Benning MA 4 User manual

5116 de

Version 1.04

10218133

08.09.2020

BENNING MA 4

CEE measuring adapter (5-pin/3-pin)

Operating manual

Original English version

I

Table of contents

1. Application........................................................................................1

1.1. General functional description...........................................................................1

2. Safety notes and precautions...........................................................1

2.1. Basic information about safety..........................................................................1

2.2. Symbols used...................................................................................................1

3. Inspection characteristics of the measuring adapter.......................2

4. Operating elements...........................................................................3

5. Connecting the measuring adapter ..................................................5

6. Testing with the measuring adapter .................................................5

6.1. Testing of three-phase devices with functional test ...........................................6

6.1.1. RPE –Protective Conductor Resistance.............................................................6

6.1.2. RInsu 1 (LN-PE).................................................................................................6

6.1.3. RInsu 2 (sec.-PE)...............................................................................................7

6.1.4. RInsu 3 (LN-sec.)................................................................................................7

6.1.5. RInsu 4 (LN-accessible parts without PE) ...........................................................8

6.1.6. IPE –Protective conductor current.....................................................................8

6.1.7. ICont –Contact current .......................................................................................9

6.1.8. ILeak –Device leakage current............................................................................9

6.1.9. IPLeak –Patient leakage current........................................................................10

6.1.10. Functional test................................................................................................10

6.2. Testing of three-phase devices with alternative leakage current method .........11

6.2.1. RPE –Protective conductor resistance.............................................................11

6.2.2. RInsu 1 –(LN-PE) .............................................................................................12

6.2.3. RInsu 2 –(sec.-PE) ...........................................................................................12

6.2.4. RInsu 3 –(LN-sec.) ...........................................................................................12

6.2.5. RInsu 4 –(LN-accessible parts without PE)........................................................13

6.2.6. IPE –protective conductor current (alt. leak.) ...................................................13

6.2.7. ICont –Contact current (alt. leak.).....................................................................13

6.2.8. ILeak –Device leakage current (alt. leak.).........................................................14

6.2.9. IPLeak –Patient leakage current (alt. leak.) .......................................................14

6.3. Testing of extension cables ............................................................................15

6.3.1. RPE –Protective conductor resistance.............................................................15

6.3.2. RPE (e. g. CEE 5-pin, 32 A).............................................................................15

6.3.3. RInsu 1 –(LN-PE) .............................................................................................16

6.3.4. Functional test and phase sequence test of cables .........................................16

6.3.5. Function table.................................................................................................18

6.4. Testing of PRCDs and mobile power distributors (RCDs)................................18

7. Internal RPE resistance of the measuring adapter........................... 19

8. Technical data................................................................................. 20

9. Maintenance.................................................................................... 20

10. Optional accessories ......................................................................20

11. Warranty terms................................................................................ 20

12. Service contacts .............................................................................21

BENNING MA4 measuring adapter

1

1. Application

The measuring adapter helps you to test portable devices. Due

to its robust design, it is particularly suited for being used in in-

dustrial environments. The measuring adapter is easy to use and

thus allows the user to work efficiently and quickly.

You can test devices and extension cables being provided with

the following connectors complying with IEC 60309-1.

CEE connector:

16 A, 50 Hz to 60 Hz, 230 V, L+N+PE, 6h

16 A, 50 Hz to 60 Hz, 380 V to 415 V, 3L+N+PE, 6h

32 A, 50 Hz to 60 Hz, 380 V to 415 V, 3L+N+PE, 6h

To do this, connect the measuring adapter to an appliance

tester for testing portable devices according to

DIN VDE 0701-0702, DIN EN 62353 (VDE 0751-1) or

DIN EN 60974-4 (VDE 0544-4).

For connection of the measuring adapter, the appliance tester

must be equipped with a shock-proof socket.

Depending on the type of test, a CEE 16 A or 32 A socket may

also have to be available. For the CEE 16 A, an optional adapter

cable (part no. 044163) is required.

