BETE HydroWhirl Orbitor Instructions for use

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 2 of 24

Contents

Maintenance 3

Recommended Tools List 5

Nozzle Head and Rear Plate – Disassembly 6

Body Shell and Inlet Casing – Disassembly 8

Turbine Shaft Subassembly – Disassembly 9

Gear Cartridge Subassembly – Disassembly 10

Main Body and Body Shell – Disassembly 11

Main Body and Body Shell – Reassembly 13

Gear Cartridge Subassembly – Reassembly 14

Turbine Shaft Subassembly – Reassembly 14

Body Shell and Inlet Casing – Reassembly 15

Nozzle Head and Rear Plate – Reassembly 16

Appendix 18

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Interchangeable Parts . . . . . . . . . . . . . . . . . . . . . . . . . 22

Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . 23

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 3 of 24

Maintenance

In order to prevent machine failures, routine maintenance should be

carried out every 500 hours of operation. This should include cleaning all

internal parts and assessing the wear of seals, gears, bearing and bushes.

Any fine solid particles left inside the machine will increase wear

considerably.

Please Note:

• The Orbitor requires no lubrication.

• The Orbitor is approved by Bureau Veritas; a copy of

certification can be provided upon request.

• The Orbitor is available with ATEX approval for Zone 0.

Attention

• Before maintenance can be carried out, it is important the machine is

not contaminated with chemicals that could be hazardous.

• Always use the tools stated throughout this manual. These can be

purchased from BETE.

• Always read the technical data thoroughly before carrying out any

work on this machine.

• Never service the Orbitor head while it is hot.

• After any maintenance is carried out it is essential the machine is

flushed and sterilized before further use.

• Any parts found to be unserviceable should be replaced before

further use.

• The machine should only be operated at temperatures below 95°C

(200°F)

• During operation, always ensure any tank openings are completely

sealed off and can withstand the full force of the striking jet.

• If the tank being cleaned contains a combustible liquid or vapor with a

risk of ignition or explosion, the Orbitor should be properly grounded.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 4 of 24

• The machine should be allowed to gradually reach its operating

pressure. A sudden spike could cause parts to wear prematurely or

fail.

Please Note – Any cleaning fluids must be stored/disposed of in

accordance with current rules/directives.

Please Note – Always record any wear found and ensure the machine

operates smoothly after maintenance.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 5 of 24

Recommended Tools List

• Allen Keys: (1) 6 mm and (1) 3 mm

• M12 Wrench

• Strap Wrench

• Screwdriver

• 3 mm Pin Punch

• Light Hammer

• Vice

• Spider Tool (Part No. DM00748)

• Set of (2) Side Plate Tools (Part No. DM00749 for the set)

• Nozzle Head Tool (Part No. DM00750)

• Loctite 638 (if ceramic seals are removed)

• Torque Wrench

• Fly-Press or Soft-Jawed Vice

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 6 of 24

Nozzle Head and Rear Plate – Disassembly

Please refer to Figures 1 and 2.

1. Place the Orbitor in the vice, holding onto rear plate flats (DM02142).

Ensure machine is securely held in place before proceeding to the

next step.

2. Use tool (DM00750) to unscrew nozzle head (DM02141), in an

anti-clockwise direction.

Please Note – The assembly has 180° of lost motion.

3. The nozzle head (DM02141) should now be free to lift off.

4. Lift machine off the nozzle head shaft (DM02143).

Please Note – Be careful not to lose any seals, spacers or

bushes.

5. Check seal in nozzle head (DM00699) for wear or damage to the

seal lip, if excessively worn or damaged, then remove by cutting free.

6. There should be a ceramic seal insert (DM00698) left in the main

body. This should be replaced if the ceramic coating is chipped or

worn.

7. The bush (DM02032) will still be inside the main body (DM02139)

and should be carefully assessed for signs of wear.

8. The nozzle head bevel gear (DM02147) should still be on the nozzle

head shaft (DM02143) and should also be assessed for any signs of

wear to the gear teeth.

9. Inspect the stream straighteners for any foreign bodies and remove if

necessary.

10. Check rear plate seal (DM00699) for wear or damage to the seal lip.

11. Turn main body (DM02139) over and inspect second ceramic seal

insert for wear or damage.

12. Now both bushes (DM02032) in main head can be removed but only

if they are required to be replaced.

13. Lastly the nozzle head bevel gear (DM02147) can be lifted off the

nozzle shaft.

