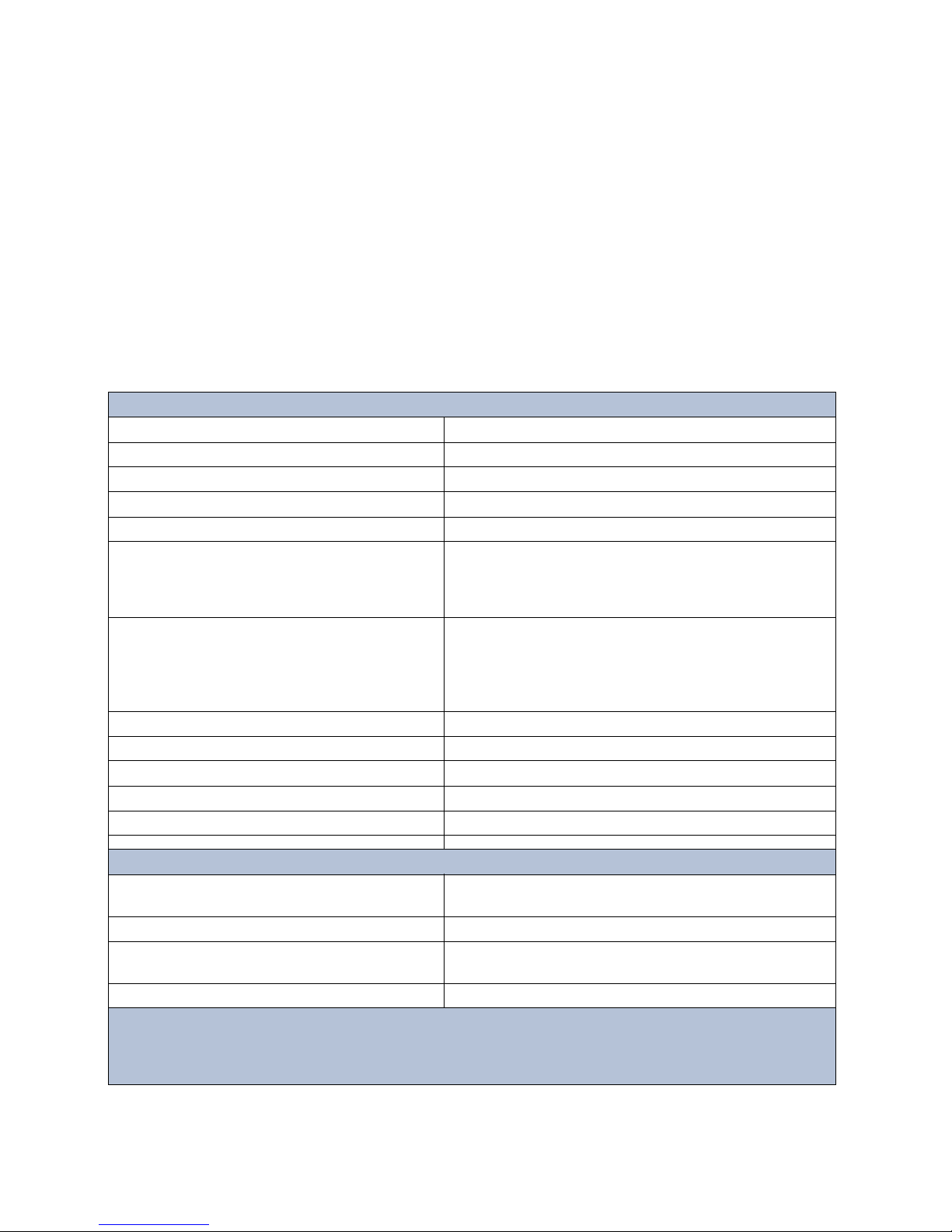

Table of Contents Manual 7-9487 - 3 05/05/11

Table of Contents

General Description ............................................................................................ 1

Tower Top Box .................................................................................................... 2

Base Control Unit ................................................................................................ 3

Base Control Unit Styles..................................................................................... 3

MCU .................................................................................................................... 3

Functional Block Diagram.................................................................................. 3

CMU .................................................................................................................... 9

Functional Block Diagram.................................................................................. 9

Unpacking .......................................................................................................... 10

Pre-Installation Checkout ................................................................................. 10

Mechanical Inspection ..................................................................................... 10

Initial Power-up Test .........................................................................................10

Bench Testing ................................................................................................... 11

Installation.......................................................................................................... 13

Test Transmission Line ..................................................................................... 13

Installing the System ........................................................................................ 14

Installing the Tower-Top Box ........................................................................... 14

In-building Lightning Arresters .......................................................................... 18

Installing the Base Control Unit ........................................................................ 18

Interference and IM Considerations..................................................................20

Feedline Data ..................................................................................................... 20

Optimizing the System ...................................................................................... 20

Attenuation Settings ......................................................................................... 21

Reserve Gain..................................................................................................... 21

Receiver Multicoupler Distribution (MCU Only) ................................................. 21

Setting the MCU Reserve Gain Attenuation ...................................................... 21

Setting the CMU Reserve Gain Attenuation ...................................................... 22

GTR8000 Attenuator Adjustment .................................................................... 23

Reserve Gain Adjustment Procedure ................................................................ 23

Setting Distribution Attenuation (MCU Only) ..................................................... 24

Adjustment Procedure ..................................................................................... 24

Spectrum Analysis ............................................................................................ 24

Procedure for Spectral Analysis ........................................................................ 25

Operational Tests (Sensitivity and Degradation) ........................................... 27

Front Panel Test Port ........................................................................................ 27

Tower Top Amplifier Inputs................................................................................ 27

Static System Sensitivity ................................................................................... 27

Measuring Static Sensitivity (Load Connected) ................................................. 27

Effective System Sensitivity............................................................................... 30

Measuring Effective Sensitivity (Antenna Connected)....................................... 30

Degradation ....................................................................................................... 30

Routine Operation ............................................................................................. 30

Amplifier Monitoring ........................................................................................... 31

LCD Display....................................................................................................... 31

Current Draw ................................................................................................... 31

TTA Temperature ............................................................................................ 31

Software Version ............................................................................................. 31

Front Panel LED’s ............................................................................................. 32

Form-C Contacts ...............................................................................................32