Bevent Rasch RCKD User manual

13/09/2017

www.bevent-rasch.com

RCKD

Duct detector

FIRE SAFETY

2BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Duct detector RCKD

12-0553_ENG / Sept. 2017 teamfront.se

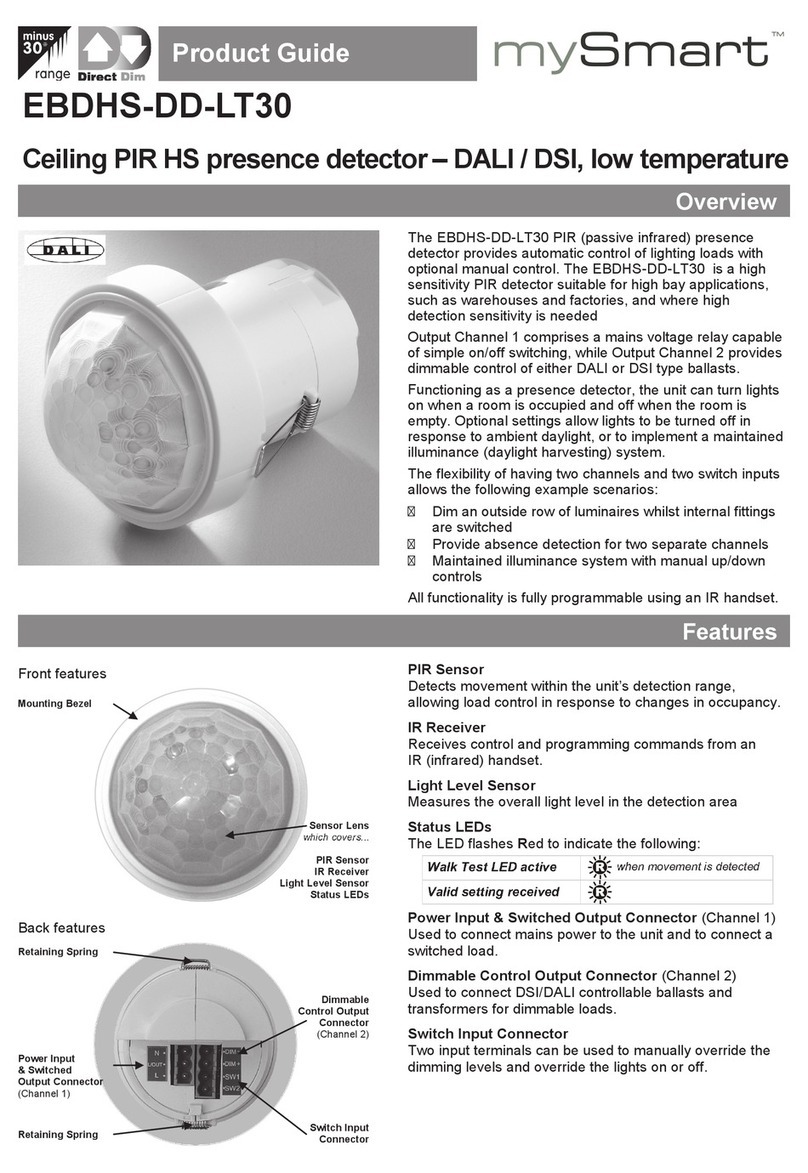

Quick facts

• Smoke detector for installation in ventilation ducts

• Optical detector head

• Indication of a dirty detector head

• 0,6 m aluminium venturi pipe included

Use

Indication of smoke in ventilation ducts.

Design

Detector for installation in ventilation ducts, with optical

detector head, encapsulation and venturi pipe. RCKD

gives indication of a dirty detector head. Power supply is

from the control panel or control unit.

Material

Detector, white PVC with metal netting. Adapter housing

with lid for single tube detector, made of clear ABS.

Aluminum venturi tube.