14. For Hi-capacity version see Figure 13.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 8 of 24

Body Shell and Inlet Casing – Disassembly

Inlet

Stator

DM00695

Rotor

DM00719

DM00696

Cartridge

Assembly

DM00685

DM00686

DM02923

DM02139

Figure 3: Body shell and inlet cas-

ing

1. Hold machine by inlet casing

at the bottom and turn the

body shell (DM02140) counter-

clockwise by hand, or alterna-

tively with a strap wrench if tight.

Please Note – To find part

number for a specific Inlet

Casing please refer to the

Interchangeable Parts list in

the Appendix as they vary by

model.

2. This should allow spring clip

(DM00686) to extrude from slot.

Unhook clip using a screwdriver.

3. Lift shell (DM02140) up from In-

let.

Please Note – You should be

left with the cartridge and tur-

bine subassemblies in inlet.

4. Pull out cartridge and turbine as-

semblies and inspect for wear.

5. Remove stator bush (DM00695)

if necessary.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 9 of 24

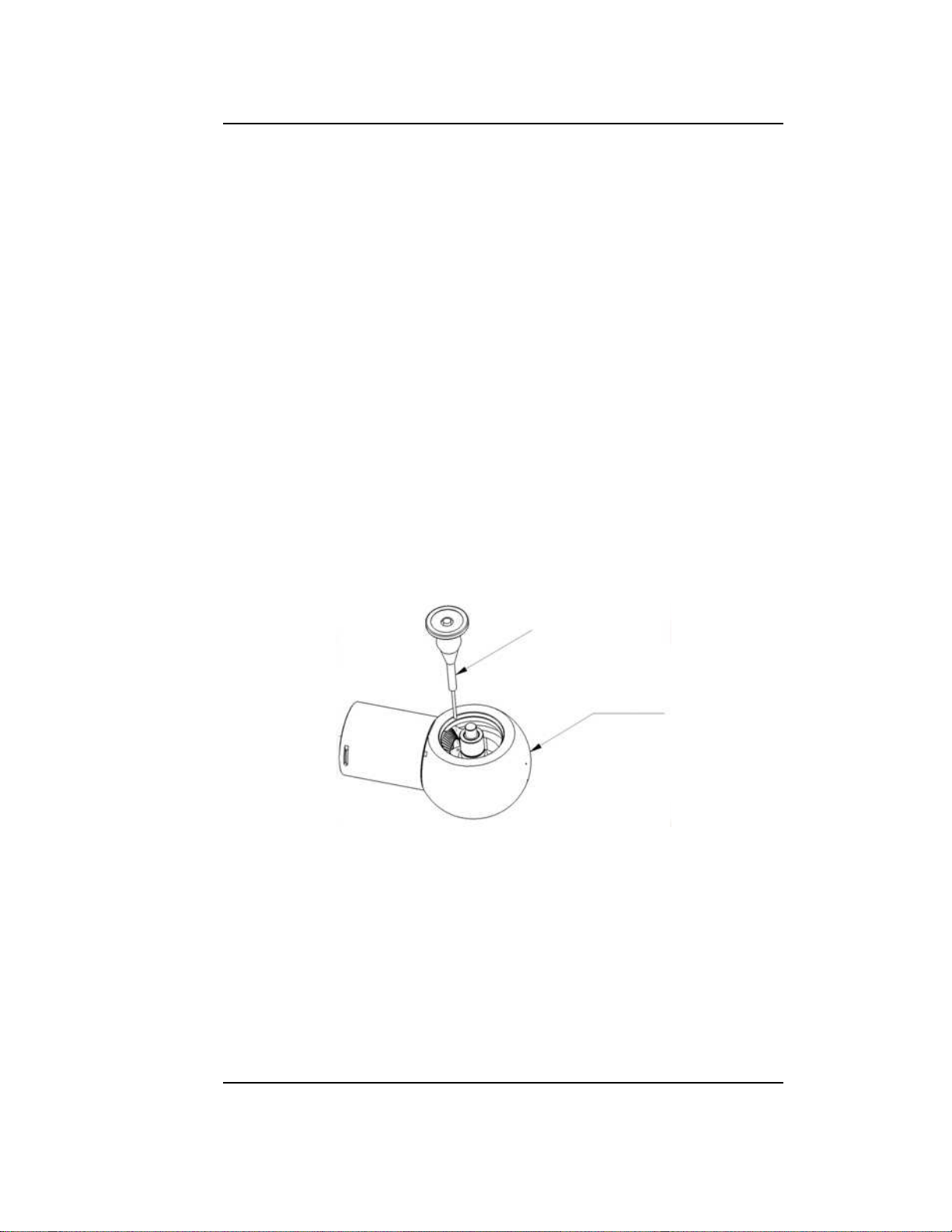

Turbine Shaft Subassembly – Disassembly

Please Note – Turbine can be removed from shaft if necessary by

unscrewing Hollow Set Screw (DM00702) (see Figure 4). For specific

turbine (rotor) part numbers refer to Interchangeable Parts list in the

Appendix as these vary depending on machine.

