Biosan Labaqua User manual

2

3

Contents

1. Safety precautions ...................................................................................................4

2. General information..................................................................................................5

3. Getting started..........................................................................................................8

4. Rinsing the system.................................................................................................11

5. Operation ...............................................................................................................12

6. TOC level reduction and monitoring.......................................................................14

7. Specifications.........................................................................................................15

8. Cleaning and maintenance.....................................................................................17

9. Warranty and Claims..............................................................................................18

10. Declaration of Conformity.......................................................................................19

4

1. Safety precautions

The following symbol means:

Caution! Make sure you have fully read and understood the present Manual

before using the equipment. Please pay special attention to sections

marked by this symbol.

Caution! Do not service the unit while the open UV lamp is switched ON.

Otherwise it can expose the operator to a dangerous level of UV

emission.

GENERAL SAFETY

Use only as specified in the operating manual provided.

The unit should not be used if dropped or damaged.

The unit must be stored and transported in a horizontal position (see package

label).

After transportation or storage, keep the unit at room temperature for 2-3 hrs before

connecting it to the electric circuit.

Use only cleaning and decontamination methods recommended by the

manufacturer.

Use only original accessories (fuses, tubes, etc.) provided by the manufacturer and

ordered specifically for this model.

Do not make modifications to the design of the unit.

Do not block any ventilation openings.

Do not operate the unit with its covers removed.

Do not drink deionized water.

WATER LEAKAGE SAFETY

Make sure that all water connection tubes are unbent, kink-free.

Make sure that all water connectors are tight.

When installing the tank, connect the fitting marked „Overflow” to the drain. Make

sure that the drain level is lower than the „Overflow” fitting level. This will prevent

water leakage in case of tank level sensor failure.

Do not operate the tank pump if there is no water in the tank. Tank pump may fail if

it is run dry.

A 5 μm sediment filter has to be installed in the feed water supply line. Failure to

install the filter may result in clogging of strainer inside the system and water flow

blockage.

Shut off tap water supply when leaving the system unattended.

ELECTRICAL SAFETY

A power line regulator may be required in the areas where the supplied power is

subject to voltage fluctuations exceeding 10% of the nominal.

Connect only to a mains outlet with voltage corresponding to that on the serial

number label.

Verify that the fuses are properly installed.

5

Do not plug the unit into an ungrounded mains outlet, and do not use an

ungrounded extension lead.

Ensure that the power switch and power connector are easily accessible during

use.

Disconnect the unit from the electric circuit before moving or performing servicing

tasks.

Turn off the unit by disconnecting the mains plug from mains outlet.

If liquid penetrates into the unit, disconnect it from the external power supply unit

and have it checked by a repair and maintenance technician.

Do not operate the unit in premises where condensation can form. Operating

conditions of the unit are defined in the Specifications section.

DURING OPERATION

Do not operate the unit in environments with aggressive or explosive chemical

mixtures. Please contact manufacturer for possibility of operation of the unit in

specific atmosphere.

Do not operate the unit if it is faulty or has been installed incorrectly.

Do not use outside laboratory rooms.

BIOLOGICAL SAFETY

It is the user’s responsibility to carry out appropriate decontamination if hazardous

material is split on or penetrates into the equipment.

2. General information

Water purification system “Labaqua” produces pure and ultrapure water that

complies with ISO 3696 Grade II and Grade I water requirements respectively.

Pure (ISO 3696 Grade II) water applications include, but are not limited to:

Feed for laboratory equipment (washing machines, clinical analysers, humidifiers,

autoclaves, hydrogen gas generators);

Manufacturing of chemical and biochemical reagents;

Buffer preparation;

Microbiological media preparation;

Sensitive analytical techniques (e.g. atomic absorption, ICP-OES).

Ultrapure (ISO 3696 Grade I) water applications include, but are not limited to:

High sensitivity analytical techniques (ICP-MS);

High performance liquid chromatography;

Molecular biology;

Cell culture.

6

There are two types of Labaqua water purification systems:

Labaqua HPLC –Ultrapure water system for analytical applications. Includes 25 l

water storage tank. Uses tap water as feed water, often referred to

as “tap water system”.

Labaqua Bio –Ultrapure water system for molecular biology and cell culture

applications. Includes 25 l water storage tank. Uses tap water as

feed water, often referred to as “tap water system”.

Principle of operation

The hydraulic diagram of Labaqua water purification system is shown below.

