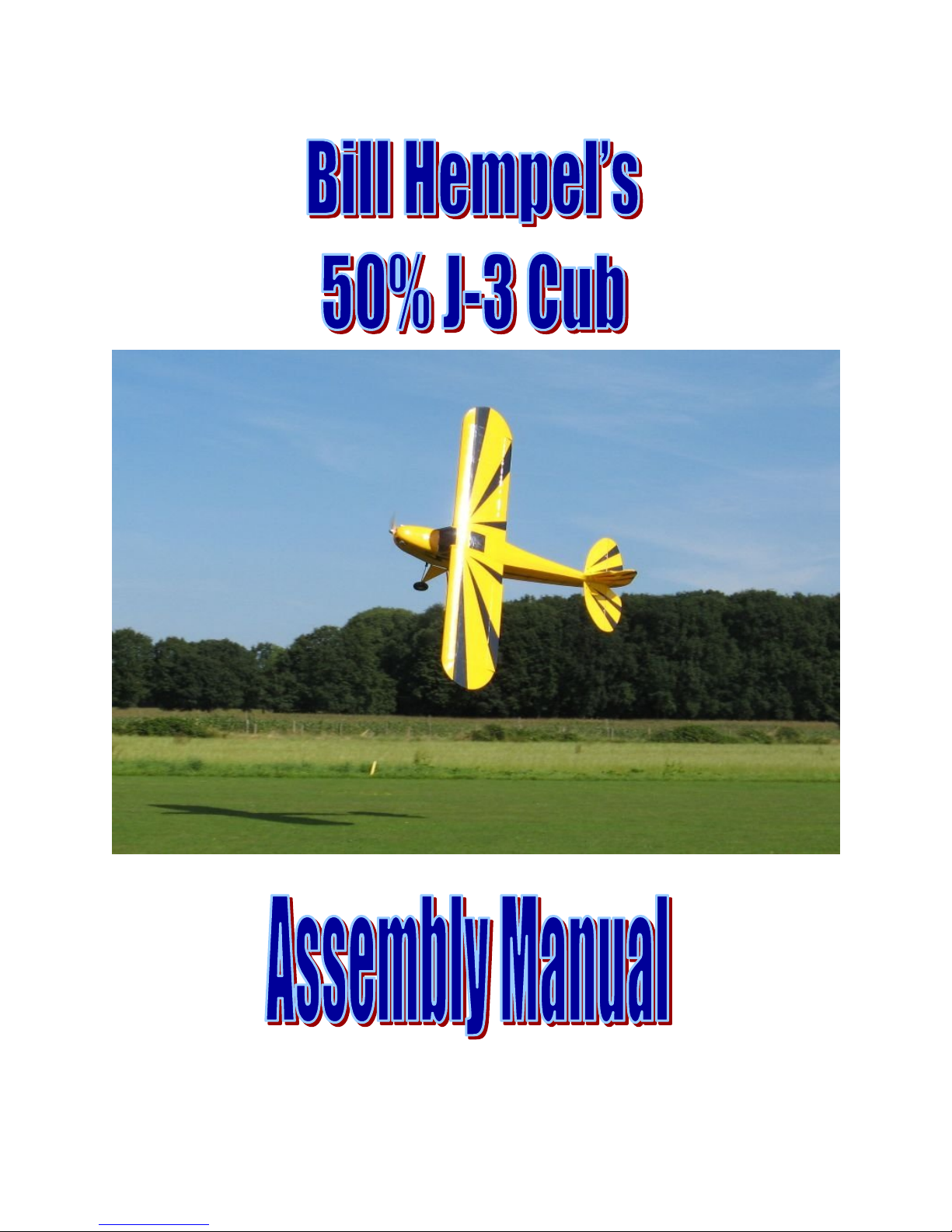

Bill Hempel 50% J-3 Cub User manual

1

2

Hello and thank you for purchasing the 50% Clipped Wing Cub. This

will be an amazing aircraft for you to show off and fly. I have made a great

effort into making this plane the best model you will ever build and fly. I

have provided you with the highest quality kit and performance possible. I

wish you great success in the assembly and flying of your new Bill

Hempel’s ‘Team Edge’ 50% Cub. The biggest ARF in the WORLD!

WARNING

An R/C aircraft is not a toy! If misused, it can cause serious bodily harm

and property damage. Fly only in open areas, and AMA approved flying

sites. Follow all instructions included with your plane, radio, and engine.

Bill Hempel’s ‘Team Edge’ airplanes guarantees this kit to be free from

defects in both material and workmanship at the date of purchase. This

warranty does not cover any component parts damaged by use or

modification. In no case shall Bill Hempel’s liability exceed the original cost

of the purchased kit. Further, Bill Hempel reserves the right to change or

modify this warrantee without notice.

In that Bill Hempel has no control over the final assembly or materials

used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled

product. By the act of using the user-assembled product, the user accepts

all resulting liability.

I, Bill Hempel as the kit manufacturer, have provided you with a top quality,

thoroughly tested ARF kit and instructions, but ultimately the quality and

flying ability of your finished model depends on how you build it; therefore,

I can not in any way guarantee the performance of your completed model,

and no representations are expressed or implied as to the performance or

safety of your completed model.

3

INTRODUCTION

The 50% ARF Clipped Wing Cub is a highly aerobatic model. It is capable

of both precision and 3D type maneuvers. Early in 2008, this airplane flew

in a Basic class IMAC event where the pilot placed 5th out of 15 contest-

ants! This airplane builds easily, quickly, and precisely, due to its state-of-

the-art CAD design, LASER cut technology, and outstanding quality. I

hope you enjoy building and flying your new 50% Clipped Wing Cub. You

will draw a crowd everywhere you fly! Congratulations!

Great care has been taken in both the design and manufacturing of the

50% Clipped Wing Cub to allow for the strongest and lightest construction

possible. Only the highest quality materials from the covering to the paint,

and wood have be used in the construction of this model.

The 50% Clipped Wing Cub has been individually hand built, covered,

painted by trained and experienced craftsman with over 20 years of

manufacturing experience. Using CAD design, laser cut technology and jig

built fixtures, tongue and groove tabs ensures the straightest and strong-

est accuracy in all stages of production and assembly.

The 50% Cub has been designed around the use of any twin cylinder

150-210cc engine. The prototype Cub flew on a 3W-157 with great suc-

cess and had almost 1:1 power. You will have to decide on the type of

flying that you want to do when deciding on an engine. If you are looking

to perform Torque Rolls then the larger 200cc+ motor will be needed.

Another consideration is that this airplanes comes out tail heavy and a

larger, heavier motor will help with the Center of Gravity. The only issue

you may experience is that the motor box has been drilled for the 150-157

motors. Modifications will be needed to mount the larger motors. The

aluminum stand-offs provided may not be the correct size needed with the

larger motors either.

IMPORTANT Please read through this manual carefully, before starting

the assembly of your new 50% Clipped Wing Cub. Inventory all parts and

hardware for any imperfections or damage. Please notify

4

INTENDED USE

This airplane should not be regarded as a toy. This is an aerobatic air-

plane and is recommended for pilots with sufficient aerobatic and R/C

flying skills. This airplane is not intended to be a trainer for beginning

pilots. This airplane must be registered in the AMA’s Experimental

Category for aircraft weighing over 55 pounds. Please visit ;

www.modelaircraft.org/documents.aspx for further information.

READ! WARRANTY READ!

It is important to notify www.billhempel.com of any damage or problems

with the model within 30 days of receipt to be covered under warranty. If

you wish to return this aircraft for any reason a 15% restocking fee will be

charges to the customer. The customer will assume full responsibility of

shipping cost and damage that may occur during the return of the air-

plane. All prior shipping cost prior to the return will not be refunded. Parts

will be exchanged or replaced once the original item is returned at the

owners' expense. If you have any problems, please contact

www.billhempel.com.

Bill Hempel can not insure the skill of the modeler and can not influence

the builder during the construction or the use of this aircraft, therefore, will

not be accountable for any property, property damage, bodily injury or

death caused by this aircraft.

Bill Hempel / Team Edge cannot insure the skill of the modeler and can not

influence the builder during the construction or use of this aircraft, and

therefore;

The Purchaser/operator accepts all responsibility of

any and all structural or mechanical failures.

