BEP FD-2 User manual

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

BEP FD-2

CONTOUR MATRIX

FUME DETECTOR

INSTALLATION

AND

OPERATING INSTRUCTIONS

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

2

Table of Contents

1WARRANTY.....................................................................................................................3

2IMPORTANT....................................................................................................................3

3CAUTIONS WHEN USING GAS SENSORS................................................................3

4FEATURES........................................................................................................................4

5SPECIFICATION.............................................................................................................4

6INTRODUCTION.............................................................................................................4

7FAULT DETECTION ......................................................................................................4

8DIMENSIONS...................................................................................................................5

9WIRING DIAGRAM........................................................................................................6

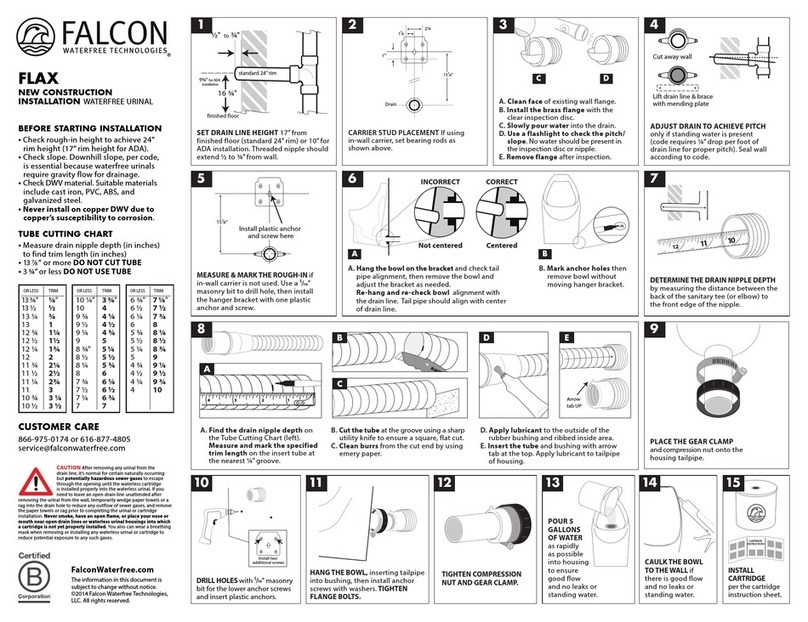

10 CONTROL HEAD INSTALLATION.............................................................................7

11 SENSOR INSTALLATION .............................................................................................7

12 OPERATION.....................................................................................................................7

13 TEST BUTTON.................................................................................................................7

14 INDICATOR DISPLAY...................................................................................................7

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

3

1Warranty

The warranty of this BEP MARINE LTD product is for Two Years from date of sale to original

purchaser. BEP MARINE LTD does not assume the cost of removal or refitting of the product, or any

other incidental cost that may arise, as the result of defect in materials or workmanship.

Warranty will only be undertaken on equipment returned to either BEP MARINE LTD or their agent.

The equipment will be replaced or repaired at the discretion of either BEP MARINE LTD or its agents.

As long as the equipment has neither been (1) Abused (2) Wrongly connected (3) Contaminated due

to neglect (4) Improper installation, (5) Used in violation of instructions supplied with equipment

manufactured by BEP MARINE LTD. On return of equipment for warranty it must be accompanied

with proof of purchase and not been tampered with.

2Important

It is the installer’s sole responsibility to install and use this product in a manner that will not cause

accidents, personal injury or property damage. Please follow the installation instructions supplied. If

installation is not correct, the unit may not perform at its designed potential. If in doubt, consult your

local BEP MARINE LTD dealer. BEP MARINE LTD disclaims all liability for any use of this product

that may cause accidents, damage or be in violation of any laws.

Copyright © 2005 BEP MARINE LTD. All rights reserved.

3Cautions when using gas sensors

1. Exposure to silicone vapours

If silicone vapours adsorb onto the sensor’s surface, the internal sensing element maybe be

coated, irreversibly inhibiting sensitivity. Avoid exposure where silicone adhesives, hair grooming

materials or silicone rubber/putty may be present.

