Blackstone Models C-19 User manual

Page 1

Operations Manual

Thank you for purchasing the Blackstone Models C-19!

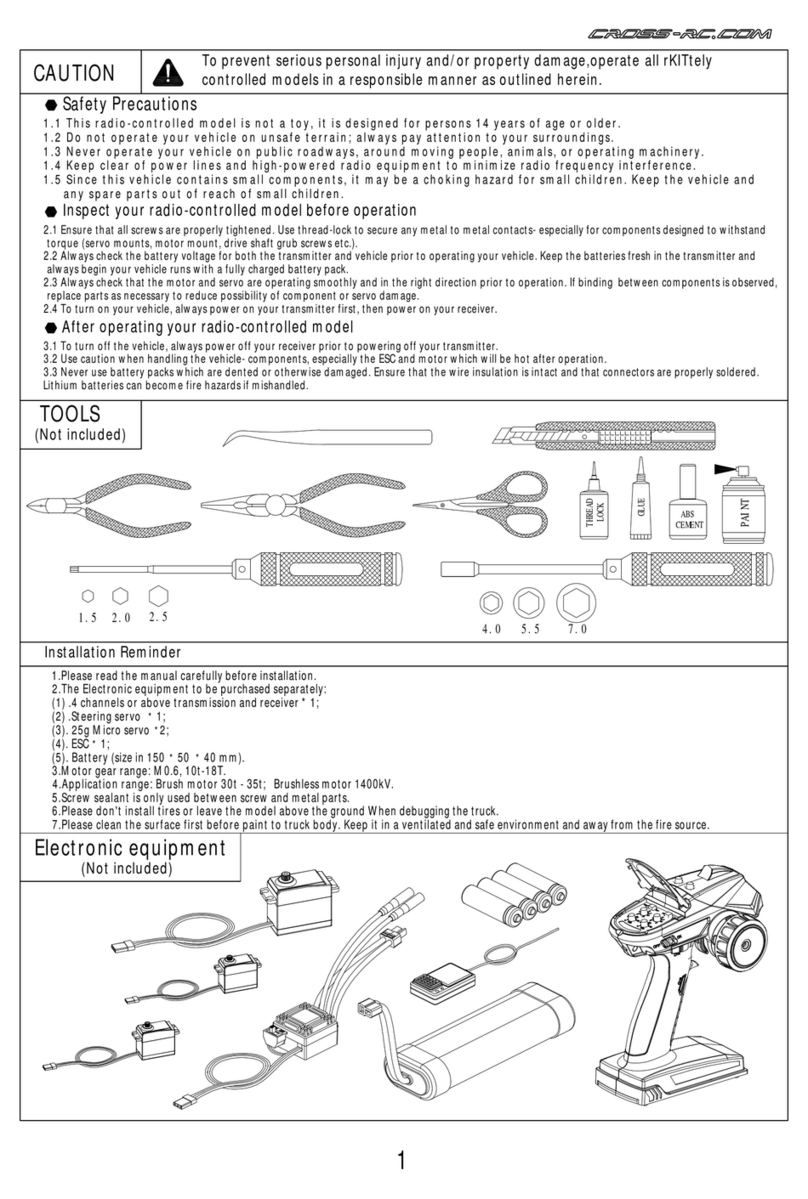

Before your little Consolidation whistles off, we want to tell you about a few

things that will enhance your operating experience and ensure that your

locomotive is maintained for years of pleasure.

We are pleased that we were able to produce some very ne details for this

model. While much of your locomotive is designed with zinc alloy for weight

and reliable operation, be aware that some of the parts are wire, styrene

and celcon. Thoughtful handling of the locomotive right out of the box will

ensure that detail parts are not broken or damaged.

The locomotive and tender are coupled together in the box. Figure 1

shows the best way to hold the locomotive and tender as you move it to

your track. Be sure your hands are free of dirt and oils, or use lightweight

gloves if desired. While the drawbar connection of the locomotive and

tender is of substantial strength, be careful not to twist at the connection

when handling in this manner.