5

Re-shrinking the covering

1. Open your kit slowly and take care not to damage any parts of the kit. Remove all parts from

their plastic protective covers for inspection. Before doing any assembly or installation it is very impor-

tant to re-shrink or retighten the already applied covering. Due to the shipping process, heat and humid-

ity changes from different climates, the covering may become lose and wrinkle in the sun. If you take

the time to re-tighten the covering, you will be rewarded with a lasting beautifully covered model.

2. Using your covering iron with a soft sock, gently apply pressure and rub in the covering. If any bub-

bles occur, your iron may be to hot. Reduce heat and work slowly. You should be able to just see the

wood grain under the covering when proper adhesion has occurred.

IMPORTANT

Go over any and all seams and color overlaps with your iron to assure good adhesion

of the covering to the wood. This is

especially important at the Leading edges of the wings and stabs and all overlapping

material.

3. After all seems have been ironed down you can then use your heat gun with extreme caution. Take

care not to apply too much heat to one area for long periods of time. This may cause the trim colors to

over shrink and pull away leaving unsightly gaps on the color lines. The trim stripes are especially vul-

nerable to over shrinking.

4. Your model is covered with Ultracote covering. In case of repairs, the colors are:

Cub Yellow #

Black #

If you have the Hazel Sig’s scheme Cub, the colors are:

Blue #

White #870

Tightening and re-shrinking the covering is now

complete.

6

ITEMS NEEDED TO COMPLETE

Hardware:

150 –210 cc twin cylinder motor

Mufflers for engine or header and canister for above engine

Engine mounting bolts

Propeller

Cub spinner (recommended)

Fuel tank and accessories (50 ounce tank recommended)

Throttle Servo (standard size)

Choke servo (optional)

Aileron servos (minimum x 4 @ 300 ounce torque each)

Rudder servo (minimum x 2 @ 300 ounce torque each)

Elevator servo (recommend x 4 servos @ 300 ounce torque for each elevator half)

Receiver battery (recommend minimum 2 batteries)

Powerbox or power distribution board (recommended)

Receiver/Ignition switches

HD 22ga. Extensions for servos/batteries

Receiver (6-channel minimum recommended. 2 receivers recommended with the

use of a power distribution board)

Dubro accessory package (optional)

TOOLS:

Allen wrenches both US and Metric

Dremel cutting wheel and accessories

Electric drill and bits

Razor saw

Hobby Heat Gun

Hobby iron

7

TOOLS (cont):

Modeling knife

Needle nose pliers

Paper towels

Pens, pencils, ruler

Screw drivers

Scissors

Adhesives:

Canopy glue

Blue Lock-tite

Epoxy and mixing cups

CA and accelerator

Rubbing alcohol

This completes the required items needed for the completion of this airplane.

8

Wing Assembly

Servos

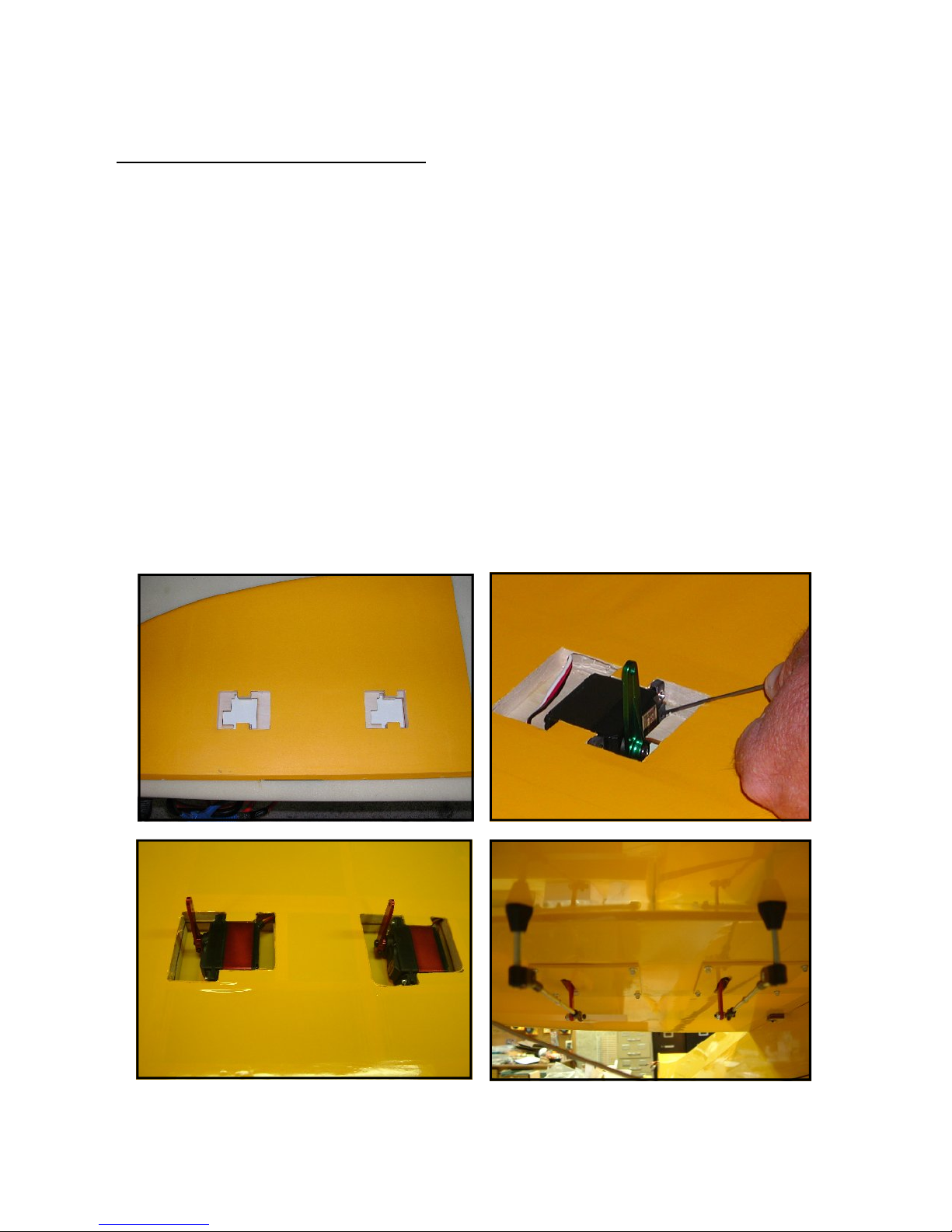

1. The ailerons have been pre-hinged and glued to the wing panels and are ready for flight. No other

steps are necessary for hinging on the wings.

2. Place the wing upside down on a clean floor or table. Use caution to verify nothing scratches the top

side covering or poke holes in the film while working on the wings. Use a blanket or large sleeping

foam to protect the wing and covering while working.

3. You will need to decide if you are using 2 or 3 servos per aileron. If you are using 3 servos per

aileron, locate and find the servo holes in the wing. Using care, cut the covering away from the

servo holes. If using 2 servos per aileron locate the inner and outer servo hole and remove the cover-

ing. A electronic soldering iron works great for cutting precise hole through the covering.

4. Place your servos in the perspective locations and measure the length of servo leads you will need

for extensions. When connecting servo extensions I use just a smear of canopy glue on connector to

help keep connectors from separating.

5. Starting with the most outer servo hole, run extension through the wing and mount servo using stan-

dard methods. If using the Futaba 9152 servos, you will first have to enlarge all servo holes in the

wing prior to installation.

6. Mount the middle servo and servo lead if running 3 servos per aileron. Install the most inner servo

next if only using 2 servos per aileron. I recommend using 3 servos per aileron for the best positive

control and least likely event of having blow-back from such a such large aileron.