The measuring adapter is suited to be connected to the fol-

lowing appliance testers:

BENNING ST725

BENNING ST750 / ST 750 A / ST 755 / ST 760

Devices of other manufacturers

The measuring adapter can be used for the following tests:

Protective conductor resistance (RPE)

Insulating resistance (RInsu)

Functional test and phase sequence test of cables

Alternative leakage current:

e. g. protective conductor current (IPE), contact current

(ICont),

device leakage current (ILeak), patient leakage current

(IPLeak)

Differential current measuring method

IPE

Leakage current

Direct measurement

Contact current

Patient leakage current

Functional test

Ua

Welding equipment (ST 760)

PRCD

The manufacturers’ specifications and normative re-

strictions with regard to alternative leakage current

testing and appliance tests must be adhered to.

To do this, thoroughly read the notes stated in the cor-

responding standard, in the manufacturers’ specifica-

tions of the test sample and in the operating manual of

the appliance tester.

1.1. General functional description

The MA 4 measures the fault current from the test sample using

the differential currentmeasuring method. This current is applied

on the N and PE line of the tester, so that this fault current can

be measured by testers using the differential current measuring

method or the direct measuring method with 1 kΩ in the PE of

the tester. Deviating measuring resistances in the PEcan lead to

an incorrect current applied.

2. Safety notes and precautions

2.1. Basic information about safety

The measuring adapter has been designed and tested incompli-

ance with the safety requirements according to

IEC/ EN 61010-1/ VDE 0411-1.

All electrically conductive parts of the housing are connected to

the protective conductor system (according to IEC 61140, pro-

tection class I).

The measuring adapter must be used only for testing in environ-

ments of measuring category CAT II according to

IEC/ EN 61010-1.

Make sure not to connect and test more than one test sample or

one extension cable at a time.

The measuring adapter must be operated under supervision

only.

In case of proper use according to the specifications, the safety

of both the user and the device is ensured.

Read this operating manual and the operating manual of the ap-

pliance tester carefully and thoroughly before using the product.

Please observe all instructions of the relevant operating manu-

als.

The measuring adapter must not be used:

with the housing being open,

in case of visible external damage,

in case of damage of the CEE connectors, CEE sockets,

connecting line or connector,

in case of strong excessive strain or if the load limits

stated in the technical data have been exceeded,

if the device has been stored under unfavourable condi-

tions for a longer period of time (high exposure to dust,

moisture or excessive temperatures).

Non-observance might involve damaging or destruction of the

measuring adapter and/or the connected test sample!

2.2. Symbols used

Attention! Danger! Please observe documentation!

Warning of dangerous voltage!

Note to be observed imperatively

CAT II

Device of measuring category II (max. 300 V)

Ground (voltage against ground)

This symbol on the measuring adapter means that

the measuring adapter complies with the relevant

EU directives.

The device must not be disposed of via the domes-

tic waste. Further information regarding the WEEE

mark can be accessed on the Internet by entering

the search term “WEEE”.

Instructions

BENNING MA4 measuring adapter

2

3. Inspection characteristics of the measur-

ing adapter

All tests that can be carried out with your appliance tester for de-

vices with shock-proof socket and that are supported by the

measuring adapter can now be performed in an identical way for

devices with CEE connector.

Please observe the following aspects during tests using

your appliance tester:

When testing the protective conductor resistance, the value

of the measured protective conductor resistance increases

by the share caused by the protective conductor line of the

measuring adapter.

In case of measuring results near the admissible limiting

value, measure the protective conductor resistance of the

measuring adapter at the PE connection of its CEE socket

and subtract it from the totalmeasuring value of the system.

Alternatively, when using the appliance testers BEN-

NING ST755 / ST 760, a probe calibration can be carried

out at the PE connection of the CEE socket.

If the measuring adapter is not used, the probe must

then be calibrated again at the PE connection of the

appliance tester.

During insulating resistance or alternative leakage current

tests, the three phases L1, L2, L3 and the neutral conduc-

tor N of the test sample are shorted.

