage for reference switch

14

Sensor supply 12V (internal regulator)

15

Deactivation of the status signal of the 4th axis (open = 4th axis present, plugged = not

present or no status signal)

16

The status/error input of the 4th axis can be deactivated with jumper 15-16. This prevents a drive error from being reported when

the RJ45 socket is unused.

Software settings

With the exception of the jumpers described above, all settings are made in the software. The installation and operation of the

software as well as the adjustment of the machine parameters is described in detail in the Beamicon2 software manuals. For this

reason, only the special features of the Triple BEAST will be discussed here. The easiest way to configure the software is to select

the default parameter set "Default_NetBob" the first time you start the software. Then you do not have to make all settings again,

but only enter the deviations from the standard values. You can also load the default values later by selecting "File -> Import

settings" from the menu and clicking "Default parameters".

After the first start, the Triple BEAST must first be connected. If the hardware dialog does not open automatically, you can do

this in the menu under "Configuration -> Hardware". Select the module and then click on "connect" and "save".

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

The step and direction signals for a maximum of 4 axes are automatically assigned to the three motors and the RJ45 socket. No

settings need to be made for this. In particular, there is no need to set a pulse time, as the step signal always has a 50% duty cycle.

The direction of movement can be reversed in the machine parameters (Menu -> Configuration -> Machine) on the "Axis

Parameters" page with the "Inverted direction" button.

For the assignment of the signals switch to the page "Inputs/Outputs". The following input signals are available and can be

assigned to the logical signals (left table in the software):

Pin Name

Signal Description

Input 1

Switch input no. 1 (terminal X3.2)

Input 2

Switch input no. 2 (terminal X3.4)

Input 3

Switch input no. 3 (terminal X3.6)

Input 4

Switch input no. 4 (terminal X3.8)

Emergency stop

Emergency stop (triggered by mushroom button terminal X2.6, undervoltage

or connection error)

D error

Drive error, one of the stepper motor or servo output stages reports error

Input signals can be used multiple times if required. For example, the same switch input can be used simultaneously as a

reference and limit switch.

The following output signals are available and can be assigned to the logical signals (in the software right table):

Pin Name

Signal Description

Release

Current reduction signal or servo enable to the output stages

Relay 1

Relay no. 1, contacts X4.3 and X4.4

Relay 2

Relay no. 2, contacts X4.5 and X4.6

Brake

Relay for holding brake or frequency converter start, terminal X2.2

PWM

PWM signal for analog output, terminal X2.4

WDog

Watchdog/Charge-Pump-Signal, switches all outputs free

Unlike inputs, output signals cannot be inverted (active low/hi) because otherwise the safe off state would not be defined. For

the function of all other outputs the charge pump signal must be assigned to pin "WDog". Otherwise all outputs, including the step

signals, are disabled.

When using stepper motor output stages, the current reduction signal must be applied to the enable pin. This is always active

when all drives are stopped. When using servos, however, the servo enable signal must be assigned to the enable pin. This is

active when the drives are moving.

The relays can be assigned to any other output signals. Examples:

Standard assignment: Relay 1 = spindle forward, relay 2 = coolant, brake = holding brake

no brake, FU, add. spray cooling: relay1 = coolant, relay2 = spray cooling, brake = spindle forward

Spindle with right/left rotation: relay1 = spindle forward, relay2 = spindle reverse

If the number of available outputs or inputs is not sufficient for the application, they can be increased with an expansion

module.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Commissioning and troubleshooting

If you are using the control unit for the first time, please check the following points again before switching it on:

Are all terminal blocks correctly aligned in the slots?

Is the power supply (24 to 55V=) correctly connected (terminal X1 on top and terminal V on the right)?

If the supply voltage is higher than 30V, jumper JP3 must be set to position 13-14 (▪ ▪ ▬ ▪, limit switch supply 12V).

Is the emergency stop switch connected? For test purposes only, a jumper may be connected between pins 5 and 6 of X2

as an alternative. An emergency stop switch is legally required on a machine.

If these requirements are met, you can establish the connection to the PC, switch on the supply voltage and start the control

software. After activating the software and successful connection in the Configuration->Hardware dialog, the status of the LED

lights should be as follows:

the two green LEDs "Power" and "Ready" must be lit,

at the network socket the LED "Network Carrier" (green) must light up, and the LED "Network traffic" (yellow) must

blink evenly and fast

the two red LEDs "Drive Fault" and "E-Stop" must be off

the two yellow LEDs relay 1 and relay 2 must be off.

If this is not the case, please refer to the chapter "Troubleshooting" below. If everything is in order, you can now check the

movement of the motors and the function of the relays and switches.

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Troubleshooting

The following table gives an overview of the most common errors and the possible causes.

No.

Symptom

Cause

1

LED "Power" (green) is not lit

a) Power supply (terminal X1 and terminal V on the right) not

connected or wrongly polarized.

b) Short circuit between switch signals (X3) and ground

2

LED "Network Carrier" (green,

left) is not lit

a) Network cable is not connected, switch is switched off

b) wrong cable (crossover?)

3

LED "Network Traffic" (yellow,

right) does not flash or flashes

irregularly

a) Software not started or running in demo mode

b) wrong module selected (if several modules are in the network)

4

LED "Charge Pump" (green) is

not lit

a) ChargePump signal not assigned, or module is not connected

b) Software not started or running in demo mode

5

LED "Drive Fault" (red top) is

on, LEDs "Fault Axis 1-3" (red

side) are off

a) Jumper 15-16 is missing, the 4th axis is not (correctly)

connected or switched off

b) One or more output stages report an error (overheating or short

circuit, see page 6)

7

LED "E-Stop" (red) lights up,

LED "Standby" (yellow) flashes

a) The emergency stop switch (X2 Pin 5 and 6) is not connected or

pressed.

b) The power supply is not sufficient or the 12V output is

overloaded (maybe fans with too high power consumption

connected?)

8

Relays do not switch

a) yellow LEDs light up, but relays do not switch: see 4a

b) yellow LEDs do not light up: Pin assignment of the outputs in

the software not configured correctly

9

Motors do not turn

a) green LED "ChargePump" is not lit: see 2

b) red LED "Drive Fault" lights up: see 5b

c) red LED "E-Stop" lights up: see 7

Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Technical data

Absolute limit values

The following parameters must not be exceeded under any circumstances to prevent damage to the device:

Parameters

min.

max.

Unit

Operating voltage

-0.5

+63

V

Storage temperature

-40

+85

°C

Ambient temperature during operation

-20

+70

°C

Voltage at limit switch inputs

-5

+63

V

Voltage at the relay terminals

30

Vdc

250

Vac

Current per relay contact (X4)

8

Aeff

Current at brake relay (X2)

5

A

Current at analog output 0..10V

20

mA

Electrical connection values

Parameters

min.

max.

Unit

Operating voltage

+24

55

V

Power consumption without motors

80

mA

12V output max. load

300

mA

5V output max. load

200

mA

Ambient temperature

0

+50

°C

Crotch frequency

0

200

kHz

Delay time automatic current reduction

0.5

0.7

s

Threshold over temperature

70

85

°C

Current control accuracy

-10

+10

%

Cable cross section for terminals Supply

0.5

2.5

mm²

Cable cross section for terminals Motor

0.22

1

mm²

Number of microsteps per full step

5

10

-

Microsteps/revolution for standard motor1

1000

2000

-

1 Standard motor: 1.8°/full step, 200 full steps/revolution

Table of contents