TAKING

DELIVERY

AND

UNPACKING

Note:

The

consignee

is

responsible

for

ensuringthat

the

packages

havearrived

in

goodcondition.Examine

the

packages

for

damages,

if

found,note

the

same

on

carriers'

bill

of

lading

and

make

a

claim

tothe

carrier.

Each

unit

is

carefully

inspectedbeforeleaving

our

factory.

Package

(1)The

cratedboiler(assembled)

Package

(2)Theoil

burnerpack:

1

-

Choice

of

Burner

1-

DamperMotor

&

Chain

1-

Vz"

DrainValve

1-

PressureReducingValve

1-

N.O.

Zone

Valve

2-24

VA

Transformers

1

-

PressureReliefValve

1

-

SingleAquastat

1-

Wiring

Harness

1

-

TripleAquastatRelay

1

-

Nozzle

3

-

Wells

1

-

Tridicator

1

-

TripleAquastat

1-

BlockedFlueSensor

2-

CirculatorPumps

c/w

Flanges

Please note:

Thetwo

circulatorpumps

are

required

for

properoperation

of

thisboiler.

Installation

of

thisunitshould

bein

accordancewith

the

regulations

ofthe

authoritieshaving

jurisdiction.

Reference

should

be

made

to:

hi

Canada,

CSA

B139,

"InstallationCode

forOil

BurningEquipment"

for

recommended

installation

practices;

Inthe

United

States,

UL

391

"Solid-Fuel

and

Combination-Fuel

Central

and

Supplementary

Furnaces

"

andUL726

"OilFiredBoilerAssemblies".

ASSEMBLY

Benjamin

"CC500"

boilers

are

factoryassembled.

The

burner

and

controls

are

field

mountedusing

the

wiring

harnesssupplied.Otherwiring

forthe

thermostats

and

zonevalves

arenot

supplied.(seewiringdiagram

on

page

12)

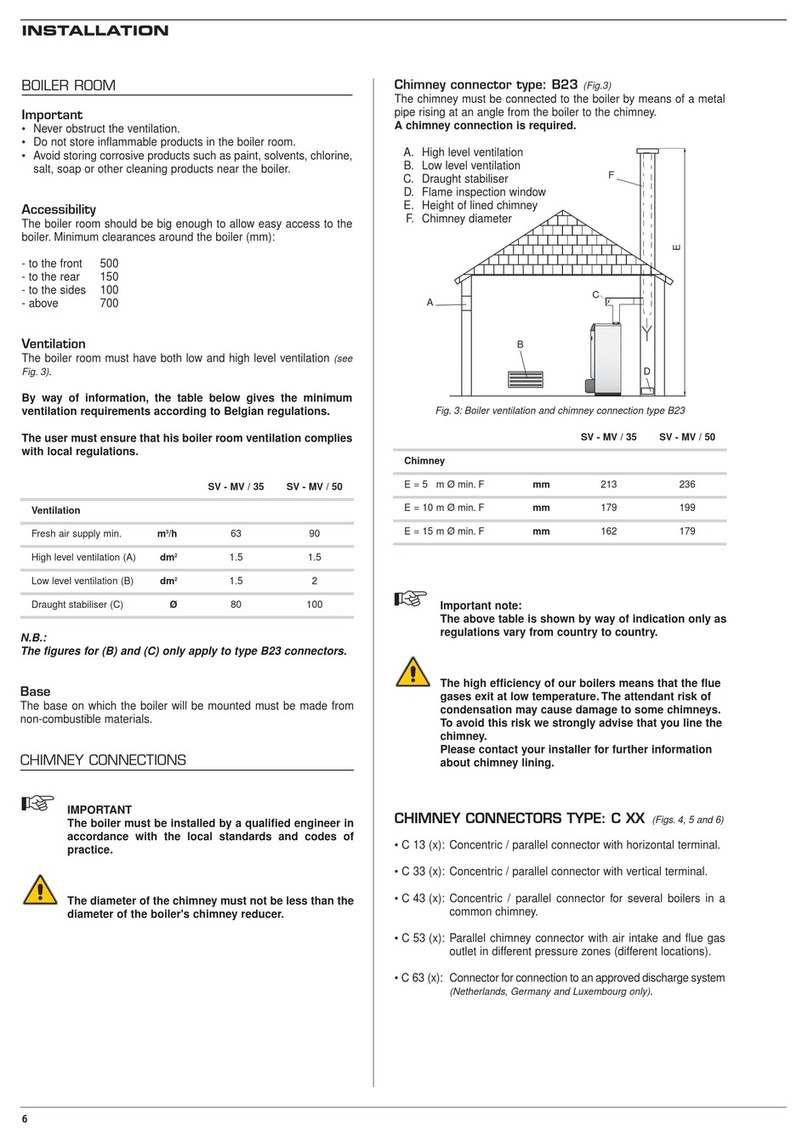

CHIMNEY

AND

SMOKE

PIPES

(For

proper

set up, see the

diagram

on

page

10)

The

specification

ofthe

chimney

tobe

usedmustcomply

with

the

requirementthatotherthan

solid-fuel/oil

combinations

and

add-ons,

woodburning

appliances

shall

notbe

connected

toa

ventingsystemserving

an

appliance

vented

by

anothertype

of

fuel.

Connect

the

boiler

toan

approvedsolid

fuel

factory-builtchimney:

In

CANADA-

CAN/ULC

S629standard

for

650°

F

chimney;

Inthe

UNITED

STATES-UL103

Chimneys

for

ResidentialType

and

BuildingHeatingAppliances,FactoryBuilt

ora

safe,clean, soundcondition,masonrychimneyequippedwith

an

approvedliner:

In

CANADA-CAN/ULC-S635-M90

Standard

for

LiningSystems

for

existingmasonry

or

FactoryBuiltChimneys

and

Vents;

hi

the

UNITED

STATES-UL1777

ChimneyLiners(e.g.,stainlesssteel,clay,

etc.).

The

chimneymust

be

equivalent

toa

minimum

of

7"

roundinsidediameter,

or8"

roundmaximum.

The

chimneymust

be

capable

of

maintaining

a

negative

updraft

atall

times

andinall

conditions.Carefullyinspect

the

chimney

for

safety

and

dirtbeforemakingconnections.Place

the

boiler

as

close

tothe

chimney

as

possible.

The

smokepipeshould

be

blue

or

blacksteel,

24

ga.

or

heavier.

Useasfew

turns

as

possiblebetween

the

boiler

and

the

chimney,

as

each

90°

elbowadds

10'

of

restriction

anda 45°

elbowadds

5'

of

restriction.

The

draft

regulator

should

be7

"

diameter

andsetat

-.04

W.C.

to

open.Install

the

regulator

a

minimum

of

18

"

anda

maximum

of

24

"

fromthe

boilerbreech.Avoidlonghorizontalruns

of

smokepipe.Maintain

a

minimum

of

Vz"

rise

per

foot

of

pipe

from

the

boiler

tothe

chimney.

DO

NOT

run

the

pipedownhill

fromthe

boiler

tothe

chimney.Confirmthat

the

installationclearances

aremet

or

exceeded.Secure

all

smokepipejointswiththreesheetmetalscrews

in

eachjoint.

DO

NOT

pass

the

smokepipesthrough

a

wall,floor

or

ceiling

to

reach

the

chimney.

-1-