BikeMaster 15-2134 User manual

InstructionDisclaimer

Dennis Kirk provides instructions to help our customers better understand how to install the

products we sell. The instructions are exact copies of what the manufacturer includes with the

product being sold.

That means the quality and accuracy of the instructions is solely dependent on what the

manufacturer produces. We do our best to make the text legible and the pictures viewable.

However, the end result depends largely on the quality of instructions the manufacturer

provides.

Therefore, you will find that some instructions are not of the highest quality. Sometimes text is

hard to read and pictures are not easy to see. At times you will find the overall look of the

instructions to be less than professional. However, we feel it is better to provide what we have

rather than provide nothing at all.

To the best of our knowledge the instructions and application information contained in the

instructions is accurate. However, Dennis Kirk assumes no liability related to any errors that

may be contained in the copy of the manufacturer’s instructions we provide. Buyers are solely

responsible to insure that product use is consistent with their application.

800-969-7501 so we can further assist you regarding additional product information or any other

business related questions.

Thank you for doing business with Dennis Kirk.

•

BikelVlaster

®

TROUBLESHOOTING

GUIDE

QUAUTY

•

PERFORMANCE

•

VAlUE

Problem

Probable

Cause

Solution

Wash

pump

will

not

run

1.Power

cord

unplugged

2.810wn

fuse

3.Pump

is

broken

1.Make

sure

power

cord

is

connected.

2.

Check

circuit

breaker

or

outlet

for

blown

fuse.

3.Call

Customer

Service.

1.Solvent

level

low.

1.Remove

strainer

bas-

2.

Clogged

pump

/

spout.

kept

and

check

the

sol-

vent

level.

Transfer

Wash

pump

runs

but

solvent

does

not

flow

3.Pump

is

broken

.

additional

solvent

to

the

wash

basin

.

2.Check

for

clogs

in

the

wash

pump

and/or

spout.

3.

Call

Customer

Service.

Vacuum

pump

sounds

too

loud

1.Debris

caught

in

pump

.

2.Pump

is

broken.

1.

Look

for

debris

under-

neath

the

pump.

debris

and

rebalance

.

2.Call

Customer

Service.

Too

much

solvent

in

wash

basin

1.

Holding

tank

has

over-

flowed

into

wash

basin

.

2.Pump

is

broken

.

1.

Remove

all

excess

fluid

and

run

a

distillation

cycle

to

move

cleaning

agent

back

into

the

holding

tank

.

2.Call

Customer

Service.

PORTABLE PARTS WASHER

15-2134

HO

SE

WITH

BRUSH

BASIN

GENERAL

SAFETY

RULES

FOR

ALL

ELECTRIC

POWER

TOOLS

CUSTOMER

SERVICE:

877-848-1320

IA

WARNING

I

READ

AND

UNDERSTAND

ALL

INSTRUCTIONS.

Fa

i

lure

to

follow

all

instructions

listed

below

may

result

in

electric

BikelVlaster

®

shock

,

fire

and

/

or

serious

personal

injury.