7. Install all aileron servos and leads on both wing panels.

9

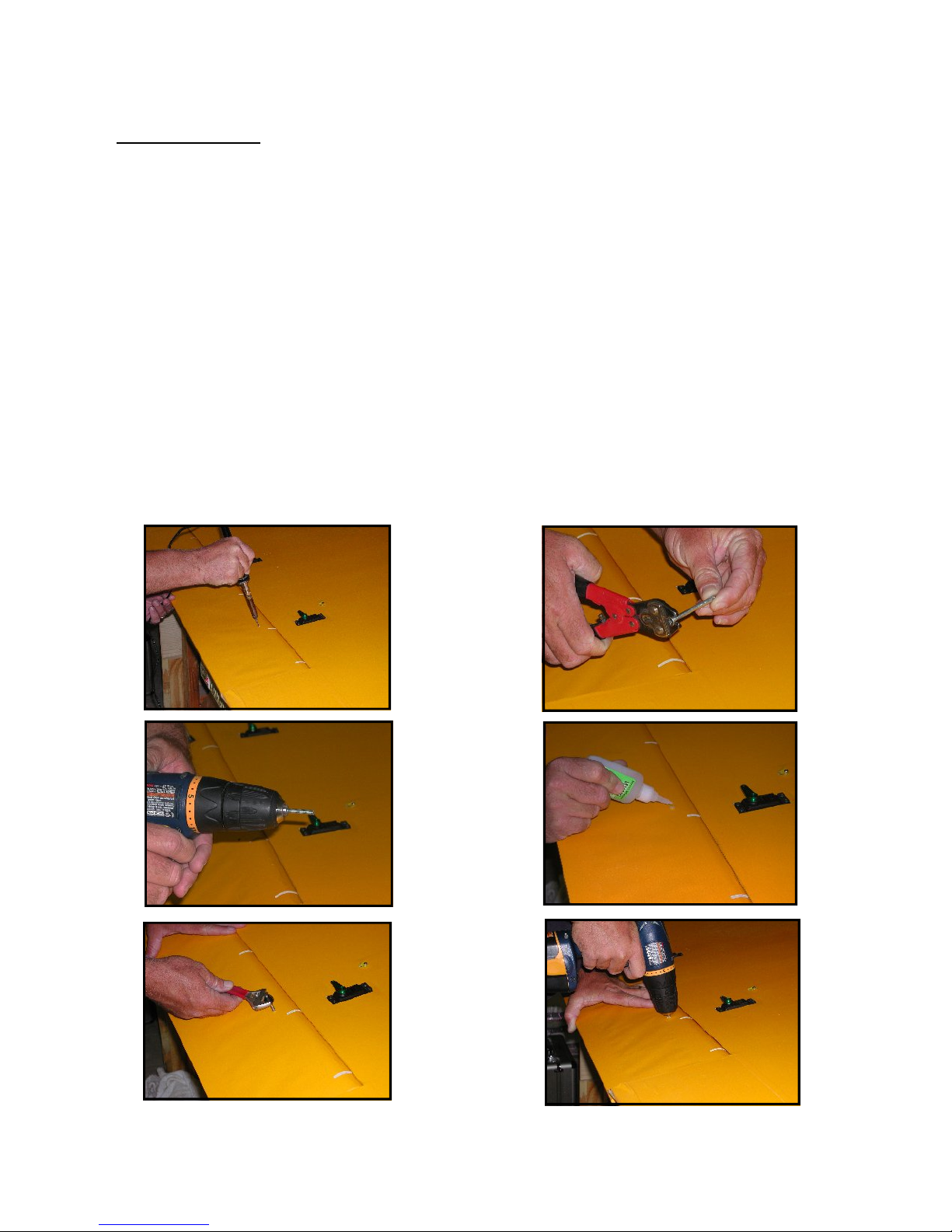

Control Arms

1. I recommend using Nelson Hobby or Hanger-9 10/32” control arms in all control surfaces on the

50% Cub.

2. Locate the 1/2” diameter harden wooden dowels in the ailerons. These will be located just behind

each aileron servo on each aileron. Using a hot soldering iron burn a quick hole in the covering to

gain access for inserting the 10/32” control arm. Do not go through to the top side of the aileron.

3. Using thin CA, put a drop in each hole to “harden” the wooden dowels. After the glue has dried,

drill and tap the hole for a 10/32” thread. Do not go through to the top side. Measure the depth of the

hole first. The threaded control arm only needs to screw into a depth of approximately 1” to 1 1/4”

to have sufficient strength.

4. Using a drill, insert the 10/32” control arm into the drill. Measure the 10/32” threaded arm and mark

it to 1” to 1/14” length. Insert the control arm into the hole and screw in place. Once the control arm

is in place remove the drill and verify your work. If you are satisfied re-attach the drill and take the

control arm back out. When ready, put a couple of drops of CA+ into the hole and one on the base of

the control arm and re-screw the arm in place.

10

Control Arms(cont)

5. Remove the drill and proceed to perform the same tasks to the remaining control arms. Note: You

will need to remove the screw head of the 10/32” control arm to use the method described for this

installation. Let the control arms (glue) dry before proceeding.

6. After all control arms are glued in place, insert the black nylon base blocks to all control arms. Use

caution when apply these base blocks and make sure you do not rip the covering as you tighten these

down. There will be a small gap underneath these blocks as the control arms are not parallel to the

aileron control surface, this is normal. Do not over tighten these blocks.

7. Locate the swivel links for the control arms. Using a drill and 10/32” tap, re-cut new 10/32” threads

in all swivels using a 10/32” tap. This will allow the swivel links to move/pivot on the control arms

while the servos move the control surface. This is very important to the smooth operation of the con-

trols.

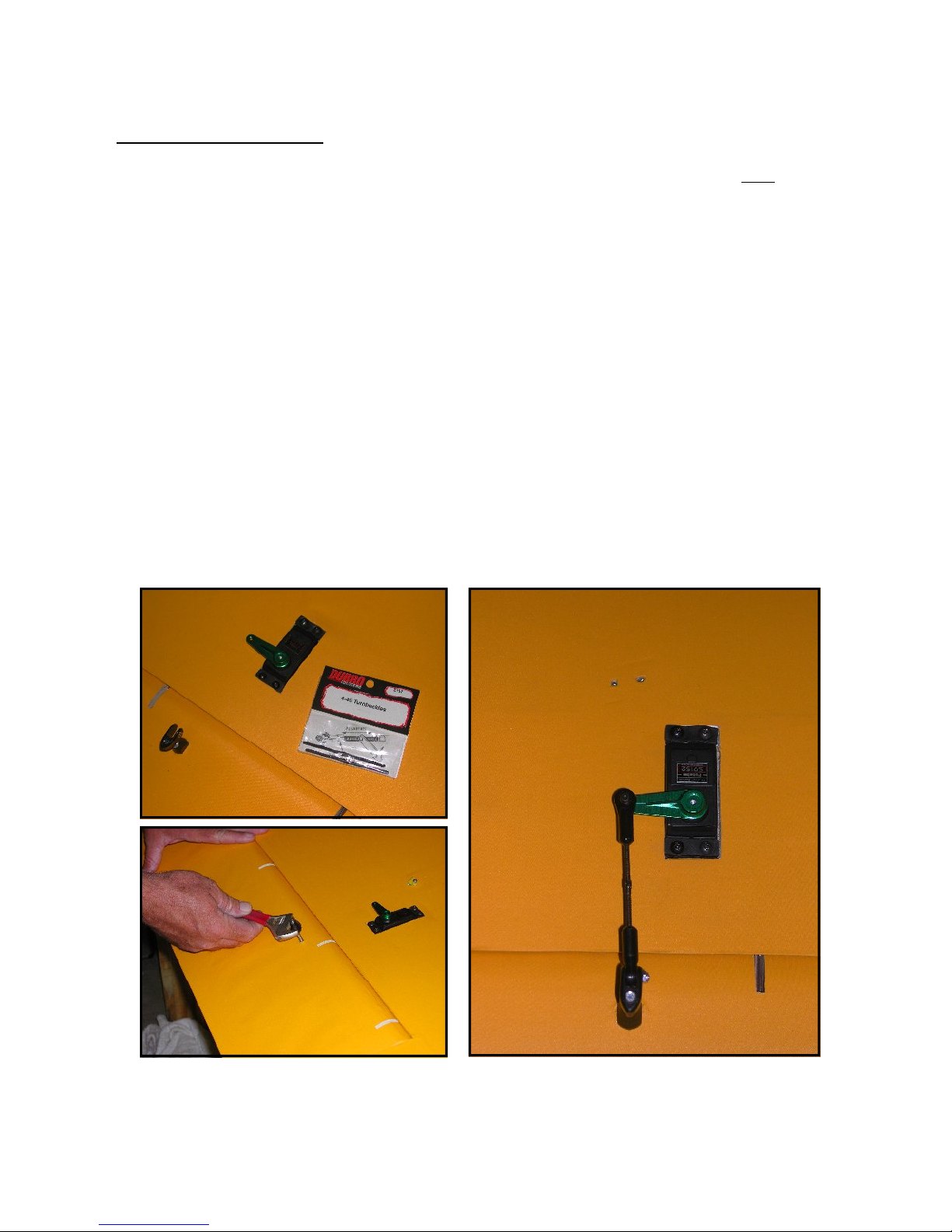

8. Once all control arm are installed the next step is to make the 4/40 pushrods to connect the servos to

the ailerons. I use Du-bro’s 4/40 threaded turnbuckles. Insert all control arms to the proper length.

