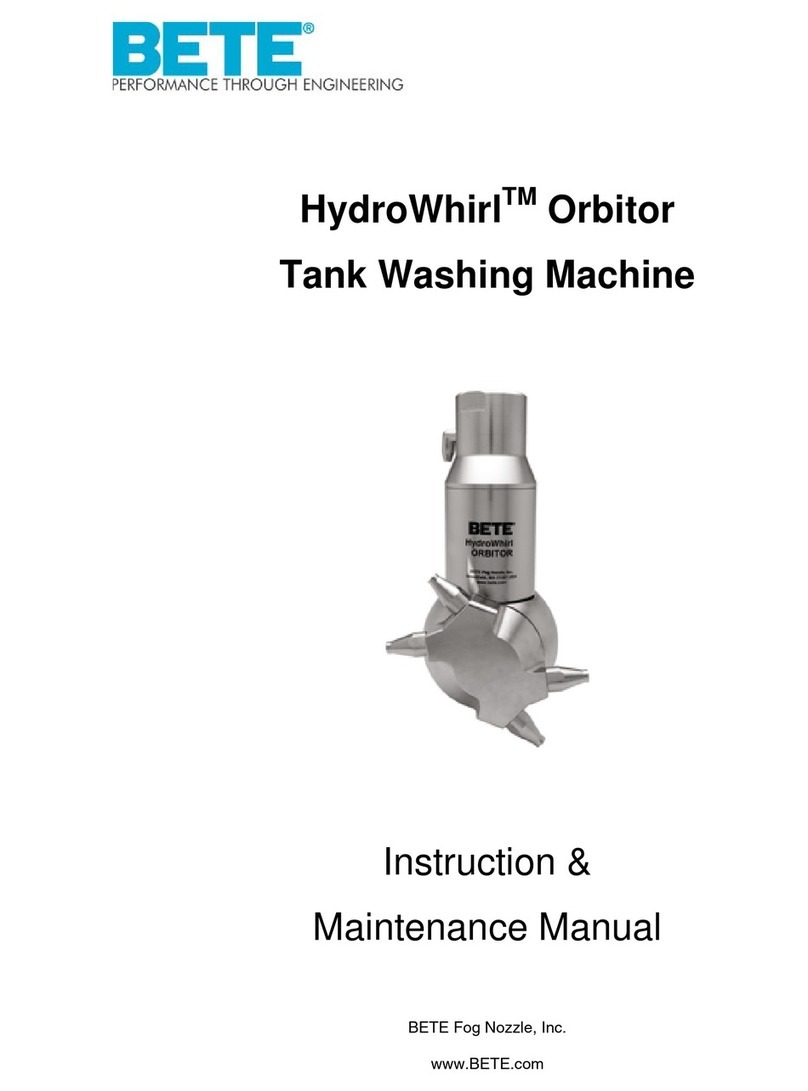

BETE HydroWhir Orbitor 100 Instructions for use

HydroWhirl® Orbitor 100

Tank Washing Machine

Instruction and Maintenance Manual

BETE Fog Nozzle Inc.

www.bete.com

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 2 of 40

www.BETE.com

20230927

Contents

Introduction to the Orbitor 100 Tank Washing Machine 5

Component Names ..............................................................................5

Operation Principles .............................................................................5

Performance and Technical Data 8

Operating Conditions ............................................................................8

Dimensions .......................................................................................... 8

Cleaning Fluids ....................................................................................9

Construction Materials ..........................................................................9

Performance Table ............................................................................. 10

Quick Wash or Rinse .......................................................................... 10

Installation, Mounting, and Washing Fluid Connection 10

Installation Checklist ........................................................................... 16

Mounting - Loads and Weights ...........................................................17

Fixed Installations ............................................................................... 17

Portable Installations .......................................................................... 18

Operation Instructions 18

Conditions for Safe Working ...............................................................18

General Operating Instructions ...........................................................19

Maintenance Manual 20

Schedule ............................................................................................ 20

Recommended Tools List.................................................................... 21