DM00702

DM00719

Rotor

Figure 4: Rotor (turbine) subassembly

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 10 of 24

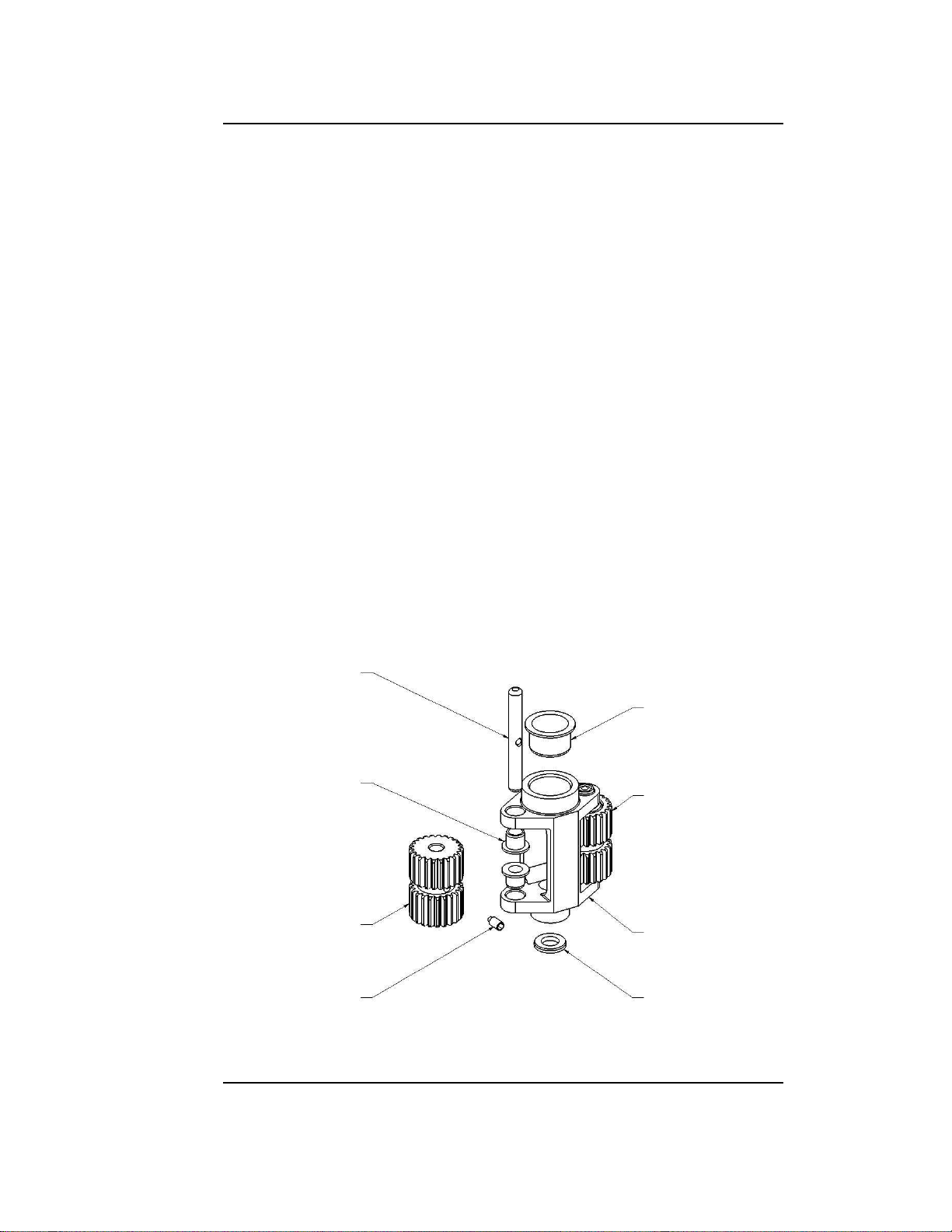

Gear Cartridge Subassembly – Disassembly

1. Check cartridge bush (DM00696), shaft bushes (DM00697), and

support washer (DM02226); inspect for wear.

2. Unscrew hollow set screws (DM00702) in both planet shafts, this

should allow you to remove both shafts (DM00736).