Function description

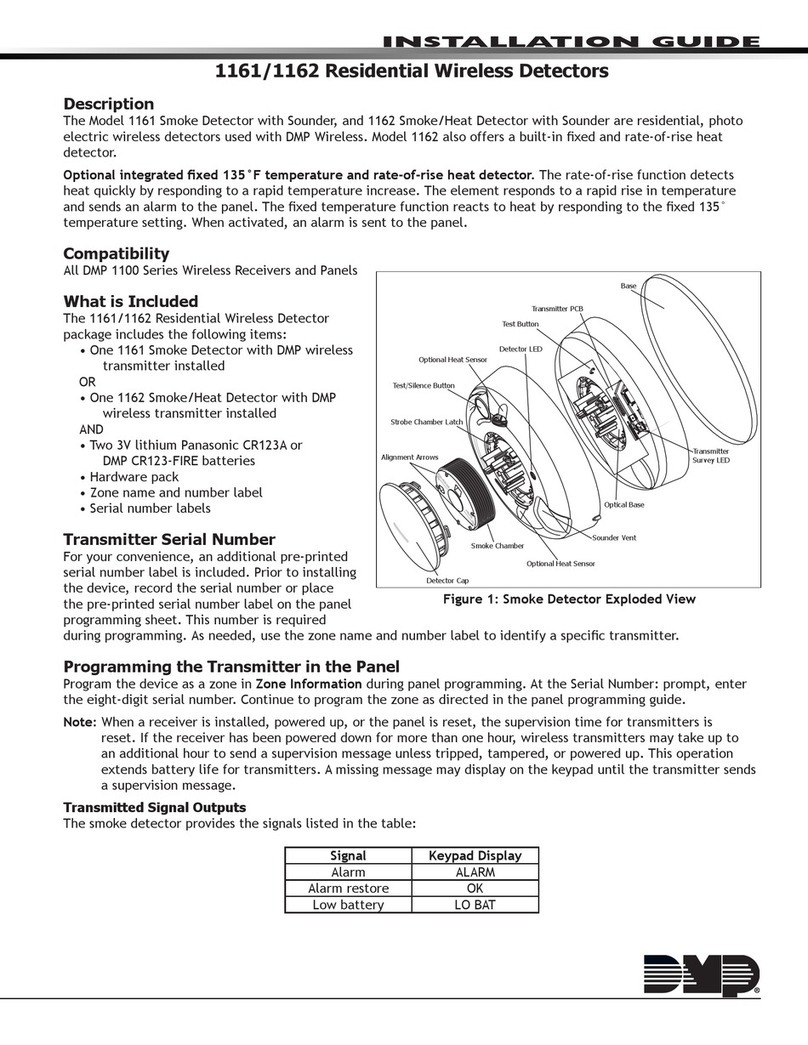

The smoke detector has an optical detector head.

It also has an LED with two functions:

• red light indicates a tripped detector

(detector, encapsulation)

• dirty detector is indicated with a green light

(detector) or yellow light (encapsulation)

The detectors must be under continuous observation and

must be cleaned at regular intervals to avoid false alarms.

The detector head is easy to change thanks to its bayonet

fastening to the base. For detection in ventilation ducts,

the detector head is mounted in an adaptor. One venturi

pipe is then installed between the adapter and the duct to

lead ventilation air into the detector head. In this way, the

requirements for good fire protection can be complied with

air speeds of 0.2 to 20 m/s. At lower air speeds, an auxi-

liary fan must be used. A metal reed/plastic strip is fitted

for visual indication of flow through a duct detector.

Installation and location

Detectors are sensitive instruments, so care should be

taken with their location. They should not be located close

to sources of interference. The distance to the source of

interference should be not less than 3 hydraulic diame-

ters upstream or 5 hydraulic diameters downstream from

the source of interference. These distances are difficult to

maintain, so 2 and 3 hydraulic diameters can be accepted

in exceptional cases.

Duct detector RCKD is delivered with a 0,6 m venturi pipe

that can easily be shortened. When the duct is wider than

0,6 m the venturi pipe should go through the whole duct in

accordance to our mounting instructions. This requires a

longer venturi pipe, RBVR.

RBMD installation shelf is used for circular ducts and for

intact insulation of duct.

For location outdoors, in cold attics etc, the duct detector

should be insulated. If the detector is concealed, light box

RBLD should be installed.

Accessories

Installation shelf for duct detector RBMD

Venturi pipe for duct detector RBVR

Light box RBLD

3BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Duct detector RCKD

12-0553_ENG / Sept. 2017 teamfront.se

Duct detector RCKD - 0

NOTE! 0,6 m venturi pipe included.

ACCESSORIES, Duct detector

Installation shelf RBMD

Venturi pipe RBVR - 2 - 0

Length

0,6 m = 1

1,5 m = 2

2,8 m = 3

Without auxiliary fan = 0

With auxiliary fan = 1

Light box RBLD

Specification

154

180

85

146

27 35

150

600

Dimensions and weight

Weight 1,1 kg

Wiring diagram without auxiliary fan

From control

unit/panel

From control

unit/panel

Termination

resistor

Termination

resistor

Wiring diagram with auxiliary fan

Note.