This should complete the control arms and pushrod installation. Remember to go through and pro-

gram all servos for proper geometry prior to connecting the servo arms to the control surface.

11

Stab and Elevator Assembly

1. The horizontal stabs uses conventional hinging and must be inserted and glued prior to flight. Locate

the Robart-type hinges and trial fit into each hole of the elevator and stab. Use a hot soldering iron

again to burn/clean each hole, this makes the gluing process easier as there is not any excess mate-

rial to get in the way.

2. With all the hinges laid out on a paper towel, put a small drop of oil/grease on the pin to prevent

glue from binding the hinge when inserted and glued.

3. Glue all hinges in the stab/elevator using hinge glue, epoxy or your preferred gluing method.

4. Locate the servo location in the stabs. Cut out for each servo using a razor blade or the hot soldering

iron. I recommend using 2 elevator servos per elevator half for redundancy and safety.

5. Carefully thread your servo connector leads through the channels provided and install each servo

starting with the most outer servo first.

12

Stab and Elevator Assembly (cont)

6. Install the 10/32” control arms in each elevator half using the same methods as used for the ailerons.

It is important that each 10/32” control arm go through the elevator to nearly the top surface of the

elevator. Going completely through the control surface is not necessary if you properly install these

arms and get a good glue job on the control arms. Measure the thickness of each hole and make sure

to install the control arms to 90-95% of the thickness of the elevator. Use enough glue to secure in

place after threading. It is important to get a 100% bond here!

7. Install the black control blocks to the base of the 10/32” control arms, secure in place with a drop of

CA prior to securing in place. These blocks should fit completely flat on the bottom of the control

surface. Remember not to over tighten these as it could tear the covering.

8. Insert the swivel links and remember to re-tap the threads in the link to prior to installation for a

smooth non-binding control surface movement.

9. Measure and cut the Du-bro’s 4/40 turnbuckles to connect the control surface to the servo arm. I

Make sure to use aluminum servo arms! Do not use servo arms bigger than 1.5” as the servo resolu-

tion with be reduced and servo power to the control surface will get weaker. Do not use plastic or

similar type servo arms as these will flex and possible loss of control could result.

10. Perform all your servo programming for servo center position and end points prior to servo arm in-

stallation to prevent binding and stripping of servo gears.

11. To mount stabilizer, insert both aluminum stab tubes and slide stabs in place. Locate and insert (2)

bolts from the top side down on each side of the stab. Secure stab with flying wires. NEVER fly the

airplane without the flying wires connected.

13

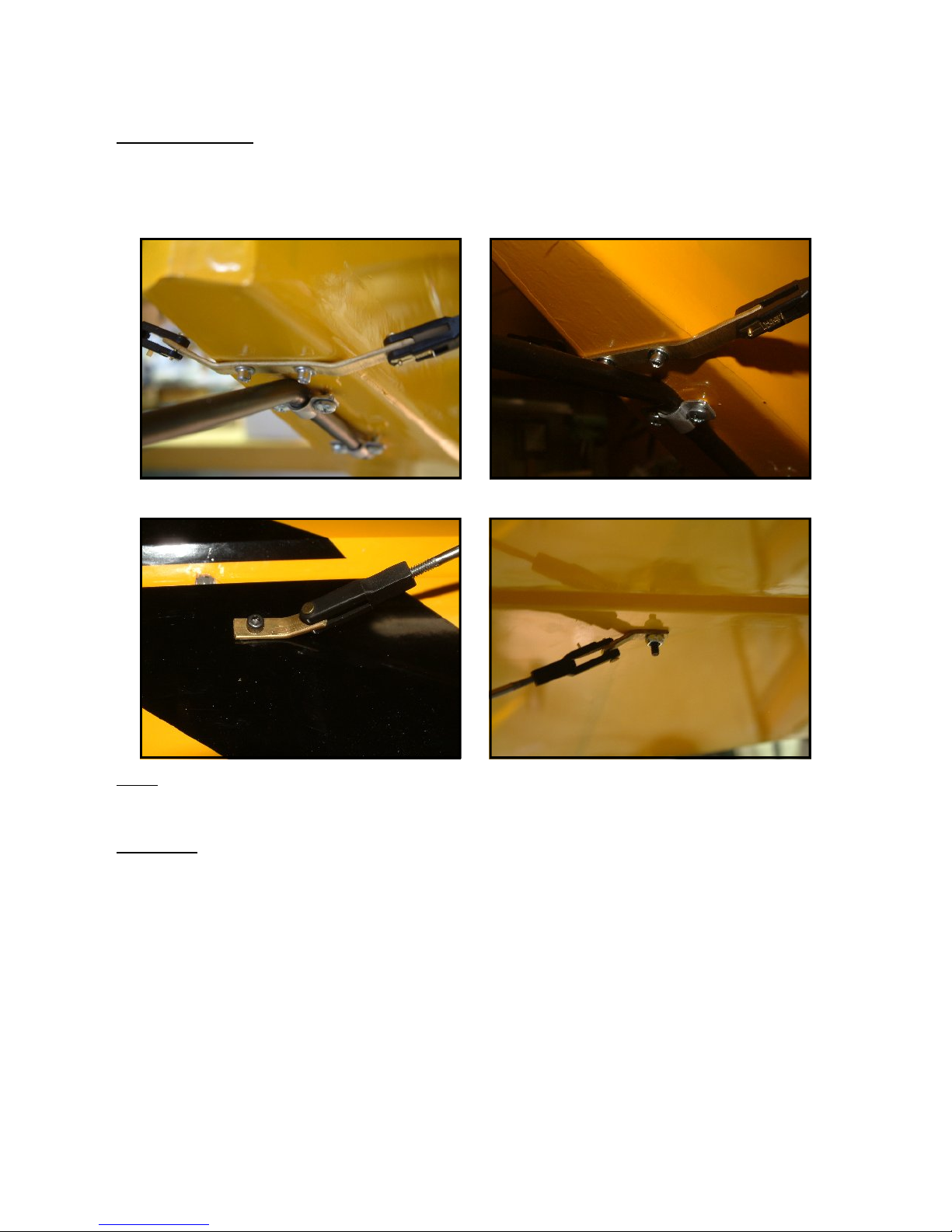

Flying Wires

1. Attach the flying wires to the vertical fin and horizontal stabilizer using material’s provided.

2. Bolt on to the bottom bracket to the bottom rear fuselage.

3. Attach all brackets to the tail

Note: Flying wires/attachments may be different in your kit versus the pictures above.

Rudder

1. Locate the hole for the rudder control arm , using a soldering iron clean out the holes for the control

arm at the bottom and also the holes for the hinges.

2. Using the methods as described above, glue the hinges in and install the rudder to the fuselage.

3. Install the 10/32” control arm to the bottom of the rudder. Drill and tap the hole prior to inserting the

control arm. Secure in place with nuts and washers. Use thin CA to coat the wood threads prior to

installation of control arm. Once the glue is dry, re-tap the threads.

