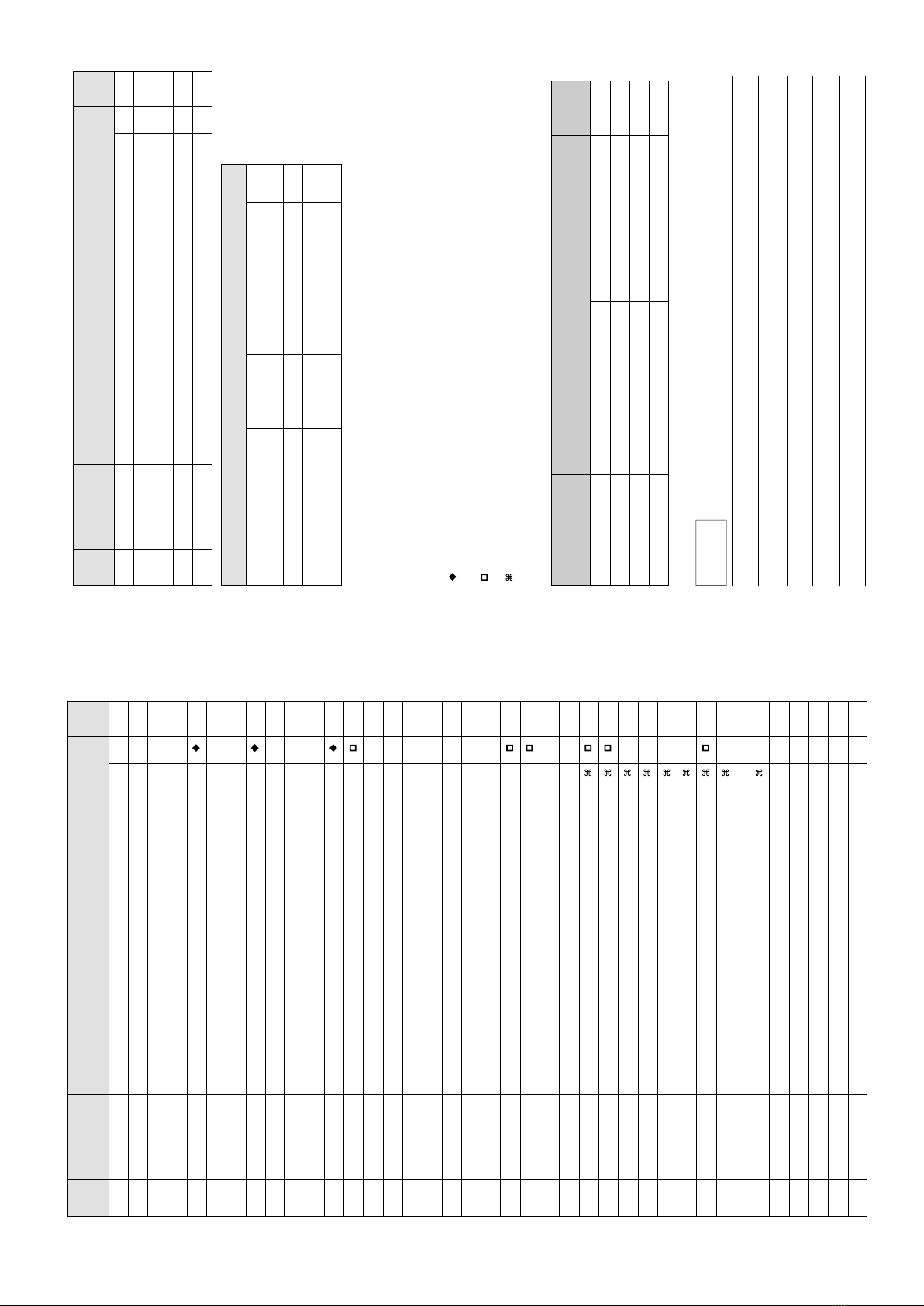

HG-CF-1100 Rev. D - 09.02.11

b50_x50_hygienic_manual-rev0220

Page 8

HG-CF-1100 Rev. G - 11.01.10 Page 8

Read these instructions

completely, before

installation and start-up. It

is the responsibility of the purchaser to

retain this manual for reference.