The solenoid valve (Fig. 1/1) controls intake of feed water from the tap. The first

purification stage consists of the pre-filter set (P/N 10019, fig. 1/2 and 1/3) that includes

sediment filter and activated carbon intended to remove particles, free chlorine, organics

and colloids. A pressure switch (Fig. 1/5) controls feed water pressure. If feed water

pressure falls below 0.7 bar, the system will automatically switch on the boost pump (Fig.

1/4) and “LowPres” message will be shown on the display.

The boost pump (Fig. 1/4) is used to maintain pressure at the level necessary for

the efficient operation of the reverse osmosis membrane (only in the tap water systems,

Fig. 1/9), deionization module (P/N 10310, fig. 1/12), and UV sterilization module (if

installed, P/N 10102, fig. 1/16).

From the boost pump, the feed flow goes to the membrane to be split into two parts:

the permeate, diffused through the membrane, and the concentrate, which passes over the

membrane, carrying away contaminants to the drain. The permeate goes to the third

purification step –the IonPro deionization module (P/N 10310, fig. 1/12) where the

remaining ions are removed.

Before entering the tank, water is sterilized by UV lamp (if installed, P/N 10102, fig.

1/16); water quality is controlled by Grade 2 water conductivity sensor (Fig. 1/11). LCD

display provides information about the system status.

Purified water is stored in the tank and recirculated on periodical basis. Water in the

tank meets requirements of ISO 3696 Grade II.

Fig. 1. Principle of operation

7

Water dispensing

To dispense ISO 3696 Grade I water, press the Pump Grade I key. The pump (Fig.

1/15) is switched on and water flows through photooxidation module (P/N 10105, fig. 1/16),

polishing cartridge (P/N 10030, fig. 1/17) and protective sediment filter (Fig. 1/18). After

several seconds the valve (Fig. 1/21) opens and Grade I water is dispensed via the 0.22

μm point-of-use microfilter. Labaqua Bio system has an ultrafilter instead of the microfilter.

To dispense ISO 3696 Grade II water, press the Pump Grade II key. Grade II

dispense pump is switched on, and water is dispensed via the “Out” port of the tank.

Possible Labaqua modifications

Labaqua HPLC: Ultrapure, equipped with photooxidation module for low TOC.

Labaqua Bio: Ultrapure, equipped with UV sterilization module, ultrafilter and photooxidation

module for low TOC.

8

3. Getting started

3.1. Unpacking.

Remove packing materials carefully and retain for them future shipment or storage

of the unit. Examine the unit carefully for any damage incurred during transit. The

warranty does not cover in-transit damage.

Caution! Due to the unit’s weight its unpacking and installing is to be carried

out by two persons.

3.2. Complete set. Package contents:

Standart set:

- Labaqua Bio / Labaqua HPLC unit....................................................................1 pce

- LLDPE tube, Ø1/4”, 3m.....................................................................................5 pcs

- point-of-use ultrafilter set (Bio) / microfilter set (HPLC)......................................1 set

- power cable.......................................................................................................1 pce

- prefilter cartridge ...............................................................................................2 pcs

- IonPro deionization cartridge.............................................................................1 pce

- polishing cartridge.............................................................................................1 pce

- controller module...............................................................................................1 pce

- Ø1/4” elbow.......................................................................................................5 pcs

- Ø1/2” NPTF tap water to Ø1/4” JG elbow adapter............................................1 pce

- Ø3/4” NPTF tap water to Ø1/4” JG elbow adapter............................................1 pce

- Ø1/2”NPT tap water to Ø1/4” JG adapter.........................................................1 pce

- Ø1/4” bypass tube with elbows .........................................................................2 pce

- Ø1/4” elbow with tube........................................................................................4 pce

- external storage tank, with pump, level switch and tap......................................1 set

- Ø3/8”with elbow, 3m overflow tube..................................................................1 pce

- Ø3/8”, 1m tank dispense tube...........................................................................1 pce

- tank cable..........................................................................................................1 pce

- hex key for controller module............................................................................1 pce

- Operation manual, declaration of conformity...................................................1 copy

Optional accessories:

- TOC monitoring module (integrated).........................................................on request

- 0.22 μm air vent filter for the storage tank ................................................on request

- Reverse osmosis membrane for higher capacity (20 L/h) ........................on request

- Electrodeionization module 10-30 L/h ......................................................on request

- Water storage tank “Comfort”

with level switch and dispense pump, 60 L ..............................................on request

- Water storage tank “Economy”

with level switch and dispense pump, 50 L ..............................................on request

- Water storage tank “Comfort” with dispense pump, 100 L .......................on request

- Water storage tank “Comfort” with dispense pump, 200 L .......................on request

- Water storage tank “Comfort” with dispense pump, 300 L .......................on request

- IQ/OQ documentation ..............................................................................on request

- For clean tap water with hardness < 130 ppm:

Pre-filter housing 10” with fittings .............................................................on request

Sediment filter 1 μm .................................................................................on request

- For muddy and/or hard tap water with hardness > 130 ppm:

Pre-filter set 3 x 10” with cartridges (polyphosphate, 5 and 1 μm) ...........on request

9

3.3. Pre-installation requirements

The Labaqua system can be placed on a bench or attached to a wall. If the system

is placed on the bench, allow space on the bench 500x500mm. Allow enough space

for the tank (DMH 400x400x600mm) under the bench.

