BIOLUX EOS-7130 User manual

Owner's Manual

For Your New Biolux Hydrogen Fountain

The Best Choice for Your Family’s Health and Hygiene

Drinking

Disinfection

Health Preservation | Healthy Drinking Water | Natural Sanitizer

Table of Contents

Hydrogen Fauntain Introduction

Introduction

To Our Valued Customers

Intended Use

Important Safety Warnings and Precautions

Product Features

Product Specications

2

2

2

3

5

5

Installation

Package Contents

Unit Overview

LCD Display & Control Panel

How to Install the Unit

6

7

8

11

Operation & Use

Unit Start-Up

Directions for Product Use

Other Functions

Recommendations for Using this Unit

19

20

23

28

Service & Maintenance

Consumable Parts

Troubleshooting Guide

EOS7130-HG_EN_V205HM

30

31

To Our Valued Customers

We are not responsible for any accidents and/or malfunctions due to improper use of this product.

•

Please refer to this manual often when you have questions during the use or when troubleshooting this unit.

•

Thank you for purchasing Biolux Hydrogen Fountain. You have just purchased the nest, most benecial and

advanced health appliance in the world! Your new Hydrogen Fountain is designed to provide you with many years

of the cleanest, healthiest and most “functional” benets available. There are many specic uses of this amazing

product, so read this manual carefully to learn how to get both optimum performance out of your Hydrogen

Fountain Unit and to protect your investment.

This product is intended for domestic use only. Please read all safety warnings and this User’s Manual carefully

before using this product to ensure proper product usage. (Keep the manual handy for easy reference.)

Intended Use

This device not only provides saturated hydrogen water for drinking, but also ozonated water for sanitation.

Furthermore, the pure hydrogen generated in the device can be extracted for use to improve heath - this is a real

one product for unlimited benets for your home!

Just exactly what are those? Your The Hydrogen Fountain employs computer accurate low-voltage electric current

and selectable proton exchange energy to perform water electrolysis through patented Indirect Electrolytic

Ozone Generation (iEOG) cell. Inside this advanced cell, driving force from the electric current and proton

exchange energy split water into pure hydrogen gas (H2) and high portion ozone (O3) contained oxygen gases (O3+O2)

without using any chemicals. Then, the hydrogen water and ozonated water are to be created by dissolving these

gaseous streams in water individually once usage is requested.

Therefore, you can choose between Ozone Water for Disinfection (the upper motion sensor) and

Hydrogen Water for Drinking (the lower button):

This is the natural bactericidal agent and disinfectant, effective against infestation of harmful

bacteria and virus as well as dangerous chemical and pesticide residues. It is highly effective,

efcient and free of residues.

Ozone Water

High-reducing power hydrogen water helps neutralize harmful free radicals, which further helps with

health improvement, anti-oxidation and anti-aging.

Hydrogen Water

Introduction Introduction

Important Safety Warnings and Precautions

These safety precautions and warnings are provided at YOUR benefit to your health and home,

for the safe and proper use of this unit and can prevent danger, bodily harm and/or possible damage

due to misuse.

Please make sure you are familiar with all the safety precautions and warnings associated with

this unit.

Biolux is not responsible for any damage or injury caused by not adhering to these precautions and

warnings.

When moving the unit, please be sure not to drag by the power cord as this could cause electric shock.

Do not place ANY objects on top of this unit regardless of how small.

Do not pull the power cord. Never touch power cord or power outlet with wet hands.

Do not use power surge protectors with this unit. Use unit with its own dedicated power source.

Do not forcibly bend, squeeze, damage or crush the power cord under heavy objects.

Do not use the unit in a dusty place. This may cause the unit to malfunction.

Do not spray water on the main unit. Do not clean with a damp cloth or any chemicals, which may leak into

the unit.

Do not place this unit on an uneven surface. Do not drop or use excessive force on this unit.

Place this product near a sink and always allow water to drain into the sink and drain.

Please be sure to keep the power cord dust free.

In case water leaks out of the unit (other than hoses) or unit is standing in a puddle of water, shut off the

water supply, unplug the power cord and refer servicing to qualied service personnel.

In the event that water gets into power supply, unplug the power cord and completely dry power outlet.

In case of strange noises, burning odor or smoke, unplug the power cord immediately and refer

servicing to qualied service personnel.

Replace pre-filter at least every 12 month or follow the recommendation from manufacturer in order to

optimize the purication performance of this unit even if the replacement indicator light isn’t turned on.

Do not poke or scratch the touch pad or LCD display with sharp objects.

Keep original packaging for storage or unit transportation.

If the power cord develops a break or short, stop using the unit and call customer service to have it replaced.

Do not reconnect or splice a defective power cord as it could result in electric shock or become a re hazard.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Please read these pages carefully. They contain very important information to protect you and the valuable

warranty on your unit. Please make sure you are familiar with all the safety warning and precautions associated

with this unit.

WARNING

Could cause personal injury or have an adverse effect on health.

Never drink ozonated water. (Ozone water is for disinfection only, not for drinking.)1.

2. Only use potable drinking water in your Hydrogen Fountain. It is recommended that you use potable municipal

water as source water (raw water).

3. Poor water quality may have negative effects on your health and your Hydrogen Fountain! Most potable

municipal water sources will be ne in your unit. If on hard water please ask about pre-treatment options.

4. Well water and water from smaller system should be checked, and may require pre-ltering. Your Hydrogen

Fountain is not under warranty for any damage or required cleaning by hard or poor quality water deposits.

5. Do not move the unit by the front cover. Move the unit by putting both hands underneath it. This will prevent

the unit from falling during movement.

DANGER

1.

2.

3.

4.

5.

6.

7.

To reduce the risk of electric shock, do not remove cover; no user-serviceable parts inside. Refer servicing to

qualied service personnel. Remove the cover will void the warranty.

Do not try to x the unit yourself. Call the dealer to have it xed by a qualied technician.

Do not use if the power cord is damaged or in a loose power outlet.

Never run hot water through this unit. Connecting it to a hot water (>35°C) source could damage the iEOG cell

or other parts of the Hydrogen Fountain.