4. Re-tap the black nylon 10/32” swivels and insert on the 10/32” control arm.

5. When applicable, hook up rudder cables once all servos are installed in the plane.

14

Fuselage

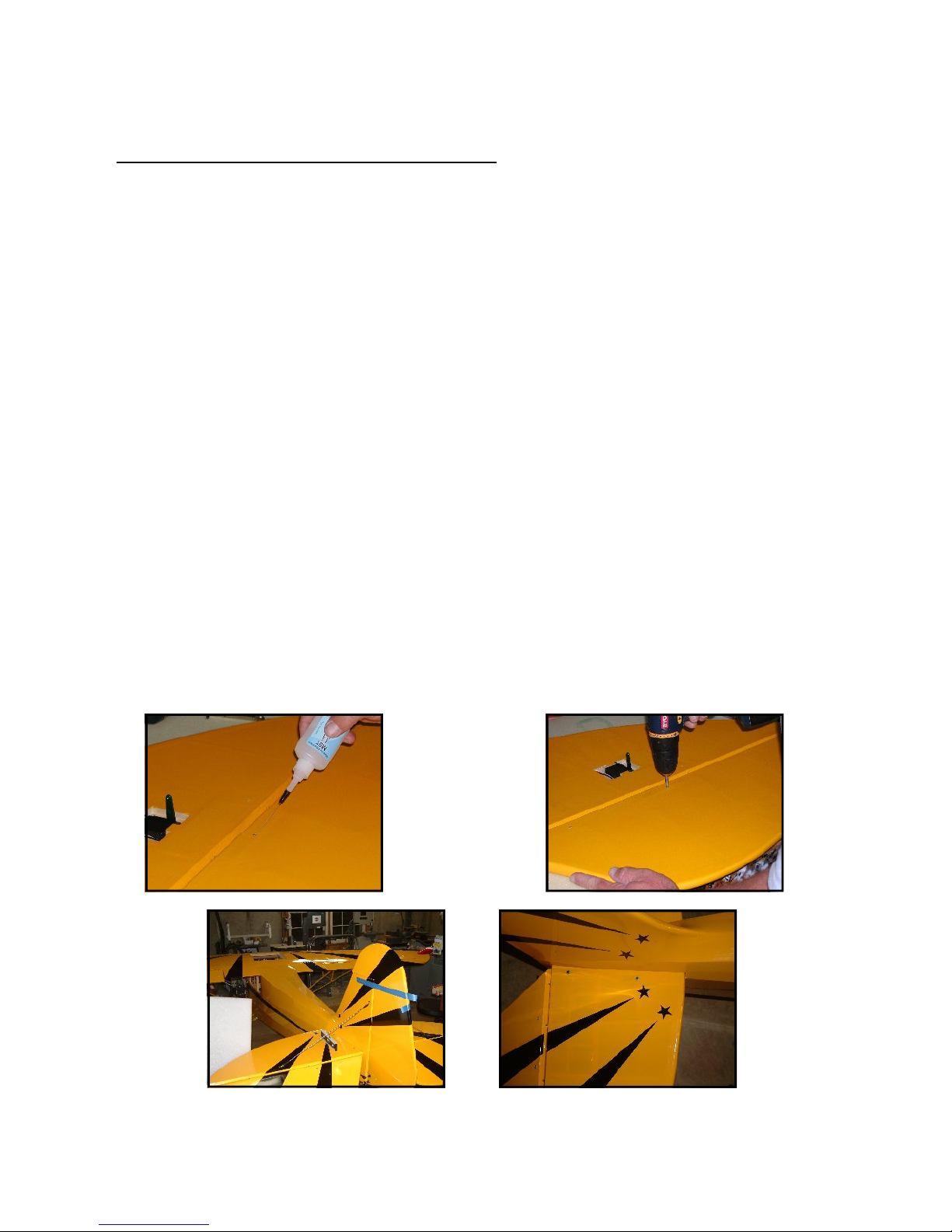

1. The first thing to make sure you have done is to go over all the seems again with an iron. For added

security, add ‘clear Monokote’ strip over each seem. Use a 3/4” clear Monokote strip and iron over

the seems. This will eliminate the seem from pulling apart while heat shrinking the material with a

gun. I know this is a lot of work but I have seen Ultracote pull apart when overlapped. Care must be

used when shrinking the large surface areas of the fuselage.

2. Lay the fuselage upside down on the floor.

3. Locate and install the tail wheel.

Landing Gear

1. To install the landing gear, it is recommended that the fuselage be placed upside down on the floor.

Use a blanket or some type of soft material to protect the finish of the plane.

2. Locate the pre-drilled holes in the bottom fuselage for the landing gear and open them up.

3. Using the bolts provided for the landing gear, assemble landing gear and place on fuselage. Use the

bungee provided to help keep gear from spreading apart.

4. Install the forward bolts into each side of the landing gear to trial fit the gear to the fuselage.

5. Temporarily install the wheels and axle to check landing gear’s alignment. Align the rear mounting

holes with the fuselage and verify the wheel alignment appears to be straight with the fuselage. If

needed, reposition the rear holes and re-install ‘T’ nuts inside the fuselage. (This procedure should

not be required but it is a good check to do now).

6. Once you are happy with the wheels alignment, install the mounting bolts for the landing gear. Re-

member to use lock-tite to help prevent the bolts from coming loose.

7. Install enough bungee cord to support the airplane while finishing the model. Final adjustments can

be made once the airplane is fully assembled .

15

Landing Gear (cont)

Wheels

1. When installing the wheels, I have found that adding a thin washer on both sides of the wheels help

reduce wear on the outer hubs.

2. Use axle grease or something similar when installing wheels to the axles. Slide the wheel assembly

onto the axle.

3. Loosen the screw on the landing gear for the axle and install axle/wheel assembly.

4. Press the axle into the landing gear and tighten screw. Verify the wheel still turn easily without bind-

ing. Use lock-tite on the axle screw to prevent loss of wheel during flight.

5. Note: A brass insert may increase the life of the wheels. You may consider drilling out the axle hole

in the yellow hub and inserting a brass sleeve to increase the strength of the wheel and longevity of

wear. My prototype did not require this and new airplanes as of Sept 08 will have a new designed

wheel with a beefier hub. (aluminum sleeve in picture was with older design wheels)

Fuselage (cont)

4. Now that the landing gear is on the airplane, the fuselage can now be placed on its wheels. Make

sure you have enough bungees to support the weight of the plane.

5. If you haven’t done so already then go ahead and glue the rudder onto the airplane. Locate and cut

out the covering for the rudder cable exit guide in the rear part of the fuselage. Do NOT install rud-

der servos in the back of the fuselage, only in the cabin area. (CG issues)

6. Install your rudder servos inside the fuselage area. The airplane will need between 1.5 – 2.5 pounds

of nose weight. Make sure when mounting equipment you plane ahead and mount everything as far

forward as possible. Do not mount the receiver near ignition module or batteries. Care must be used

to protect your receiver from RF noise.

16

Fuselage (cont)

7. Trial fit your cowling and become familiar with the process for assembly and removal of cowling.

The use of cotter pins and washers will be needed to secure the cowling to the fuselage.

8. Mount your 150cc—210cc engine to the firewall. Use the lower half of the cowling to verify the

engine is in the correct location. The firewall comes pre-marked for the standard 150cc engine but

use this only as a guide and not an absolute. You should plan for up to 1” clearance between the pro-

peller and the front of the cowling. The further forward your engine is mounted, the better the CG

and also the better cooling you will have of your cylinders.

9. Once the engine is in the correct location verify the cowling will attach without interference. You

should have ample clearance between the cylinder fins and cowling to prevent rubbing. Newer

planes as of Sept 08 should have the new cowling which incorporates the ‘dummy engine’ as part of

the cowling. The use baffles to help keep the engine cool is recommended.

NOTE: New kits as of Sept 08 will have the new designed cowling with the dummy engine as part of

the cowling and not as a separate item. This will make construction and assembly easier.