Disassembly Operations 22

Nozzle Head and Retaining Head Bolt – Disassembly ....................... 22

Body Shell and Inlet Casing – Disassembly ....................................... 24

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 3 of 40

www.BETE.com

20230927

Rotor Shaft Subassembly – Disassembly .......................................... 25

Gear Cartridge Subassembly – Disassembly ..................................... 26

Main Body and Body Shell – Disassembly ......................................... 27

Inspection .......................................................................................... 29

Seal Insert Removal ........................................................................... 30

Reassembly Operations 31

Main Body and Body Shell – Reassembly .......................................... 31

Gear Cartridge Subassembly - Reassembly ...................................... 31

Rotor Shaft Subassembly – Reassembly ........................................... 32

Body Shell and Inlet Casing – Reassembly ........................................ 33

Nozzle Head and Retaining Head Bolt – Reassembly ........................ 34

Parts List 35

Interchangeable Parts ......................................................................... 37

Service Tool Kit .................................................................................. 38

Rebuild Kits ........................................................................................ 38

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 4 of 40

www.BETE.com

20230927

Contact Details

For technical support, replacement parts, or additional equipment, please

contact us at:

BETE Fog Nozzle, Inc.

50 Greenfield St

Greenfield MA 01301 USA

Telephone: +1 (413) 772-0846

Fax: +1 (413) 772-6729

Email: sales@bete.com

Web: http://www.bete.com

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 5 of 40

www.BETE.com

20230927

Introduction to the Orbitor 100 Tank Washing Machine

This document is the Installation, Operation and Maintenance Manual,

also known as the Product Manual, for the Orbitor 100 Tank Washing

Machine (TWM). These machines are supplied for use in the marine,

industrial, and food processing industries.

Component Names

For part numbers and names see the Maintenance Manual section starting

on page 20. The figures shown throughout the manual are typical of a 4

nozzle machine. These examples may not directly resemble the machine

supplied but are fundamentally the same in construction and part

materials.

Operation Principles

The basic tank cleaning process is achieved by impinging high impact

cleaning fluid jets on the inner walls of the vessel. The TWM action moves

the jet nozzles in a spiral pattern that ensures correct and even coverage

of the vessels surfaces through a washing cycle.

The flow of the cleaning fluid drives the machine causing the spherical

body and nozzle head to rotate. There are no other power sources, control

systems or electrical devices. The mechanism is self-lubricated and

internally self-cleaned by the cleaning fluid. Three small fixed jets wash the

machine exterior. The Orbitor 100 TWM can be used with pressures as

low as 45 psi (3 bar) due to a very low starting torque.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 6 of 40