Light box RBLD, if installed, is connected as follows:

– RCKD = between base terminals 3 and 4

Single connection

Series connection

Technical data

System voltage

– optical 16-30V DC

– auxiliary fan 24V AC, 75 mA

Operation current 0,04 mA

Alarm current 40 mA

Service alarm current 10 mA

Ambient temperature -10 to +55°C

Permitted humidity 99% rF

Max. air speed 20 m/s

Service alarm Indicated by:

green LED (detector)

yellow LED (encapsulation)

Smoke gas alarm Indicated by:

red LED (detector, encapsulation)

Encapsulation class IP54

From control

unit/panel

From control

unit/panel

24V AC from

ventilation unit

24V AC from

ventilation unit

Auxiliary fan

Termination

resistor

Termination

resistor

Single connection

Series connection

4

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Fire damper BSKC6 EI60

Dimensions and weight

Actuator - damper sizes

Actuator BLF-T is supplied to damper sizes Ø100-315 mm.

Actuator BF-T is supplied to damper sizes Ø400-630 mm.

Electrical data (values in brackets refer to 230V)

Actuator type BF... BLF...

Sizing, max ...................... 10 VA (12.5 VA) 7 VA (7 VA)

Running time:

– motor opening, max ..... approx. 120 s 40-75 s

- spring return, max ......... approx. 20 s

Protection class ............... IP 54

Power supply .................. 24V~ ±20%, 50/60Hz

24V= ±10%

(220-240V~ , 50/60Hz)

Ambient temperature ....... -30° to +50°C

Safety temperature .......... -30° to +75°C

(24 hrs. guaranteed safety)

Tripping temperature

thermal sensor .................

72°C

End position contacts

- load ≤ 300 mW ..... min 1 mA/5V=, max 100 mA/250V~

After exceeding the above values it applies:

- load > 300 mW ..... min 100 mA, max 3 A/250~

Sound level when opening approx 45 dB(A)

Sound level when closing approx 62 dB(A)

Chart indicates in

the de-energized

state

Wiring

diagram

Actuator

Size Ød 100 125 160 200 250 315 400 500 630

A – – – – – 35 75 125 190

Weight, incl, actuator, kg 3,4 3,7 4,3 5,0 6,0 7,2 10,6 13,0 17,0

Tf1 Tf2 BAE72-S

S

Ö

N

L1

M

1

2

1

2

3

4

5

6

5°

80°

Thermal

sensor

257

100

Ød Ød

+105

A

max

90

max 200

max 55

5

EI60 Brand-/Brandgasspjäll BSKC6

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

EI60 Fire damper BSKC6

Size chart

Sound power level

LWt , dB

Air flow, l/s

10

30

20

40

50

100

200

Total pressure drop, Pa

10 20 30 40 50 100 200 300 500 1000 2000 3000 10.000

125 160 200 250 315Size 100 400 500

630

45 dB

50 dB

55 dB

60 dB

65 dB

70 dB

Correction of sound power level, LWok, in octave band

Lwok = Lw+ Kok

Sound data

Correction, Kok

Size

Ø mm

Centre Frequency Hz

63 125 250 500 1000 2000 4000 8000

100 -4 -6 -7 -12 -17 -24 -26 -33

125 -5 -5 -8 -14 -22 -25 -27 -35

160 -5 -4 -8 -13 -17 -20 -28 -34

200 -3 -6 -10 -14 -15 -19 -27 -40

250 -1 -11 -15 -20 -22 -23 -29 -37

315 -2 -8 -11 -12 -13 -19 -23 -29

400 -2 -8 -14 -12 -15 -22 -30 -41

500 -2 -8 -13 -13 -15 -21 -28 -36

630 0 -15 -23 -23 -28 -35 -41 -48

Tol. ± dB 2 3 4 4 6 7 9 9

6

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Options 1 and 2

1. Install and join the damper in the ventilation duct that

ends at the wall or floor face (after the lead-through).

2. The damper is secured flat and tight using fire stopping

sealant (Intumex AN) against the wall/floor structure

with the fastening lugs, which are opened out.

3. Sealing is carried out by caulking with mineral wool,

min 40 kg/m3.

4. Use brackets to fasten the duct to the wall.

Supporting construction (wall or floor)

in fire resistance class EI60.

Damper’s fire resistance class: EI60

(ve ho i <-> o) S.

EC certificate 0402-CPD-SC0900-13

Option 1 Option 2

5. If fire damper is not connected to the duct system, fit

non-combustible grilles designed for the damper on the

unconnected sides. The minimum distance between

the damper blade in the open position and the grille is

50 mm.