2. Highly corrosive environment

Exposure to corrosive materials such as H2S, SOx, Cl2, HCl, etc. for extended periods may

cause irreversible damage to the sensor.

3. Water

Sensor performance maybe adversely affected due to soaking, splashing or water condensing on

the sensor surface. Exposure to salt water spray will adversely affected sensor performance.

Light condensation under conditions of indoor usage should not pose a problem for sensor

performance.

4. Freezing

If freezing occurs on the sensor’s surface irreversible damage may occur to the internal sensing

element.

5. Usage in high density of gas

Sensor performance maybe adversely affected if exposed to a high density of gas for a long

period of time.

6. Explosive Limits

Different combustible gasses have their own Lower Explosive Limits (LEL). Our gas sensors are

calibrated against 20% LEL LPG in Air.

7. False positive alarms

False positive alarms can be caused by differing concentrations of various aerosols, perfumes,

resins, epoxies, paints, solvents, alcohol, hydrogen, gases and fuels.

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

4

4Features

The FD-2 gas detector offers the following features –

§Self testing capability

§Microprocessor control

§Single Sensor

§Audible and visual alarms

5Specification

Voltage: 10V-30V DC

Current: Total 350mA Max

Alarm: 20% LEL (Lower Explosive Limit)

6Introduction

The Contour model LPG, Petrol and CNG detector is the product of continuing research and

development, which BEP Marine Ltd devotes to their product range. The 600 series detectors use the

latest in solid state technology available, with a microprocessor control head connected to the latest in

sensor technology. The FD-2 detector uses a single sensor with both visual and audible alarms.

There is a test switch to check the operation of the sensor with indicators for fault detection.

Read these installation and operation instructions carefully before installing, as any damage caused

by faulty installation will result in the warranty being null and void.

There is no power on/off switch provided. It is intended that for maximum protection the unit should be

on all the time while you are on your boat or in your vehicle.

7Fault Detection

The nominal alarm point of the FD-2 is 20% of the LEL (Lower Explosive Limit) of LPG/CNG in Air. In

the event of a gas leak and the alarm activating, close the manual valve on your gas bottles and open

hatches to ventilate the area. All fans and blowers used to ventilate must be ignition-protected types.

In the event of a sensor being contaminated, damaged, cable shorting or a faulty connection, the

amber light will come on for the sensor. If the sensor fault persists then the sensor could be damaged

and will need to be replaced.

In detecting LPG the sensor can also detect hydrocarbons in other products such as cleaners and

strong adhesives, this can cause nuisance alarms. See section 3 - ‘Cautions when using gas sensors’

for more details.

