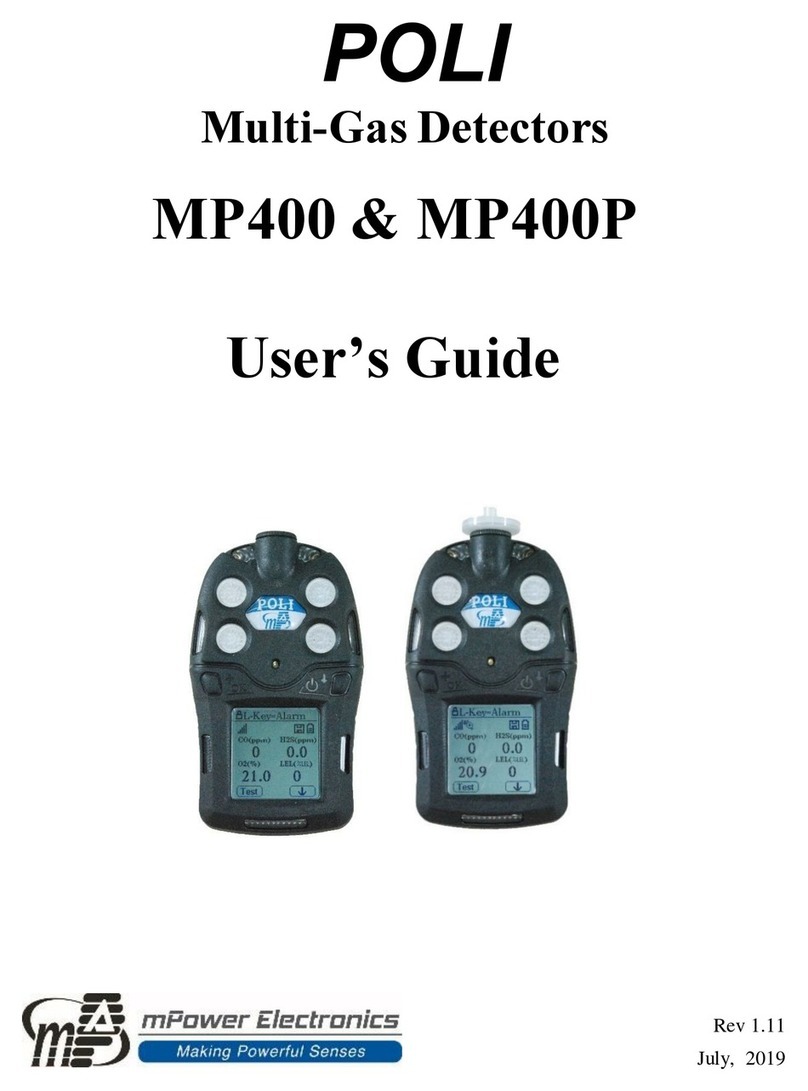

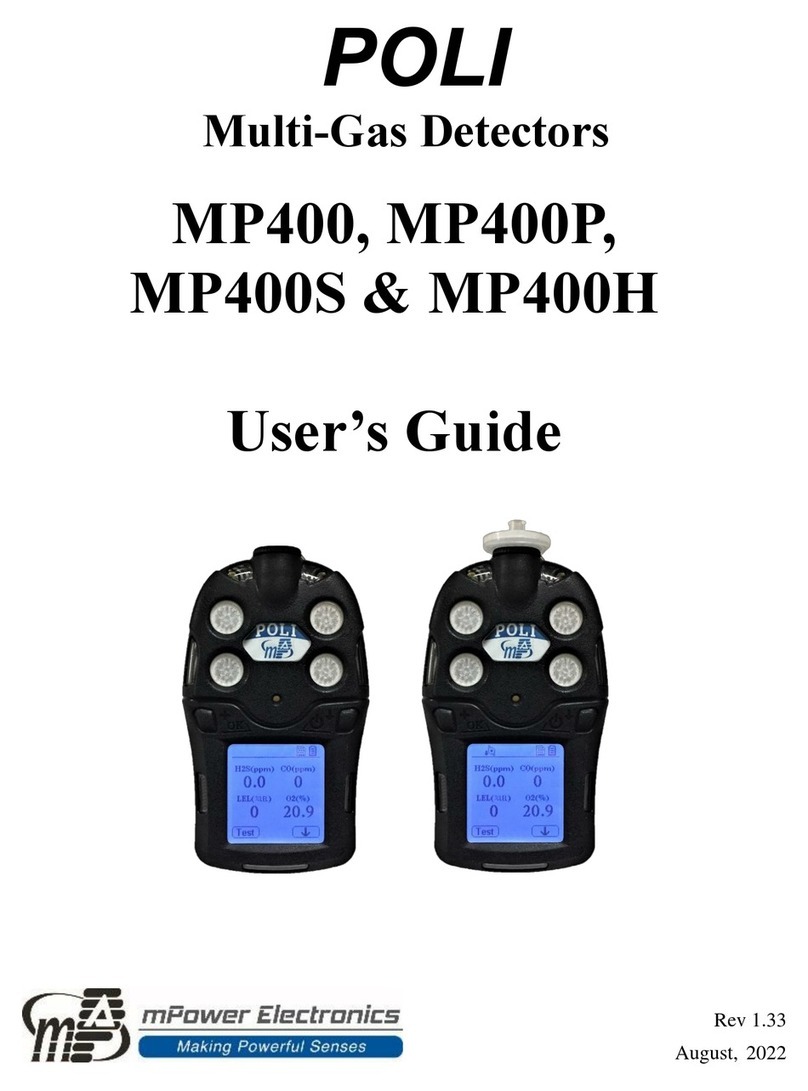

POLI User’s Guide

1

Contents

1. General Information........................................................................................................ 5

1.1 Main Features............................................................................................................ 5

2. User Interface.................................................................................................................. 6

2.1 Displays and Keys..................................................................................................... 6

2.2 Active Sensor Displays............................................................................................. 8

2.3 User Menu................................................................................................................. 9

3. Battery........................................................................................................................... 10

3.1 Replacing A Battery................................................................................................ 10

3.2 Battery Status.......................................................................................................... 10

4. Turning On or Off......................................................................................................... 11

4.1 Turning On.............................................................................................................. 11

4.2 Turning Off............................................................................................................. 11

4.3 Testing Alarm Indicators ........................................................................................ 12

4.4 Pump Status ............................................................................................................ 12

4.5 Calibration Status.................................................................................................... 12

4.6 Bump Status............................................................................................................ 13

5. Config Mode................................................................................................................. 14

5.1 Entering Config Mode ............................................................................................ 14

5.2 Menus and Sub-menus............................................................................................ 15

6. Calibration and Test...................................................................................................... 24

6.1 Manual Alarm Test................................................................................................. 24

6.2 Bump Testing and Calibration................................................................................ 24

7. Data Communication.................................................................................................... 28

8. Maintenance.................................................................................................................. 29

8.1 Replacing Filters..................................................................................................... 29

8.2 Removing/Cleaning/Replacing Sensor Modules.................................................... 29

8.3 Replacing Pumps .................................................................................................... 30

9. Alarm Overview............................................................................................................ 31

9.1 Alarm Signals.......................................................................................................... 31

9.2 Testing Alarms........................................................................................................ 31