35

1.1

EN

General warning

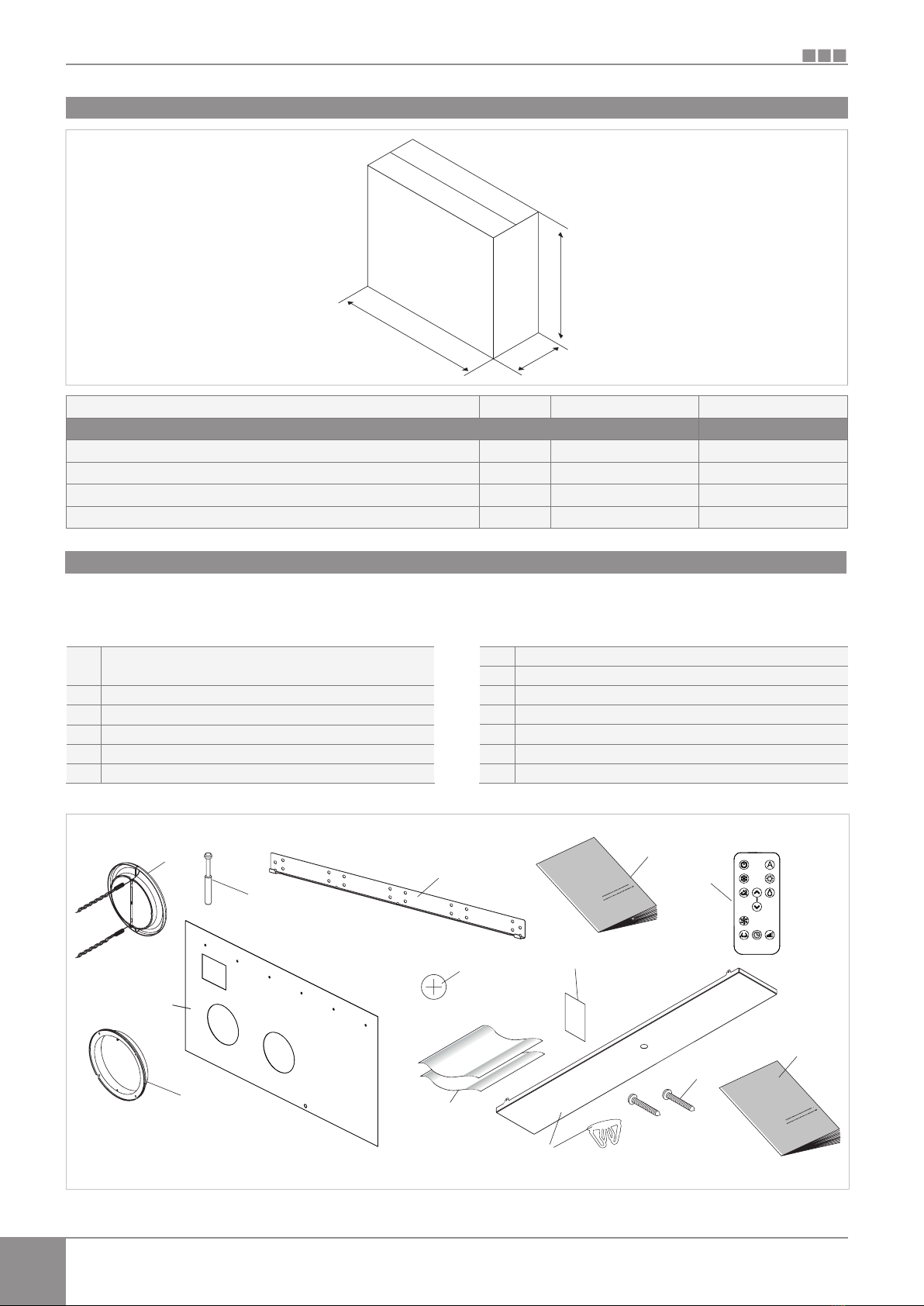

After unpacking, check that the contents are intact

and that all parts are included. If they're not, please

contact the Agent who sold you the appliance.

The appliance must be installed by an authorised

company. Once the work is done, it must issue a

declaration of conformity to the client in compliance

with current Regulations and with indications on the

instruction manual supplied with the appliance.

These appliances have been designed for

conditioning and/or heating rooms and they must be

destined solely for this purpose compatibly with their

performance characteristics.

The manufacturer refuses any contractual or extra-

contractual responsibilities for damage caused to

people, animals or things resulting from incorrect

installation, adjustment, maintenance or improper

use.

In the event of water leaks, turn off the main switch

and close the water taps.

Immediately call the Technical Assistance Service

or other qualified personnel and do not intervene

personally on the appliance.

If the temperature is set too low or too high, not only it

is unhealthy, but it is also a useless waste of energy.

Avoid prolonged direct contact with the air flow.

Do not leave the room closed for long. Open the

windows periodically to change the air.

This instruction booklet is an integral part of the

appliance and therefore it must be kept with care and

must ALWAYS accompany the appliance even when

the latter is transferred to another owner or user or

transferred to another system. If it gets damaged or

lost, please request another copy to the local BKL line

Technical Assistance Service.

Any repair or maintenance operations must be

performed by the Technical Assistance Service or by

qualified personnel in accordance with this booklet. Do

not modify or tamper with the appliance as this could

lead to dangerous situations and the manufacturer will

not be liable for any damage caused.

Attention. Cutting danger, please wear suitable gloves.

