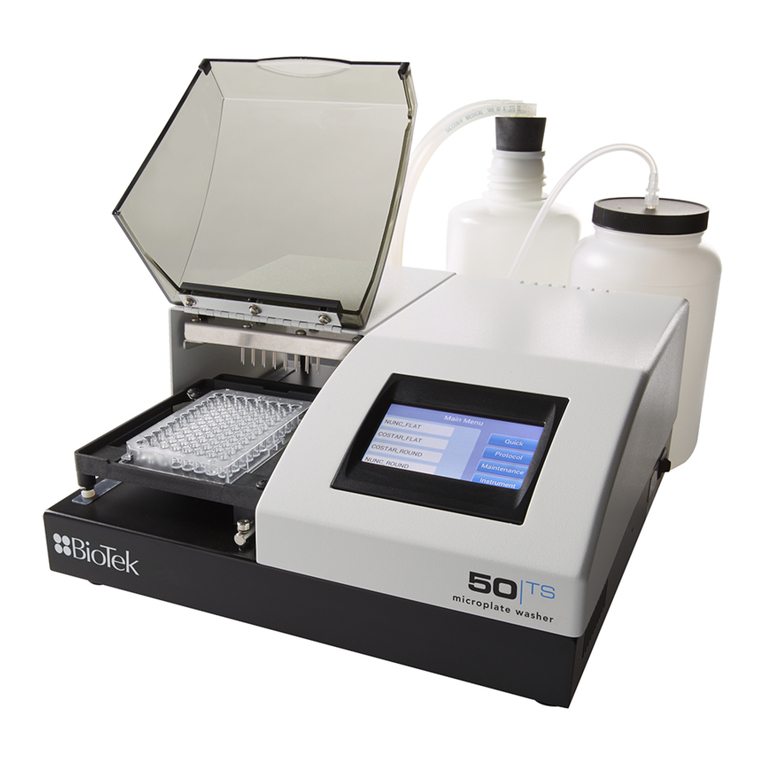

Bio-Tek 405 LS User manual

Operator’s Manual

Microplate Washer

405™ LS

405™ Microplate Washer LS

Operator's Manual

BioTek Instruments, Inc.

January 2013

© January 2013

Part Number 1171030

Revision B

ii | 405 LS Operator's Manual

Notices

BioTekInstruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

All Rights Reserved

© 2013, BioTek®Instruments, Incorporated. No part of this publication may be

reproduced, transcribed, or transmitted in any form, or by any means electronic

or mechanical, including photocopying and recording, for any purpose other

than the purchaser’s use without written permission of BioTek Instruments, Inc.

Trademarks

BioTek®is a registered trademark and 405™ Microplate Washer LSis a

trademark of BioTek Instruments, Inc.

Microsoft®, Internet Explorer®, Windows®, Windows 7, Windows Vista®,

Windows XP, and Excel®are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

All other trademarks are the property of their respective holders.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a

commitment by BioTek Instruments, Inc. Changes made to the information in

this document will be incorporated in new editions of the publication. No

responsibility is assumed by BioTek for the use or reliability of software or

equipment that is not supplied by BioTek or its affiliated dealers.