17

Fuselage (cont)

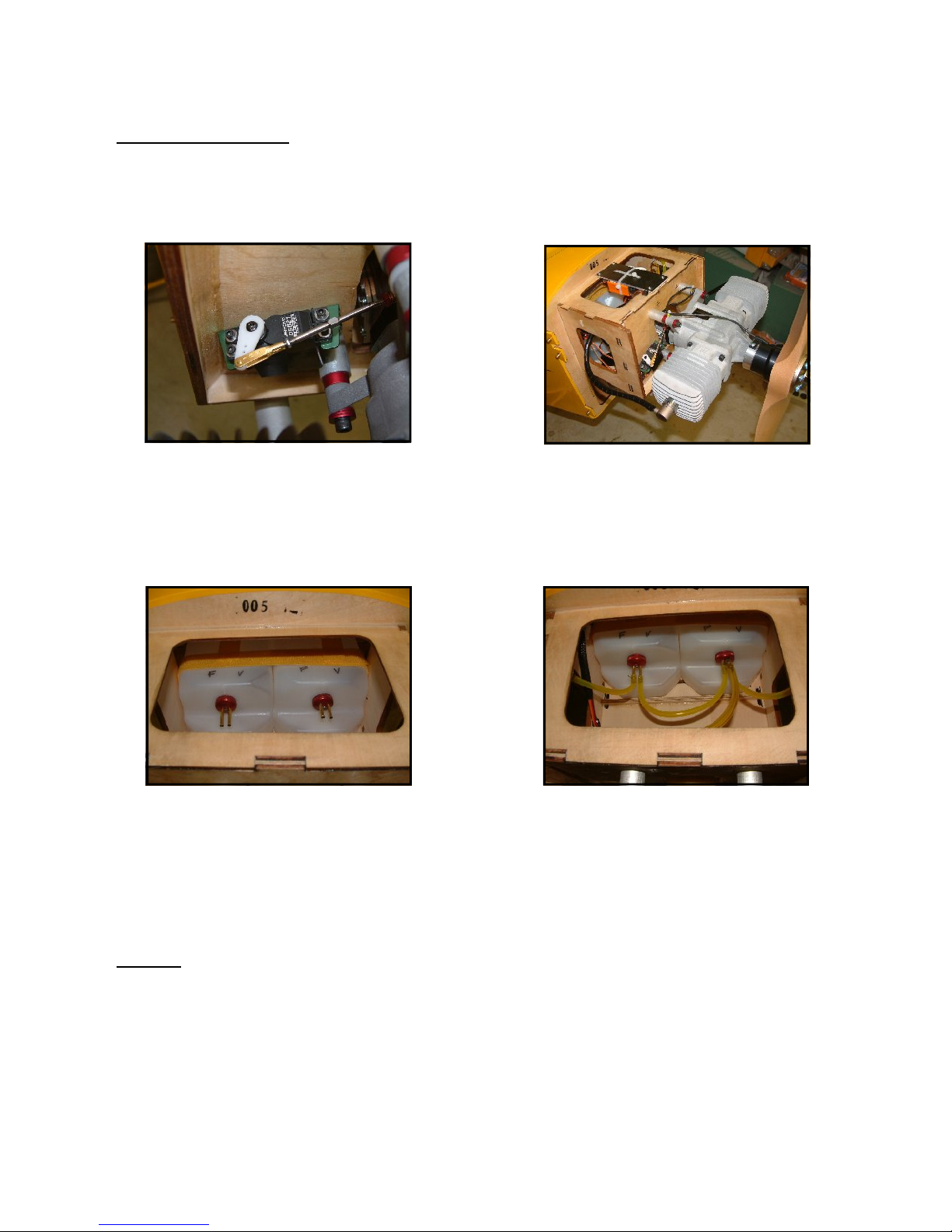

10. Mount the throttle servo on the motor box. Using a side mount single servo tray or something simi-

lar, install the servo to the motor box, secure tray. Install throttle linkage. (Picture is of ZDZ-210

rear induction motor which requires the throttle servo in the front of the firewall).

11. Install fuel tank in the rear portion of the motor box. Velcro tape works great for mounting the fuel

tank. Use 3/4”-1” wide Velcro in the front and rear portion of the fuel tank to hole in place. You will

need to cut the appropriate holes in the mounting floor for the Velcro to go through. Route all fuel

lines and fuel dots at this time. If you choose to do so, a smoke tank may be added as well. A 50

ounce fuel tank will give you about 18 minutes of flying on a 150cc motor.

12. Install your ignition module, battery and switch. Remember to mount these items up front in the mo-

tor box area to help with the CG. There are 2-holes cut on each side of the fuselage for mounting

your ignition and or receiver switch. The use of foam padding and velcro make for an easy way to

secure ignition/ receiver batteries.

Radio

1. With the rudder servos mounted inside the cabin area, the next step is to mount the rest of your radio

gear.

2. The receiver batteries should be wrapped in foam and with velcro, mounted to the forward motor

box area.

18

Radio (cont)

3. I highly recommend using a power board or power box distribution unit. I like using the SMART-

FLY boards personally. These board are a great way to add safety to your plane’s redundancy . In-

stall your receiver or power board behind the fuel tank area. You may have to make additional

power leads to run from you receivers/power boards to your batteries or voltage regulators.

4. Install some type of separate ignition cut-off unit to meet the AMA’s safety guideline for the experi-

mental category as published on the AMA’s website. Again, SMART-Fly has a very nice fiber-optic

unit that plugs directly in-between your receiver and ignition module.

5. Connect/install the rudder cables from your servo’s to the rudder.

6. Install switches, servo extensions and the rest of the radio gear. Complete a full system check out

with your airplane and all servos. Make sure you have set the correct directions on all surfaces and

throttle.

Assembly

1. Now it is time to finish up and prepare your plane for final assembly. Install both forward and rear

wing tubes into the fuselage.

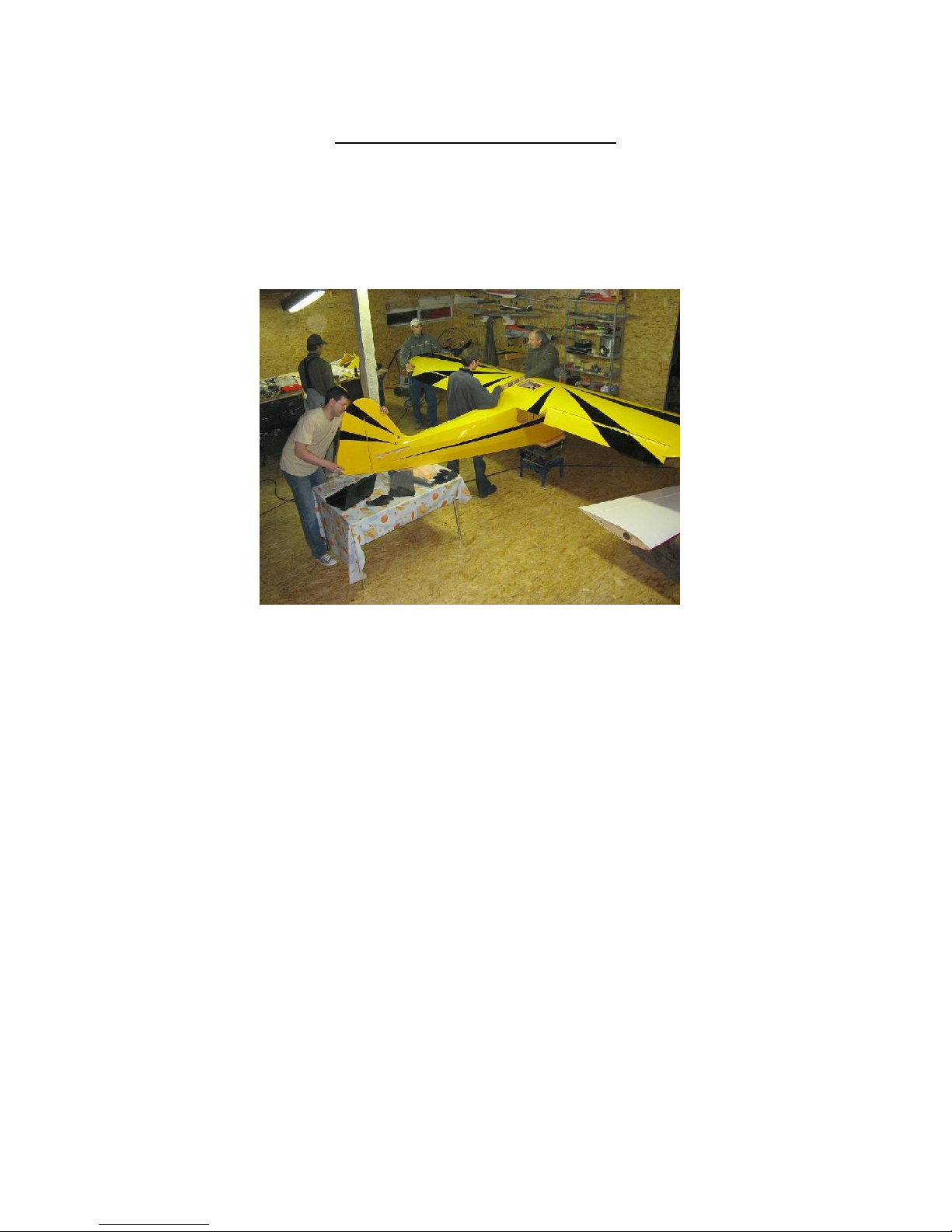

2. Install both wing panels to the airplane. Make sure you have a helper helping you!

3. Install the horizontal stab and connect all servo leads both for elevators and ailerons.

4. Run all the required servo extensions and permanently mount them in place where they need to go.

19

Assembly (cont)

5. With help, you will need to turn the airplane up-side-down again. The best way to do this is to place

the airplane on its nose and flip the airplane over in this direction. 2-people should be able to accom-

plish this without too much trouble. You may need to take your airplane outside if you do not have

sufficient room. Remember to always protect the airplanes covering from scratches, use a blanket or

something soft to lay the airplane on once it is inverted.