www.BETE.com

20230927

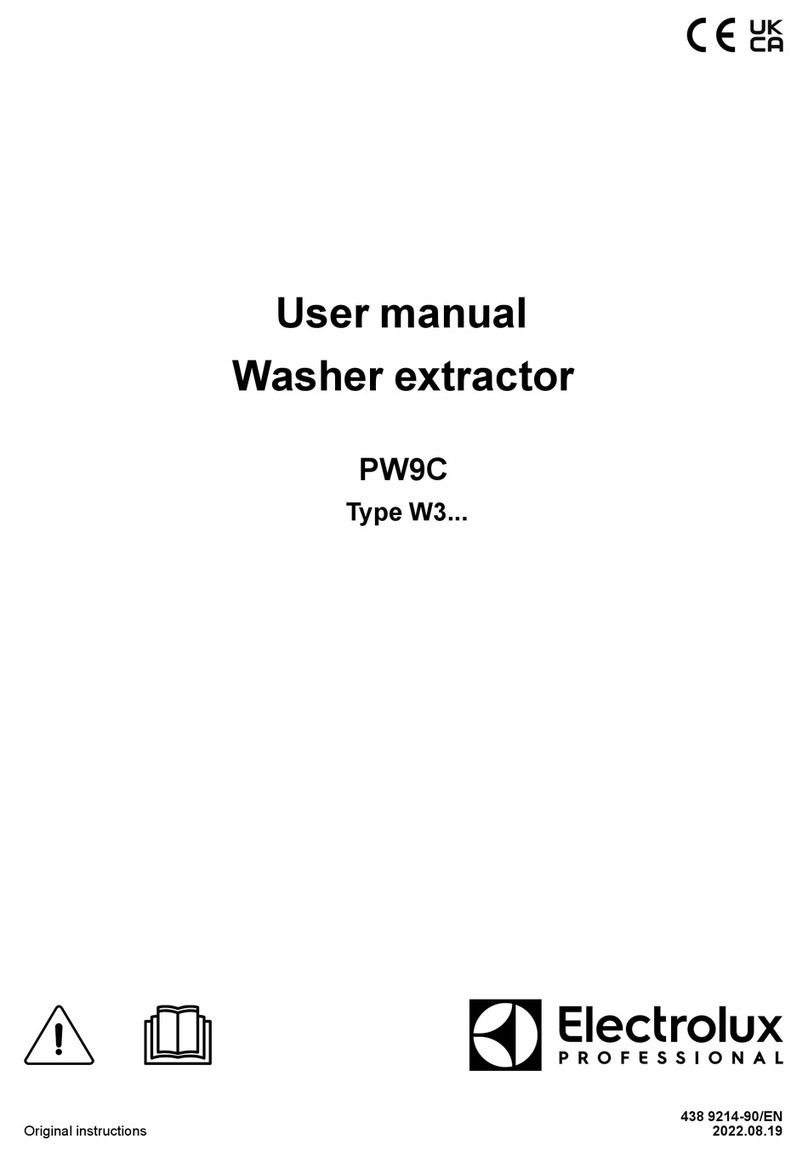

Inlet

Casing

Nozzle Head

Nozzle

Main Body

Figure 1: General arrangement.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 7 of 40