405™ Microplate Washer LS

Notices| iii

Contents

Notices ii

All Rights Reserved ii

Trademarks ii

Restrictions and Liabilities ii

Contact Information viii

Customer Service and Sales viii

Service/TAC viii

European Coordination Center/Authorized European Representative viii

Document Conventions ix

Document Revision History ix

Intended Use Statement ix

Quality Control x

Warranty and Product Registration x

Repackaging and Shipping x

Warnings x

Hazards and Precautions xi

Hazards xi

Precautions xii

CE Mark xiv

Directive 2004/108/EC: Electromagnetic Compatibility xiv

Directive 2006/95/EC Low Voltage (Safety) xv

Directive 2002/96/EC: Waste Electrical and Electronic Equipment xv

Directive 98/79/EC: In Vitro Diagnostics(if labeled for this use) xv

Electromagnetic Interference and Susceptibility xv

USA FCC CLASS A xv

Canadian Department of Communications Class A xvi

User Safety xvi

Safety Symbols xvii

Introduction 1

Introducing the 405™ Microplate Washer LS 2

Instrument Models 3

BioStack Compatibility 3

Package Contents 5

Waste and Dispense System Accessories 6

Optional Accessories 7

Physical Specifications 9

Performance Specifications 10

BioTek's Customer Resource Center 12

Installation 13

Unpack and Inspect the Instrument 14

Remove the Shipping Hardware 14

Setting Up the 405 LS 18

Install the Microplate Carrier 18

Connect the Vacuum Pump, Tubes, and Bottles 18

Waste System 19

BioTek Instruments, Inc.

