Bieler+Lang ExDetector HC 150 User manual

Gas Detection and Warning Systems

Operating and

Installation Instructions

ExDetector HC 150

ExDetector HC 150-K

Page 2 Technical Status: 11/2010

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Prerequisites for safe operation of the system:

●Appropriate transport and handling

●Appropriate installation and commissioning by suitably qualified personnel

(e.g. a qualified electrician)

●Observance of the data sheet, the operating instructions and relevant

safety regulations, e.g.:

-Explosion Protection Regulation (ExVo)

-Explosion Protection Rules (BGR 104)

-BGV B 6 Gases

●Use only in areas where there is a potenial explosion hazard and an

oxygen concentration of not more than 20.9 vol. %

Important Instructions

●Avoid external influences such as waves of water, oil etc., and exposure to

causes of mechanical damage.

●Observe the air flow situation! Always place the sensor head in an air flow

between a potential release or collection point and a possible ignition

source.

●Consider the density of the gas! For gases with a lower density than air, for

example methane, the detector must be located above a possible leakage

point, or at the highest point at which the gas can collect. When monitoring

gases and vapours that have a higher density than air, the detector must,

accordingly, be positioned at the lowest point, or near a potential leakage

point.

●Install the detector in a location where there is low vibration, and where the

temperature is as stable as possible.

●Ensure that there is adequate space for maintenance of the detector.

Installation

Follow the prescribed specifications for cables and connections. It is important

that the cable does not pass close to a source of electromagnetic interference.

Compliance with the limits specified in standards relevant for the CE-symbol is

only assured with proper use and electromagnetically-compatible installation

of the system.

Installation Notes

74 mm

74 mm

ExDetector HC 150

10 cm Wartungsfreiheit

Technical Status: 11/2010 Page 3

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Connections

●Max. lead length: 1000 m

●Max. lead resistance: 12 ohm per conductor

Important Instructions

Never open the ExDetector housing in the presence of an explosive

atmosphere.

Terminal Assignment

●Max. outside diameter of cable: 10 mm

●Three-core cable with screen

●Terminal assignment

24VDC

4-20 mA

GND

0,4-2V

Br

N

VBr

4

5

6

1

2

3

KL 1

KL 2

KL 3

KL 4

KL 5

KL 6

power supply +24VDC SELV/PELV

output 4 ... 20 mA

GND

Sensor

Sensor

Sensor

Please note (when used without a Bieler + Lang evaluator):

the power supply at KL 1 must be within the safe limits and have a

100 mA/T series fuse.

Page 4 Technical Status: 11/2010

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Connections

Potential Equalisation The detector housing must be connected to the equipotential bonding of

the explosion hazard zone.

In addition, valid national installation regulations must be observed. The

following regulations were valid in Germany at the time of going to press:

●ElexV Regulations covering electrical installations in areas where there is

an explosion hazard

●DIN VDE 0165 / 2.91 Installation of electrical apparatus in areas where

there is an explosion hazard

●Ex-RL Rules for avoiding dangers from a potentially explosive atmosphere

with a collection of examples - Explosion Protection Rules

Example: Connection to GMC8022

Screening The screen is to be connected to the detector housing by means of the

cable gland. Connect the screen as shown in the diagram.

●The screen conductor must be connected to the equipotential bonding of

the area where there is an explosion hazard.

Commissioning ●Switch on the evaluation unit (power supply).

●After 30 minutes warm-up time, check operation of the detector / evaluator

combination with test gas.

Evaluation

instrument

Safe area Hazardous area

Voltage equalisation point

ExDetector

HC 150

KL 1+24VDC KL 2

4...20mA KL 3

GND

Detector-

elektronic KL 1 +24VDC

KL 2 4...20mA

KL 3 GND

GMC

8022

Zone 2 safe area

Technical Status: 11/2010 Page 5

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Adjustment Important note!

The relevant regulations for work in areas where there is an explosion

hazard must be observed without fail.