Electrical connections: 230 V, 3A.

Feed water should be filtered with 5 μm sediment filter (not included).

Feed water should be filtered with at least one 5 μm sediment filter. If the filter is

not installed, the input strainer may become clogged thus blocking the water

flow, or pre-filter life can be reduced.

Sediment filter for tap water line is usually available from a local plumbing shop. If

necessary, the sediment filter set (that consists of 5 um sediment filter and 1 um

sediment filter) can be obtained (example below). The part number is 10168.

Attention! In case of Labaqua system pre-filter set (P/N 10019) pre-mature

clogging, we ship the new pre-filter under warranty only if we get a

photo of the sediment filter installed in the tap water line.

Feed water hardness does not affect produced water quality. However, operation of

the system with hard fed water may result in premature clogging of reverse osmosis

membranes and reduced Grade 2 water flow. Therefore, it is strongly

recommended to install a water softener or polyphosphate filter if water

hardness is above 160 ppm.

Drain level should be lower than Overflow port of the tank. Drain is required. The

water purification system is equipped with Ø1/4’’ drain pipe. Overflow port pipe is

Ø3/8’’.

Feed water outlet for Labaqua system connection has to be ½’’ or ¾’’ male thread.

A feed water outlet with ½’’ female thread is acceptable although not

recommended. The system is equipped with feed water tube (1/4’’ OD) and

adapters for ½’’ threaded outlets (male and female thread) as well as for ¾’’

threaded outlet (male thread). The feed water tube should be connected to the ¼’’

JohnGuest fitting of the adapter. Feed water outlet should be equipped with a valve

for shutting off water supply.