Failure to comply with the

recommendations stated in this

manual will damage the pump, and

void factory warranty.

IMPORTANT!

SERVICE

The following sections give a general

overview on how to service all models of

BLAGDON Diaphragm Pumps. For

details on individual part numbers,

quantities, materials, etc., please consult

the parts list supplied with the pump.

NOTE : Before commencing any

service or maintenance work on the

pump, ensure that the air supply has

been disconnected or isolated.

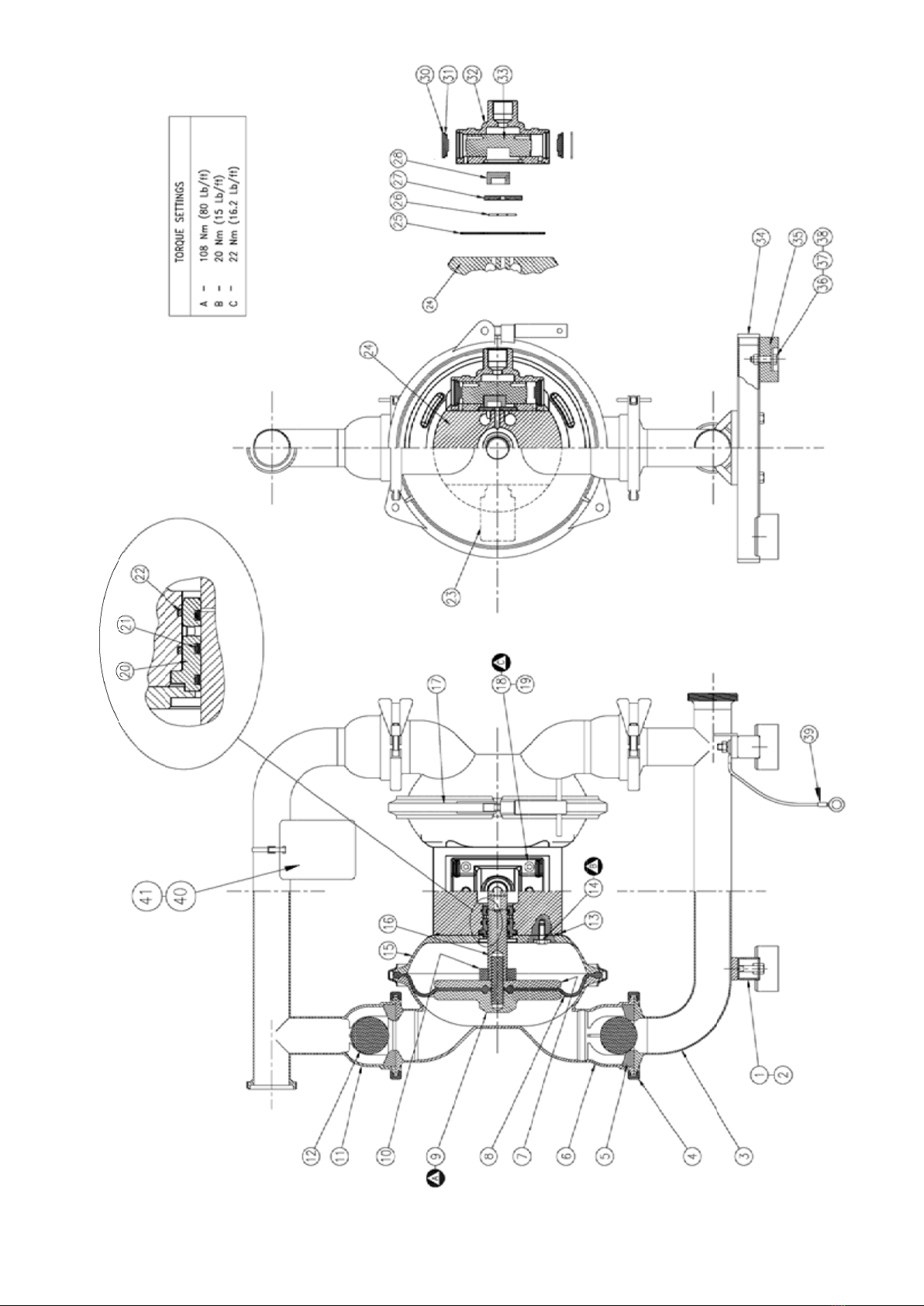

AIR VALVE SYSTEMS

PNEUMATIC TYPE Remove the 4

screws securing the valve block to the

valve chest, together with any associated

gaskets or seals.

