Sewing start / Sewing test

Adjusting the thread tension

Sewing start

•The machine is switched on and the presser foot is raised.

•The fabric and the application have been selected.

Selecting the

fabric

•The thread has been selected.

Selecting the thread

•The combination of the needle and the thread is correct.

Selecting

the needle

•The stitch has been selected.

Stitch chart

•The machine settings based on the stitch selection have been

adjusted.

Machine settings

•Threading has been performed according to the stitch chart.

Threading preparation

•All threads are beneath the presser foot positioned to the back and left.

•The threader cover is closed.

> Lower the presser foot.

> Press the foot control to start the sewing process.

A thread chain is formed.

If no thread chain is formed.

Machine settings

Sewing test

> Raise the presser foot.

> Place the fabric sample under the presser foot in front of the knife.

> Start sewing slowly, guiding the fabric lightly.

> Sew beyond the fabric end so that a thread chain is formed.

> Pull the thread chain over the thread cutter.

> Assess the test sample and make the necessary ne adjustments, if

necessary. |

Machine settings / Troubleshooting

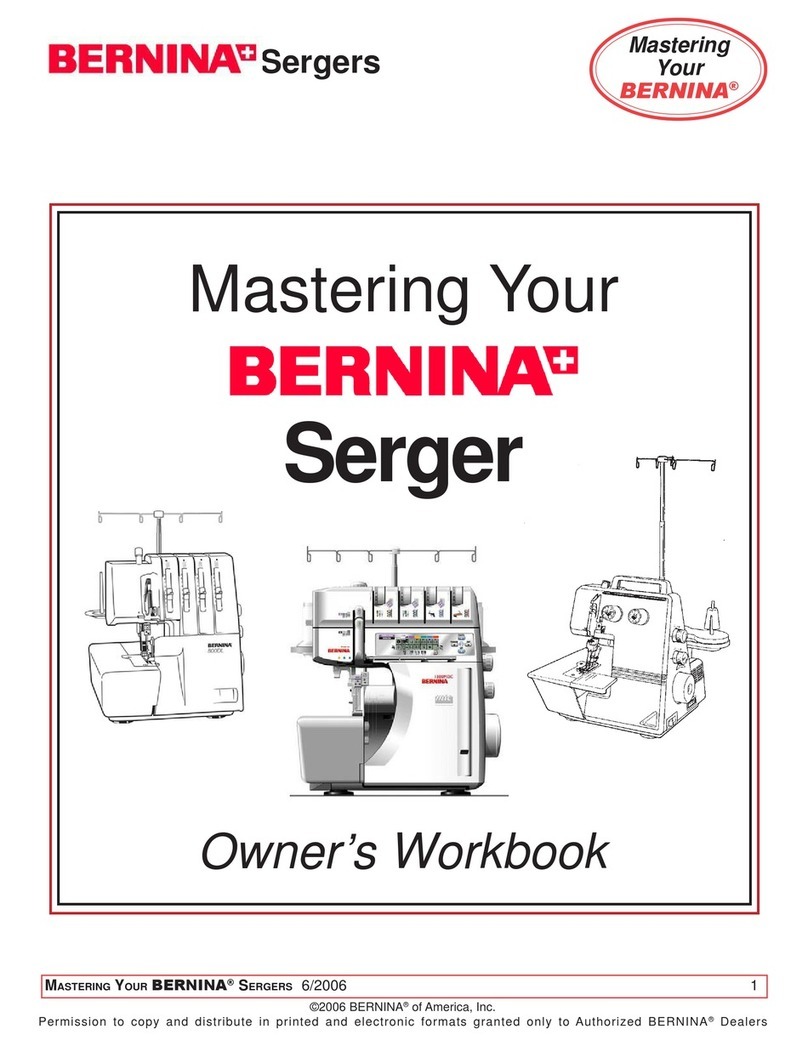

The thread tension has influence on the stitch formation. The stitch

chart provides a recommended default value for each stitch. This

recommended value can optimized for the different thread/fabric

combinations as follows.

The looper threads are intertwined on the wrong side of the fabric.

> Reduce the lower looper thread tension (red).