10

3.4. Setting up

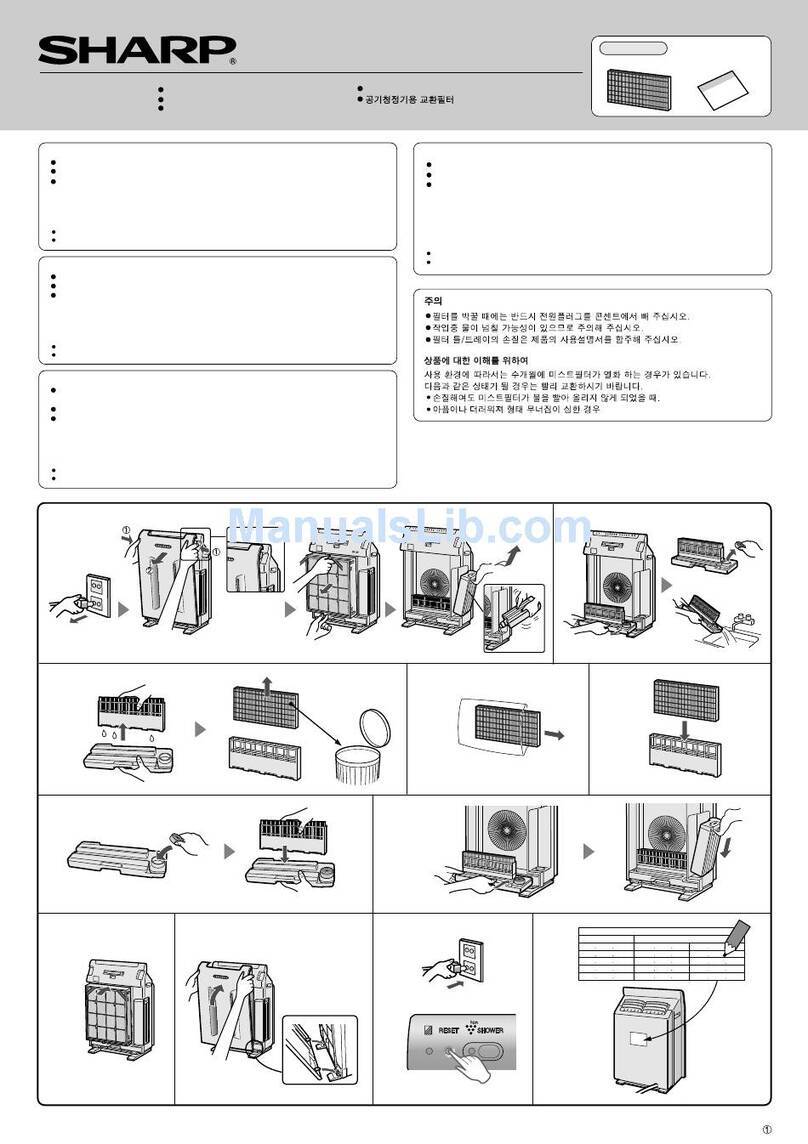

3.4.1. Install the controller module and connect the cable (Fig. 2/1).

3.4.2. Carefully attach the controller module to the holder at the top right of the system

(Fig. 2/2)

3.4.3. While the system is disconnected from mains, it is recommended to carefully

remove the rear panel and check for any transportation damage. Reinstall the panel

before connecting the power cable to 230V AC power supply socket.

3.4.4. Fix the controller module with two screws on the lower side of the module.

3.4.5. Unpack the microfilter/ultrafilter and screw it into the threaded outlet under the

controller module holder (Fig. 2/3). Before connecting, make sure that the sealing

O-ring is inside the holder.

3.4.6. Connect the feed water to the Ø1/4’’ John Guest inlet marked Tap Water. Use an

appropriate adapter from tap water to Ø1/4’’ tube, see p. 3.2. Tap water should be

filtered with 5-micron mechanical filter (not included).

3.4.7. Connect Ø1/4’’ JG connector marked Drain to the drain using Ø1/4’’ plastic tube.

Note: Unscrew the cap of the purified water storage tank and remove the

packing material inside.

3.4.8. Connect Ø1/4’’ John Guest outlet “OUT”to the inlet “In”of the tank.

3.4.9. Connect Ø1/4’’ John Guest outlet “Rec Out”to the inlet “Rec In”of the tank.

3.4.10.Connect Ø1/4’’ John Guest outlet “Rec In”to the inlet “Rec Out”of the tank.

3.4.11.Connect the tank cable to the TANK connector.

Note: If nothing is connected to the TANK connector, the system will show

“TnkFull”.

3.4.12.Connect the power cable. Make sure the system is properly grounded.

3.4.13.Connect approximately 1 m of Ø3/8’’ tube to the tank Out connector to ensure

convenient Grade II water dispensing. The end of the tube should be free and must

not be connected to anything. The backpressure will damage the pump.

3.4.14.Connect the Overflow connector of the tank to the drain with Ø3/8’’ tube.

Fig. 2. Setting up

3.5. Feed water and drain requirements

3.5.1. Feed water should be filtered with 5 μm sediment filter. If the filter is not installed,

the input strainer may become clogged and block the water flow. Life of pre-filters

can be reduced too.

3.5.2. Feed water connector port can be Ø1/2’’ (male or female) or Ø3/4’’ NPTF (male)

thread. The system is equipped with adapters for both water supply connectors.

The feed water tube should be connected to the Ø1/4’’ JG port of the adapter.

11

3.5.3. Tap water pressure should be above 0.7 bar.

3.5.4. Drain pipe should be lower that the level of the instrument and the level of the

Overflow connector of the tank. The water purification system has Ø1/4’’ OD drain

pipe. The Overflow connector of the tank is for Ø3/8’’ OD pipe.

3.5.5. Feed water supply connector and drain should be within 3 meters from the

installation site.