3. Now remove the planet gears; both the Aligned (DM00721) and the

1

/2Displaced (DM00722); check for wear.

DM00736

DM00697

DM00722

DM00702

DM00696

DM00721

DM02144

DM00685

Figure 5: Gear cartridge subassembly

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 11 of 24

Main Body and Body Shell – Disassembly

Please Note – Before attempting to unscrew shell from main body,

ensure you knock pin out of main body using a 3mm pin punch

(Figure 6).

3mm Pin Punch

DM02139

Figure 6: 3mm Pin Punch

1. Fit the two side plate tools (DM00749) to the faces of the body and

place in vice.

2. Using spider tool (DM00748), loosen spider (DM02145 Figures 7

and 8) from main body.

3. Lift shell and spider from ball and separate internal components to

ensure all thrust bearing balls (DM00703) are retained. (Figure 8).

4. Inspect all seals, bearings, and bushes for signs of wear and replace

if necessary.

5. Check spider and bevel gear teeth for wear.

6. Check ceramic seal insert (DM00698) on body shell.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 13 of 24

Main Body and Body Shell – Reassembly

1. If removed, push ceramic seal inserts back into main body and body

shell using Loctite 638.

2. Re-assemble bearing assembly to spider and insert into body shell.

3. Pick up the main body and place the side plate tools on the sides of

main body and hold in vice.

Please Note – This is to protect the ceramic seal inserts.

4. Insert seal (DM00698) to top of main body, if removed.

5. Locate spider using spider tool and screw assembly to main body

through body shell. Using Loctite 638 on thread of spider shaft.

6. Using torque wrench, tighten spider to 60 N·m (45 ft·lbf).

7. Remove whole assembly from vice and remove side plates.

8. Replace 3mm pin (DM00709) in hole inside main body.

3mm Pin Punch

DM02139

Figure 9: 3 mm Pin Punch

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 14 of 24

Gear Cartridge Subassembly – Reassembly

1. Replace cartridge bush (DM00696), shaft bushes (DM00697), and

support washer (DM02226) if removed.

2. Slide both gears into place and insert shafts aligning holes in gears

and shafts for hollow set screw.

3. Insert set screw (DM00702) and tighten.

Turbine Shaft Subassembly – Reassembly

Please Note – Turbine can be replaced on shaft if necessary by

sliding onto shaft and reinserting hollow set screw (DM00702). For

turbine part number refer to the Interchangeable Parts list in the

Appendix.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 15 of 24

Body Shell and Inlet Casing – Reassembly

Inlet

Stator

DM00695

Rotor

DM00719

DM00696

Cartridge

Assembly

DM00685

DM00686

DM02923

DM02139

Figure 10: Body shell and

inlet casing

1. Hold machine with main body

(DM02139)under body shell (DM02923)

and insert gear cartridge subassembly.

2. Insert turbine shaft subassembly guiding

turbine into cartridge.

Please Note – Check for smooth oper-

ation by spinning the turbine shaft by

hand.

3. Replace stator bush (DM00695) in stator

inside inlet casing, if removed.

4. Hold machine with main body under

body shell and slide the inlet casing into

body shell.

Please Note – Ensure hole in inlet

casing is aligned with slot in main

body shell.

5. Fit spring clip through slot in the shell

into the hole in the inlet connection and

turn slightly to locate in its position.

6. Rotate machine vertically and hold inlet

connection in vice, located on flats.

7. Turn shell 360°clockwise to fit spring clip

completely in inlet connection.

Please Note – Use new spring clip (DM00686) if necessary.

Please Note – Tighten with strap wrench if necessary.

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 16 of 24

Nozzle Head and Rear Plate – Reassembly

Please refer to Figures 11 and 12.

1. Hold rear plate in vice using flats and place new seal, if necessary.

2. Slide nozzle head bevel gear onto nozzle shaft.

3. Push bushes (DM02032) into main body if necessary and slide

assembly back onto nozzle shaft.

4. Fit stainless steel spacer (DM02221) onto nozzle shaft.

5. If nozzles were removed now replace nozzles to nozzle head.

Please Note – Ensure nozzles are tightened sufficiently in order

to avoid machine failure.

6. Locate seal into grove of nozzle head.

7. Finally screw nozzle head back onto main assembly using Loctite

638 and tighten with tool (DM00750) to 60 N·m (45 ft·lbf).

8. For Hi-capacity version, see Figure 13.

9

DM02142

DM02147

DM02143

DM00699

DM00698

DM02139

DM02032

DM02032

Figure 11: Back plate reassembly

www.BETE.com 20150421

BETE Fog Nozzle, Inc.