6. Install the thermal sensor with the sensor body in the air

flow without obstructing the movement of the damper

blade.

7. Install the duct system according to applicable require-

ments.

• Minimum distance between dampers must be 200 mm.

• Minimum distance to joist structure/wall must be 75 mm.

Installation instruction

Fire damper BSKC6 EI60

d+40

Duct Duct

Seal with fire

stopping sealant,

e.g. Intumex AN

(Possible protective grille,

see section 5)

Metal anchor 6x50 mm

Fastening lugs

Brackets

Min. thickness 95 mm

Concrete wall or drywall

panel insulated with mineral

wool ≥40kg/m3 or

equivalent fire class ≥EI60

Seal acc. to

section 3

d+40

Floor structure

in lightweight

concrete or

equivalent

fire class ≥EI60

Min. thickness

125 mm

Duct

Brackets

Fastening lugs

Protective

grille, see

section 5

Protective

grille, see

section 5

Plug and screw

M8x40 mm in concrete.

Duct

Seal with fire

stopping sealant,

e.g. Intumex AN

Seal acc. to

section 3

13-0184_ENG / Sept. 2017 teamfront.se

7BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

1. Install the damper in the duct.

2. Duct going through supporting construction, is fastened

using brackets. Seal according to applicable require-

ments, such as caulking with mineral wool, min 40 kg/

m3and fire stopping sealant.

3. If fire damper is not connected to the duct system, fit

non-combustible grilles designed for the damper on the

unconnected sides. The minimum distance between

the damper blade in the open position and the grille is

50 mm.

4. Install the thermal sensor with the sensor body in the air

flow without obstructing the movement of the damper

blade.

Installation in horizontal duct

.

Damper’s fire resistance class: EI60

(ve i <–> o) S.

EC certificate 0402-CPD-SC0900-13

5. Duct is fastened/supported according to applicable

requirements.

6. Insulate the duct according to applicable requirements

using instructions from the insulation supplier, min.

80 mm and 55 kg/m3. Note that insulation must cover

the damper.

• Minimum distance between dampers must be 200 mm.

• Minimum distance to joist structure/wall must be 75 mm.

• The damper spindle may be installed in any position.

d+40

Duct Duct

Seal acc. to

section 2 Support of duct,

see section 5

Seal with fire

stopping sealant,

e.g. Intumex AN

(Possible protective grille,

see section 3)