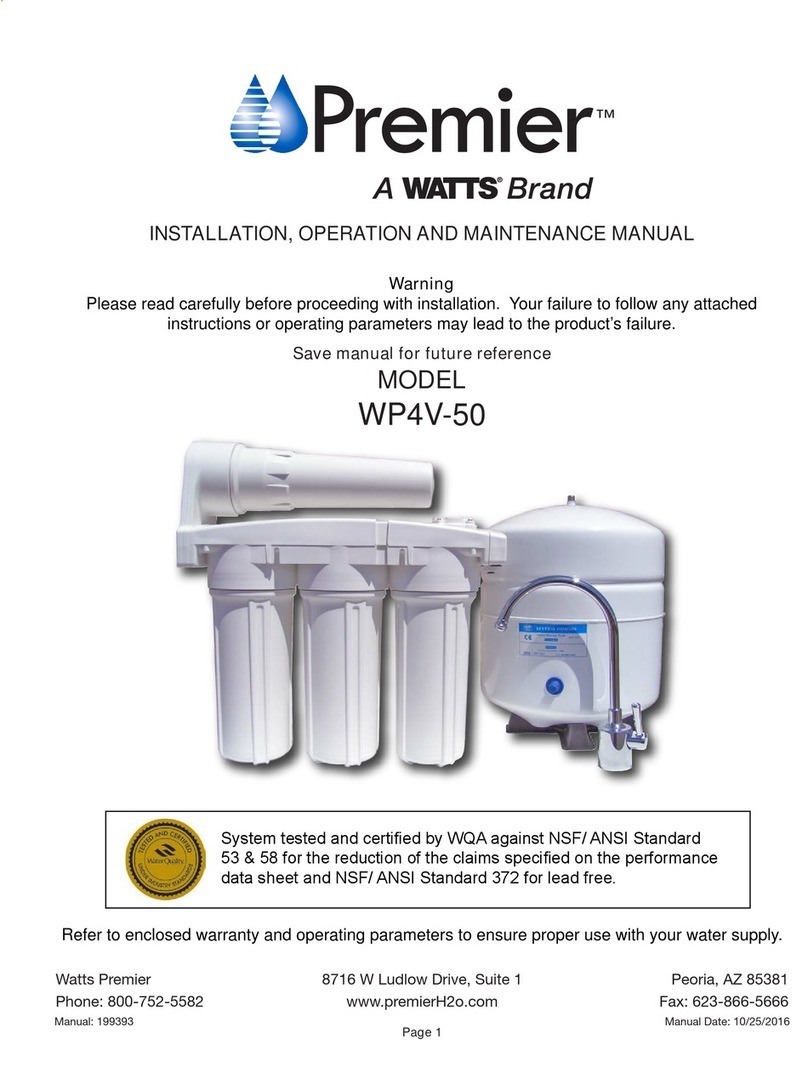

3.6. Deionization and Polishing module installation.

3.6.1. Push the stems in the ¼’’ elbows with ¼’’ tubes into the John Guest fittings of the

Deionization and Polishing modules.

3.6.2. Install the deionization and polishing modules. The positions of the modules are

marked with labels “IonPro deionization module” and “Polishing module”. Each

module has now John Guest elbows and short tubes installed. Open the front door.

Place a module at the labelled site; push the tubes into John Guest fittings at the

inner wall. Then attach the module fully to the inner wall by putting the latch at the

bottom of the module into slot on the wall.

3.6.3. Screw the pre-filters into the grey filter heads.

4. Rinsing the system

Note: The pre-filter should be rinsed prior operation and each time new

filter is installed. Failure to do so can lead to reduced life of the

reverse osmosis membrane.

Rinse the system according to the following procedure:

4.1. Open the front door. Disconnect the pre-filter outlet tube (right behind the prefilter

heads) from the John Guest fitting (see pictures below). Put a beaker under the

tube.

4.2. Switch on the unit. The display is switched on and “STANDBY” message is shown.

4.3. Open the tap water supply.

4.4. Press and hold the Run key (Fig. 4/8) for 2 seconds and collect approximately 1

litre of water and press the Run key to stop the water flow. The pre-filter is rinsed.

Note: If “TnkFull” message is shown then probably the tank plug is not

connected.

12

4.5. Reconnect the outlet tube to the outlet John Guest elbow.

4.6. Press Run key and wait until storage tank is filled with water.

4.7. Put the end of 3/8’’ tank “Out” tube into a sink, press “Pump Grade 2” and dispense

water from the tank.

4.8. Let the system fill the tank again. As the tank is full, ask the customer to leave the

system overnight (shut off tap water supply for safety reasons). The system will

recirculate water in the tank and get rid of organic compounds as well as rinse the

polishing module.

4.9. The microfilter (or ultrafilter) should be rinsed prior to use! Ask the customer to

press “Pump Grade 1” next morning and dispense water in the tank through point-

of-use filter (microfilter on Labaqua HPLC or ultrafilter on Labaqua Bio). The

microfilter (or ultrafilter) needs to be rinsed with at least 20 litres of purified water.

Fig. 3. Deionization and polishing module sites. The grey fittings above are used for

connecting the modules.