www.BETE.com

20230927

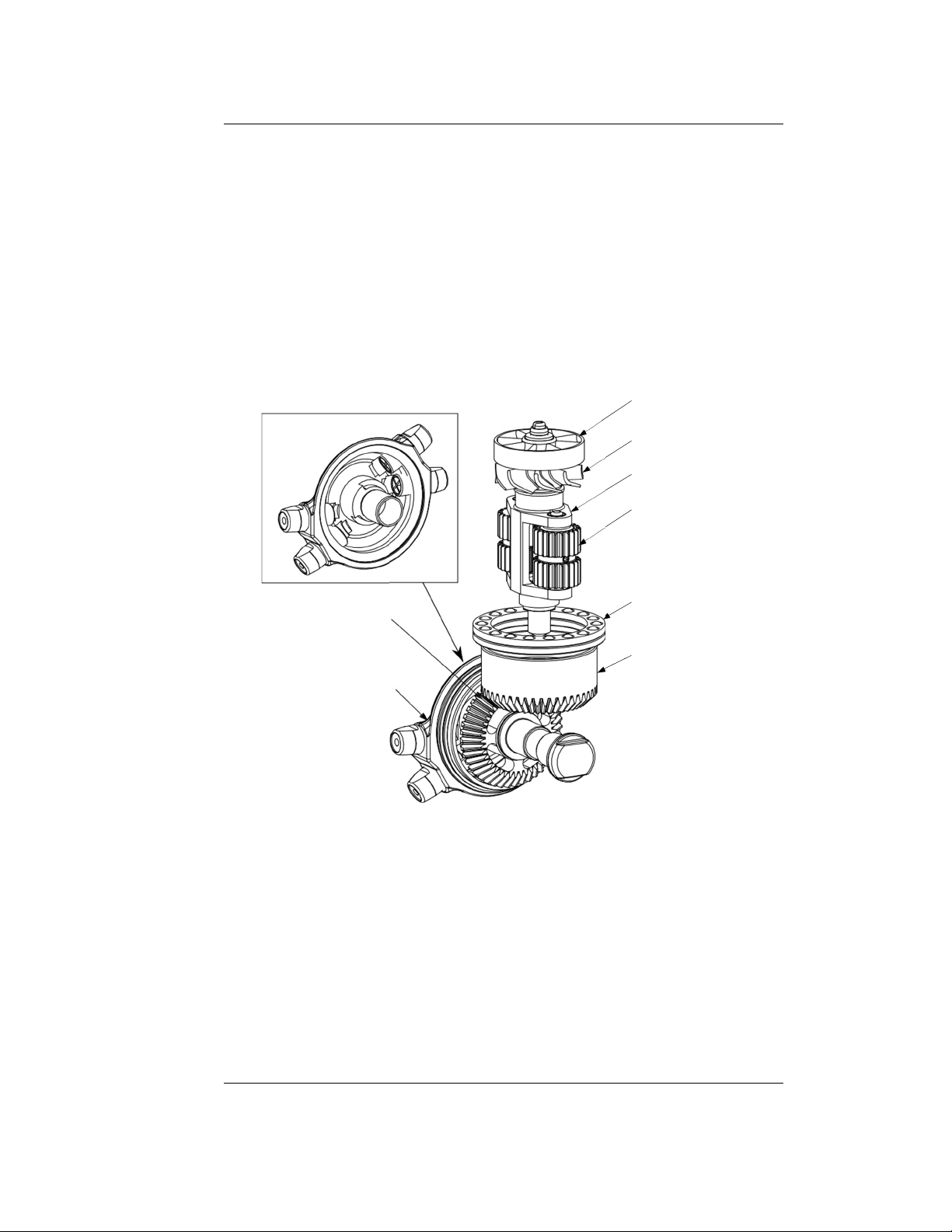

Stator

Rotor

Gear Cartridge Ass’y

Planet Gear

Nozzle Head Bevel Gear

Nozzle Head

Ball Thrust Bearing

(Top Race Removed)

Entry Bevel Gear

Figure 2: Orbitor 100 tank washing machine with housings removed.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 8 of 40

www.BETE.com

20230927

Performance and Technical Data

Operating Conditions

Operating pressure range 3 bar to 10 bar 45 psi to 145 psi

Maximum pressure 12 bar 175 psi

Maximum operating temperature

95

◦

C

195 °F

Minimum ambient storage temperature

−40

◦

C

−40 °F

Maximum ambient storage temperature

140

◦

C

285 °F

Dimensions

Available inlet connections, 3/4 BSP (G) 3/4 NPT

female pipe thread 1 BSP (G) 1 NPT

Length, not including nozzles 193 mm 7.6 in

Width, not including nozzles 76 mm 3.0 in

Height 76 mm 3.0 in

Minimum opening diameter,

nozzles in any orientation

100 mm 4.0 in

Minimum opening diameter,

nozzles vertically aligned

85 mm 3.35 in

Installed weight, approximate 2.5 kg 5.5 lb

Packed Dimensions

Length

545 mm

21.5 in

Width 270 mm 10.6 in

Height 280 mm 11.0 in

Total gross weight < 4 kg < 9 lb

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 9 of 40

www.BETE.com

20230927

Cleaning Fluids

Orbitor 100 TWMs are capable of resisting most cleaning fluids provided:

•

They contain no

–

Solid abrasive particles

–

Chemicals liable to attack the TWM construction materials. See

materials list below.

•

Temperatures specified in Operating Conditions are not exceeded

Approved cleaning fluids:

•

Water at a temperature below 200 °F (below 95 ◦C)

•

< 5 % NaOH caustic soda solution

•

Other cleaning fluids can be used with advice of BETE

Construction Materials

Component Material

Nozzle head, nozzles and inter-

nal parts unless specified below

316L stainless steel

Body shell Kolsterised 316L stainless steel

Gears PEEK

(PVDF or other materials available

by special order)

Seals PTFE, 10 % carbon filled

Seal seats Ceramic coated

Bushings PTFE, carbon filled

Ball bearings / race Kolsterised 316 stainless steel

Duplex 2205 steel (hardened)