Insulation equivalent to

fire resistance class of the

supporting construction

Brackets

Max. 1000 mm

Installation instruction

EI60 Fire damper BSKC6

13-0184_ENG / Sept. 2017 teamfront.se

Table of contents

Popular Security Sensor manuals by other brands

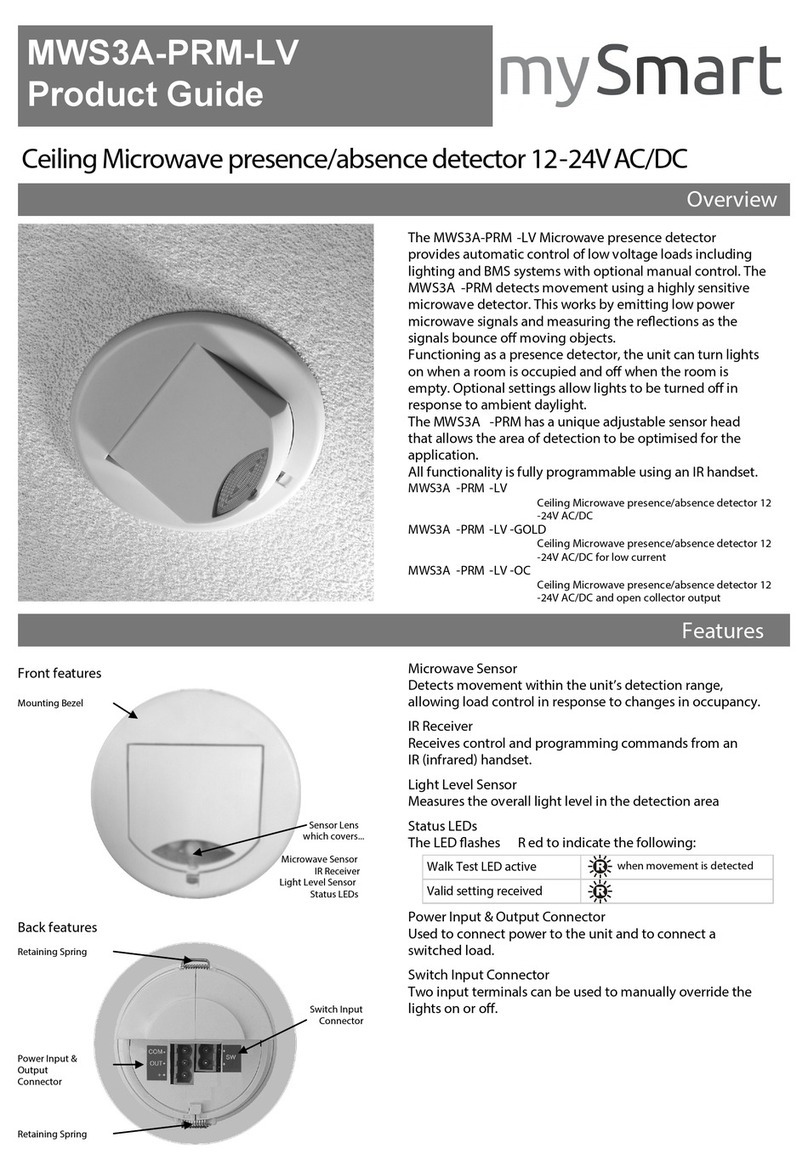

PCB Piezotronics

PCB Piezotronics 260M36 Installation and operating manual

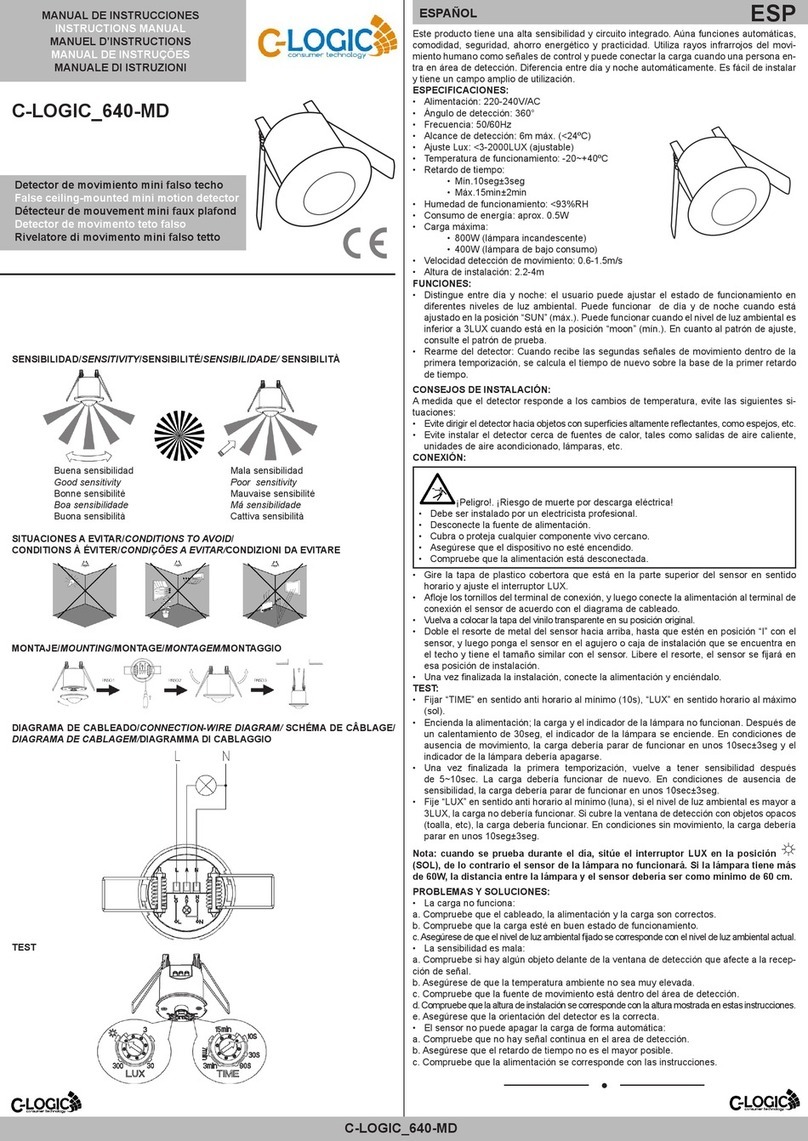

C-LOGIC

C-LOGIC 640-MD instruction manual

STEINEL

STEINEL IS 3360 COM1 Information manual

Mustang Survival

Mustang Survival ELITE INFLATABLE PFD MD5153 owner's manual

Global Fire Equipment

Global Fire Equipment GFE-H Installation

Dräger

Dräger Oxyboks K 25 Instructions for use