> Increase the upper looper thread tension (blue).

The looper threads are intertwined on the right side of the fabric.

> Reduce the upper thread tension (blue).

> Increase the lower looper thread tension (red).

The left needle thread forms loops on the wrong side of the fabric.

> Reduce the lower looper thread tension (red).

> Increase the left needle thread tension (yellow).

The right needle thread forms loop on the wrong side of the fabric.

> Increase the right needle thread tension (green).

> To reduce the thread

tension, turn the thread

tension adjustment dial

down to a lower value.

> To increase the thread

tension, turn the thread

tension adjustment dial

down to a higher value.

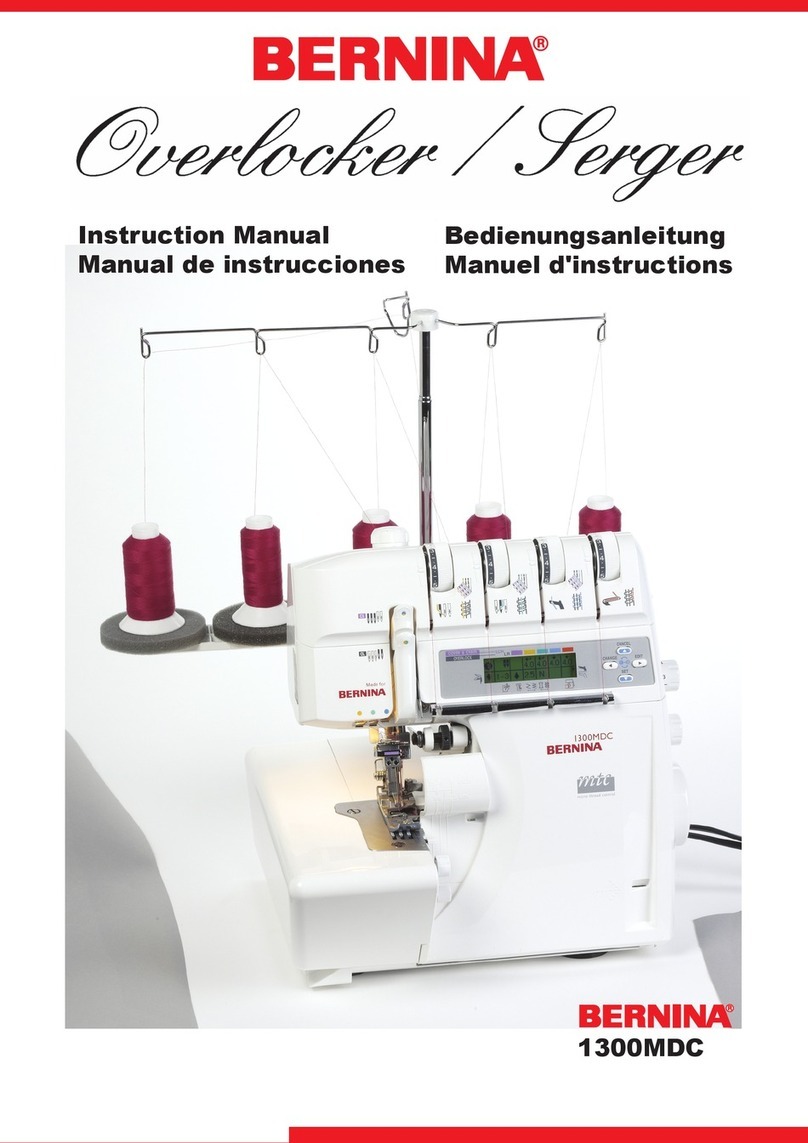

Threading the machine

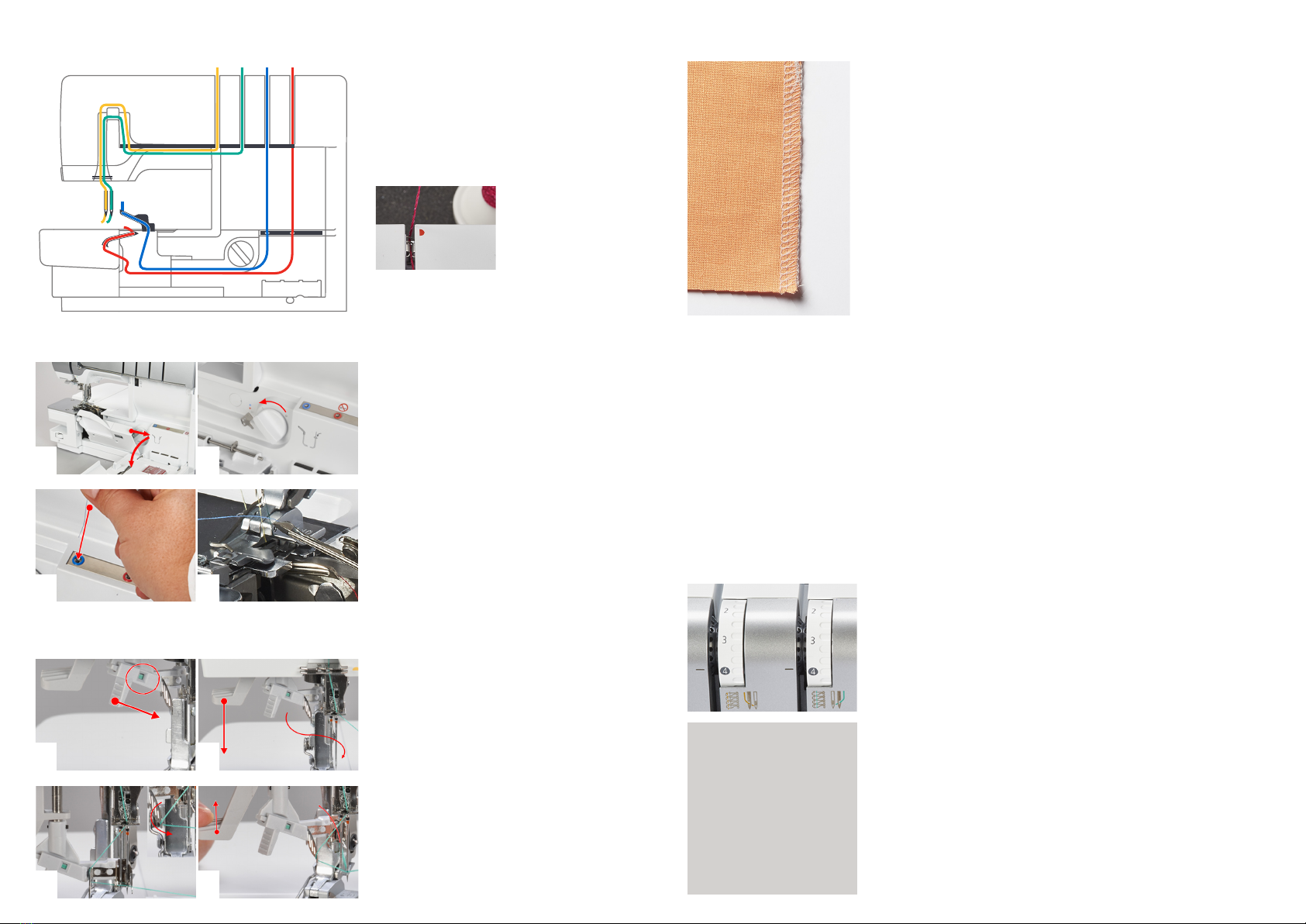

> Raising the needle via back-kick.

> Raise the presser foot and swing it out.

> Place the thread cones on the respective

spool pin.

> Engage the thread in the thread

pretension.

> Thread along the colored thread paths

markings.

Threading the looper

1 Open the threader cover and the looper

cover.

2 Set air threader connector to «I». The air

threader pipes are coupled.

3 Hold the thread end above the respective

air threader nozzle and press the foot

control.

4 Release the foot control as soon as the

looper thread emerges from the looper

eye.