BENNING MA4 measuring adapter

3

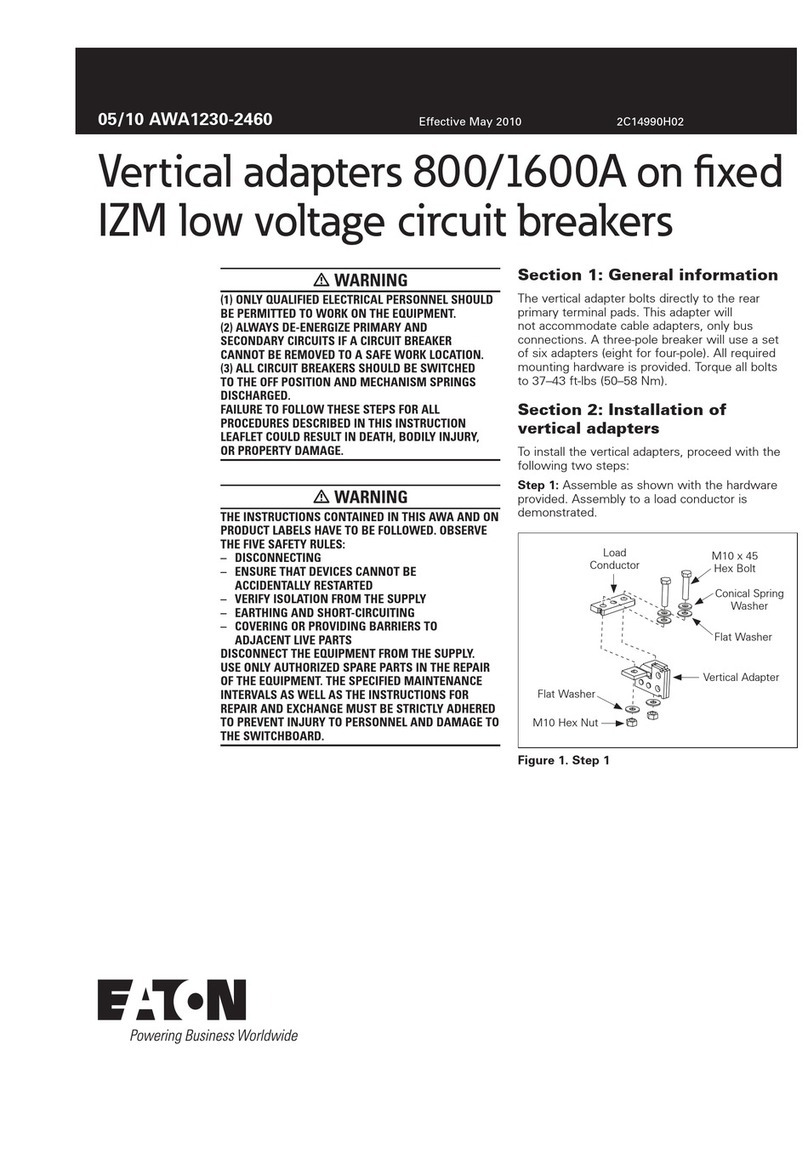

4. Operating elements

12

15

14

13

BENNING MA4 measuring adapter

4

Pos.

Meaning

1

PE socket for PE test probe (for RPE cable test)

2

CEE connector: 16 A, 50 Hz to 60 Hz, 380 V to 415 V

3L+N+PE, 6h

3

CEE connector: 16 A, 50 Hz to 60 Hz, 230 V

L+N+PE, 6h

4

CEE connector: 32 A, 50 Hz to 60 Hz, 380 V to 415 V

3L+N+PE, 6h

5

The mains LED lights up as soon as 230 V are connected to the shock-proof plug.

6

The LED indications L1-N, L2-N, L3-N light up as soon as the corresponding connections have been

established (e. g. via extension cables).

7

Rotary switch

Cable

The switch can be used to toggle between all three phases and the individual phases. This

function is active when the rotary function selector switch (pos. 8) is set to the cable test

function. The testing personnel can use this to detect or limit faults during the cable function

test. The switch is not used during the functional testing of devices.