iv | 405 LS Operator's Manual

Install the Vacuum Line Filter 21

Install the Fluid Supply System 22

Final Check 24

Attach the Mist Shield 24

Install Software/Connect to Computer 25

Connect to Host Computer 25

Connect to Power 26

Define Instrument Settings 26

LHC Users Only 26

Standard Vacuum Pump Users 27

Define Startup Preferences (LHC users only) 27

Verify Performance 29

Verify the Washer 30

Run the Verify Test ("Q" Models Only) 30

Repacking the 405 Washer 32

Operation 37

Basic Operation 38

About the 405 LS Wash Step 38

Optimize Performance 39

405 Recommendations for Priming the Washer 39

Optimize protocols to improve evacuation 40

Running Predefined Protocols 41

Creating Protocols: Washing, Aspirating and Dispensing Fluid 41

LHC Users Only: Customize the Predefined Protocols 41

Predefined Protocols Listing 43

Predefined Sample Protocols 44

Introducing the 405 LS Keypad 46

Quick Wash (Keypad only) 47

Quick Prime (Keypad only) 48

Create or Edit a Protocol (Keypad Only) 48

How to name a protocol (Keypad only) 49

Define the Plate Type and Plate Map (or Partial Plate) 50

How to shake the plate 51

How to enter negative numbers (Keypad only) 52

How to copy a protocol 52

How to delete a protocol 52

Using LHC to Control the 405™ Washer 54

Introducing the LHC Workspace 54

Communications Port 55

405 Steps 55

LHC Protocols 56

LHC Protocols Explained 57

Target Instrument Settings 58

How to define a Protocol (LHC only) 59

How to use the Adjust Utility- LHC 60

Upload-Download Protocols (LHC Only) 62

Wash Step Parameters Table 62

405™ Microplate Washer LS

Notices| v

Shake/Soak Step Parameters 66

Pre-Dispense 67

Washer Flow Rates 68

How to define a Final Aspiration step 69

Add a secondary aspiration to a wash cycle 70

Bottom Wash 70

Verify Performance 72

Handling the Verify Test Plate 73

Verify™ Technology Flowchart Diagram 75

Verify Test Corrective Action 75

About Verify™ Technology 76

Sensitivity: Verify Sensor vs. Absorbance Reader 78

Configure Verify™ Technology Utilities 79

Operating with the BioStack 81

BioStack Alignment Utility 82

Cell Wash 84

Cell Wash Strategies 85

Biomagnetic Separation - Magnetic Bead Assays 89

Perform Magnetic Bead Assays 90

Optimize Magnetic Bead Protocols 90

Flat Magnets 91

Ring Magnets 92

Magnet Height Offset 93

Determine Magnet Height Offset 93

Manifold Stop Screw Adjustment Kit 94

Vacuum Filtration for Filter Plate Assays 97

Install the side bracket 98

Set up the Vacuum Filtration module 99

Enable Vacuum Filtration 101

Create a Vacuum Filtration Protocol 101

Install Vacuum Filtration Plate Carrier 103

Control the Vacuum Level 104

Washer Settings 105

Change the Washer Manifold Setting (Keypad) 107

Change the Plate Carrier Setting (Keypad) 107

Change the Plate Clearance Setting (Keypad) 108

Adjust Utility 108

Run the Adjust Utility (Using the Keypad) 109

Plate Types and Processing Patterns 110

Plate Types Table 111

About Wash Processing Patterns 111

Maintenance 115

Overview 117

Recommended Maintenance Schedule 119

Daily Maintenance 121

Overnight/Multi-Day Maintenance 121

AutoPrime 122

BioTek Instruments, Inc.

vi | 405 LS Operator's Manual

AutoPrime for Overnight-Weekend Maintenance 123

Turn on AutoPrime for the Washer 123

Removing Protein Residuals and Fungi Growth 124

AutoClean the Washer 125

Quick Clean (Keypad Only) 126

Create an AutoClean protocol 127

Periodic Maintenance 128

Clean the Bottles 128

Clean the Plate Carrier 129

Clean the Vacuum Filtration Carrier 129

Clean the exterior surfaces and mist shield 130

Clean the Buffer Bottle Filter 130

Remove and clean the washer manifold 131

Maintaining the Vacuum Filtration System 133

Clean the Vacuum Filtration Carrier 133

Maintain the Verify™ Technology Components 133

Clean the Verify™ Level Sensor 133

Replacement Procedure for Verify Test Plate 134

Volume coefficients - Slope and Offset 137

Decontamination 138

Tools and Supplies 138

Decontaminate Exterior Surfaces 139

Decontaminate Tubing and Manifold 140

Alternate Decontamination Procedure for Tubing and Manifold 141

Decontaminate the Vacuum Filtration System 142

Long Shutdown Procedure (Prepare for Storage or Shipment) 143

Storing the Instrument 144

Replace Components 144

Remove/Change Wash Manifold 145

Replace the Vacuum Pump Fuse 145

Vacuum Filtration Carrier: Replace the Gasket 146

Qualification 147

Qualification Overview 148

Qualification Schedule 149

System Self-Test, Verify Information 149

Record Basecode 150

Sensor Test: Fluid, Waste, Plate Detection 150

Ultrasonic Cleaner Test 151

Liquid Testing the 405™ Microplate Washer LS 152

Which Tests to Perform? 152

Important Recommendations for All Liquid Tests 153

Washer Liquid Tests 154

Dispense Precision Test 154

Evacuation Efficiency Test 154

Predefined Test Protocols 154

Washer Qualification Test Materials 155

Dispense Precision Test (96) 157

405™ Microplate Washer LS

Notices| vii

Evacuation Efficiency Test (96) 158

Evacuation Diagnostic Test 159

Buffer Switching Dispense Test 160

Dispense Precision Test (192) 161

Evacuation Efficiency Test (192) 162

Evacuation Diagnostic Test (192) 163

Vacuum Filtration Evacuation Efficiency Test 165

Qualify the Verify™ Technology Sensor 167

Troubleshooting 179

Troubleshooting 180

General Operation Troubleshooting 182

Washer Problems 183

Communication Errors 188

Error Codes 191

System Error Codes 192

405 LS-LHC Software Error Codes 200

205

BioTek Instruments, Inc.

Index .............................................................................................................

viii | 405 LS Operator's Manual

Contact Information

BioTekInstruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

Customer Service and Sales

Internet: www.biotek.com

Phone: 888-451-5171 (toll free in the U.S.)

802-655-4740 (outside the U.S.)

Fax: 802-655-7941

E-Mail: customercare@biotek.com

Service/TAC

Phone: 800-242-4685 (toll free in the U.S.)

802-655-4740 (outside the U.S.)