Separating the Locomotive and Tender

The metal drawbar is secured by screws located on both the locomotive

and tender. You may wish to separate the locomotive and tender at some

point. If this is desired please follow these steps:

1. With the locomotive and tender on a soft surface, turn them upside

down and remove the four small Phillips head screws that secure the

tender tank to the tender chassis.*

*It may be necessary to remove the tender trucks from the chassis to access these

screws. This may be done by using a small Flathead screwdriver to pry the snap t trucks

out of the chassis holes. Note: Each tender truck had insulated wheel sets, one pair

for left rail and one for right rail. Always ensure that the trucks are re-installed with the

insulators on the correct side or electrical problems will ensue!

Figure 1 - Handling the Locomotive and Tender

Page 2

2. After lifting the tank off of the chassis use tweezers or a small pair of

needle-nose pliers to unplug the 6-pin connector from the socket.*

*This is the largest connector on the soundboard, (or PCB) located on the end of the

circuitboard nearest the locomotive.

3. With the front tender trucks removed from the chassis, thread the 6-pin

connector down and out through the hole in the bottom of the chassis.

4. Turn the locomotive and tender upside down again, then remove the

small Phillips head screw and washer that secure the drawbar to the

tender.

Detail Parts

Take a closer look in the packaging and you will notice that we have added

a locomotive tool box along with some extra screws. The tool box was

often seen on the pilot deck, rear tender platforms, or behind the coal bin

on top of the tender. For an example of placement options, Robert Grandt’s

“Narrow Gauge Pictorial” Volumes I and XI are excellent photo resources

for placing specic details. We recommend the use of RTV silicon to attach

this piece as it will allow easier removal at a later date. ACC glue is best if

you wish to permanently afx the tool box.

While each C-19 has been test run at the factory, a little break-in time is

always a good idea to enhance the running qualities of your engine. We

recommend operating the locomotive for approximately 2-3 hours using

both directions at varying speeds. We have designed your locomotive for

smooth operation and consistent electrical pick-up. In order to enhance

your operation, ensure that your locomotive and tender wheels, as well as

your track, is kept clean on a regular basis.

Maintaining your Locomotive

Before you run your C-19 it is best to place some light lubrication on the

rods, bushings, and electrical contact points. The gearbox is lubricated

at the factory and will not need immediate attention. In order to keep the

mechanism running smoothly, please follow these instructions.

After some running time and prior to adding new lubrication, be sure to wipe

off old/dirty oils and grease that have accumulated on the moving parts of

the locomotive. Isopropyl alcohol may be used for this purpose. Always

ensure that any cleaning uids used will not remove any paint or glues from

the model. Remember to periodically wipe the tread of all wheels to keep

them free of accumulated dirt and oil. You may already have a favorite line

of hobby lubricants. If not, Blackstone Models recommends lubricants from

Aero-Car Hobby Lubricants*.

Page 3

*Aero-Car Hobby Lubricants, Inc

P.O. Box 336

Western Springs, IL 60558-0336

www.aerocarlubricants.com

708-246-9027

The following products may be

applied as stated below:

Motor Bearing Lube ACT 2112:

On both sides apply a very small

drop at the union of each wheel and

side rod. (Initially and after every 25

hours of operation). See Figure 3.

Apply to all moving parts on the

crosshead guides as shown in

Figure 4.