6. With the airplane up-side-down on a flat surface, we may now proceed to install the wing struts to

the airplane and make the proper adjustments to the attachment points.

7. Locate and assemble each side’s wing strut assembly.

8. Install the lower mounting tab to each side of the lower fuselage for the wing strut attachment.

9. Mount each side’s wing strut assembly to each wing half. Install the brass linkage adjustments to

the strut and match up with the fuselage tab. Once final alignment is complete use lock-tite and se-

cure connector to the strut. The pin /strut attachment should line up easily without having to bend or

add pressure to align.

NOTE: The reason we place the airplane inverted is to insure there is no load on the wings when mak-

ing the final adjustments to the wing strut linkage. This will also insure that the wing is flat without

dihedral or anhedral, this will also prevent the builder from ‘pulling” a warp into the wing trying to

get the struts to attach.

20

Assembly (cont)

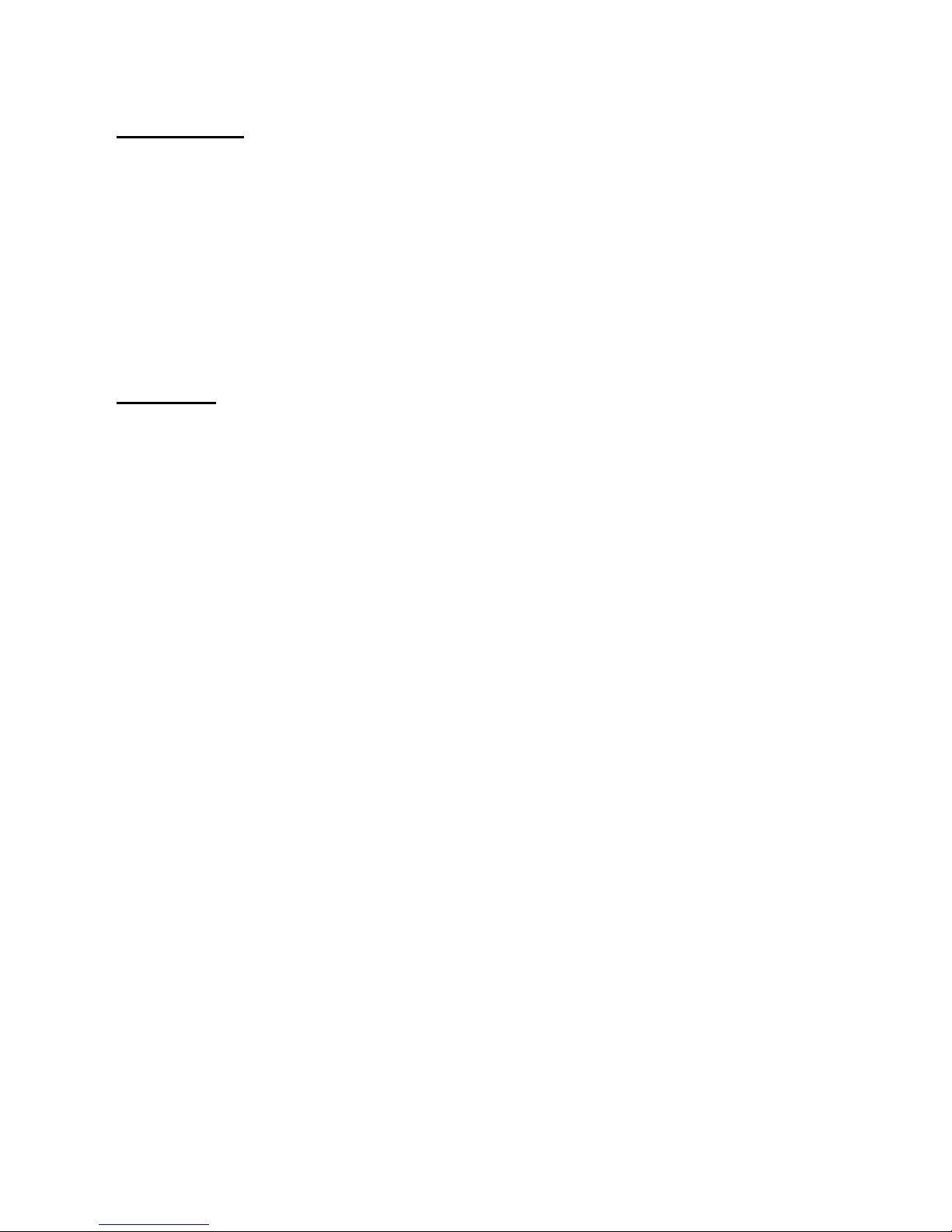

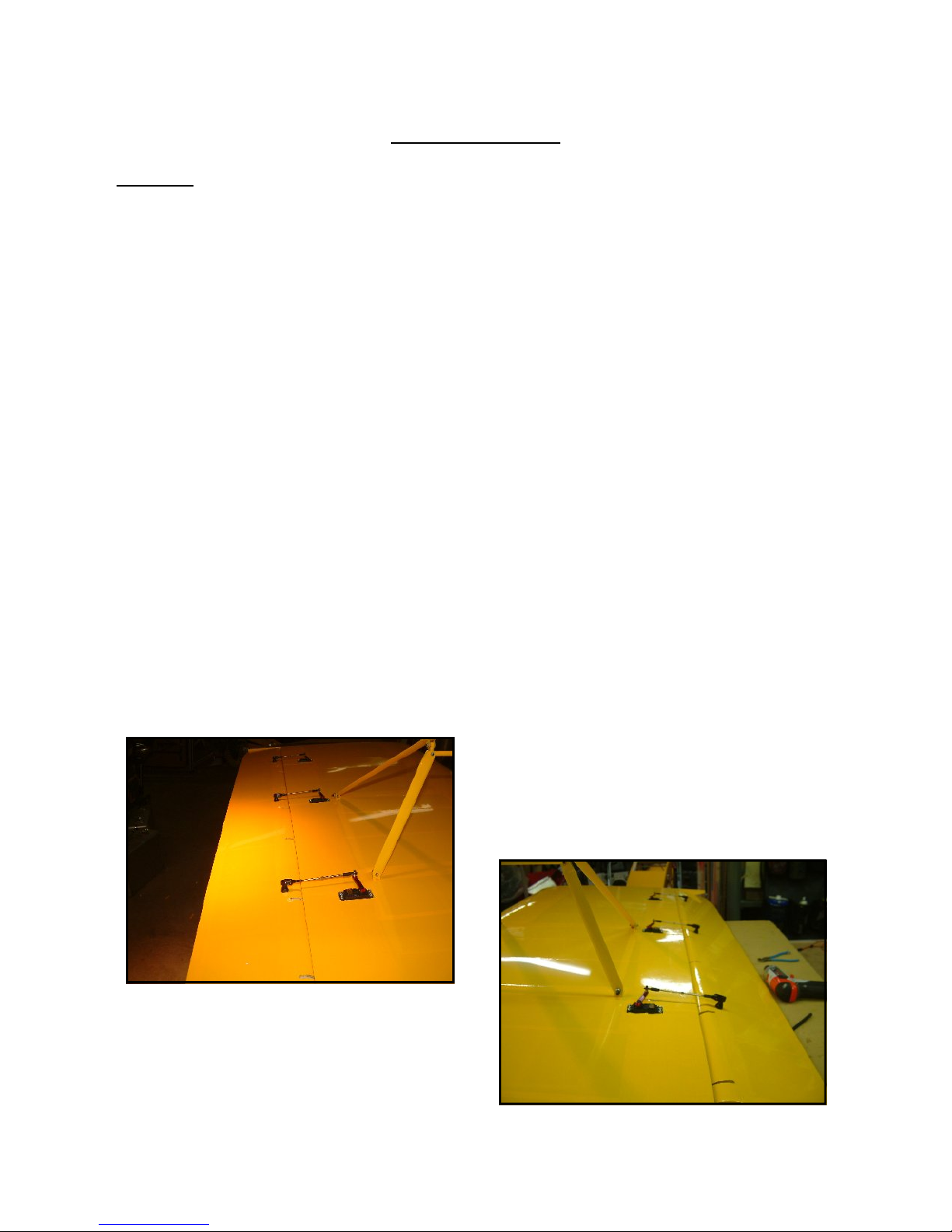

10. Once you have completed the adjustments necessary for the wing struts, you make turn your airplane

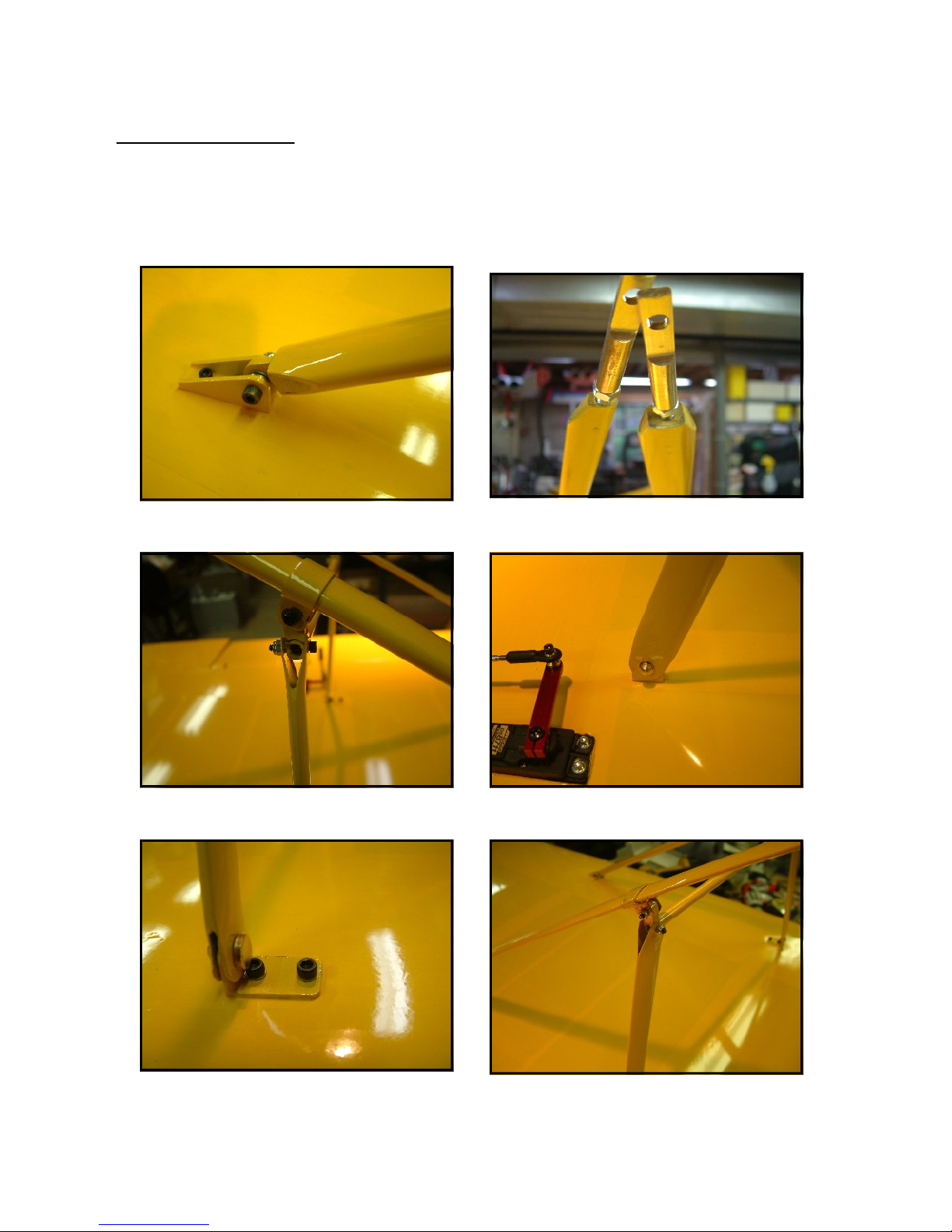

over and sight down the wings, everything should be perfect using this method. Here are a few pic-

tures to help you with the struts:

Table of contents

Other Bill Hempel Toy manuals

Popular Toy manuals by other brands

Eduard

Eduard Ju 88A-4 exterior Assembly instructions

Ravensburger

Ravensburger Gravitrax TRAMPOLINE manual

iDventure

iDventure Marble Run Dragon Assembly instructions

Fisher-Price

Fisher-Price RESCUE HEROES ACTiON TRaCKERS H7233 instruction sheet

Flight Model

Flight Model P-51 Mustang Assembly manual

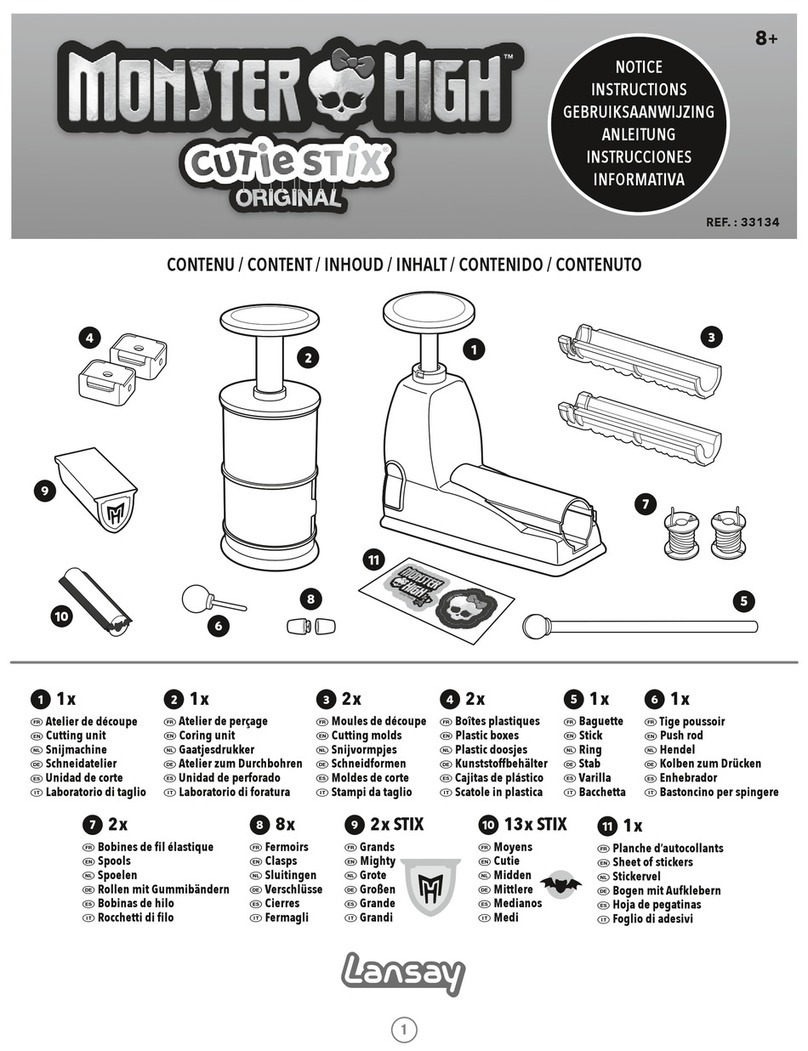

Lansay

Lansay MONSTER HIGH CUTIE STIX ORIGINAL instructions