Power and water MUST be connected at all times! Do not plug and unplug power cord repeatedly. The

product’s limited warranty does not cover any damage to the iEOG cell resulting from power disconnection for

many times repeatedly. Reconnecting power for 72 times (or more) a year will void the limited warranty to the

entire product.

Protect your unit from freezing temperatures or from direct sunlight.

Keep the unit and power cord away from hot surfaces or appliances – failure to do so may result in electric

shock or re!

Could cause damage to Hydrogen Fountain and possibly void the warranty.

Risk of Fire and Electric Shock

CAUTION

3 4

Introduction Installation

Product Features Package Contents

Sensor and/or touch button and color LCD screen for simple operation.

•

For health improvement, anti-aging and home sanitation.

•

99.995% pure Hydrogen and NOx-Free Ozone in outputs.

•

Zero latency operation, high concentrations right on starting-up.

•

Built-in gas-liquid separation and off-gas destruction at all time.

•

ORP (oxidation-reduction potential) and mv (millivolts) displays.

•

ppm (concentration of dissolved ozone) display.

•

Automatic self-cleaning and internal disinfection.

•

Food-grade and antioxidant/ozone-compatible piping and plumbing materials.

•

Certications granted by major global authorities in certication of disinfection.

•

Sufcient ow design for family use.

•

Modern design for enhanced decor.

•

Remark: The output concentrations may vary depending on intervals of usage and inuences from input pressure

and temperature.

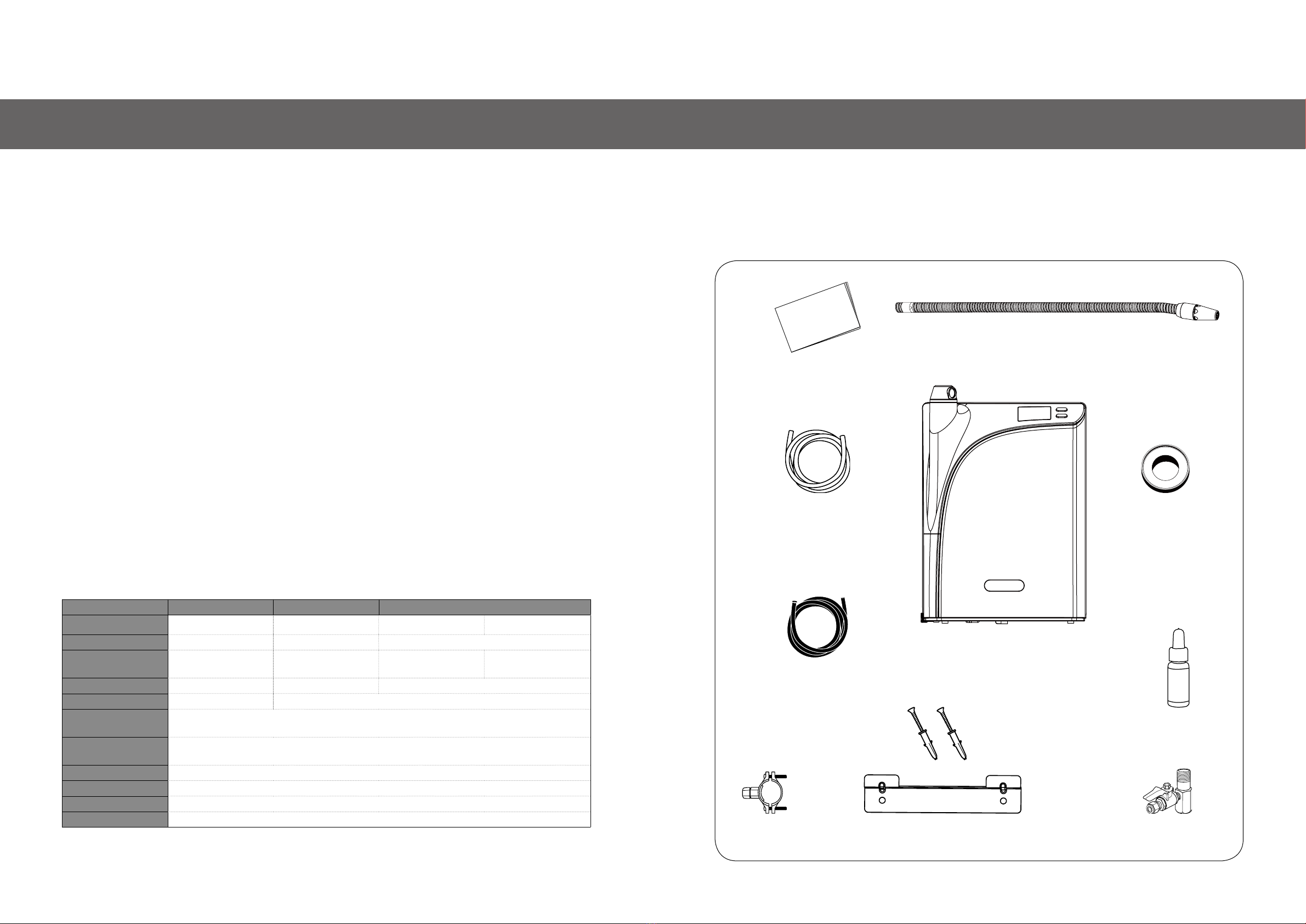

Out

Hydrogen Fountain Specications

−

Hydrogen Fountain Main Device (x1)

Owner’s Manual ( x1)

Water Outlet Tube (x1)

Drain Clamp

Plumber’s Tape ( x1 )

Mounting Bracket ( x1 ) with Screws ( x2 )

Input Hose ( PE, white, 1.5 m )

Drain Hose ( PVC, black, 1.5 m )

Connecting Adapter

OM100 Titration Ink (x1)

(Dissolved Ozone Measurement)

65

Model: EOS7130-HG

Output Features Pure Hydrogen Hydrogen Water Ozone Water

Activation method Air valve switch

(Continuous)

Touch Button 0.2s

(5min output)

Sensor 1s

(20s output)

Sensor 3s

(5min output)

Output ow 40ml/min±10% 90L/hr (1.5L/min) 180L/hr (3.0L/min)

Concentrations > 99.995%

(Hydrogen Gas)

>1200ppb

(Dissolved Hydrogen)

4.3ppm

(Dissolved Ozone)

4.3-1.0ppm

(Dissolved Ozone)

ORP - -518 ~ -558mv -

Output pH - Neutral (No pH change to the incoming water)

Applicable water

quality at the source

Tap water that meets quality criteria for drinking water

(hardness of <200 ppm CaCO3, residual chlorine of <0.1 ppm, conductivity of <500 μs/cm, pH6.8~8.0)

Applicable incoming

water pressure 2~7kg/cm2(3kg/cm2is optimal.)