QUAUTY

•

PERFORMANCE

•

VALUE

www.bikemaster.com

SAVE

THESE

INSTRUCTIONS

FOR

FUTURE

REFERENCE

RECOGNIZE

SAFETY

SYMBOLS,

WORDS

AND

LABELS

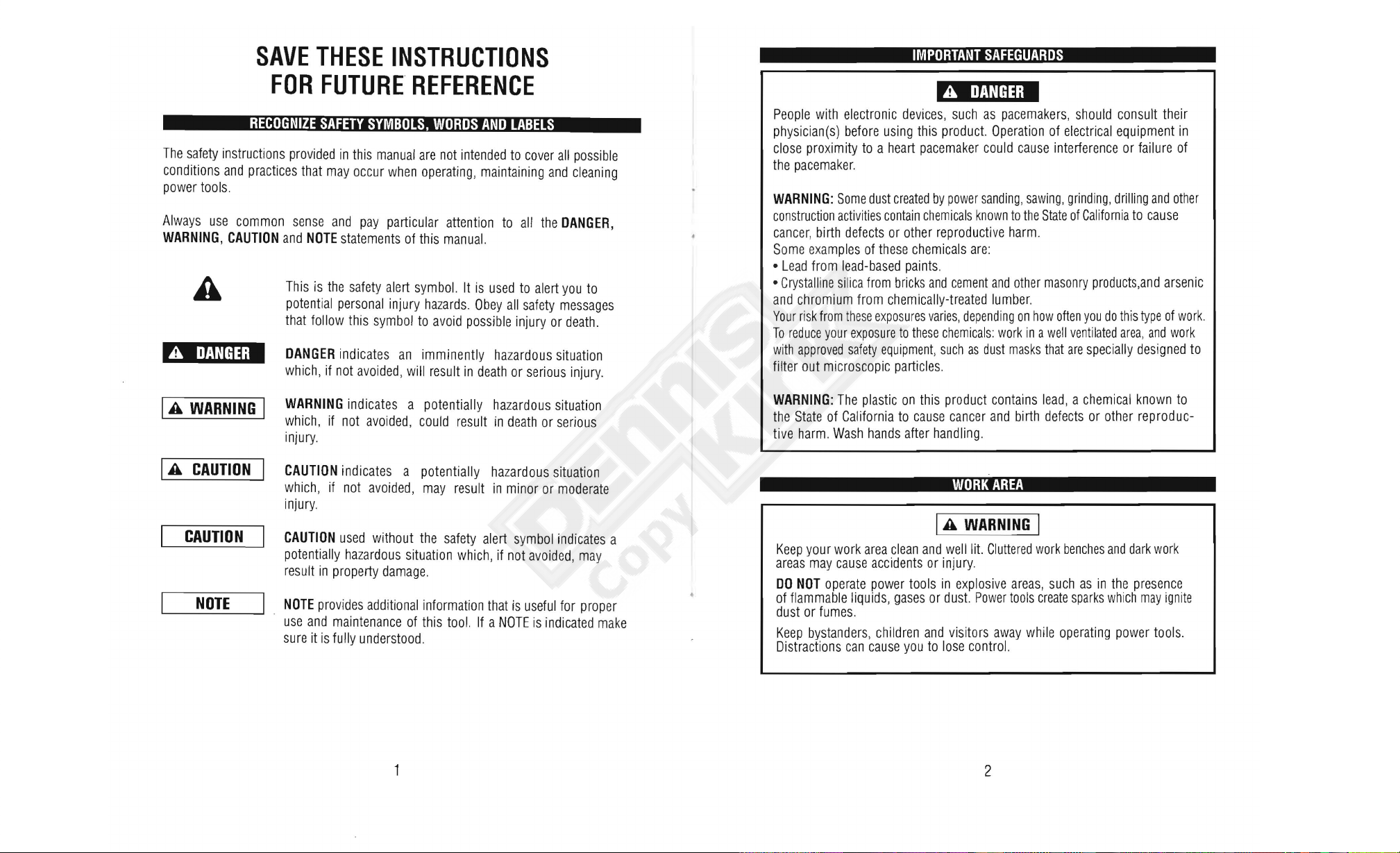

The

safety

instructions

provided

in

this

manual

are

not

intended

to

cover

all

possible

conditions

and

practices

that

may

occur

when

operating

,

maintaining

and

cleaning

power

tools.

Always

use

common

sense

and

pay

particular

attention

to

all

the

DANGER,

WARNING,

CAUTION

and

NOTE

statements

of

this

manual.

A

This

is

the

safety

alert

symbol.

It

is

used

to

alert

you

to

potential

personal

injury

hazards.

Obey

all

safety

messages

that

follow

this

symbol

to

avoid

possible

injury

or

death.