Please note – Do not use any chemicals on the TWM while cleaning

that might affect the integrity of the non-metallic component parts. If

in doubt contact BETE for advice.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 10 of 40

www.BETE.com

20230927

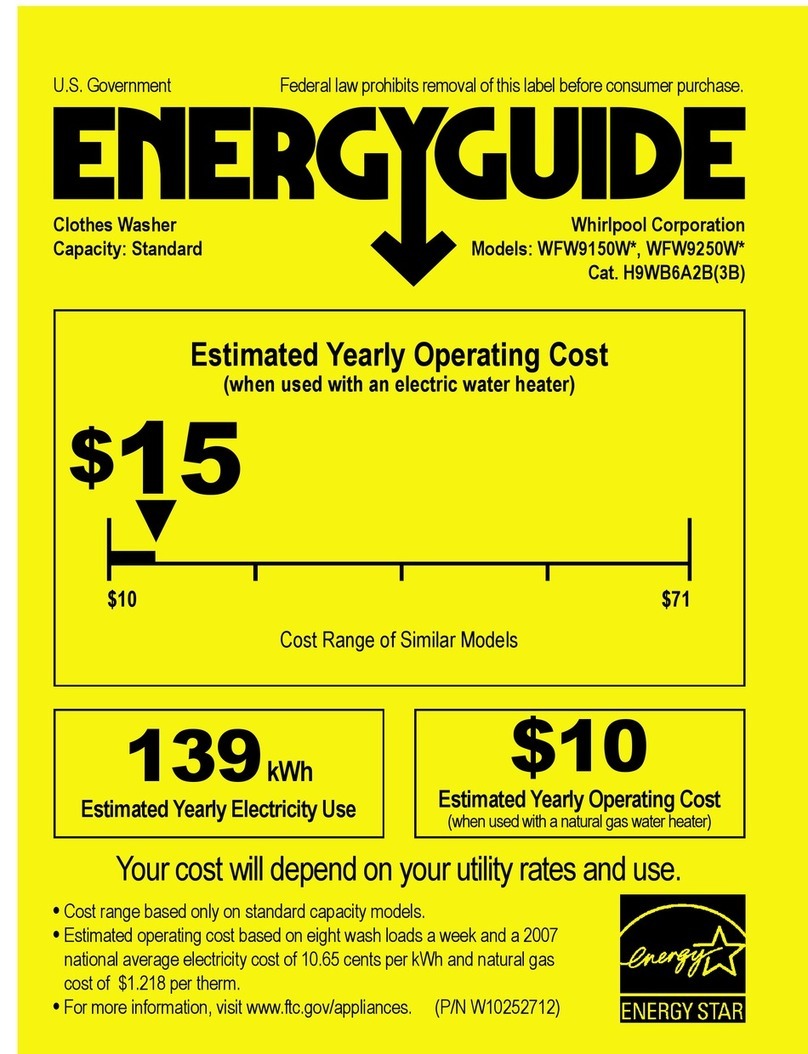

Performance Table

Tables 1 – 4 show total water flow, total jet length (effective cleaning may

vary based on application), and typical cycle time for various nozzle

configurations and sizes at different pressures.

Quick Wash or Rinse

The cycle times defined in the above table are for a full wash cycle.

Wash cycles can be repeated as many times as necessary. The TWM can

also be stopped after one pattern generation for a quick rinse.

Installation, Mounting, and Washing Fluid Connection

Correct installation of an Orbitor 100 TWM is the responsibility of the tank

owners, constructors, or installers. Mounting and connecting is a

straightforward task for a competent fitter or technician.

BETE is happy to offer technical support and recommendations upon

request but does not normally carry out installation work and cannot be

responsible for ensuring correct installation practice or application.

TWM machine installation - key points:

•

Machines will be positioned in the tank to permit the best cleaning jet

coverage of walls, floor and tank cover.

•

The cleaning pattern required and selection of flow and jet length

depends on:

–

Tank dimensions.

–

Properties of the stored product residue.

–

Available flow and pressure.

•

The axis of rotation of the spherical main body is along the axis of

the inlet.

•

The axis of rotation of the nozzle head is perpendicular to inlet axis

— see Fig. 3).