Required voltage AC 100 ~ 240V / 50 ~ 60Hz

Consumed power 60W (In standby≤30W)

External dimension 300(W) x 165(D) x 400(H) [mm]

Net Weight 7.5kg (Around 9.5 kg at a full level)

Installation Installation

Unit Overview LCD Display & Control Panel

Front View

Water Outlet Cap

Motion Sensor (Ozone Water)

Control Button (Hydrogen Water)

LCD Display Screen

Water Outlet Tube

Rear View

Hanging Grooves

Water Inlet Fitting

Drain Fitting

Hydrogen Gas Outlet

Programming Port (Service Use Only)

Power Cord

Note: The Water Outlet Cap comes with a removable plug that needs to be removed prior to Water Outlet Tube

installation. Please see page 15 for further instruction.

Ready Indicator

The ready indictor shows the system is ready and output functions are available for use.

Error Indicator

When the system displays a ashing red error icon, this means there is a detectable error or problem, which has

caused the system to stop function normally. Conditions which can attribute to an error could include the following:

E10, Faulty iEOG generator (iEOG cell)

•

E45, Water Input Failure (iEOG water lling process timeout)

•

E60, Internal water leakage

•

E75, Power off exceeding number limitations

•

Due for service (consumable parts)

•

Disinfection

Drinking

Waiting Indicator

The waiting indicator indicates to wait for certain amount of time before functions can become available.

This waiting requirement can be indicated by two modes - light on/blinking under following conditions:

Light On:

First time start-up - The waiting icon will stay on until system preparation (iEOG water lling process) gets ready

(30 to 55 minutes based on input pressure).

•

Blinking:

Drinking pre-ush - The waiting icon will remain ashing during the rst 7 sec of hydrogen water output.

•

Automatic internal cleaning - The waiting icon will remain ashing during the cleaning is in process.

•

Re-start - The waiting icon will remain flashing until a compulsory time out period for re-start protection is

completed (30 minutes).

•

87

Installation Installation

System Temperature

System’s temperature is measured and displayed during normal standby for user’s reference. Standard display is

in Degrees Celsius; Degrees Fahrenheit is optional. Please consult technician for setting.

Output Feature Indicator

Lighting up when specic function is selected. blinks during drinking pre-ush.

Parts Per Million Display

PPM stands for Parts Per Million (or mg/L), referring to the relative dissolved ozone concentration of the ozone

water output.

Oxidation-Reduction Potential Display

ORP stands for Oxidation-Reduction Potential, expressed in "mV" (millivolts), referring to the relative anti-oxidation

power of the hydrogen water output.

Ozone Performance Meter

The performance icon shows the performance charge level, from full to empty when using continuously,

filling to full in standby. When the meter shows that every segment is filled, the system is ready with peak

performance on standby.

Performance at peak

Full

Consuming or recharging performance

Vanished/Appeared

Performance at baseline

Empty

Internal Cleaning Indicator

CLEAN shows that the system is processing internal cleaning. All functions are suspended and little noise is normal

during this cleaning period. This function is available both for automatic and manual. In manual mode the water

will be discharged from the output.

Power Disconnection Warning

Service Notication

Call customer service notication

CLEAN shows that the system is processing internal cleaning. All functions are suspended and little noise is normal

during this cleaning period. This function is available both for automatic and manual. In manual mode the water

will be discharged from the output.

Phase 1 - Within allowed power disconnection limits :

This icon is displayed when:

•

•

Phase 2 - Exceeding allowed power disconnection limits :

•

Displayed together with accumulated power off times.

- Service due.

- Error detected.

Displayed together with ERROR (E75) and accumulated power off times (Disconnection reached 72

times or more).

Service due in 3 weeks. Check service code(s).

Blink

Service due, functions suspended. Check service code(s).

On

•

•

• •

•

•

Metering life-cycle consumption for :

- iEOG module(Left)

Blinking when :

- Showing Power Disconnection Warning

- Exceeding power-off limits (equivalent to E75 code).

- Pre-filter(Right)

Disinfection

Drinking

•

•

Ozone Water Motion

Sensor

Hydrogen Water

Button

Full

Empty

Level Indicator

109

Installation Installation

How to Install the Unit

Consult your local Biolux dealer for installation arrangements. The information described below in this section is

intended for user’s reference.

The most common configurations for home kitchens are discussed here. For additional installation options or

questions on your specic installation, please contact your regional Biolux service provider.

Tool You Will Need

Plumbing and Installation Instructions

A typical scheme for installation of Hydrogen Fountain is shown below. Please follow all local plumbing and

construction codes in setting up the unit and all required water input, output and drain plumbing in accordance

with the scheme.

Diverted Water Line

Isolation

Valve

Pre-Filter

Output

DrainCold Water In

Main Water Line

Typical Scheme of Installation

1. Unit location and setup

2. Locate a source for input water

3. Setup input water pre-lter

4. Connect input water and drain hoses

5. Setup and connect the water output

Instruction 1 – Counter-top or Wall-mount Installation Overview

Determine if you will place your unit simply on a stable counter or mount it on a wall near and above a sink. To

mount the Hydrogen Fountain, please follow the directions below:

1. Drill two 6 mm holes with 30 mm in depth in the wall 400 mm above the top of the sink or counter. The

distance between the 2 holes must be 100 mm.

2. Press the plastic anchor inserts into the holes as pictured below. Push the plastic anchor insert so that the

opening is ush with the wall.