A

DANGER

DANGER

indicates

an

imminently

hazardous

situation

which,

if

not

avoided

,

will

result

in

death

or

serious

injury

.

WARNING

indicates

a

potentially

hazardous

situation

IA

WARNING

I

which,

if

not

avoided,

could

result

in

death

or

serious

injury

.

IA

CAUTION

CAUTION

indicates

a

potentially

hazardous

situation

which,

if

not

avoided,

may

result

in

minor

or

moderate

injury.

CAUTION

CAUTION

used

without

the

safety

alert

symbol

indicates

a

potentially

hazardous

situation

which,

if

not

avoided

,

may

result

in

property

damage.

NOTE

NOTE

provides

additional

information

that

is

useful

for

proper

use

and

maintenance

of

this

tool.

If

a

NOTE

is

indicated

make

sure

it

is

fully

understood

.

IMPORTANT

SAFEGUARDS

A

DANGER

People

with

electronic

devices,

such

as

pacemakers,

should

consult

their

physician(s)

before

using

this

product.

Operation

of

electrical

equipment

in

close

proximity

to

a

heart

pacemaker

could

cause

interference

or

failure

of

the

pacemaker

.

WARNING:

Some

dust

created

by

power

sanding,

sawing

,

grinding,

drilling

and

other

construction

activities

contain

chemicals

known

to

the

State

of

California

to

cause

cancer,

birth

defects

or

other

reproductive

harm.

Some

ex

amples

of

these

chemicals

are:

•

Lead

from

lead-based

paints

.

•

Crystalline

silica

from

bricks

and

cement

and

other

masonry

products,and

arsenic

and

chromium

from

chemically-treated

lumber.

Your

risk

from

these

ex

posures

varies

,

depending

on

how

often

you

do

this

type

of

work.

To

reduce

your

exposure

to

these

chemicals:

work

in

a

well

ventilated

area

,

and

work

with

approved

safety

equipment

,

such

as

dust

masks

that

are

specially

designed

to

filter

out

microscopic

particles.

WARNING:

The

plastic

on

this

product

contains

lead

, a

chemical

known

to

the

State

of

California

to

cause

cancer

and

birth

defects

or

other

reproduc-

tive

harm.

Wash

hands

after

handling

.

WORK

AREA

IA

WARNING

I

Keep

your

work

area

clean

and

well

lit.

Cluttered

work

benches

and

dark

work

areas

may

cause

accidents

or

injury.

DO

NOT

operate

power

tools

in

explosive

areas,

such

as

in

the

presence

of

flammable

liquids,

gases

or

dust.

Power

tools

create

sparks

which

may

ignite

dust

or

fumes.

Keep

bystanders

,

children

and

visitors

away

while

operating

power

tools.

Distractions

can

cause

you

to

lose

control.

2

ELECTRICAL

SAFETY

IMPORTANT

SAFETY

RULES

FOR

PARTS

WASHERS

IA

WARNING

I

Grounded

tools

must

be

plugged

into

an

outlet

properly

installed

and

grounded

in

accordance

wi

th

all

codes

and

ordinances.

Never

remove

the

grounding

prong

or

modify

the

plug

in

any

way

.

Do

not

use

any

adaptor

plugs.

Check

with

a

qualified

electrician

if

you

are

in

doubt

as

to

whether

the

outlet

is

properly

grounded.

If

the

tools

electrically

malfunction

or

breakdown

,

grounding

provides

a

low

resistance

path

to

carr

y

electricity

away

from

the

u

se

r.

Avoid

bod

y

contact

with

grounded

s

urfaces

such

as

pipes,

radiat

ors,

range

s

and

refrigerators.

There

is

an

increased

ri

sk

of

electric

s

hock

if

your

body

is

grounded

.

Do

not

expose

power

tools

to

rain

or

wet

conditions.

Water

entering

a

power

tool

will

increase

the

risk

of

electric

shock.