•

Machines will normally be mounted to the tank top cover and project

down.

Table 1

Orbitor 100 Performance Information, US Units

4 ×,03.0 4 ×,04.0 4 ×,05.0 4 ×,06.0

Pressure Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

psi gpm ft min gpm ft min gpm ft min gpm ft min

45 12.0

3.3 6.0

17.8

6.6 5.4

23.7

8.2 4.4

30.6

9.8 3.9

60 13.9

4.9 5.4

20.3

8.2 4.7

26.7

9.8 3.9

34.0

11.5 3.4

75 15.8

6.6 4.8

22.7

9.8 4.1

29.6

11.5 3.4

37.3

13.1 3.0

90 17.6

6.6 4.3

25.1

9.8 3.6

32.3

11.5 3.0

40.6

13.1 2.6

100 18.8

8.2 4.0

26.6

11.5 3.3

34.1

13.1 2.8

42.8

14.8 2.4

115 20.5

8.2 3.6

28.9

11.5 2.9

36.7

13.1 2.4

46.0

14.8 2.1

130 22.2

9.8 3.2

31.2

13.1 2.7

39.1

14.8 2.2

49.2

16.4 1.9

145 23.9

11.5 2.9

33.4

13.1 2.5

41.4

14.8 2.0

52.4

16.4 1.7

BETE Fog Nozzle, Inc.

HydroWhirl

®

Orbitor 100

Page 11 of 40

www.BETE.com

20230927

8

Table 2

Orbitor 100 HR Performance Information, US Units

4 ×,03.0 4 ×,04.0 4 ×,05.0 4 ×,06.0

Pressure Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

psi gpm ft min gpm ft min gpm ft min gpm ft min

45 12.9

12.5 19.5

16.5

14.4 25.5

24.2

16.4 16.3

30.6

18.0 21.5

60 14.2

14.9 16.8

19.2

17.1 21.6

26.9

19.1 14.1

34.0

20.6 18.7

75 15.7

17.0 14.6

21.8

19.4 18.3

29.6

21.4 12.2

37.3

22.9 16.3

90 17.2

18.8 12.8

24.2

21.3 15.7

32.2

23.2 10.9

40.6

24.7 14.3

100 18.3

19.8 11.8

25.7

22.3 14.2

33.8

24.3 10.2

42.8

25.7 13.2

115 20.1

21.0 10.7

27.9

23.6 12.5

36.3

25.4 9.6

46.0

26.9 11.8

130 21.9

22.0 10.0

29.9

24.5 11.5

38.7

26.2 9.5

49.2

27.8 10.8

145 23.8

22.6 9.7

31.8

25.0 11.0

40.9

26.6 9.8 52.4

28.2 10.3

BETE Fog Nozzle, Inc.

HydroWhirl

®

Orbitor 100

Page 12 of 40

www.BETE.com

20230927

Table 3

Orbitor 100 Performance Information, SI Units

4 ×,03.0 4 ×,04.0 4 ×,05.0 4 ×,06.0

Pressure Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

bar L/min

m

min L/min

m

min L/min

m

min L/min

m

min

3

45.0

1.0 6.0

66.7

2.0 5.5

88.3

2.5 4.5

115 3.0 4.0

4

51.7

1.5 5.5

75.0

2.5 4.8

100 3.0 4.0

127 3.5 3.5

5

58.3

2.0 5.0

85.0

3.0 4.3

110 3.5 3.5

138 4.0 3.0

6

65.0

2.0 4.4

93.3

3.0 3.8

120 3.5 3.0

152 4.0 2.7

7

71.7

2.5 4.0

102 3.5 3.3

130 4.0 2.8

163 4.5 2.4

8

78.3

2.5 3.5

110 3.5 2.9

140 4.0 2.5

175 4.5 2.1

9

85.0

3.0 3.1

118 4.0 2.6

148 4.5 2.1

187 5.0 1.8

10 90.0

3.5 3.0

127 4.0 2.5

157 4.5 2.0

198 5.0 1.8

BETE Fog Nozzle, Inc.