3. Place the mounting bracket on the wall and x with screws as pictured below. Hang the unit on the mounting

bracket.

Hanging Grooves

100mm

400mm

6mm

1211

Important: Instruction 2 – Input Water Setup

Installation Installation

For counter-top installation, two 10 mm holes on the counter will be required for passing the input water and drain

hoses through the surface. This is in order to allow the connections from the back of the unit to under sink area for

input water and drain.

Below drawing shows the installation and relevant plumbing as installed with a counter-top scheme:

100mm

PS. before U trap

Hanging

Grooves

10mm holes x2 110~240V

Connect to drain

Tap water input

6mm

Find the ½" to ⅜" Ball Valve T-Adapter (diverter & valve) in the accessory box. Assemble and seal the threaded

connection with the plumber’s tape included in the accessory box:

1.

Instruction 3 – Setup Input Water Pre-Filter

Select an easy-to-access location and install your input water pre-lter between cold water supply and the unit (ex.

under the sink). It should be noted that after ltration water quality must meet your local standards for drinking

water requirements.

Locate the cold water supply under the sink. Shut off water supply.2.

Connect the adapter to the cold water line between the wall and the sink faucet as follows:3.

Connect the unit to the cold water line with input water pre-lter in between.4.

Input hose

Screw anchors

Washer

Diverter & Valve

To your existing faucet

Water ow direction OD 1/2"

ID 1/2"

1413

Installation Installation

Instruction 4 – Input & Drain Connection

Remove the joint tube from the unit’s inlet and outlet ttings on the back of the unit. This joint tube is used for

shipping purposes only.

1.

Find the input hose (white) and drain hose (black) in the accessory box.2.

Insert the input hose into the unit’s tting (COLD WATER IN). Tightly screw the nut onto the tting to secure the

hose into place. Then, attach the drain hose to the unit’s drain tting (DRAIN).

3.

For counter-top installation, two 10 mm holes on the counter will be required for passing the input water and

drain hoses through the surface.

4.

Setup the drain hose under-sink connection:

Drill a 10 mm hole into the sink drainpipe and install the drain hose with the drain clamp (included accessory)

in accordance with the below scheme.

5.

Insert and lock the Input water hose (white) into

“COLD WATER IN” fitting (white). Attach the drain

hose (black) to “DRAIN” tting (black).

PS. before U trap

Instruction 5 – Connect Water Output

To locate the water outlet, remove the plastic cap positioned at the top of the unit (rotating water output cap).

Find the exible water outlet tube in the accessory box. Screw the tube anticlockwise into the water outlet

until there is no gap. Do not over tighten.

1.

LOCK

OPEN

Instruction 6 – Nasal Cannula Installation Kit & Instructions

Your Hydrogen Fountain applies patented iEOG technology which uses membrane electrode in indirect electrolysis

process. Pure water is used in the electrolysis to produce not only the ozone but also pure hydrogen gas with purity

>99.995%. When the hydrogen is used directly, due to the gas has moisture, using a Liquid Collector bottle before

the nasal cannula to block the moisture will prevent water from going into the nasal tubing and promote your

comfort and convenience when using the gas directly.

1615

Pay attention on the angle of connections. Be sure not to compress or bend the pipe.

Recommended to attach the "Liquid Collector" bottle on the side of the unit at

around 1/2~1/3 height position.

PACKAGE CONTENT

Liquid Collector (1x) Connection Gas Pipe (30cm, 1x)Bottle Holder (1x) Nasal Cannula (2m, 1x)

Remove the lock buckle on the gas supply switch valve

quick-connect tting on the "Liquid Collector" bottle.

❶

Install the gas pipe into the switch valve tting.

❷

Push the pipe to the end and then pull it reversely a bit to

secure the attachment.

❸

Put the buckle back on the tting.

❹

Connect the "Liquid Collector" bottle to the other end of "Connection Gas Pipe" : 3.

Fix the location of "Liquid Collector". Using the included "Holder" to hold and

attach the "Liquid Collector" bottle on the side of the unit or on the wall near the

unit.

NOTE: How to Install Quick-Connect ("Push to Connect") Fittings:

To install a pipe into a Quick-Connect ("Push to Connect") Fitting, rst remove the lock buckle on the tting.

Push the pipe into the tting to the bottom and then pull it reversely a bit to secure the attachment. Finally,

put the buckle back to complete the connection. If the pipe was cut, make sure the cut surface is at. To

remove the pipe, remove the lock buckle rst. Push the pipe and the tting's head to the bottom and then

hold the position of the head to pull out and remove the pipe.

4.

INSTALLATION

Remove the lock buckle.

❶Push the head to the bottom

and hold the position.

❷Remove the seal plug.

❸

Insert the pipe into the hydrogen gas supply outlet.

❶

Push the pipe to the end and then pull it reversely

a bit to secure the attachment.

❷

Put the lock buckle back on the tting.

❸

Connect the "Connection Gas Pipe" to the hydrogen gas supply outlet quick-connect tting and secure the

attachment:

2.

Remove the seal plug from the hydrogen gas supply outlet quick-connect tting on the main device:1.

1817

InstallationInstallation

Operation & Use

Unit Start-Up

Conrm all below points prior to start-up:

The following sequence of steps must be followed for manual shut-down:

The unit is switched ON by plugging the cord into wall outlet (power supply). There is no ON/OFF control switch.

Before plugging unit into wall outlet, all plumbing works should be completely set up.

The Hydrogen Fountain is intended for constant power-on, unless in necessary situations, such as before machine

servicing activities.

The unit can be switched OFF by un-plugging the cord from wall outlet (power supply). Before shutting down the

unit, the water supply to the unit should be completely turned off.

To use the machine at the rst time, connect the unit to power to switch on and the system preparing indicator

“ ” will light up on the display panel. At this point, the unit is in preparation stage relling water for iEOG

start-up. This process will take about 30~55 minutes according to water pressure.

Note: Draining during this stage is normal.

Once this preparation phase is complete, the “ ” will go out automatically, and “ ” will light up,

indicating the unit is now ready for use. At this point, the panel displays the detected internal system temperature

on the display panel, too.