The following accessories and equipment are required:

●Voltmeter

●Test gas set consisting of:

- 1 x Minican of test gas (e.g. 40% LEL)

- 1 x Minican of synthetic air

- Pressure regulator unit with regulating valve and flow meter.

- Test gas cap (see Accessories)

- Measurement leads (see Accessories)

Adjustment

●Remove the cover from the housing.

Important: before opening make sure that an explosive atmosphere is not

present.

●Fit test-gas cap to the sensor.

●The flow rate of the two gases should be 10 to 15 l/h (second graduation).

Setting the bridge voltage

●Apply zero-response gas (synthetic air) if the environment contains the gas

to be detected.

●Connect the voltmeter at the measurement socket „Br“.

●Wait for the voltage reading to stabilise.

●Adjust the „Br“ potentiometer until the voltmeter reads 0 mV.

Setting the base current to 4 mA

●Connect the voltmeter at the „0.4-2V“ socket.

●Wait for the „0.4-2V“ voltage signal to stabilise.

●Adjust the „N“ potentiometer until the voltmeter reading is 400 mV (4 mA).

Setting the 4-20 mA output current

●Apply test gas of a known concentration C1.

●Wait for the „0.4-2V“ voltage signal to stabilise.

●Adjust the „V“ potentiometer until the voltage corresponds to the value US

U = 0,4V +1,6V

s C

Cmax

1

C = testgas concentration in % LEL

1

max

C = Measuring range (100%LEL)

U = Signal voltage

s

24VDC

4-20 mA

GND

0,4-2V

Br

N

VBr

4

5

6

1

2

3

Measuring the sensitivity (bridge voltage)

●Connect the voltmeter at the measurement socket „Br“.

●Note the voltage reading UBr in mV.

●Remove the test gas.

●Write a test report.

Testing sensor sensitivity E:

●Calculate E using the following formula:

UBR = bridge voltage

C1= known test gas concentration

●If sensor sensitivity E < 0.5, the sensor must be replaced.

●If sensor sensitivity E is below 50% of the E value from initial adjustment

(works calibration), the sensor also must be replaced.

E = UBR (mV)

C1(%UEG)

Page 6 Technical Status: 11/2010

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

0,4-2V

Br

N

VBr

4

5

6

Replacing the Sensor Please note:

Sensors may only be replaced by specialist personnel authorised to do so by

Bieler+Lang. Do not open the housing when the power supply is switched on!

locknut

seal ring

sensor

Procedure:

●Switch off the power supply to the detector

●Remove the housing cover

●Disconnect the leads from terminals 4, 5 and 6

●Undo the locknut

●Unscrew the sensor

●Screw the replacement sensor in.

Make sure the sealing ring is correctly seated.

●Screw the locknut on (serrations towards the housing wall)

●Connect the leads according to their markings

●Replace the housing cover

●Switch on the power supply

●Calibrate the detector

Spare Parts ●Replacement sensor for ExDetector HC 150 D1

●Replacement sensor for ExDetector HC 150-K D1

Technical Status: 11/2010 Page 7

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Regular maintenance ensures the safety and longterm reliability of your gas

warning installation. For this reason it is absolutely essential that the system is

checked at regular intervals. We therefore strongly recommend that you

conclude an installation-specific maintenance contract with us.

Maintenance Instructions

At least once a year the condition (correct operation) of a gas warning

installation must be checked by a qualified person (§8 and §53; BGV 61 UVV

Gases). Before commissioning and at appropriate intervals the gas warning

installation is to be checked by an expert (§56; BGV 61, UVV Gases).

In addition the requirements of BG-Bulletin T023 (BGI 518), Gas warning

devices for explosion protection - selection and operation, must be observed.

Further relevant standards:

●DIN EN 60079-14 Electrical apparatus for explosive gas atmospheres -

Electrical installations, design selection and erection

●DIN EN 60079-17 Electrical apparatus for explosive gas atmospheres -

Electrical installations, inspection and maintenance.