5. Operation

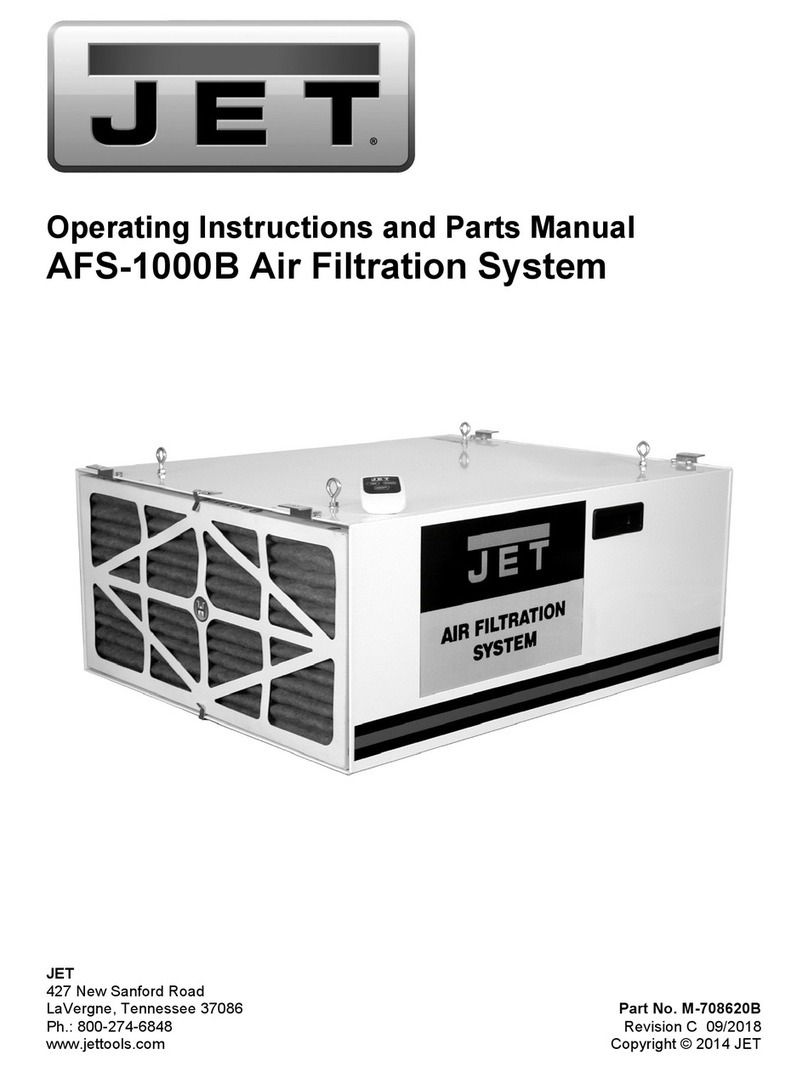

5.1. Switch on the system with the power switch. The display (Fig. 4/1) lights up after

few seconds.

5.2. The display shows information in several rows:

- system messages and current status;

- error messages, if present;

Status messages

Description

Standby

Labaqua is switched off and does not produce water to the

tank.

LowPres

Input pressure is too low.

TnkFull

The storage tank is full.

Disp.

Water is being dispensed.

Recirculate

Water in the storage tank is being recirculated

13

Error messages

Description

Filter

Pre-filter set (P/N 10019) needs replacement

DI Err.

Deionization module (P/N 10310) needs replacement

TankS

Tank sensor is damaged

Beeping sound during

“Running” stage

Sterilization UV bulb needs replacement.

- indication of current water grade (superscript) and water conductivity (precise

readings of water quality are shown when the system is in Running, Grade I

dispense or Recirculation mode);

- water temperature and filter life counter.

5.3. If the system is equipped with TOC (total organic carbon) level monitoring module,

display shows TOC reading (e. g. <2 ppb). TOC level reading will be shown only

after the storage tank is at least partially filled with water and recirculation stage has

started.

5.4. The purified water quality is controlled by two sensors. First sensor (Fig. 1/11)

measures and displays conductivity of Grade II water, flowing into or recirculating in

the storage tank. Second sensor (Fig. 1/19) measures and displays conductivity of

Grade I water that is dispensed at the moment.

5.5. Indication in superscript next to the conductivity can take values “1” or “2”, showing

current water grade.

5.6. To fill the tank with purified water, press and hold the Run key (Fig. 4/8) for 2

seconds. If tank is neither full nor disconnected and the feed water pressure is

enough, the display shows “Running”. Now the Labaqua system is filling the tank

with Grade II water. As soon as the tank is full, the system shuts down the water

supply and shows the “TnkFull” message.

5.7. To dispense Grade I water, press Pump Grade I key (Fig. 4/6). After five to ten

seconds, Grade I water is dispensed through the 0.22 μm filter. If ultrafilter is

installed, loosen the degassing valve to get rid of air. Press the Pump Grade I key

again to stop water dispensing.

5.8. To dispense Grade II water from the tank, press the Pump Grade II key (Fig. 4/7).

To stop dispensing, press the Pump Grade II key again.