Fax: 802-654-0638

E-Mail: tac@biotek.com

European Coordination Center/Authorized European Representative

BioTekInstruments GmbH

Kocherwaldstrasse 34

D-74177 Bad Friedrichshall

Germany

Internet: www.biotek.de

Phone: +49 (0) 7136 9680

Fax: +49 (0) 7136 968 111

E-Mail: info@biotek.de

405™ Microplate Washer LS

Document Conventions| ix

Document Conventions

This manual uses the following typographic conventions:

nThis note format calls attention to important information.

Warnings are presented in this style to call attention to potential hazards and other

safety concerns.

This icon calls attention to important safety information.

Tips and suggestions for improving performance are formatted this way.

Navigation instructions: how to get to the function being described

nWater: Daily maintenance is the key to keeping the liquid handler performing

to specifications. In the maintenance procedures provided in this manual, the

requirement to use distilled (dH2O) or deionized (DI) water can be met by

numerous water purification methods, including MilliQ™. A minimum water

purity of 2mOhm is expected.

Document Revision History

Rev Date Changes

A 5/2012 First issue

B 1/2013 Added content about BioTek's Verify™ Technology, including the Plate

Detection sensor and new shipping hardware. Added instructions for running

the Verify test, analyzing its test results, maintaining the device, replacing

the test plate and qualifying the device. Note: the vacuum filtration plate

carrier was modified to accommodate the Verify device. Pinch hazard

warning label updated. Packing materials modified for all models.

Intended Use Statement

lThe 405™ Microplate Washer LS provides microplate priming, washing, and dispensing

for ELISA™, fluorescence and chemiluminescence immunoassays, cellular and

BioTek Instruments, Inc.

x | 405 LS Operator's Manual

agglutination assays.

lIf the instrument has an "IVD" label it may be used for clinical and non-clinical purposes,

including research and development. If there is no such label the instrument may only be

used for research and development and non-clinical purposes.

Quality Control

It is considered good laboratory practice to run laboratory samples according to

instructions and specific recommendations included in the assay package insert for

the test to be conducted. Failure to conduct Quality Control checks could result in

erroneous test data.

Warranty and Product Registration

Please take a moment to review the Warranty information that shipped with your

product. Please also register your product with BioTek to ensure that you receive

important information and updates about the product(s) you have purchased.

You can register online through BioTek’s Customer Resource Center (CRC) at

www.biotek.com or by calling 888/451-5171 or 802/655-4740.

Repackaging and Shipping

If you need to ship the instrument to BioTek for service or repair, contact BioTek

for a Return Materials Authorization (RMA) number and use the original packing

materials. Other forms of commercially available packaging are not recommended

and can void the warranty. If the original packing materials have been damaged or

lost, contact BioTek for replacement packing.

Warnings

Operate the instrument on a level, stable surface away from excessive

humidity.

When operated in a safe environment, according to the instructions in this

document, there are no known hazards associated with the 405 LS. However,

the operator should be aware of certain situations that could result in serious

injury; these vary depending on the instrument type. See Hazards and

Precautions.

Strict adherence to instrument maintenance and qualification procedures is

required to ensure accurate dispense volumes and risk-free operation.

405™ Microplate Washer LS

Hazards and Precautions| xi

Hazards and Precautions

Hazards

The following hazards are provided to help avoid injury:

Warning! Power Rating. The instrument’s power supply or power cord must

be connected to a power receptacle that provides voltage and current within the

specified rating for the system. Use of an incompatible power receptacle may

produce electrical shock and fire hazards.

Warning! Electrical Grounding. Never use a two-prong plug adapter to

connect primary power to the external power supply. Use of a two-prong

adapter disconnects the utility ground, creating a severe shock hazard. Always

connect the power cord directly to an appropriate receptacle with a functional

ground.

Warning! Service. Only qualified technical personnel should perform service

procedures on internal components.

Warning! Accessories. Only accessories which meet the manufacturer’s

specifications shall be used with the instrument.