Do

not

abuse

the

cord.

Never

use

the

cord

to

carry

the

tool

or

pull

the

plug

from

an

outlet.

Keep

the

cord

away

from

heat,

oil,

s

harp

edges,

or

moving

parts

.

Replace

damaged

cords

immediately

.

Damaged

cords

increase

the

risk

of

electric

shock.

Always

unplug

tool

from

the

electrical

receptacle

before

making

adjustments,

changing

parts,

or

performing

any

maintenance

.

IA

WARNING

J

NEVER

use

gasoline

,

toluene

,

thinner

or

any

other

volatile

solvent

t

ype

cleaner

with

this

parts

washer.

These

types

01

solvents

will

dam

age

the

pump

and

the

part

s

was

her

it

sell

.

Use

water-soluble

cleaning

agents

only

.

ALWAYS

wear

salety

goggles,

gloves

and

protective

clothing

while

operating

this

was

her

.

II

cleaning

agent

co

mes

in

contact

with

the

skin

,

follow

manufacturer's

removal

instructions

immediately

DO

NOT

allow

cleaning

agent

to

remain

on

the

ski

n.

ALWAYS

clean

up

work

area

after

u

se.

Spilled

cleaning

agents

should

be

wiped

up

as

soon

as

possible

to

avoid

as

lipping

hazard

.

NEVER

leave

the

parts

washer

unattended.

When

washer

is

not

in

use

,

close

the

cover

and

disconnect

the

cord

from

the

power

supply.

Alwa

ys

unplug

power

cord

from

the

electrical

receptacle

before

making

adjustments

,

changing

parts,

or

performing

any

maintenance.

DO

NOT

touch

hot

parts.

Unit

will

heat

up

during

use.

ALWAYS

clean

filter

after

use.

Clean

sludge

out

of

water

tank

periodically

to

prevent

clogging.

Be

careful

not

to

damage

parts

PERSONAL

SAFETY

washer

when

cleaning

parts

with

s

harp

points

or

edges.

IA

WARNING

I

DO

NOT

unplug

power

cord

with

wet

hands

.

Keep

cleaning

agent

temperature

between

32°and

Stay

a

lert,

watch

what

you

are

doing

,

and

u

se

common

sense

when

operating

a

power

tool.

Do

not

use

tool

while

tired

or

under

the

influence

of

drugs,

alcohol

or

medication.

A

moment

of

inattention

while

operating

power

tools

may

re

s

ult

in

se

rious

personal

injury.

Dress

properly

.

Do

not

wear

loose

clothing

or

jewel

ry.

Contain

long

hair.

Keep

your

hair

,

clothing

,

and

gloves

away

from

moving

part

s.

Loose

clothing

,

jewelry

or

long

hair

can

be

caught

in

moving

parts.

Never

leave

tool

running

unattended.

Unplug

when

not

attended.

Do

not

overreach.

Keep

proper

footing

and

balance

at

all

times.

Proper

footing

and

balance

enable

better

control

of

the

tool

in

une

xpe

cted

situations.

Use

safety

equipment.

Always

wear

eye

protection.

Everyday

eyeglasses

only

have

impact

resi

s

tant

lenses,

they

are

NOT

safety

glas

ses

.

Du

st

mask,

non-skid

salety

shoes,

hard

hat,

or

hearing

protection

must

be

u

sed

for

appropriate

conditions.

Use

parts

washer

only

in

well-ventilated

areas.

Cleaning

agents

emit

fume

s

which

can

be

dangerous

if

inhaled

in

concentrated

do

ses.

Unit

heats

while

in

use

. 00

NOT

touch

hot

parts.

3

104

of

(OO

to

40°C)

.

FIRST

AID

Cleaning

Agent

in

Eye-

Flush

with

large

quantities

of

wate

rlor

at

least

15

minutes

and

call

a

phYSician.