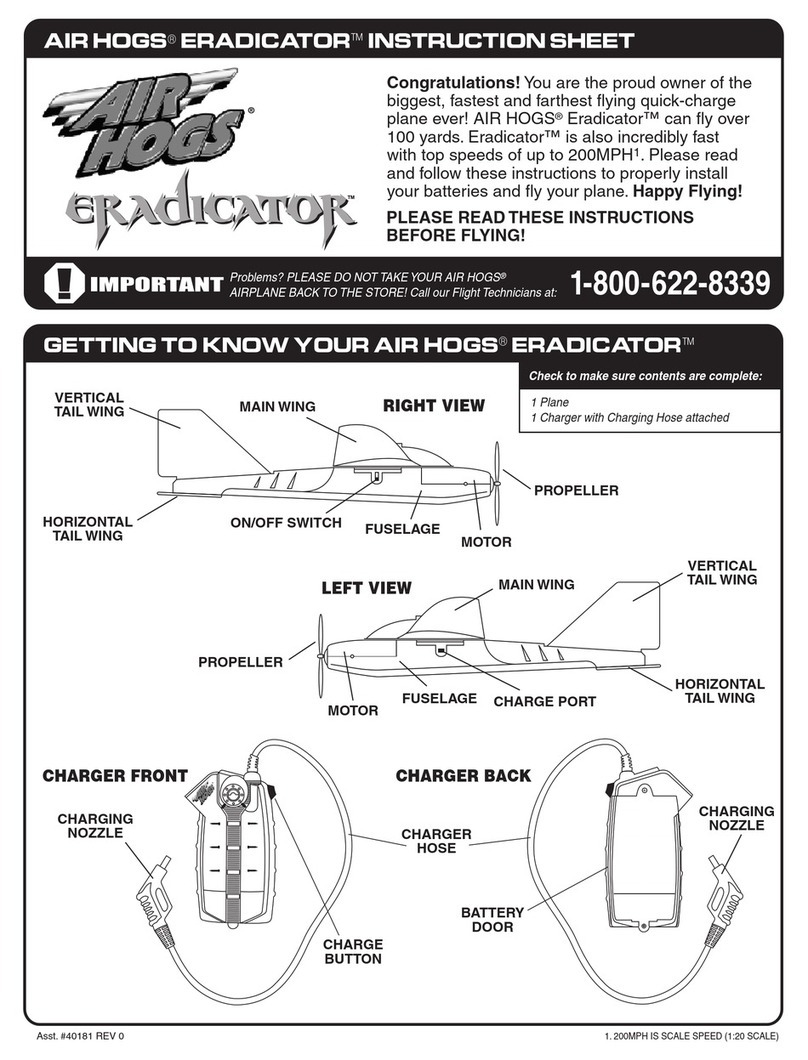

Conducta-Lube ACT 3753:

Apply a small drop between the

inside of each drive wheel and the

frame allowing the oil to permeate the

bearing area for each wheel. (Initially

and after every 25 hours of operation,

Figure 5).

Apply a small drop on each of the

four tender axles where the electrical

wiper ngers contact the axles.

(Initially and after every 25 hours of

operation.) See Figure 6.

When re-lubricating this area, check

to see that the wiper ngers are still

properly contacting the wheel axles.

If for any reason one or more of the

wipers are not making solid contact,

remove the axle from the truck frame

by slightly widening the frame and

pulling out the desired wheel set.

Using a small jeweler’s screwdriver

or pair of small tweezers, carefully

bend each wiper nger upward just

enough to where each prong will

Figure 4 - Apply to the crosshead guides and

piston rods.

Figure 3 - Apply lubricant to all

the side rod connections

Figure 5 - Lubricate axle bearings with

conductive lubricant.

Figure 6 - Lubricate tender axles with

conductive lubricant.

Page 4

contact the axles when replaced.

To replace the wheel set, gently spread the truck frame apart and re-insert

in the appropriate location.

Important!

Don’t forget that

each tender truck is

insulated from the

rail on one side. The

wheels on the front

truck are insulated

from the right rail pick-

up, while the wheels

of the rear truck are

insulated from the left

rail pick-up. Please

see Figure 7 showing the proper placement of these insulated wheels

and be sure to replace accordingly. Failure to adhere to this could cause

serious electrical issues to your locomotive. If you have an unexpected loss

of electrical contact after replacing wheel sets, this is probably where you

should look rst!

NG Jell Gear Lubricant ACT 1111:

Inspect the main gears after 50

hours of operation to determine the

need of adding more lubrication. If

you do not see a reasonable lm of

grease on the gear teeth, apply an

appropriate amount to lightly coat

the teeth throughout.

To access the main gears: turn the

locomotive upside down and carefully

remove the ve screws that secure

the chassis plate to the underside of

the frame.* See gure 8.

* Be careful to keep the locomotive upside down! The drivers may come out of the frame if it

is tilted to any extreme.

Note the gears and inspect for lubrication. See Figure 9. This may also be

a good time to clean or lubricate the wheel axles if needed. Remember that

an abundance of grease collecting around the gears in the box will only

attract dirt and other foreign matter. Focus on the gear teeth contact points

and avoid over-lubrication of the gearbox.*

Figure 8 - Remove the five Phillips head

screws on the chassis plate.

Front Figure 7 - Proper placement of insulated wheels.

Page 5

*Applying a very light electrical current to

the locomotive to turn the wheels will help

to spread the grease around the gears.

This is best accomplished after replacing

the chassis plate.

Optional: You may wish to access

the motor for inspection and/or

lubrication around the worm gear, to

do so you will need to remove the

boiler from the chassis as shown

in gures 10 through 15.