Remove slide valve plate & slide valve

from the valve block assembly. Clean all

parts thoroughly and inspect for

excessive wear, replacing where

necessary.

The slide valve and valve plate contact

faces should be flat and free from

scratches. A light polishing on a flat

surface with a fine abrasive paper will

remove most scratches.

If excessive wear is suspected in the

valve block bore or valve carrier, remove

the valve block plugs and withdraw the

valve carrier. Check valve block plug o-

rings for wear or attack & replace where

required.

Clean the valve carrier & valve block

bore with white spirits to remove any oil

films.

NOTE : The nominal diametrical

clearance between the valve carrier and

the valve block bore should be 0.05 -

0.09mm. A clearance in excess of this

will cause the valve system to run

erratically.

Apply a light grease to the valve block

plug O-rings when re-assembling into the

valve block bore. Any damage to the O-

ring may cause the valve system to

malfunction.

Re-assemble the valve block assembly &

re-torque in accordance to the settings

shown in the parts list.

In the event of a complete air-side

overhaul, the pump should be dis-

assembled down to the centre section

assembly as described later in the “Wet-

Side Overhaul” section.

With the valve block assembly

dismantled, remove the inner covers

where appropriate.

A careful note of the position of all

related seals and gaskets should be made

to facilitate re-assembly.

Remove diaphragm shaft bushes, where

appropriate, and check all seals and ‘O’

rings for wear or damage. If worn,

replace immediately.

NOTE:- The integrity of the diaphragm

shaft seals is essential for the correct

functioning of all pneumatically

actuated valve systems.

Check the diaphragm shaft for excessive

wear as this will result in premature seal

failure. Replace as required. Lubricate

all components and re-assemble as

detailed above, in reverse order. Ensure

the correct position of all components

detailed in all sectional assembly

drawings.

WET-SIDE OVERHAUL

REPLACING BALL VALVES

Remove discharge manifold from pump

assembly together with associated valve

balls, seats and ‘O’ rings.

NOTE :- The orientation of the valve

seat relative to the valve ball should be

noted as incorrect positioning may

result in a performance loss.

Turn pump through 180oand remove the

suction manifold. Clean and inspect the

components. Check for any wear or

damage and replace as required.

NOTE :- Ball or valve seat wear may

result in loss of performance and

suction lift.

Re-assemble the valve balls/seats and

ensure manifolds are adequately torqued

to the settings shown in the parts list.

REPLACING DIAPHRAGMS

Remove both suction and discharge

manifolds as detailed in the previous

section, removing all ball valves, seats

and ‘O’ rings.

Loosen and remove both outer covers

from the pump assembly. The

orientation of the covers should be noted

so as to facilitate re-assembly.

Holding one of the frontplates in a vice,

(‘soft jaws’ should be fitted), or with an

adjustable spanner, loosen and remove

the frontplate from the opposite end.

Remove the diaphragm, backplate and

bumpstop from diaphragm shaft.

Carefully withdraw the diaphragm shaft

from the centre section and hold the free

end in a vice, holding between the flats

machined on the end. Loosen and

remove the frontplate and remove the

diaphragm together with backplate and

bumpstop (where fitted).

NOTE :- Care should be taken with all

plastic, coated and hygienic pumps, so

that the surface of the frontplate is not

damaged.

Thoroughly clean all parts and check for

wear, damage, swelling, cracking,

delamination and chemical attack.

Replace components where required.

NOTE :- Rubber diaphragms should be

replaced if they are worn to such an

extent that the fabric re-enforcing is

evident on the surface of the diaphragm.

For pumps fitted with PTFE diaphragms,

a light coating of grease should be

applied to the back-up diaphragm prior to

re-assembly.