●DIN EN 60079-29-2 Explosive atmospheres - Part 29-2:

Gas detectors - Selection, installation, use and maintenance of detectors

for flammable gases and oxygen

Accessories ●Test gas set

●Calibration gases

●Measurement lead

For all deliveries the general delivery conditions for products and services of

the electrical industry apply.

There is a guarantee on all parts for two years from the delivery date or from

the date of commissioning for the first time by our customer service or by our

representative, with the exception of of parts subject to wear (e.g. sensors).

In particular, please note that in the event of improper operation the right to

notify material defects is forfeited. The time limit for notifying claims for material

defects is 12 months.

Guarantee

Page 8 Technical Status: 11/2010

Gas Detector

Operating and Installation Instructions

ExDetector HC 150 / HC 150-K

Bieler + Lang GmbH

Gas Detection and Warning Systems

PO Box 1129, D-77842 Achern

Oberkirchstr. 19-21, D-77855 Achern

Telephone +49 (0) 78 41 / 69 37 - 0

Telefax +49 (0) 78 41 / 69 37 - 99

E-mail [email protected]

Internet www.bieler-lang.de We reserve the right to make technical changes!

This manual suits for next models

1

Table of contents

Popular Gas Detector manuals by other brands

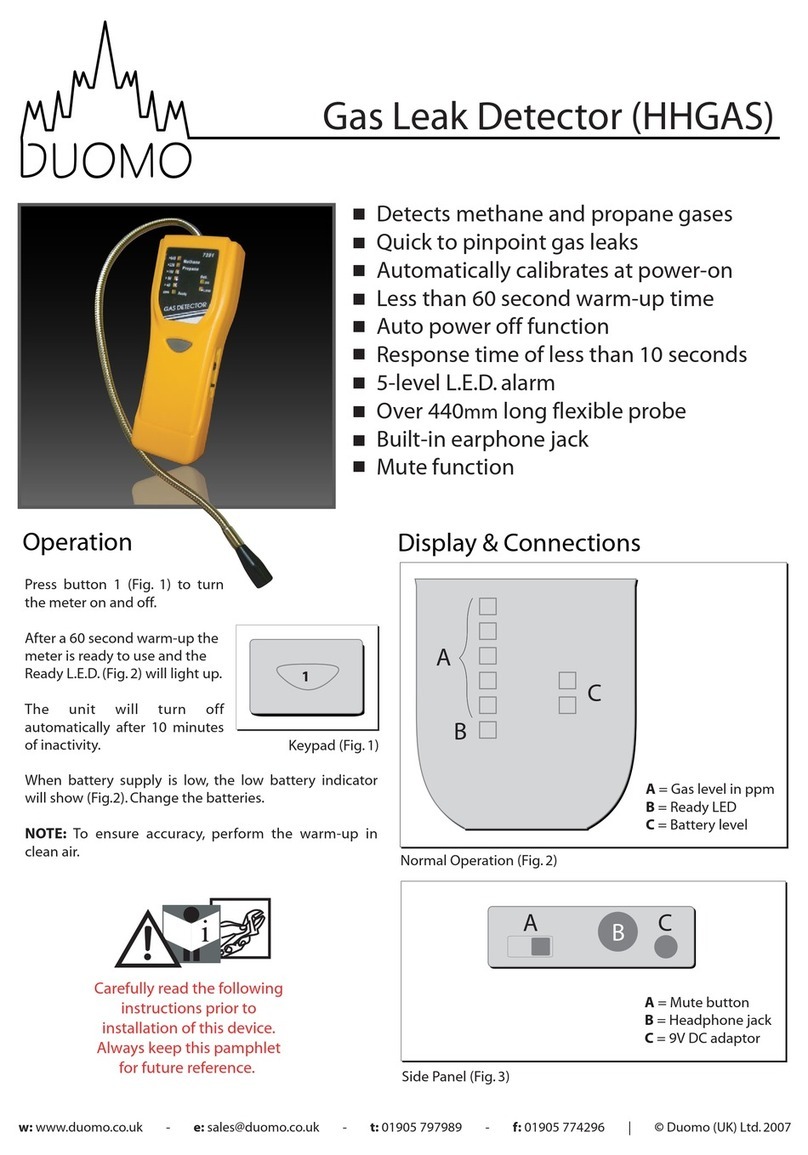

Duomo

Duomo HHGAS quick start guide

S&S Northern

S&S Northern Merlin 1000BH Installation, operating and maintenance

Honeywell

Honeywell BW Technologies GasAlertMicroClip Firmware update procedure

Riken Keiki

Riken Keiki SD-1RI operating manual

Honeywell

Honeywell Touchpoint 4 quick start guide

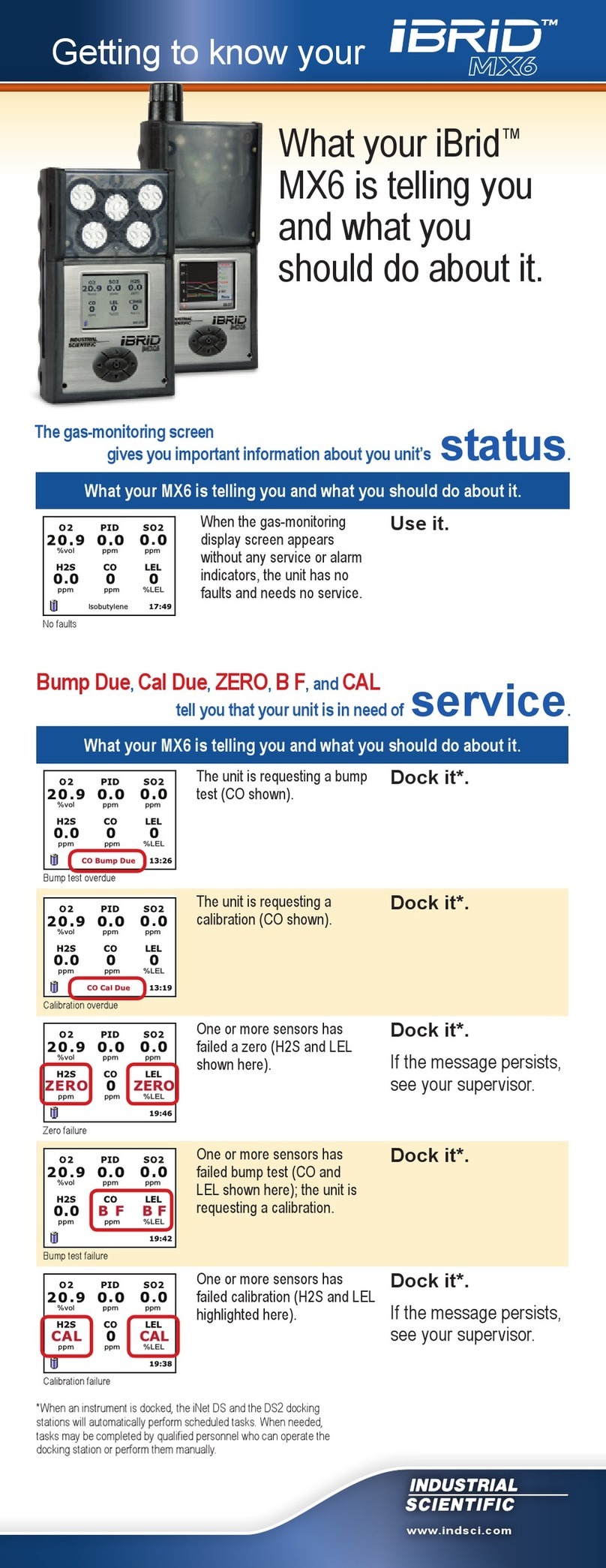

IBRID

IBRID MX6 Getting to know