All inputs, output and drain are correctly installed to their corresponding connections.1.

Shut off water supply.1.

Ensure that the unit is connected to cold water supply input.2.

Turn off the system by un-plugging the cord from the wall outlet.2.

The power supply meets the requirements as indicated in the product specications.3.

Input water pressure is 2.0~7.0 kg/cm2 (29~100psi).4.

The area of operation is well ventilated.5.

Connection Check

Initial Start-Up

Conditionally Shut-Down

Re-Start & 30 Minutes Re-Start Protection

Note: Disconnecting the power frequently may cause unexpected impacts on the iEOG module and result in

degradation to the product performance. 72 times of power off in a year will void warranty.

To re-start the unit, connect the unit to power to switch on. In system re-starting, all functions are suspended for

30 minutes along with “ ” ashing slowly (blink/0.5 sec). During this waiting period, maintenance program

is running at background for self-check.

Operation & Use

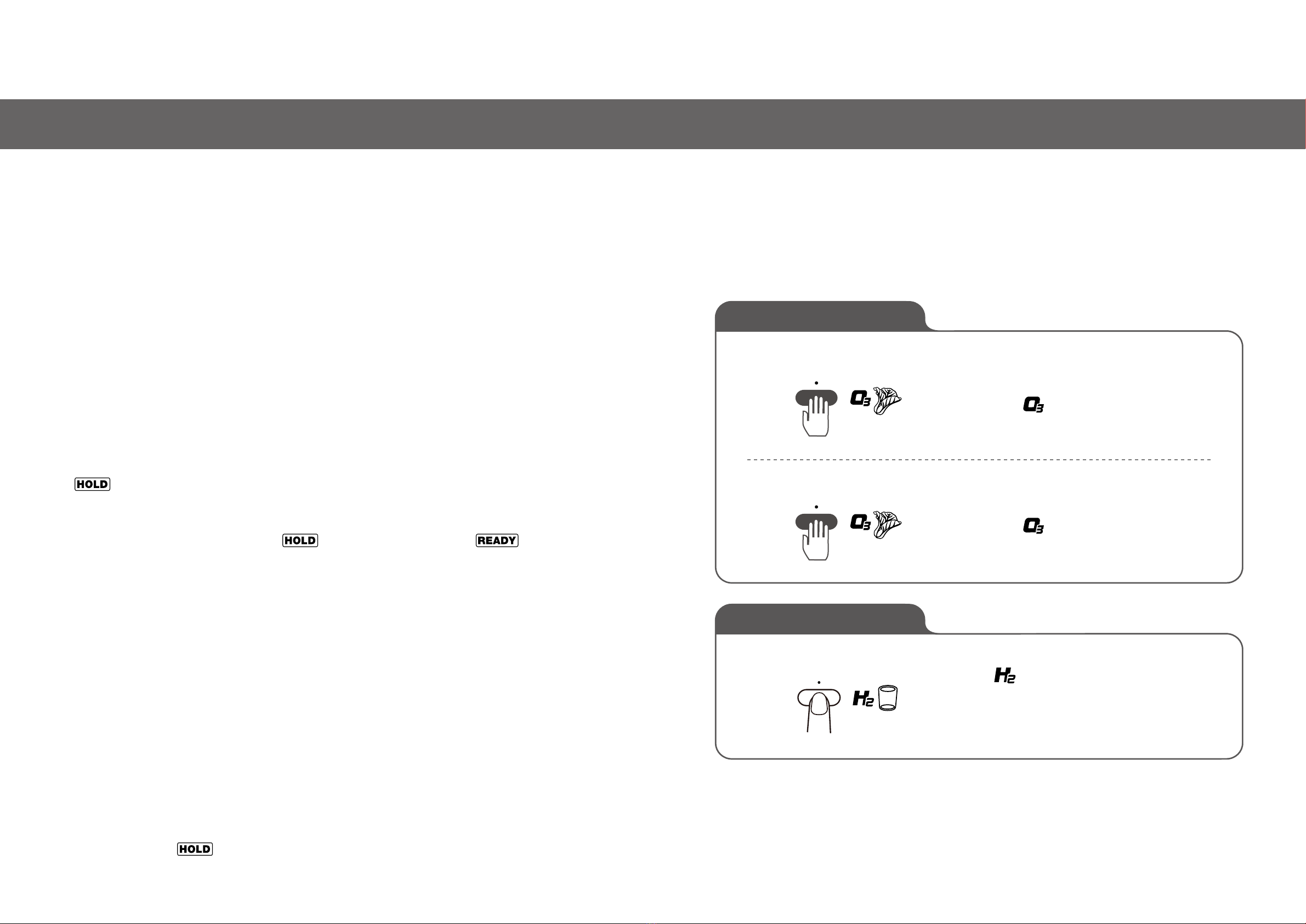

Directions for Product Use

Select a desired water mode: you can choose between Ozone Water for disinfection (using the motion sensor) or

Hydrogen Water for drinking (pressing the lower button) following the below instructions:

SENSOR 1 SEC to activate 20 sec ozone water output; Sensor

1 secagain to stop. " " icon is displayed during output.

1. 20 SEC Ozone Water Outow

2. 5 MIN Ozone Water Outow

Disinfection

Disinfection

Beep~

Beep~

SENSOR 1 SECOND

SENSOR 3 SECOND

SENSOR 3 SEC to activate 5 min ozone water output; Sensor

1 sec again to stop. " " icon is displayed during output.

To Select Ozone Water

1. 5 MIN Hydrogen Water Outow

Drinking

Beep~

0.2 SECOND

Press once on the lower button and again to stop

To Select Hydrogen Water

The specific " " icon is displayed during output. If the

button is not pressed again, the unit will automatically stop

after 5 minutes of water outow.

Note: a LIGHT PRESS is all that is required when pressing the button.

2019

Follow below directions for setting or reset life reset:

Operation & Use Operation & Use

The monitored remaining lifecycle for the

pre-filter is displayed on the right side

“Life Meter” on the display. Each segment

represents 10% of the monitored remaining

lifecycle.