If conditions occur, please respect the rules for works

at height.

Refrigerant must always be recovered and never be

disposed directly into the environment.

Refrigerant must never be released into the

atmosphere.

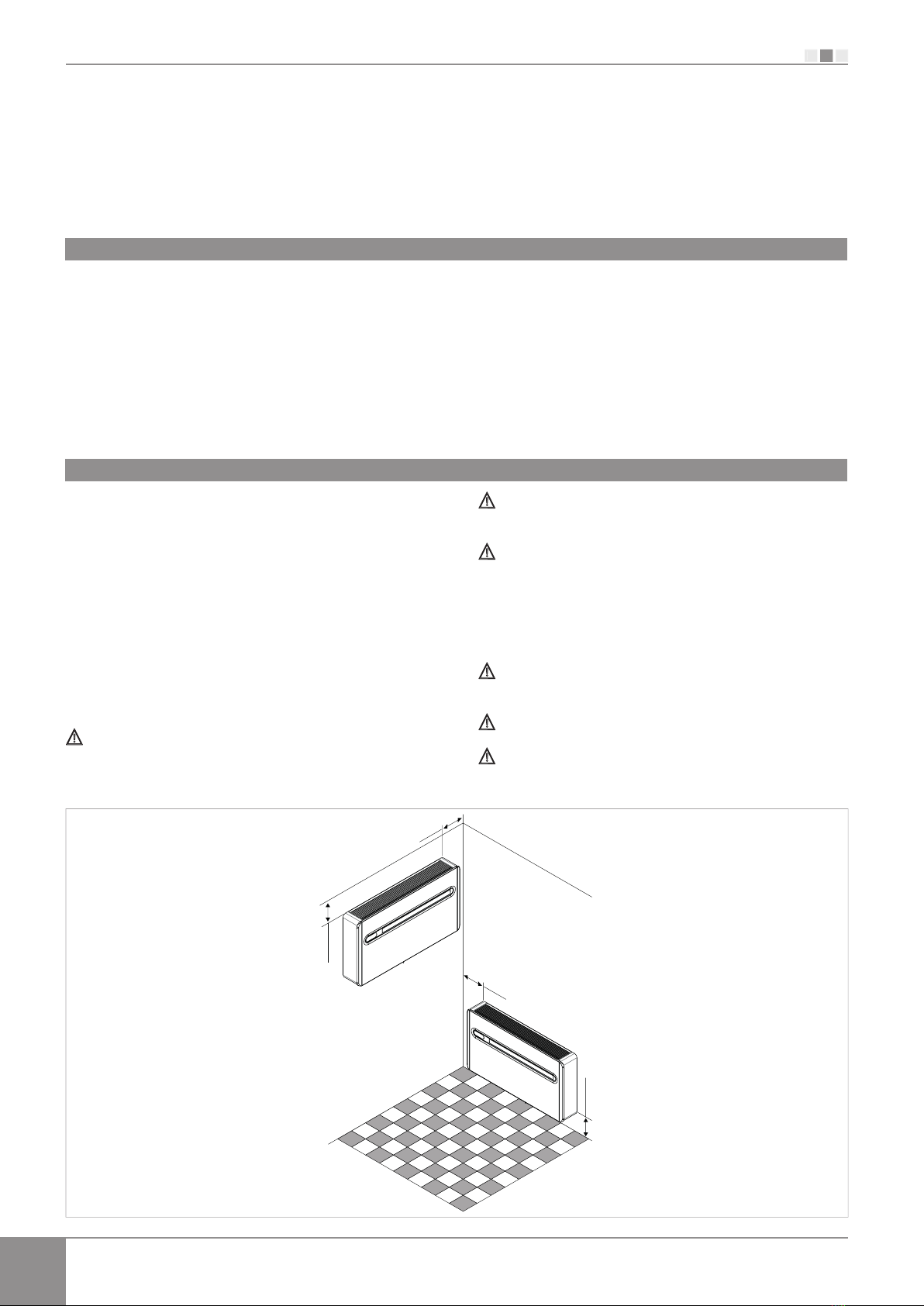

The appliance is declared to have an IPX0 protection

rating, therefore, it cannot be installed outdoors or in

laundry rooms.

GENERAL

Refrigerant gas R 410 A

GWP 2087,5

Composition 50% Difluoromethane

50% Pentafluoroethane

Hazard indications

Major hazards Asphyxiation

Specific hazards Rapid evaporation can cause frostbite

First aid measures

General information Do not administer anything if patient has fainted

Inhalation Move to open air. - Administer oxygen or artificial respiration if necessary. - Do not administer adrenaline

or similar substances.

Contact with eyes Rinse thoroughly with plenty of water for at least 15 minutes and call a doctor.

Contact with the skin Wash immediately with plenty of water. - Remove contaminated clothing immediately.

Firefighting measures

Extinguishing methods Any

Specific hazards Increase in pressure

Specific methods Cool containers by spraying with water

Measures in case of accidental escape of gas

Individual precautions Evacuate personnel to area of safety - Ensure adequate ventilation - Use personal protective equipment

Environmental precautions Evaporation

Method of cleaning Evaporation

Handling and storage

Handling Ensure sufficient air changes and/or

measures/technical precautions use forced ventilation at places of work

Recommendations for safe use Do not breathe vapour or droplets

Storage Shut off carefully and keep in a cool, dry and well-ventilated place.

Keep in original containers.

Incompatible products: explosives, inflammable materials, Organic peroxide

Part of the refrigerant safety table