Cleaning

Agent

on

Skin-

Remove

contaminated

clothing

and

wash

area

01

contact

thoroughly

with

warm

soapy

water.

Wash

contaminated

clothing

belore

reuse.

Throwawa

y

contaminated

shoes

.

Inhalation

01

Fumes-

Get

to

Ire

sh

air

right

away

.

II

victim

is

having

breathing

difficulties,

give

oxygen

and

call

a

physiCian

immediately.

Cleaning

Agent

is

Swallowed

-

DO

NOT

induce

vomiting

Call

a

physician

immediat

el

y.

4

SOLVENT

HANDLING

IA

WARNING

I

Adding

additional

chemicals

to

the

cleaning

agent

(gasoline,

fuel

oil,kerosene,

etc.)

,

may

increase

the

danger

of

a

hazardous

situation.

NEVER

add

anything

to

the

cleaning

agent.

USE

WATER-SOLUBLE

SOLVENTS

ONLY!

Promptly

clean

up

any

spills.

If

parts

washer

is

leaking,

repair

the

leak

as

soon

as

it

is

safe

to

do

so.

DO

NOT

operate

the

parts

washer

if it

is

leaking.

Practice

proper

hygiene

when

handling

solvent.

Always

wash

hands

before

eating,

drinking

or

smoking.

Do

not

eat,

drink

or

smoke

in

the

work

area.

DO

NOT

operate

this

equipment

in

an

area

without

ventilation.

Solvent

fumes

can

be

dangerous

in

concentrated

doses.

NEVER

spray

aerosols

or

other

combustible

gasses

around

the

parts

washer.

Sparking

parts

inside

the

parts

washer

can

cause

combustible

fumes

to

ignite.

DO

NOT

smoke

near

cleaning

agent.

Combustible

residue

from

the

cleaning

agent

may

remain

on

the

cleaned

parts

or

in

the

washer

itself.

To

reduce

residue

,

replace

the

cleaning

agent

and

clean

the

parts

washer

frequently.

DO

NOT

attempt

to

clean

absorbent

materials

like

paper,

cloth

,

wood

or

leather.

DO

NOT

put

hot

parts

into

the

parts

washer.

NEVER

open

the

distillation

drain

knob

while

it

feels

hot.

Wait

until

the

parts

washer

has

completed

its

cycle

and

cooled

down

before

removing

any

oil

waste.

Keep

lid

closed

when

not

in

use

.

Avoid

splashing

or

spilling

cleaning

agent

while

cleaning

.

Use

only

water

soluble

solvents

and

mineral

spirits

with

a fI

ash

point

greater

than

140°.

CAUTION:

Avoid

solvents

with

unstable

reactives

The

appliance

is

not

to

be

used

by

children

or

person

with

reduced

physical

sensory

or

mental

capabilities

or

lack

of

experience

and

knowledge,

unless

they

have

been

given

supervision

or

instruction.

Children

should

be

supervised

to

ensure

that

they

do

not

play

with

the

appliance.

REPAIR,

DISPOSAL

AND

HANDLING

IA

WARNING

I

If

the

supply

cord

is

damaged,

it

must

be

replaced

by

the

manufacturer

,

its

service

agent

or

similarly

qualified

persons

in

order

to

avoid

a

hazard.

DO

NOT

dispose

of

electrical

appliances

as

unsorted

municipal

waste,

use

separate

collection

facilities

Contact

your

local

government

for

information

regarding

the

collection

systems

available

If

electrical

appliances

are

disposed

of

in

landfills

or

dumps

,

hazardous

substances

can

leak

into

the

groundwater

and

get

into

the

food

chain,

damaging

your

health

and

well-being.

When

replacing

old

appliances

with

new

one

,

the

retailer

is

legally

obligated

to

take

back

your

old

appliance

for

disposal

at

least

for

free

of

charge

.

FOR

INDOOR

USE

ONLY.

5

INSTALLATION

BEFORE

USAGE

1

Unpack

the

unit

from

carton

and

inspect

for

damage

.