After the lter is replaced, follow above instructions to reset the life.

Pre-Filtration Service Indicato

Pre-Filtration Monitoring Program Setting & Life Reset

By default, Hydrogen Fountain is available with “Pre-Filtration Service Indicator” - the “Life Meter” on the right side

of screen that can assist user to monitor the replacement cycle of the lter(s) (or the cartridge(s)). There are total

of ten monitoring programs based on treatment capacity for options, from “PF00” to “PF09”. If monitoring is not

required, select “PF00” to deactivate the function. Otherwise, select your option based on the capacity provided by

the manufacturer of the product:

• •

•

•

•

•

PF00 : ∞ L ( ∞ gal) PF05 : 25,000 L ( 6,604.5 gal)

PF06 : 30,000 L ( 7,925.4 gal)

PF07 : 35,000 L ( 9,246.3 gal)

PF08 : 40,000 L (10,567.2 gal)

PF09 : 45,000 L (11,888.1 gal)

• PF01 : 5,000 L ( 1,320.9 gal)

• PF02 : 10,000 L ( 2,641.8 gal)

•

•

PF03 : 15,000 L ( 3,962.7 gal)

PF04 : 20,000 L ( 5,283.6 gal)

Hold and press the lower button for 30 seconds to enter the setting mode.

Step 1

Use the sensor to select program from PF00 to PF09 according to the lter’s capacity.

Step 2

Press the “Lower Button” to save the setting and one beep sounds. Once the setting is conrmed, the life

will also be reset to full.

Step 3

To Use Hydrogen Gas

2221

NOTES & RECOMMENDATIONS

Before and after use: Clean and sanitize the Liquid Collector bottle (inside & to the

ttings) using ozonated water from the main device.

After Use: To ensure normal function for the main device, be sure to close the valve switch for

the hydrogen gas supply.

The main device's automatic internal cleaning function will not affect the supply of hydrogen

gas. The usage can be continued if the cleaning mode is on.

In the Use: Make sure the water level does not exceed the maximum scale marked on the bottle.

a.

Avoid to operate other functions from the main device (i.e., Hydrogen Water or Ozonated Water Output)

b.

Must keep the tubing and the relevant parts away from re or any source of ignition.

c.

INSTRUCTION OF USE

Fill water in the Liquid Collector bottle to the marked minimum level. [Using hydrogen water from the

unit is recommended.]

Remove the seal plug from the gas outlet on the Liquid Collector bottle. Attach the nasal tubing.

Open the switch valve on the bottle. Discharge the output for 3 min before use.

After the use, be sure to close the switch valve on the bottle and put the seal plug back on to the outlet.

Before attempting to use the hydrogen gas with nasal tube application, ensure the main device is in

normal standby mode (seeing a solid on ).

1.

2.

3.

4.

5.

Operation & Use Operation & Use

Internal waterline cleaning and disinfection

Automatic

Manual

Backstage Control Panel

The backstage control panel is for service use only. The display status is shown as below:

If the status of backstage control panel is entered, press and hold the lower button for 5 seconds to return to

standard user phase, or await 30 seconds to return to the user phase automatically.

Internal waterline cleaning and disinfection will be performed automatically. Icon “ ” will light on as an

indication. Internal tubing will be washed and sanitized by ozonated water and the water will be discharged through

the drain. All functions are suspended during this cleaning and disinfection process !

Press the lower button for 20 seconds can run this function in manual mode. Icon “ ” will light on to

indicate the operation and water will be discharged from the output. All functions are suspended during the

process !

The Hydrogen Fountain can display various Service Codes as notifications to users when standard service is

required. The information is displayed on the display panel. Please contact your regional Dealer for service

arrangements when the code(s) are present.

For Remaining Lifecycle of any consumable part that is recorded, the unit will provide service notication once the

service or replacement is required. The Service Notication will be displayed in two different modes according to

the degree of urgency: “ 2% Remaining Notication” and “Life Ending Notication ” .

Service Notication Displays

2% Remaining Notication

In this mode, “ ” is ashing in slow mode, 2 beeps are sounded when pressing any key. At this time, the user

should contact the local dealer to schedule a service and part replacement within 3-week time.

Life Ending Notication

In this mode, 10 second buzz will be sounded when the state occurs, “ ” lights up, 5 beeps are sounded when

pressing any key. All functions are suspended. At this time, the user should contact the local dealer to schedule a

service and part replacement IMMEDIATELY.

Drinking pre-ush

Other Functions

Drinking pre-ush lasts 5 seconds and is performed during hydrogen water outow after more than 20 minutes of

non-operation, or each time if ozonated water outow has been used previously within the 20 minutes.

“ ” , and “ ” will blink slowly on the display panel of the unit, indicating this ushing mode.

If an "internal cleaning (described below)" was performed within previous 20 min, the period of "Drinking Pre-ush"

will be extended, up to 25 sec.

After 7 seconds, the selected “ ” water mode will be dispensed.

2423

Operation & Use Operation & Use

The coding for each service requirement and the interpretation is listed as follows:

Wording translation: S11

Coding Interpretation: Replace Pre-lter

Wording translation: S31

Coding Interpretation: Replace Reverse Osmosis(RO) module

Wording translation: S32

Coding Interpretation: Replace Deionizer(DI) module

Wording translation: S34

Coding Interpretation: Replace Off-Gas Destructor

Wording translation: S38

Coding Interpretation: Replace Fan

Wording translation: S39

Coding Interpretation: Replace Input hose

Wording translation: S71

Coding Interpretation: Replace iEOG Cell

Service Code Service Requirement Interpretation

For following detectable errors, once detected, the codes will be displayed on the display panel:

Error Notications Displays

Wording translation: E10

Error Interpretation: iEOG Cell fails.

All functions are suspended.

Wording translation: E45

Error Interpretation: Preparation (timeout) iEOG water relling

fails during. All functions are suspended.

Wording translation: E60

Error Interpretation: Internal water leakage. All functions are

suspended.

Wording translation: E75

Error Interpretation: Power supply failure or power

disconnection exceeds 72 times a year recorded.