5.9. System will circulate water on periodical basis to prevent growth of microorganisms

in the tank. During recirculation phase, the reading of Grade II water is shown on

the display. For the systems with TOC monitoring module, display shows TOC

reading in ppb. TOC reading appears in the left bottom display when purified water

storage tank is full and recirculation stage starts.

5.10. Recirculation is switched off when the system is in the Standby mode. To prolong

life of polishing module, please set the system to the Standby mode if it is not used

for long time (e.g. for the night).

5.11. Press Run key to toggle Standby mode on and off.

5.12. If feed water pressure falls, the display indicates “LowPres”.

Note: To actuate a key, press and hold it for two seconds.

14

Note: If the system is newly installed or has not been used for a long time,

it recommended to leave it in the Recirculating mode for several

hours before usage. It will allow the system to fill the tank and

recirculate water to reduce TOC content.

Fig. 4. Control panel of Labaqua Bio/HPLC

5.13. Navigating the menu. To enter menu, press Menu ESC key (Fig. 4/5). Press ▼ and

▲ keys (Fig. 4/2 and 4/4) to select options, OK key (Fig. 4/3) to confirm and Menu

ESC key to exit.

5.14. Menu consists of two options, “Reset filter counter” that is required to reset filter life

counter when changing filters, and “Options” submenu:

- switch between MΩ*cm and μS/sm conductivity units;

- set recirculation period (time between recirculation cycles);

- set recirculation cycle duration time;

6. TOC level reduction and monitoring

Total organic carbon (TOC) describes level of organic contaminants in pure water.

High concentration of organic contaminants may affect results of several analytical

methods, e.g. high performance liquid chromatography. Therefore, for some applications

TOC level should be controlled and kept minimal.

Grade II water coming to the storage tank generally has low TOC level if proper

deionization resins are used. However, TOC level may rise during storage, therefore water

recirculation through photooxidation module and polishing cartridge is necessary to keep

TOC level low.

Unfortunately, organic contaminants may not have effect on conductivity of water,

so conductivity sensors cannot be used for TOC level monitoring. A special TOC level

monitoring module is needed to measure TOC level. The monitoring module consists of a

TOC photooxidation module, valve and a conductivity sensor.

15

TOC monitoring module (optional) operation principle

During recirculation stage a water sample is introduced into the TOC photooxidation

module where it is oxidized for several minutes. During this phase, water conductivity rises

because of the oxidation of organic molecules. The rise of conductivity is proportional to

TOC level of water.

After the oxidation phase is finished, water is released from the TOC photooxidation

module and its conductivity is measured by the conductivity sensor. TOC level is calculated

from the rise of conductivity.

Note: As TOC level measurement is made during the recirculation stage,

the TOC level value is shown on the display only with storage tank

partially filled with water and during recirculation.

7. Specifications

The unit is designed for operation in cold rooms, incubators and closed laboratory

rooms at ambient temperature from +15°C to +30°C with maximum change at less than

2°C in 24 hours, in a non-condensing atmosphere and relative humidity between 20% and

80%. Biosan is committed to a continuous programme of improvement and reserves the

right to alter design and specifications of the equipment without additional notice.

7.1. Purified water specifications

Grade II water conductivity...................................................................... <0.1 μS/cm

Grade I water resistivity....................................................................... 18.2 MΩ x cm

Grade I water conductivity..................................................................... 0.055 μS/cm

TOC.................................................................................................................<2 ppb

RNase (Labaqua Bio).............................................................................<0.01 ng/mL

DNase (Labaqua Bio)..................................................................................<4 pg/mL

Bacteria.....................................................................................................< 1 cfu/mL

Endotoxins

Labaqua HPLC............................................................................................................................. <0.15 EU/mL

Labaqua Bio............................................................................................................................... < 0.001 EU/mL

Particles larger than 0.22 μm .................................................................... <1 per mL

Nominal flow, Grade II water............................................................................10 L/h

Dispense flow, ultrapure water.......................................................................2 L/min

Dispense flow, pure water..............................................................................4 L/min

Deionization module life (standard module).......................................................1 m3

Recovery......................................................................................................... >30 %

16

7.2. General specifications

Dimensions .................................................................................... 500x400x600mm

Weight*..............................................................................................................30 kg

Storage tank........................................................................................................25 L

Input current / Power consumption......................... AC 200-240 V, 50-60 Hz / 130W

Fuse...........................................................................................................220V, 3 A

Feed water pressure .................................................................................0.5 –5 bar

Feed water conductivity ........................................................................ < 900 μS/cm

Water connections ............................................Ø1/2’’ and Ø3/4’’ NPTF, Ø1/2’’ NPT