HydroWhirl®Orbitor Page 20 of 24

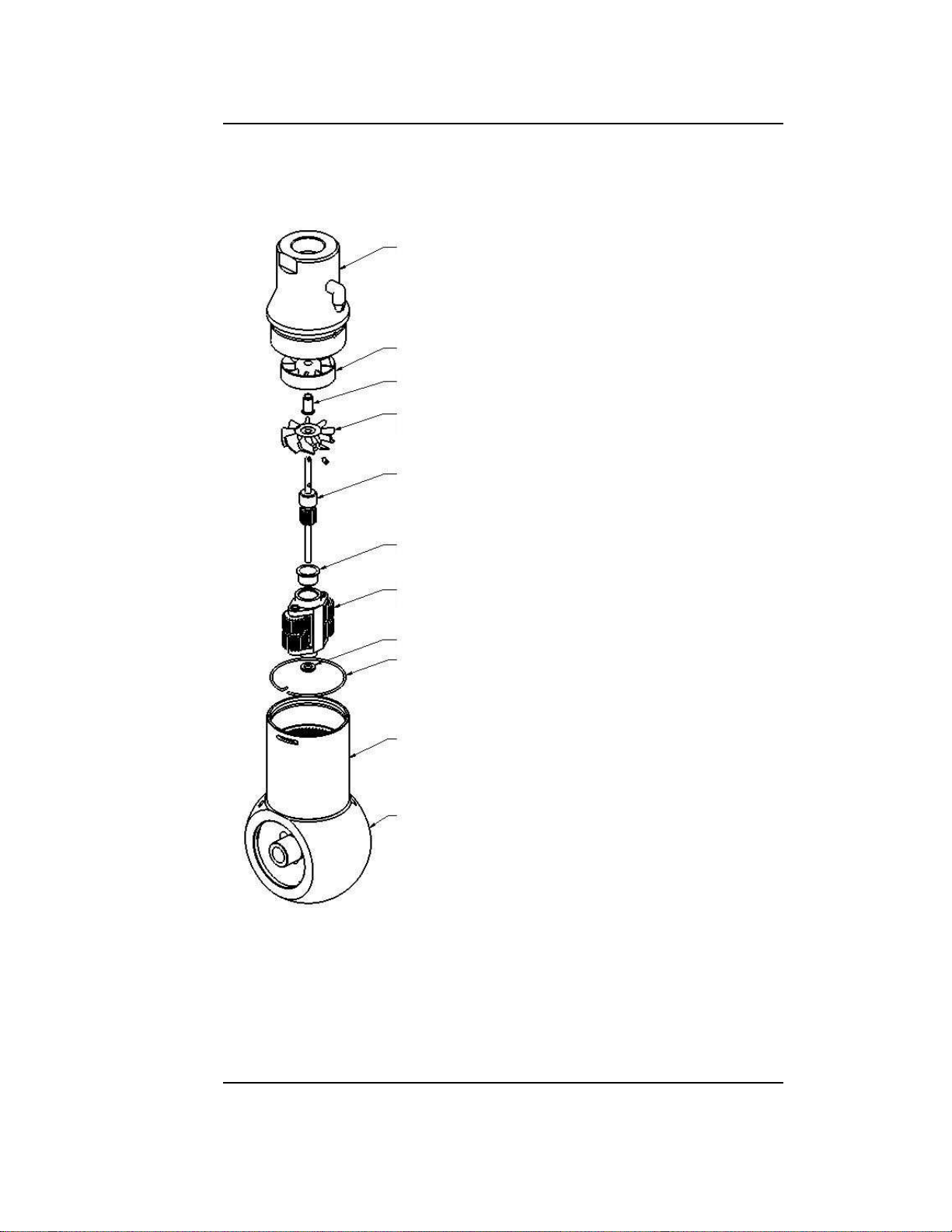

Inlet

Stator

DM00695

Rotor

DM00702

DM00719

DM00696

DM00721

DM00685

DM00686

DM00693

DM02145

DM02135

DM02135

DM00703

DM02923

DM02142

DM00699

DM00699

DM02143

DM02147

DM02032

DM02032

DM02139

DM00698

DM02221

DM02141

Stream

Straightener

Nozzle

DM00709

DM00699

DM00698

DM00688

DM00722

DM00697

DM00736

Figure 15: Exploded view of the Orbitor

www.BETE.com 20150421

Other manuals for HydroWhirl Orbitor

1

Table of contents

Other BETE Washer manuals