Error Code Error Interpretation

2625

An incident reminder will be displayed once a “monthly notifying point” is reached. At this stage, accumulated

number of power off incident at the time will be displayed on the panel, icon “ ” and “ ” will blink slowly,

and Icon “ ” will light on. This reminder is provided with intention to bring up attention to users with respect to

the fact that the accumulated number of power off incident has exceeded the acceptable number based proper

maintenance.

This status comes is present during the waiting period of 30 min re-start protection and can be removed and

returned to normal standby status by pressing any key after the completion of the waiting time.

At this point, users should read the displayed number on the panel, and call the dealer to discuss and understand

the circumstance if necessary. Most importantly, following effort should be made in order to try to avoid any further

incident of man-made power off.

The monthly notifying point will be determined by system to the recorded number of actual power off according to

the following statistical principle:

For example, the incident is notied once the 6th time of power off occurs within the rst operating month in total,

or the 12th time within the second operating month, and so on for the following months.

Considering proper maintenance, the acceptable number of power off incident averaged in each operating month

is 6 times.

Monthly notifying point = 6×N (times) [N.B.: N stands for operating month(s), N≥1]

Phase 1: Reminder notication to accumulated power off times

Determination of monthly notifying point:

Operation & Use Operation & Use

For 72 times (or more) power off in an operating year recorded by the unit, a “ ” as notification will be

displayed on the panel, together with the accumulated number of incident at the time displayed one after the

other. Similar to phase 1, icon “ ” and “ ” will blink slowly, and icon “ ” will light on.

All these displays is present during the waiting period of 30 min re-start protection and can be removed and

returned to normal standby status by pressing any key after the completion of the waiting time.

After removing the notication display, despite the icon “ ” will remain blinking slowly, all functions will still be

available for use after the status removed. However, impacts on the iEOG module may have been resulted and

degradation to the performance may have occurred. At this point, the warranty has become partially invalid. This is

for your reference that you should call your dealer to discuss your usage and discuss service if necessary.

Phase 2: Warning to power off limit

Drinking Hydrogen Water helps the selective scavenging of harmful ROS such as hydroxyl and peroxinitrites

and preserving the good ROS required.

Hydrogen is the newest antioxidant that is capable of increasing the cells and organs' antioxidant, anti-

inammatory and anti-apoptotic abilities. Meanwhile it protects DNA and ensures cell survival by its effect

against the possible cellular damages and/or deaths induced by hydroxyl radicals.

Hydrogen molecules as a powerful antioxidantcan quickly penetrate the biolm and then diffuse into the cell

membrane. It is therefore capable of resisting oxidative damage and promoting cell activation, enabling anti-

aging, aging prevention, and health improvement.

Drinking Hydrogen Water, through a reducing effect, neutralize the increasing excess free radicals formed

as a result of body acidification, effectively suppresses the symptoms and improve physical fitness after

acidication and restores health.

Hydrogen & Hydrogen Water

Recommendations for Using this Unit

1.

2.

3.

4.

Hydrogen molecules are small and can quickly penetrate the biolm and then diffuse into tissues, cytoplasm,

mitochondria and nuclei.

The effective dose of hydrogen molecules is not toxic. There is no concern about the safety problem of

excessive use of hydrogen.

Hydrogen is a moderate antioxidant, which does not interfere with the oxidation-reduction reaction of

metabolism.

Comparing to other antioxidants, hydrogen molecules has better compatibility with tissues and organs.

This is the reason that deep-sea divers tend to use hydrogen to replace oxygen to avoid lung damage.

In addition, no matter by orally or injection, hydrogen molecules can easily move to the lungs for easy

metabolism. This is extremely safe.

Hydrogen is a new antioxidant and is found to be better than currently known anti-oxidants with

following features:

1.

2.

3.

4.

To maintain the system’s best performance, power must be connected at all times. Unless in necessary situations,

such as due to servicing activities or supply outage that may occur occasionally and/or unexpectedly, attempt and

care should be made in order to avoid any man-made incidence of power off. Disconnecting the power frequently

and too many times may cause unexpected impacts on the iEOG module and will result in degradation to the

product performance.

Associated with the accumulated number of times of power off, system notification will be provided with two

phases. Phase 1 is to be provided as a reminder to the recorded number at the time, whereas phase 2 noties the

limitation reached and invalid warranty on the iEOG cell, i.e., 72 times of power off recorded in an operating year.

Power Disconnection Warnings

Note: To keep the warranty vaild, power disconnection should not reach to 72 times in an operating

year (6 times per month).

2827

Benets of Ozone Water

Operation & Use Service & Maintenance

Pure ozone and oxygen obtained from pure water electrolysis are used to prepare ozonated water at high

concentrations with the process of gas storage, nebulization and efficient pressurization and saturated

dissolution. It is safe and reliable in effectively killing bacteria and disinfection.

The ozonated water prepared with the pure ozone from pure water electrolysis by electrolytic hydrogen and

ozone generator is free from hazardous, or even carcinogenic, toxins such as nitrogen oxides (NOx), nitrates

(NO3) and nitrites (NO2).

Gained approval from U.S. Food and Drug Administration (FDA): pure ozone and ozonated water can be used

as bactericidal agents for foods as well as surface disinfectants.

Gained approval from U.K. Campeden BRI: the application can be used as bactericidal agents for terminal

disinfectants.

The design conforms with the requirements of UL (U.S.), CE (Europe), PSE (Japan) and SAA (Australia)

certications.

1.

2.

3.

4.

5.

Rinsing vegetables and fruits directly with ozonated water rapidly and effectively degrades pesticide residues

as tested by SGS: it removes pesticide residue in 1~2 minutes and makes the “ shelf life” longer.

Ozone water achieves rapid and effective disinfection and bacteria elimination. Certied by Campden BRI in

UK and SGS: 5 log kill in 10~20 seconds when used against E. coli, Salmonella spp., Staphylococcus aureus, P.

aeruginosa and C. albicans. (i.e., 99.999%)

Rinsing fish, shrimp, meat and poultry directly with ozonated water is associated with rapid and effective

disinfection, bacteria elimination as well as pollutant removal.