8

Rotary switch

Function

This rotary selector switch can be used to toggle between cable test, appliance test, appli-

ance test 1 mA and appliance test +3 mA. The IPE currents of 1 mA and 3 mA are only gen-

erated when testing with mains voltage.

No fault current is generated in the switch position of cable testing!

9

CEE socket: 16 A, 50 Hz to 60 Hz, 380 V to 415 V

CEE socket: 16 A, (3L+N+PE, 6h)

10

CEE socket: 16 A, 50 Hz to 60 Hz, 230 V

CEE socket: 16 A, (L+N+PE, 6h)

11

CEE socket: 32 A, 50 Hz to 60 Hz, 380 V to 415 V

CEE socket: 32 A, (3L+N+PE, 6h)

12

Shock-proof plug to the tester

Shock-proof plug (types E and F)

13

Mains connection

CEE 32 A connector (3L+N+PE, 6h)

14

Mains fuse

T 16 A (6.3 x 32)

15

Mains connection for tester

Shock-proof socket (type E)

BENNING MA4 measuring adapter

5

5. Connecting the measuring adapter

The measuring adapter is equipped with a PTC ther-

mistor as short-circuit protection for cable testing, but

not for appliance testing.

Use the measuring adapter only for the intended tests

described in this manual.

The manufacturers’ specifications or normative re-

strictions with regard to all tests involved must be ad-

hered to.

To do this, thoroughly read the notes stated in the

corresponding standards, in the manufacturers’ speci-

fications of the test sample and in the operating man-

ual of the appliance tester.

Before you can start testing, you have to connect the measuring

adapter to your appliance tester.

To do this, proceed as follows:

Make sure that the appliance tester you are using is ready

for operation.

Connect the shock-proof plug of the measuring adapter to

the test socket of your appliance tester.

Connecting the measuring adapter to the appliance tester

This is a connection method for appliance testing and cable

testing.

For appliance testing, the MA 4 must be connected to the

mains. Connect the ST 755 / 760 to the socket of the MA 4.

Connection diagram

6. Testing with the measuring adapter

Testing the adapter for compatibility with third-

party manufacturers / self-testing the device

In the switchposition forappliance testing +1 mA and

in the switch position for appliance testing +3 mA, an

internal fault current is generated in the MA 4. The

fault current becomes detectable for the measuring

instruments when 230 V are applied to their test

socket. For appliance testing, the MA 4 must be con-

nected to the mains via the CEE 32 A cable. If such

a functional test is carried out, no fault current is gen-

erated in the switch position for appliance testing

without any test samples being connected. By select-

ing the position for appliance testing +1 mA, a fault

current of approx. 1 mA is generated. The fault cur-

rent depends on themains voltage. Now, it should be

possible tomeasure this faultcurrent bymeansof the

tester. The fault current is applied on the N conductor

and on the PE conductor of the measuring instru-

ment.

The current in the N conductor can be determined by

any measuring instrument using the differential cur-

rent measuring method. In order to detect the applied

current in the PE, a measuring resistance of 1 kΩ is

required. Otherwise, a deviating applied fault current

will occur. In case of the ST 755 / 760, this load is au-

tomatically selected as soon as three-phase meas-

urement has been activated.

For this test, no test sample may be connected!

Before carrying out the functional test and all tests

for which the test sample must be supplied with

mains voltage and put into operation, make sure

that there are no short-circuits in the test sample

within phases L1, L2, L3 and the neutral conduc-

tor N! Non-observance might involve damaging or

destruction of the measuring adapter and possibly of

the test sample as well!

Within the framework of the functional test, it is not

possible to determine the values of the power and

current consumption of the test sample by means of

the measuring adapter. The displayed values refer

to the power consumption of the measuring adapter

itself.

BENNING MA4 measuring adapter

6

6.1. Testing of three-phase devices with func-

tional test

For appliance testing with the differential cur-

rent measuring method, the measuring adapter

must be connected to the mains via the CEE 32

connector.