2.

Place

washer

on

a

stable

surface

,

such

as

a

work

bench

or

table

.

3.Connect

pump

cord

to

standard

power

outlet

.

DETERGENT

FILLING

PROCEDURE

1.Make

sure

the

drain

cap

on

the

side

of

the

unit

is

tightly

closed.

2.Remove

the

filler

cap

and

fill

with

recommended

detergent

(Water

Soluble

Cleaning

Agent),

the

tank

volume

is

approximately

5

gallons/20

Liters.

IA

WARNING

I

WARNING:

Do

not

use

Flammable

solvents

(gasoline,

toluene,

thinner

and

etc.)

OPERATING

INSTRUCTION

1.

Open

lid

and

secure

in

open

position.

2.

Make

sure

the

unit

contains

at

least

15

liters/approximately

4

gallons

of

cleaning

solvent.

IA

CAUTION

I

Never

allow

the

cleaning

solvent

level

to

.

fall

below

the

level

of

the

pumpinlet,

thiS

can

cause

the

pump

to

run

dry

causing

pump

damage

and

overheating

I

3.

The

detergent

can

be

reused

many

times,

provided

it

is

still

functioning

well.

There

is

no

need

to

change

solvent

for

every

job.

4.

Turn

on

the

unit

using

the

switch

on

the

side

of

the

unit.

5.

Wash

parts

in

basin

using

brush

to

assist

in

removing

heavier

deposits.

6.

Switch

unit

off,

and

allow

parts

to

drain

completely

before

removing

from

basin.

7.

When

finished,

close

lid

and

unplug

the

unit.

8.

Check

the

basin

filter

in

the

unit

periodically

,

especially

if

you

have

just

complete

a

cleaning

with

heavy

deposits.

Failure

to

do

so

can

lead

to

excess

detergent

in

basin

.

DETERGENT

REPLACEMENT

PROCEDURE

1.

Make

sure

that

you

have

a

container

with

sufficient

volume

to

accept

ALL

the

old

detergent

(AT

LEAST

5

GALLONS!)

2.

Place

a

funnel

of

sufficient

size

in

the

5

gallon

container,

and

place

the

unit

in

a

position

so

that

the

old

detergent

will

go

into

the

funnel

when

released.

3.

Open

the

drain

cap

on

the

side

of

the

unit.

IA

CAUTION

I

The

detergent

can

spray

out

as

the

drain

cap

is

being

removed,

make

sure

you

are

prepared

for

this,

AND

MAKE

SURE

YOU

ARE

WEARING

SAFETY

GLASSESI

4.

As

the

detergent

flow

slows,

tip

the

unit

in

the

direction

of

the

funnel,

to

insure

that

as

much

of

the

old

detergent

as

possible

is

drained

from

the

unit.

5.

Once

all

the

old

detergent

has

been

removed,

replace

and

secure

the

drain

cap

firmly.

6.

Take

this

opportunity

to

clean

the

basin

area,

the

filter

basket,

and

the

unit

overall.

This

will

help

avoid

contamination

of

the

fresh

detergent.

7.

Refill

the

unit

with

fresh

detergent

as

described

above

in

Detergent

Filling

Procedure.

8.

ALL

OLD

DETERGENT

MUST

BE

TAKEN

TO

AN

OFFICIAL

HAZARDOUS

LIQUIDS

DISPOSAL

FACILITY!

These

are

available

locally,

and

some

are

provided

by

the

city

in

which

you

live

,

or

you

can

check

with

your

local

Gasoline

Station,

Car

Mechanic

Shop,

Dealership

,

Machine

Shop,

Specialized

Disposal

Company,

or

City

Government.

DO

NOT

DISPOSE

OF

DETERGENT

IN

AN

IRRESPONSIBLE

OR

DANGEROUS

MANNER!

To

do

so

is

against

the

law!

6

Table of contents