HydroWhirl

®

Orbitor 100

Page 13 of 40

www.BETE.com

20230927

Table 4

Orbitor 100 HR Performance Information, SI Units

4 ×,03.0 4 ×,04.0 4 ×,05.0 4 ×,06.0

Pressure Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

Flow

Jet

Length

Cycle

Time

bar L/min

m

min L/min

m

min L/min

m

min L/min

m

min

3

48.3

3.7 20.0

61.7

4.3 26.0

90.0

4.9 17.0

115 5.4 22.0

4

53.3

4.5 17.0

71.7

5.1 22.0

102 5.7 14.0

127 6.2 19.0

5

57.5

5.1 14.5

80.0

5.8 19.0

110 6.4 12.0

138 6.9 16.5

6

64.2

5.6 13.0

90.0

6.4 16.0

120 7.0 11.0

152 7.4 14.5

7

70.0

6.1 12.0

98.0

6.8 14.0

128 7.4 10.5

163 7.9 13.0

8

76.7

6.4 10.8

107 7.2 12.5

138 7.8 10.0

175 8.2 12.0

9

83.3

6.7 10.0

113 7.5 11.5

147 8.0 9.5

187 8.5 11.0

10 90.0

6.9 9.5

120 7.6 11.0

155 8.1 9.5

198 8.6 10.0

BETE Fog Nozzle, Inc.

HydroWhirl

®

Orbitor 100

Page 14 of 40

www.BETE.com

20230927

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 15 of 40

www.BETE.com

20230927

Figure 3: Rotation direction of nozzle head and body.

•

Machines may also be inverted and project through the tank floor.

– Please assume the vertical down orientation in following text.

•

BETE or its agents will be pleased to offer application and installation

advice and can produce cleaning diagrams (also known as shadow

diagrams) if required (refer to the Installation Checklist provided in

this document).

The inlet comprises a cylindrical housing with an internal (female) thread

sized for alternative pipe thread systems. The standard internal threads

are:

3/4 NPT 3/4 BSP (G)

1 NPT 1 BSP (G)

This threaded interface provides both fluid connection and structural

machine mounting functions. It is recommended to install a coarse filter of

0.06 in (1.5 mm) minimum mesh in the supply line.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 16 of 40

www.BETE.com

20230927

Installation Checklist

TWM Serial Number

Location of TWM Installation

Date

Stage Task

✓

Details Name of Technician

Pre-Installation

Has a system level

Hazard

Analysis

been

conducted?

Is

the

cleaning

fluid

supply

filtered?

Test

and

record

cleaning

fluid

supply

pressure.

Record

here

the

normal

cleaning

fluid

specification

and

temperature.

Post-Installation

Check pipe tightness.

Check nozzle

tightness.

Test electrical

resistance between

nozzle

tips

and

installation

pipe

and

tank structure.

Test electrical

resistance

of

portable

hoses.

Rinse the system with

clean water.

Test for smooth

operation

and

regular

running speed.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 17 of 40

www.BETE.com

20230927

Mounting - Loads and Weights

Tank owners, constructors, or installers are responsible for the structural

integrity of the TWM mounting. The installation specification and design

should consider the following.

•

Maximum static weight is 5.5 lb (2.5 kg, 24.5 N).

–

Weight of pipe work and fluids are additional.

•

Single nozzle reaction forces can be up to 9 lb (40 N) depending on

pressure and nozzle size.

–

Normally these forces are balanced by opposing nozzles.

•

Structural strength and stiffness of the mounting must be sufficient.

–

The natural vibration frequency of the mounting must be many

times the forcing frequency.

–

Masonry vessels are a particular concern and may require

manufacture of large pipe flanges or structures to spread loads.

•

Pipe work systems must be designed to prevent water hammer

effects.

–

Forces produced by water hammer can far exceed normal

reaction loads and can damage the TWM and supply pipework.

•

Installations must be designed by a competent engineer or other

qualified individual.

Fixed Installations

Fixed machines are used for applications where the stored media or

process will not be affected by the presence of a permanent machine. This

type of installation requires the least operator intervention and the lowest

component costs. In practice, specification differences between fixed and

portable machines are few.