Warning! Lubricants. Do not apply lubricants to the microplate carrier or

carrier track. Lubricant on the carrier mechanism will attract dust and other

particles, which may obstruct the carrier path and cause the instrument to

produce an error.

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential for shock hazard or instrument

damage. If a spill occurs while a program is running, abort the program and

turn the instrument off. Wipe up all spills immediately. Do not operate the

instrument if internal components have been exposed to fluid.

Warning! Unspecified Use. Failure to operate this equipment according to

the guidelines and safeguards specified in this manual could result in a

hazardous condition.

Warning! Direct Drain Waste. If installed, the direct drain waste system

pumps waste fluids from the washer directly into a sink or tank, and, potentially

into public waste water systems. Because the waste may be a biohazard, you

must ensure that you are in compliance with your local or national

government’s laws regarding safe disposal of the waste.

Warning! Ultrasonic Energy. Ultrasonic energy is present in the ultrasonic

cleaner reservoir (if equipped) when AUTOCLEAN/Quick Clean programs are

running. Avoid putting your fingers in the bath. Ultrasonic energy can be

destructive to human tissue.

Warning! Software Quality Control. The operator must follow the

BioTek Instruments, Inc.

xii | 405 LS Operator's Manual

manufacturer’s assay package insert when modifying software parameters and

establishing washing or dispensing methods. Failure to conduct quality

control checks could result in erroneous test data.

Warning! Internal Voltage. Always turn off the power switch and unplug the

power supply before cleaning the outer surface of the instrument.

Warning! Potential Biohazards. Some assays or specimens may pose a

biohazard. Adequate safety precautions should be taken as outlined in the

assay’s package insert. This hazard is noted by the symbol shown here. Always

wear safety glasses and appropriate protective equipment, such as chemically

resistant rubber gloves and apron.

Warning! Pinch Hazard. Some areas of the instrument or its components can

present pinch hazards when the instrument is operating. Depending on the

instrument or component, these areas are marked with the symbol shown here.

Keep hands/fingers clear of these areas when the instrument is operating.

Precautions

The following precautions are provided to help avoid damage to the instrument:

Caution: Service. The instrument should be serviced by BioTek authorized

service personnel. Only qualified technical personnel should perform

troubleshooting and service procedures on internal components.

Caution: Spare Parts. Only approved spare parts should be used for

maintenance. The use of unapproved spare parts and accessories may result in

a loss of warranty and potentially impair instrument performance or cause

damage to the instrument.

Caution: Environmental Conditions. Do not expose the instrument to

temperature extremes. For proper operation, ambient temperatures should

remain within the range listed in the Specifications section. Performance may

be adversely affected if temperatures fluctuate above or below this range.

Storage temperature limits are broader.

Caution: Sodium Hypochlorite. Do not expose any part of the instrument to

the recommended diluted sodium hypochlorite solution (bleach) for more than

20 minutes. Prolonged contact may damage the instrument surfaces. Be certain

to rinse and thoroughly wipe all surfaces.

Caution: Buffer Solution. Although many precautions have been taken to

ensure that the instrument is as corrosion-proof as possible, the instrument is

not sealed and liquids can seep into sensitive components. Make sure that any

spilled buffer solution is wiped off the instrument. Prolonged exposure to salt

solution may corrode parts of the microplate carrier, movement rail, springs,

405™ Microplate Washer LS

Hazards and Precautions| xiii

and other hardware.

Caution: Chemical Compatibility. Some chemicals may cause irreparable

damage to the instrument. The following chemicals have been deemed safe for

use in the instrument: buffer solutions (such as PBS), saline, surfactants,

deionized water, 70% ethyl, isopropyl, or methyl alcohol, 40% formaldehyde,

and 20% sodium hydroxide. Never use acetic acid, DMSO, or other organic

solvents. These chemicals may cause severe damage to the instrument.

Contact BioTek for more information and prior to using other questionable

chemicals.