Optional accessories

Catalogue number

Integrated TOC monitor

BS-070102-S05

0.22 μm air vent filter for the storage tank

BS-070102-AK

Reverse osmosis membrane for higher capacity (20 L/h)

BS-070102-BK

Electrodeionization module 10-30 L/h

BS-070102-CK

Water storage tank “Comfort” with level switch and dispense pump, 60

L

BS-070102-EK

Water storage tank “Economy” with level switch and dispense pump,

50 L

BS-070102-DK

Water storage tank “Comfort” with dispense pump, 100 L

BS-070102-FK

Water storage tank “Comfort” with dispense pump, 200 L

BS-070102-GK

Water storage tank “Comfort” with dispense pump, 300 L

BS-070102-HK

IQ/OQ documentation

BS-070102-IK

For clean tap water with hardness < 130 ppm:

Pre-filter housing 10” with fittings

BS-070102-JK

Sediment filter 1 μm

BS-070102-KK

For muddy and/or hard tap water with hardness > 130 ppm:

Pre-filter set 3 x 10” with cartridges (polyphosphate, 5 and 1 μm)

BS-070102-LK

Replacement parts

Catalogue number

Pre-filter set

10019

Deionization module

10310

Polishing module

10030

Photo-oxidation module

10105

Photo-oxidation UV bulb

10018

Point-of-use microfilter*

10012

UV sterilization module**

10102

Sterilization UV bulb**

10011

Point-of-use ultrafilter**

10120

* Accurate within ±10%

* In Labaqua HPLC only.

** In Labaqua Bio only.

17

8. Cleaning and maintenance.

8.1. If the unit requires maintenance, disconnect the unit from the mains and contact

Biosan or your local Biosan representative.

8.2. Clean the exterior of the system with soft tissue. Do not use chemicals.

8.3. The water storage tank should be cleaned and disinfected every 2-3 months.

8.4. When the filter counter goes to zero, the pre-filters should be replaced.

- Press the Run key to set the system into the Standby mode.

- Open the front panel and unscrew old pre-filters.

- Rinse and install the new pre-filters (see 4. Rinsing the system).

- Close the front panel.

- Enter menu (see 5.13), select the “Reset filter counter”. Press OK key (Fig. 4/3) two

times to select and confirm.

- Switch off the system.

- Wait 5 seconds and switch on the system again.

8.5. Expendable parts and the replacement interval are shown below:

Description

Replacement interval

Catalogue number

Pre-filter set

When filter life counter goes to zero or

when the filter is clogged (LowPres

appears on the screen even if tap

water pressure is > 1 bar)

10019

Deionization module

When “DI Err” error message is

shown, or when water conductivity is

constantly more than 0.5 μS/cm

10310

Polishing module, double

When Grade I water conductivity is

constantly more than 0.2 μS/cm

10030

Sterilization UV bulb*

When beeping sound is heard during

Running stage

10102

Photooxidation UV bulb

Every 2 years

10018

Point-of-use microfilter**

Every 6-12 months

10012

Point-of-use ultrafilter*

10120

* In Labaqua Bio only.

** In Labaqua HPLC only.

18

9. Warranty and Claims

9.1. The Manufacturer guarantees the compliance of the unit with the requirements of

Specifications, provided the Customer follows the operation, storage and

transportation instructions.

9.2. The warranted service life of the unit from the date of its delivery to the Customer is

24 months (excluding expendable parts mentioned in 8.5.). For extended warranty,

contact your local Biosan representative or our service department through the

Technical support section on our website at the link below.

9.3. Warranty covers only the units transported in the original package.

9.4. If any manufacturing defects are discovered by the Customer, an unsatisfactory

equipment claim shall be compiled, certified and sent to the local distributor

address. To obtain the claim form, visit section Technical support on our website

at link below.

Technical support

biosan.lv/en/support

9.5. The following information will be required in the event that warranty or post-warranty

service comes necessary. Complete and retain for your records.

Model

Labaqua HPLC / Labaqua Bio water purification system

Serial number

Date of sale

19

10. Declaration of Conformity

Biosan SIA

Ratsupites 7, build.2, Riga, LV-1067, Latvia

Phone: +371 67426137 Fax: +371 67428101

http://www.biosan.lv

Edition 4.06 - April 2017

Table of contents

Other Biosan Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Blue Wave

Blue Wave EASY CLEAN 100 instruction manual

Philips

Philips WP3870 user manual

Beko

Beko QWIK-PURE 200 Instructions for installation and operation

Brita

Brita PURITY C iQ Quick installation guide

A.O. Smith

A.O. Smith Z2 user guide

Franklin Water Treatment

Franklin Water Treatment POZ1-10 Installation instructions and owner's manual