6.1.1. RPE –Protective Conductor Resistance

Before testing

Before starting the test, determine the internal RPE

resistance of the measuring adapter (see chapter 7).

Disconnect the test sample from the mains supply!

Switch the rotary switch (7) of the measuring

adapter to position "L1-L2-L3".

The rotary switch (8) of the measuring adapter

must be set to the position for appliance testing.

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the RPE measurement on your appliance tester.

Use the test probe to scan all accessible conductive

parts of the test sample that are connected to the protec-

tive conductor.

As a result, you will obtain the measured RPE value of the test

sample.

Connection diagram

Circuit diagram

6.1.2. RInsu 1 (LN-PE)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the RInsu measurement on your appliance tester.

The insulating resistance is measured between the bridged

LN conductor and the PE of the shock-proof socket.

As a result, you will obtain the measured RInsu value of the test

sample.

Connection diagram

Circuit diagram

7

8

BENNING MA4 measuring adapter

7

6.1.3. RInsu2 (sec.-PE)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Connect the test probe to the bridged secondary side of

the device.

Start the RInsu measurement on your appliance tester.

As a result, you will obtain the measured RInsu value of the test

sample.

The insulating resistance ismeasured between thePE of the test

socket and the secondary side (probe).

Connection diagram

Circuit diagram

6.1.4. RInsu 3 (LN-sec.)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Connect the test probe to the bridged secondary side

of the device.

Start the RInsu measurement on your appliance tester.

As a result, you will obtain the measured RInsu value of the test

sample.

The insulating resistance is measured between the bridged LN

conductor and the secondary side (probe).

Connection diagram

Circuit diagram

BENNING MA4 measuring adapter

8

6.1.5. RInsu 4 (LN-accessible parts without PE)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the RInsu measurement on your appliance tester.

Use the test probe to scan all accessible conductive

parts of the test sample that are not connected to the

protective conductor.

As a result, you will obtain the measured RInsu value of the test

sample.

The testing voltage is applied to the bridged L and N conductors

and measured to parts without PE connection.

Connection diagram

Circuit diagram

6.1.6. IPE –Protective conductor current

Test procedure (VDE 0701 –0702 / 0544-4)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the IPE measurement on your appliance tester.

As a result, you will obtain the measured IPE value of the test

sample.

The test sample is supplied with mains voltage and must be

tested in all switch positions (device functions).

Please observe inductive/capacitive circuits.

Connection diagram

Circuit diagram

BENNING MA4 measuring adapter

9

6.1.7. ICont –Contact current

Test procedure (VDE 0701 –0702 / 0544-4)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the ICont measurement on your appliance tester.

The test sample is supplied with mains voltage and must

be tested in all switch positions (device functions).

Use the test probe to scan all accessible conductive

parts of the test sample that are not connected to the

protective conductor.

As a result, you will obtain the measured ICont value of the test

sample.

Connection diagram

Circuit diagram

6.1.8. ILeak –Device leakage current

Test procedure (VDE 0751-1)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the ILeak measurement on your appliance tester.

The test sample is supplied with mains voltage and must

be tested in all switch positions (device functions).

Use the test probe to scan all accessible conductive

parts and applied parts.

As a result, you will obtain the measured ILeak value of the test

sample.

Connection diagram

Circuit diagram

BENNING MA4 measuring adapter

10

6.1.9. IPLeak –Patient leakage current

Test procedure (VDE 0751-1)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Place the test sample onto an insulated surface.

Start the IPLeak measurement on your appliance tester.

The test sample is supplied with mains voltage and must

be tested in all switch positions (device functions).

Use the test probe to scan all accessible conductive

parts and applied parts.

As a result, you will obtain the measured IPLeak value of the

test sample.

Connection diagram

Circuit diagram

6.1.10. Functional test

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

The test sample is supplied with mains voltage and must

be tested in all switch positions (device functions).

Please observe inductive/capacitive circuits.

As a result, you will obtain the measured IPE value of the test

sample.