Caution: Bovine Serum Albumin. Solutions containing proteins, such as

bovine serum albumin (BSA), will compromise the instrument’s performance

over time unless a strict maintenance protocol is adhered to. See

Maintenance procedures regarding BSA.

Caution: Power Supply. Only use the power supply shipped with the

instrument. Operate this power supply within the range of line voltages listed

on it.

Caution: Disposal. This instrument contains printed circuit boards and wiring

with lead solder. Dispose of the instrument according to Directive 2002/96/EC,

“on waste electrical and electronic equipment (WEEE),” or local ordinances.

Caution: Warranty. Failure to follow preventive maintenance protocols may

void the warranty.

Caution: Shipping Hardware. All shipping hardware (e.g., shipping bracket

etc.) must be removed before operating the instrument and reinstalled before

repackaging the instrument for shipment.

Caution: High Flow Pump Installation. DO NOT plug the High Flow vacuum

pump cable into a wall outlet! Use the adapter provided with the pump to

connect the pump to the accessory outlet on the back of the washer. See the

Installation instructions.

Caution: WasteSensorPort on 405 LS. (For customers who have

purchased the BioStack Microplate Stacker.) Although the waste sensor port on

the back of the 405 LS is the same type as the 24-VDC power connector on the

back of the BioStack, if an external 24-VDC power supply is plugged into the

405 LS’s port, it will permanently damage internal components.

Caution: Electromagnetic Environment. Per IEC 61326-2-6 it is the user’s

responsibility to ensure that a compatible electromagnetic environment for this

instrument is provided and maintained in order that the device will perform as

intended.

BioTek Instruments, Inc.

xiv | 405 LS Operator's Manual

Caution: Electromagnetic Compatibility. Do not use this device in close

proximity to sources of strong electromagnetic radiation (e.g., unshielded

intentional RF sources), because these may interfere with the proper operation.

CE Mark

Based on the testing described below and information contained

herein, this instrument bears the CE mark.

nNote: See the Declaration of Conformity for specific information.

Directive 2004/108/EC: Electromagnetic Compatibility

Emissions—Class A

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1: Class A for

Radiated Emissions and Line Conducted Emissions.

Verification of compliance was conducted to the limits and methods of EN 55011

(CISPR 11) Class A. In a domestic environment it may cause radio interference,

in which case, you may need to mitigate the interference.

Immunity

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1 and EN 61326-2-6

for Immunity. Verification of compliance was conducted to the limits and

methods of the following:

EN 61000-4-2, Electrostatic Discharge

EN 61000-4-3, Radiated EM Fields

EN 61000-4-4, Electrical Fast Transient/Burst

EN 61000-4-5, Surge Immunity

EN 61000-4-6, Conducted Disturbances from RFI

EN 61000-4-8 Power Frequency Magnetic Field Immunity Test

EN 61000-4-11, Voltage Dips, Short Interruptions and Variations

405™ Microplate Washer LS

Electromagnetic Interference and Susceptibility| xv

Directive 2006/95/EC Low Voltage (Safety)

The system has been type-tested by an independent testing laboratory and was

found to meet the requirements of this Directive. Verification of compliance was

conducted to the limits and methods of the following:

EN 61010-1, “Safety requirement for electrical equipment for measurement,

control and laboratory use. Part 1, General requirements.”

Directive 2002/96/EC: Waste Electrical and Electronic Equipment

Disposal Notice: This instrument contains printed circuit boards and wiring with

lead solder. Dispose of the instrument according to Directive 2002/96/EC, “on

waste electrical and electronic equipment (WEEE)” or local ordinances.

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use)

lProduct registration with competent authorities.

lTraceability to the U.S. National Institute of Standards and Technology (NIST).

EN 61010-2-101 Particular requirements for in vitro diagnostic (IVD) medical

equipment.

Electromagnetic Interference and Susceptibility

USA FCC CLASS A

RADIO AND TELEVISION INTERFERENCE

NOTE: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at their own expense.