Before re-assembly, it is advisable to

check the condition of the diaphragm

shaft seal/’O’ rings for wear or attack. If

either is evident, it is recommended that

they be replaced.

Assemble the diaphragms onto the shaft

in a reverse sequence to their removal.

Care should be taken as to the orientation

of the diaphragm relative to the front and

back plates. All diaphragms have “AIR

SIDE” moulded onto one side. The

backplate must be fitted adjacent to the

AIR SIDE of the diaphragm.

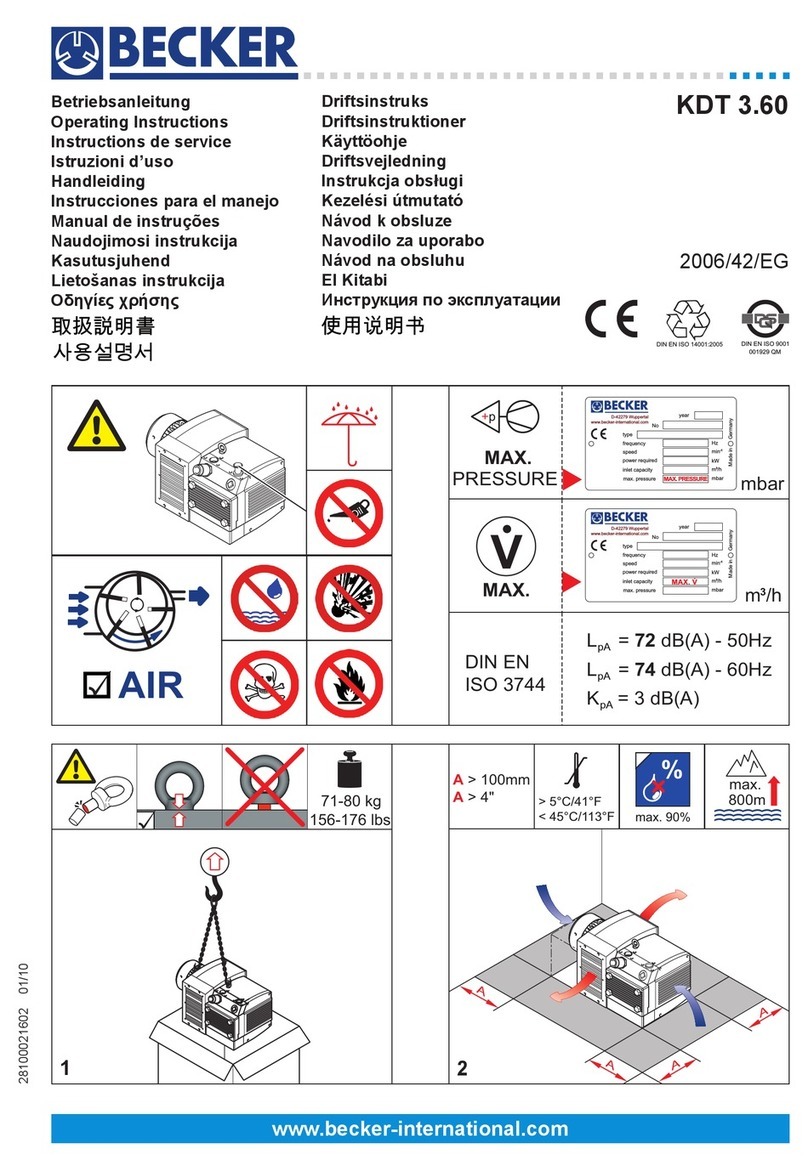

NOTE :- To achieve a leak free seal

around the clamp bands a plastic mallet

(A) should be used to gently tap the

clamp band into position, in a circular

manner. (Ref Fig. 2) The clamp (B)

should be tightened simultaneously

whilst using the mallet.

On all pumps fitted with stainless steel

fasteners, including clamp bands, it is

recommended that anti-seizure paste is

applied to the threads .

Bolted assemblies

should be torqued

to the settings

shown in the parts

list.

The manifolds

should be re-

assembled as

described in the

previous section.

Fig. 2

A

B