The fluid coupling and machine mounting is specific to each tank

installation. Normally, fixed machines are mounted on rigid pipes, often

flange mounted to the tank roof or floor. BETE can supply suitable flanged

and weld prepared pipe assemblies. Pipe length depends on tank size and

required jet pattern. Short flanged pipes form a compact unit ideal for top

down washing.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 18 of 40

www.BETE.com

20230927

Longer pipes, also known as Drop Pipes or Free Standing Units (FSU’s),

will require additional strengthening to prevent fatigue fracture due to

vibration. Long pipe installations are designed in collaboration with the

customer and often include steadying cable rigs or tie bars.

A machine fixed in a dirty environment might experience the nozzles

becoming blocked by the contaminant which will affect the machines

performance. If this condition is likely to occur, inspection and cleaning of

the nozzles prior to use is advised.

Ensure all fixed installations are clear from any obstructions that might

prevent the nozzle head from rotating.

Portable Installations

Portable machines are only needed while cleaning and are moved out the

way during normal operation. The equipment is stowed when not in use.

Portable machines are most often used with a large bore flexible hose with

pipe threaded end couplings. Flexible hose mounting allows the cleaning

machine to be guided into different positions in the tank with manually

controlled cables. The TWM operator can thereby concentrate the

cleaning action in particularly stubborn areas.

Operation Instructions

Conditions for Safe Working

•

Only competent and qualified persons should carry out and check

installation work.

•

Follow the installation instructions in this manual.

•

Complete the Installation Checklist printed in this manual.

–

Record installation details.

–

Store manuals with check lists appropriately in an accessible

location.

•

Use Orbitor 100 TWMs within the technical parameters defined in the

Operating Conditions.

•

Ensure that personnel cannot touch hot TWM surfaces or be hit by

high power cleaning fluid jets.

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 19 of 40

www.BETE.com

20230927

–

Beware of hazardous cleaning fluids.

•

Maintain Orbitor 100 TWMs in accordance with the instructions

provided in this Product Manual.

–

Check nozzle tightness regularly.

General Operating Instructions

•

Always

–

Rinse with clean water after operation.

–

Ensure that any tank openings are completely sealed off and

can withstand the full force of the striking jet.

–

Allow the machine to gradually reach its operating pressure to

avoid water hammer effects. A sudden spike could cause parts

to wear prematurely or fail.

–

Store and dispose of cleaning fluids in accordance with current

rules and directives.

•

Never

–

Back drive the TWM by manually rotating nozzle heads.

–

Drive the TWM with steam or with a liquid at a temperature

above 200 °F (95 ◦C).

BETE Fog Nozzle, Inc.

HydroWhirl® Orbitor 100

Page 20 of 40

www.BETE.com

20230927

Maintenance Manual

The Orbitor 100 TWM is designed to allow for field maintenance. These

machines may also be returned to BETE for maintenance if desired. To

ensure correct operation of the machine, it is mandatory that all spare

parts be supplied by BETE.

Once maintenance has been carried out by either party the installation test

procedure must be conducted on reinstallation. A new Installation

Checklist is required to be completed and maintained.

Schedule

In order to prevent machine failures, routine maintenance should be

carried out at a maximum of

500 hours of operation

Maintenance should include cleaning all internal parts and assessing the

wear of seals, gears, bearing and bushes.

•

Any fine solid particles left inside the machine will increase wear

considerably.

•

Orbitor 100 TWM requires no lubrication.

–

The Orbitor 100 TWM is lubricated by the spray media during

operation.

Attention

•

Before maintenance can be carried out, it is important the machine is

not contaminated with chemicals that could be hazardous.

•

Always

–

Use the tools stated throughout this manual. Special tools for

Orbitor 100 maintenance can be purchased from BETE.

–

Read the technical data thoroughly before carrying out any work

on this machine.

–

Record any wear found and check for smooth operation of the

machine after maintenance.

Table of contents

Other BETE Washer manuals