Connection diagram

Circuit diagram

BENNING MA4 measuring adapter

11

6.2. Testing of three-phase devices with alterna-

tive leakage current method

The alternative leakage current measuring method must not be

carried out as an alternative to insulating resistance measure-

ment. DIN VDE 0702 para. 5.7 expressly points out thatmeas-

uring the alternative leakage current is an alternative measuring

method for measuring the protective conductor current or con-

tact current after an insulating resistance measurement has

been passed. Exceptions are devices of protection class I with

switched on heating elements and a total connected load of

more than 3.5 kW. If such a device does not pass the insulating

resistance measurement, it is still considered to be in proper

condition if the protective conductor current according to para-

graph 5.5 of the mentioned standard is not exceeded.

Symbol:

The measuringadapter can beused formeasuring thefollowing

leakage orfault currents bymeans ofthe alternative leakage cur-

rentmeasuringmethod, provided that the testis supported by the

connected appliance tester:

IPE –protective conductor current

ICont –contact current

ILeak –device leakage current

IPLeak –patient leakage current

For alternative leakage current measurement, the

measuring adapter must not be connected to the

mains via the CEE 32 connector.

Single-phase devices can be tested in the same

way.

Before testing

Disconnect the test sample from the mains supply.

Switch the rotary switch (7) of the measuring

adapter to position "L1-L2-L3".

The rotary switch (8) of the measuring adapter

must be set to the position for appliance testing.

6.2.1. RPE –Protective conductor resistance

Before testing

Before starting the test, determine the internal RPE

resistance of the measuring adapter (see chapter 7).

Disconnect the test sample from the mains supply!

The maximum testing current for RPE measurement

is 10 A!

The rotary switch (7) of the measuring adapter can

be used in any position for RPE measurement.

The rotary switch (8) of the measuring adapter

must be set to the position for appliance testing.

Test procedure (VDE 0701-0702)

Portable test sample

Connect the CEE connector of the test sample to the

corresponding CEE socket of the measuring adapter.

Start the RPE measurement on your appliance tester.

Use the test probe to scan all accessible conductive

parts of the test sample that are connected to the protec-

tive conductor.

Application

Portable test sample

Connection diagram

Circuit diagram

8

7

8

7

BENNING MA4 measuring adapter

12

6.2.2. RInsu 1 –(LN-PE)

Before testing

Disconnect the test sample from the mains supply.

Switch the rotary switch (7) of the measuring

adapter to position "L1-L2-L3".

The rotary switch (8) of the measuring adapter

must be set to the position for appliance testing.

Test procedure (VDE 0701-0702)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the RInsu measurement on your appliance tester.

As a result, you will obtain the measured RInsu value of the test

sample.

Application

Portable test sample

Connection diagram

Circuit diagram

6.2.3. RInsu 2 –(sec.-PE)

Portable test sample

Connection diagram

Circuit diagram

6.2.4. RInsu 3 –(LN-sec.)

Portable test sample

Connection diagram

Circuit diagram

8

7

BENNING MA4 measuring adapter

13

6.2.5. RInsu 4 –(LN-accessible parts without PE)

Portable test sample

Connection diagram

Circuit diagram

6.2.6. IPE –protective conductor current (alt. leak.)

Test procedure (VDE 0701-0702)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the IPE measurement on your appliance tester.

As a result, you will obtain the measured IPE value of the test

sample.

Application

Portable test sample

Connection diagram

Circuit diagram

6.2.7. ICont –Contact current (alt. leak.)

Test procedure (VDE 0701-0702)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the ICont measurement on your appliance tester.

Contact the test probe(s) of the appliance tester with all

necessary measuring points.

As a result, you will obtain the measured ICont value of the test

sample.

Application

Portable test sample

Connection diagram

Circuit diagram

The contact current is determined for devices of protection

class II that raise concerns as to an RInsu measurement. Moreo-

ver, it is checked to prove the proper insulation capacity under

mains voltage. This also applies to devices of protection class I

with accessible conductive parts which are not connected to the

protective conductor.