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

5

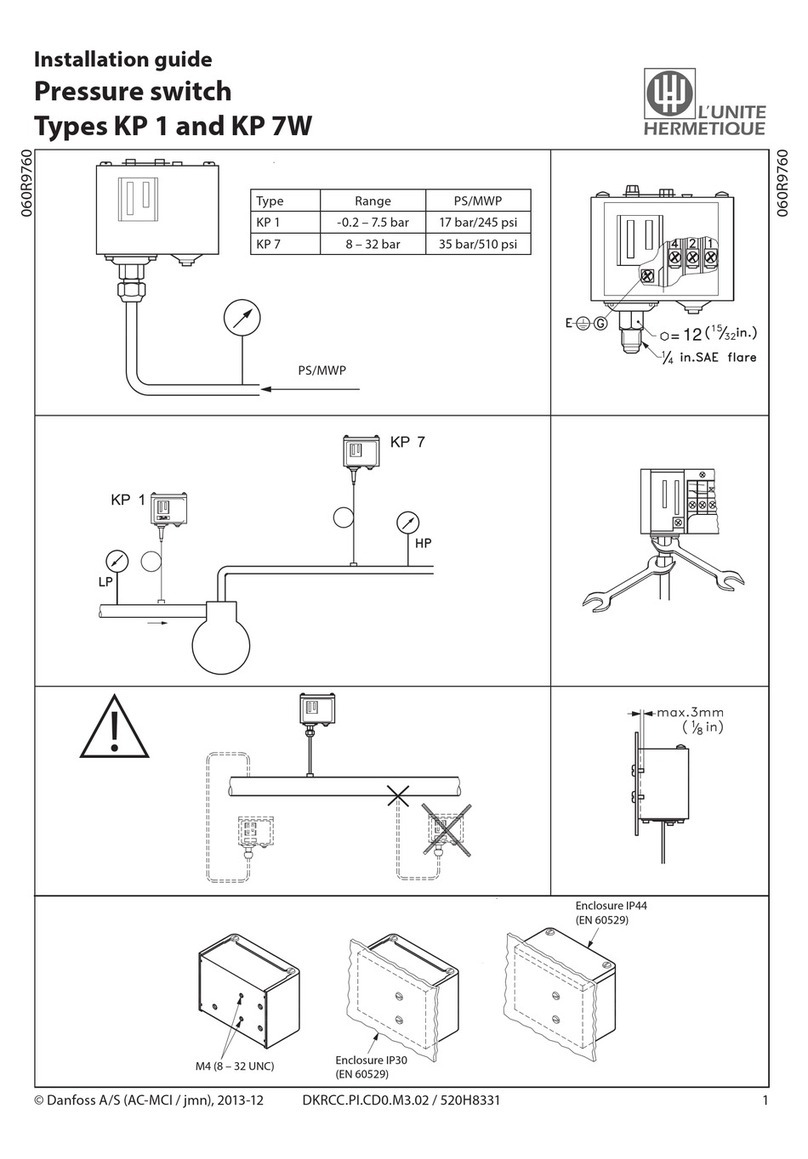

8Dimensions

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

6

9Wiring Diagram

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

7

10 Control Head Installation

For ease of operation, the control head should be mounted in a convenient position close to your gas

appliances and in a position where the control head can be seen and heard easily. The unit can be

either surface mounted or recessed into a 2.5mm panel.

11 Sensor Installation

§The sensor is supplied with a 5-meter cable.

§For LPG and Petrol fumes, which are heavier than air, mount the sensor in a low dry position

where the gas is likely to collect. The sensor must be mounted clear of bilge water.

NOTE: If the sensor gets wet then the sensor becomes inoperable and must be replaced.

§For CNG, which is lighter than air, mount the sensor just below ceiling height but not above

cooking or heating appliances.

§Fasten the sensor with the supplied screws.

§Route the sensor cable through to the control head and connect as per the wiring diagram.

12 Operation

On applying power to the unit, the control head goes through a test cycle. This will take approximately

45 seconds. During this period the sensor heads are being cleaned and tested, at this time there will

be a slow beep from the audible alarm and all the lights will flash amber. Towards the end of this

period the pulse of the beeper and lights will increase, if the unit senses that the environment is clear

then the control head will go into safe mode. The beeper will turn off and the sensor lights will change

to green.

13 Test Button

When operated in normal operation it will -

§Sounds the keyboard beeper

§Turn light red

Pressing the switch again cancels the above.

14 Indicator Display

SENSOR

Green: Sensor on safe, no fumes, no beeping

Amber: Sensor fault, slow beeping

Red: Alarm. Gas present, fast beeping

AUDIBLE ALARM SOUNDS

Warming up: Medium slow, all lights flash amber

Alarm: Fast, sensor lights red

Fault: Slow, sensor lights amber

Copyright © BEP Marine Limited, All rights reserved

INST-FD2-V2

16/02/06

Page

8

BEP MARINE

13 Tarndale Grove

Albany, Auckland, N.Z.

Ph: +64 9 415 7261

Fax: +64 9 415 9327

www.bepmarine.com

BEP AUTOMOTIVE

13 Tarndale Grove

Albany, Auckland, N.Z.

Ph: +64 9 415 7261

Fax: +64 9 415 9327

www.bepautomotive.com

E-mail: [email protected]

Please visit our website for the latest International Distributor List

Table of contents