1

3

2

4

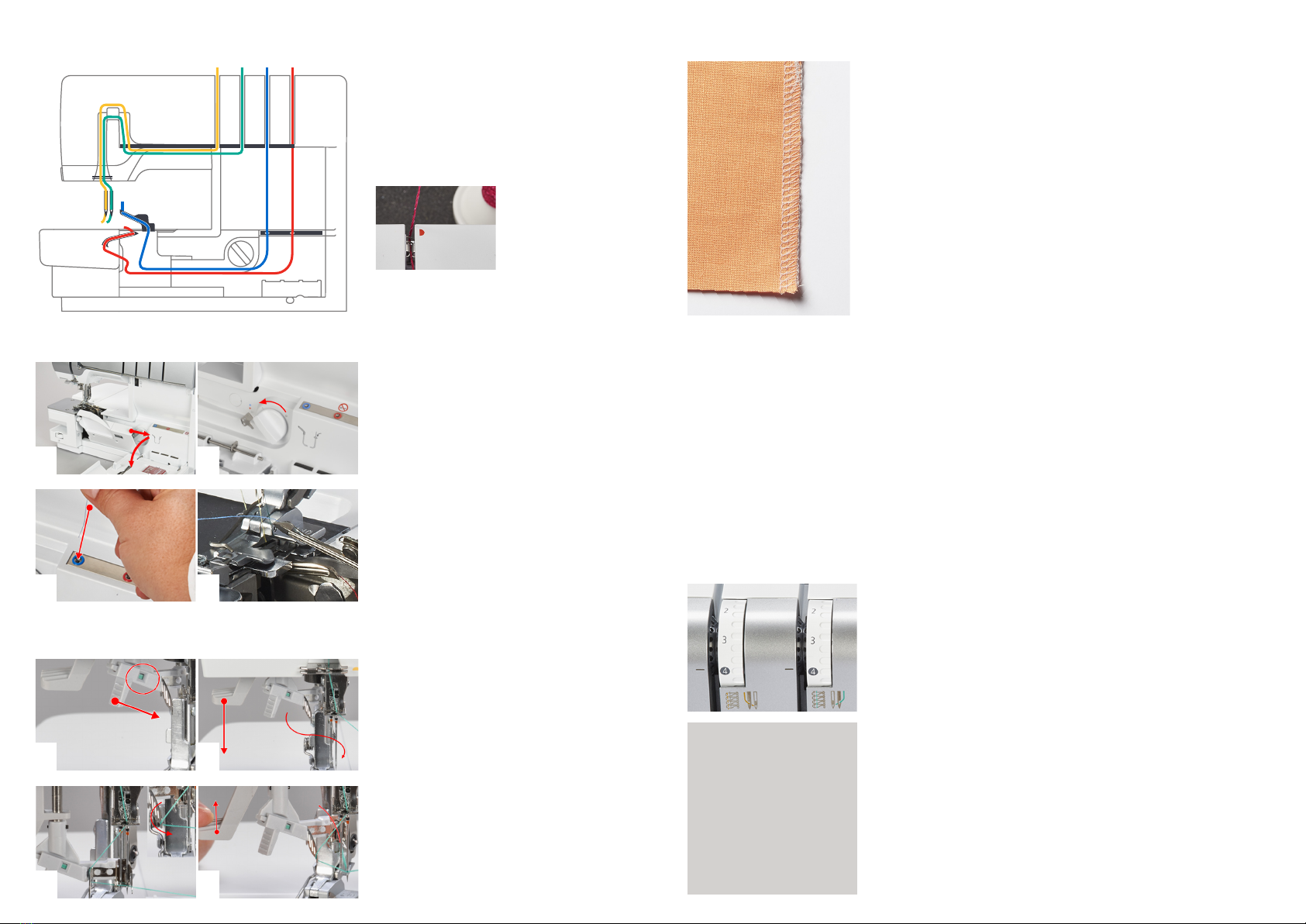

Threading the needle

1 Select needle position yellow or green.

2 Press the needle threader lever down.

3 Pull the thread counterclockwise around

the thread deector and through the

guide slots at the threader head.

4 Release the pressure on the needle

threader lever and let it go back to its

initial position. A thread loop is formed

behind the needle eye.

> Pull the thread end back.

1

3

2

4