BENNING MA4 measuring adapter

14

6.2.8. ILeak –Device leakage current (alt. leak.)

Test procedure (VDE 0751-1)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the ILeak measurement on your appliance tester.

Contact the test probe(s) of the appliance tester with all

necessary measuring points.

As a result, you will obtain the measured ILeak value of the test

sample.

Application

Portable test sample

Connection diagram

Circuit diagram

6.2.9. IPLeak –Patient leakage current (alt. leak.)

Test procedure (VDE 0751-1)

Portable test sample

Connect the CEE connector of the test sample to the

CEE socket of the measuring adapter.

Start the IPLeak measurement on your appliance tester.

Contact the test probe(s) of the appliance tester with all

necessary measuring points.

As a result, you will obtain the measured IPLeak value of the

test sample.

Application

Portable test sample

Connection diagram

Circuit diagram

BENNING MA4 measuring adapter

15

6.3. Testing of extension cables

Symbol:

6.3.1. RPE –Protective conductor resistance

For these tests, the MA 4 must be connected to the

mains using the CEE 32 connector.

The ST 755 / 760 must be connected to the shock-

proof socket of the measuring adapter.

Before testing

Before starting the test, determine the internal RPE

resistance of the measuring adapter (see chapter 7).

The maximum testing current for RPE measurement

is 10 A!

The rotary switch (7) of the measuring adapter can

be used in any position for RPE measurement.

The rotary switch (8) of the measuring adapter

must be set to the position for cable testing.

6.3.2. RPE (e. g. CEE 5-pin, 32 A)

Test procedure (VDE 0701-0702)

Cable test

Connect both cable connections to the corresponding

CEE sockets of the measuring adapter.

Connect the test probe of your appliance tester to the

PE socket (see pos. 1, chapter 4) of the measuring

adapter.

Start the RPE measurement on your appliance tester.

Read the RPE measuring result shown on the display of

the appliance tester.

Subtract the measured RPE value of the

measuring adapter from the RPE measuring result of

the test sample.

As a result, you will obtain the measured RPE value of the test

sample.

Edit the measured RPE value in the appliance tester ac-

cording to the calculated measuring value.

Application

Cable test

Connection diagram

Detailed view

Circuit diagram

8

7

BENNING MA4 measuring adapter

16

6.3.3. RInsu 1 –(LN-PE)

Before testing

Switch the rotary switch (7) of the measuring

adapter to position "L1-L2-L3".

The rotary switch (8) of the measuring adapter

must be set to the position for cable testing.

Test procedure (VDE 0701-0702)

Cable test

Connect both cable connections to the corresponding

CEE connectors of the measuring adapter.

Start the RInsu measurement on your appliance tester.

Application

Cable test

Connection diagram

Circuit diagram

6.3.4. Functional test and phase sequence test of

cables

Before testing

The functional test and phase sequence test of cables can be

applied to CEE connecting cables and extension cables.

The measuring adapter is supplied with mains volt-

age.

The functional test and phase sequence test of ca-

bles

may only be carried out after the RPE and RInsu tests

have been passed.

For single-phase connecting cables or extension ca-

bles (CEE socket, 3-pin), the rotary switch must be

set to the locking position “L1” or “L1-L2-L3”.

Test procedure

Cable test

Switch the rotary switch (7) of the measuring

adapter to position "L1-L2-L3".

The rotary switch (8) of the measuring adapter

must be set to the position for cable testing.

Connect both cable connections to the corresponding

CEE sockets of the measuring adapter.

Switch the mains voltage to the test socket of the appli-

ance tester.

Observe the status LED indication of the corresponding

CEE socket.

Compare the indicated LED status with the function ta-

ble in chapter 6.3.5.

Successively turn the rotary switch (7) to the positions

“L1”, “L2” and “L3”.

The LED indication must show the status “pass” in any rotary

switch position.

Application

Cable test

Connection diagram

8

7

8

7

BENNING MA4 measuring adapter

17

Circuit diagram

This manual suits for next models

1

Table of contents

Other Benning Adapter manuals