In order to maintain compliance with FCC regulations shielded cables must be

used with this equipment. Operation with non-approved equipment or

BioTek Instruments, Inc.

xvi | 405 LS Operator's Manual

unshielded cables is likely to result in interference to radio and television

reception.

Canadian Department of Communications Class A

This digital apparatus does not exceed Class A limits for radio emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n'émet pas de bruits radioelectriques depassant

les limites applicables aux appareils numerique de la Class A prescrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

User Safety

This device has been type-tested by an independent laboratory and found to meet

the requirements of the following:

lUnderwriters Laboratories UL 61010-1 “Safety requirements for electrical

equipment for measurement, control and laboratory use; Part 1: general

requirements.”

lCanadian Standards Association CAN/CSA C22.2 No. 61010-1 “Safety

requirements for electrical equipment for measurement, control and

laboratory use; Part 1: general requirements.”

lEN 61010 Standards, see CE Mark on page xiv.

405™ Microplate Washer LS

Safety Symbols| xvii

Safety Symbols

Some of these symbols appear on the instrument or accessories:

Alternating current

Courant alternatif

Wechselstrom

Corrientealterna

Correntealternata

Both direct and alternating current

Courant continu et courant alternatif

Gleich - und Wechselstrom

Corriente continua y corrientealterna

Corrente continua e

correntealternata

Direct current

Courant continu

Gleichstrom

Corriente continua

Corrente continua

Earth ground terminal

Borne de terre

Erde (Betriebserde)

Borne de tierra

Terra (difunzionamento)

On (Supply)

Marche (alimentation)

Ein (VerbindungmitdemNetz)

Conectado

Chiuso

Protective conductor terminal

Borne de terre de protection

Schutzleiteranschluss

Borne de tierra de protección

Terra diprotezione

Off (Supply)

Arrêt (alimentation)

Aus (TrennungvomNetz)

Desconectado

Aperto

(scon-

nessionedallaretedialimentazione)

Caution (refer to accompanying

documents)

Attention (voir documents

d’accompanement)

AchtungsieheBegleitpapiere

Atención (vease los

documentosincluidos)

Attenzione, consultare la doc annessa

Warning, risk of electric shock

Attention, risque de choc électrique

Gefährlicheelektrischeschlag

Precaución, riesgo de

sacudidaeléctrica

Attenzione, rischiodiscossaelettrica

Warning, risk of crushing or pinching

Attention, risqued’écrasement et

pincement

Warnen, Gefahr des Zerquetschens

und Klemmen

Precaución, riesgo del

machacamiento y sejeción

Attenzione,

rischiodischiacciareedintrappolarsi

Warning, hot surface

Attention, surface chaude

Warnen, heißeOberfläche

Precaución, superficiecaliente

Attenzione, superficiecalda

Warning, potential biohazards

Attention,

risquesbiologiquespotentiels

Warnung!

MoeglichebiologischeGiftstoffe

Atención, riesgosbiológicos

Attenzione, rischiobiologico

In vitro diagnostic medical device

Dispositif médical de diagnostic in

vitro

Medizinisches In-Vitro-Diagnostikum

Dispositivo médico de diagnóstico in

vitro

Dispositivo medico diagnostico in

Separate collection for electrical and

electronic equipment

Les équipements électriques et

électroniques font l’objet d’une

collecte sélective

Getrennte Sammlung von Elektro-

und Elektronikgeräten

BioTek Instruments, Inc.

xviii | 405 LS Operator's Manual

vitro Recogida selectiva de aparatos

eléctricos y electrónicos

Raccolta separata delle

apparecchiature elettriche ed

elettroniche

Consult instructions for use

Consulter la notice d’emploi

Gebrauchsanweisung beachten

Consultar las instrucciones de uso

Consultare le istruzioni per uso

405™ Microplate Washer LS

Table of contents

Other Bio-Tek Washer manuals