Removing the Boiler

Should you desire to remove the boiler from the chassis in order to access

the motor assembly please follow these steps.

1. You may remove the tender from the locomotive as discussed on page

1 of this manual, or simply remove the Phillips head drawbar screw

and washer on either the locomotive or tender connection, then pull the

tender off to view the locomotive backhead.

2. With a small hobby screwdriver or blade, pry the rebox door casting

away to reveal a rear chassis/boiler screw. Remove this screw. See

gures 10 and 11.

3. Using a small Phillips screwdriver,

insert into the smoke stack, nd

the screw, and remove. See

gure 12.

Figure 9 - Inspect gears for lubrication.

Figure 10 - Remove the firebox door casting. Figure 11 - Remove the chassis/boiler rear

screw.

Figure 12 - remove the smokestack/cylinder

casting screw.

Page 6

4. Remove the boiler supports from

each side of the smokebox as

shown in Figure 13.

5. With tweezers gently pull the

reversing reach rod on the right

side and, both of the chest

lubricator lines (wires) from both

the frame and steam chest tops

respectively. See gure 14.

6. The vertical handrails at the

rear of the cab plug into the rear

cab support frame located on

the chassis. These will need to

be replaced in the proper holes

when re-assembling.

7. Lift the front and rear of the

boiler assembly, rocking it gently,

and remove the boiler assembly

from the chassis as shown in

Figure 15. Please note that

cab rear handrails, and cylinder

cock wire attached to the cab

front, all need special care when

separating the boiler from the

chassis.

Accessing the Motor for

Maintenance

Motor Bearing Lube ACT 2112:

If you determine that the motor bearings require lubrication, you may apply

this oil very sparingly to the motor bearings on each side of the motor.*

* Apply this oil only if you notice any unusual noise or drag on the motor due to friction at

these bearings.

Generally the bearings should last for the running life of the locomotive

without supplemental lubrication. Please note that over-lubrication on

motor bearings could potentially shorten motor life as excessive lubricant

may work into the commutator or magnet areas of the motor. Excessive

lubricant in the motor may also simulate a motor overload condition that

interferes with the operation of your Tsunami decoder.

Figure 15 - Lubricate the worm and gears if

needed.

Figure 14 - Remove the reach rod and steam

chest lubricator wires.

Figure 13 - Remove the boiler supports.

Page 7

Procedure for Motor Bearing Lubrication

1. Detach the motor securement clip by removing the Phillips head screw

shown in Figure 16, then remove the small plastic part.

2. Pry the motor away from the

gear box cradle. Note: It may

be necessary to use a small

screwdriver and pry up between

the motor and cradle to lift

the motor out of the gearbox

assembly. (See Figure 17).

3. Place a small drop of lubricant

on the front and rear motor

shafts where they protrude from the bearing as shown in Figure 18.

When performing routine maintenance on your locomotive, remember to

inspect the screws that attach the side rods and various moving parts for

the proper tightness. When re-assembling your locomotive, replace screws

with only enough pressure to ensure that the parts properly contact and

will not work loose. Over tightening of screws could hinder operation and

movement of certain parts, as well as breaking parts made of engineering

plastic.

Thank you again for making Blackstone Models products part of your

model railroading experience! If you have further questions contact us at

This document contains information protected by copyright. No part of this document may be photocopied or

reproduced in any form without the prior written consent of Throttle Up! Corp.

Figure 16 - Remove screw and securement clip. Figure 17 - Remove from cradle.

Figure 18 - Lubricate bearings.

Page 8

TM

A Division of SoundTraxx

210 Rock Point Drive, Durango, Colorado 81301 (970) 259-0690 Fax: (970) 259-0691

©2010 Throttle Up! Corp. All Rights Reserved.

Other manuals for C-19

1

Other Blackstone Models Toy manuals

Popular Toy manuals by other brands

KNEX

KNEX SESAME STREET Neighborhood Collection School Bus Building... quick start guide

Air Hogs

Air Hogs Air Hogs RC Sky Patrol Helicopter instruction manual

PLAYTIVE JUNIOR

PLAYTIVE JUNIOR XXL TRAIN STATION PLAYSET Instructions for use

Hot Wheels

Hot Wheels SUPER SPEED BLASTWAY instructions

easymaxx

easymaxx MT20188 instruction manual

LaserPegs

LaserPegs NFL003 Team Spirit Assembly instruction