Ozone water rapidly and effectively eliminates any “shy smell” and odors when used for direct rinsing.

Ozone water has wide disinfecting and bactericidal applications in daily life: hand-washing, tableware,

household utensils, knives and forks, bowls and chopsticks, cutting board, cleaning rag, towels as well as

baby’s paciers, feeding bottles and diapers.

2.

1.

3.

4.

5.

Ozone is the most powerful bactericidal agent in the nature.

It becomes oxygen after it’s reaction with the following features:

Consumable Parts Life Cycle

Name of Parts Servicing Cycle

Depend on lter's capacity or at

least 1 year recommended

3 year

Pre-lter

Reverse Osmosis ( RO ) Assembly

Deionization ( DI ) Assembly

iEOG Cell

Off-Gas Destructor

System Cooling Fan

Input Hose

3029

Consumable Parts

Service & MaintenanceService & Maintenance

Troubleshooting Guide

Please check out the following troubleshooting suggestions before calling for repair.

Symptom Possible Cause Resolution

Display panel does not light up.

Plug the power cord in properly.

Unplug the unit and contact your

dealer to arrange service

Turn the water supply valve on.

Be sure the water supply hose is

connected properly.

Be sure the water line is not bent.

Replace the pre-lter Contact your

dealer to arrange service.

Connect the hose to the attachment.

Unplug the unit and contact your

dealer to arrange service.

Let ozonated water ow through the

unit for 5 minutes or more. If the water

does not improve, contact your dealer

to arrange service.

Unplug the unit and contact your

dealer to arrange service.

Contact your dealer to arrange

service.

Correct input water pressure and

then re-start the unit

Clean or replace as needed and

then re-start the unit.

Contact your dealer to arrange

service.

Contact your dealer to arrange

service.

Press any key to return to normal stand-

by, but contact your dealer for further

information and performance check.

Replace the notied part. Contact

your dealer to arrange service ASAP

Replace the notied part. Contact

your dealer to arrange service

IMMEDIATELY.

Is the power cord plugged in

correctly to an active outlet?

Electronic failure

Is the source water valve line

closed?

Is the source water line

connected?

Is the hose bent?

Is the water pressure too low?

Check to see if the hose is

disconnected.

Unknown.

Has the unit been unused for a

long time?

Unknown.

Faulty iEOG module.

iEOG water relling timeout by

low water pressure.

iEOG water relling timeout by

iEOG Pre-lter jammed.

Internal water leakage.

Unknown.

Power interruptions or re-start

exceeds 72- times a year.

2% life remaining notication for

iEOG pre-lter.

Service due and life ending

notication for iEOG pre-lter.

Water does not ow out or the

unit has stopped functioning.

Water is leaking from the hose at

the attachment.

Water is leaking from inside the unit.

The water has a strange odor or

tastes bad.

There is a strange noise coming

from the unit.

Display Code: E10

All functions suspended.

Display Code: E45

All functions suspended.

Display Code: E75

Warranty void for iEOG cell

Display Code: E60

All functions suspended.

Display Code: S11

2 beeps when pressing any key

Display Code: S11

All functions suspended.

10 sec alarming, followed by 5

beeps when pressing any key.

Symptom Possible Cause Resolution

Display Code: S31

2 beeps when pressing any key.

2% life remaining notication for

Reverse Osmosis module

Replace the notied part. Contact your

dealer to arrange service ASAP.

Replace the notified part. Contact

your dealer to arrange service

IMMEDIATELY.

2% life remaining notication for

Deionization module

Replace the notied part. Contact your

dealer to arrange service ASAP.

2% life remaining notication for

Off-gas Destructor

Replace the notied part. Contact your

dealer to arrange service ASAP.

Replace the notied part. Contact your

dealer to arrange service ASAP.

Replace the notied part. Contact your

dealer to arrange service ASAP.

Replace the notied part. Contact your

dealer to arrange service ASAP.

2% life remaining notication for

System Cooling Fan.

2% life remaining notication for

Source Water Hose.

2% life remaining notication for

iEOG Cell.

Service due and life ending

notication for Reverse Osmosis

module

Service due and life ending

notification for Deionization

module

Replace the notified part. Contact

your dealer to arrange service

IMMEDIATELY.

Service due and life ending

notication for Off-gas Destructor

Replace the notified part. Contact

your dealer to arrange service

IMMEDIATELY.

Replace the notified part. Contact

your dealer to arrange service

IMMEDIATELY.

Service due and life ending

notication for System Cooling Fan.

Service due and life ending

notication for Source Water Hose.

Replace the notified part. Contact

your dealer to arrange service

IMMEDIATELY.

Contact your dealer to arrange

service IMMEDIATELY.

Notication for iEOG Cell.

Display Code: S31

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S32

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S34

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S38

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S39

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S71

All functions suspended.

10 sec alarming, followed by 5 beeps

when pressing any key.

Display Code: S38

2 beeps when pressing any key.

Display Code: S39

2 beeps when pressing any key.

Display Code: S71

2 beeps when pressing any key.

Display Code: S32

2 beeps when pressing any key.

Display Code: S34

2 beeps when pressing any key.

3231

www.besgroups.com www.besgroups.com

Memo Memo

www.besgroups.com

Table of contents

Popular Water Filtration System manuals by other brands

Astral Pool

Astral Pool APR-3 Series operating instructions

Pegasus Astro

Pegasus Astro Indigo installation guide

Water Care

Water Care Ion Pro Series Installation instructions & owner's manual

Pure-Pro

Pure-Pro EC106R user manual

Pureit

Pureit Marvella instruction manual

Abus

Abus Security-Center ProfiLine TV8727 installation guide

Pure Water

Pure Water MINI-CLASSIC owner's manual

Pureit

Pureit ADVANCED PRO MINERAL RO+UV instruction manual

Aqua Medic

Aqua Medic Miniflotor Operation manual

Pureit

Pureit CLASSIC instruction manual

Aqua Guard

Aqua Guard Eterniti user manual

Water Care

Water Care TotalCare Series Installation instructions & owner's manual