Blancett B2800 Standard User manual

Flow Monitor

B2800 Advanced

DSY-PM-00286-EN-03 (October 2015) User Manual

Flow Monitor, B2800 Advanced

Page ii October 2015DSY-PM-00286-EN-03

CONTENTS

Scope of This Manual � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Terminology and Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Considerations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Introduction� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Operating the Monitor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Buttons� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Modes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Programming � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Programming Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Return to Run Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Run Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Additonal Scaling Parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Flow 4 mA Setting� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Flow 20 mA Setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

4…20 mA Calibration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

4…20 mA Test � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Battery Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Additional Input Options � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Additional Scaling Information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Pulse Output Signals for Linear Processes � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Pulse Output Signals for Non-linear Processes � � � � � � � � � � � � � � � � � � � � � � � � � 19

Default K-factor Values � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

User Manual

Page 3October 2015 DSY-PM-00286-EN-03

Installation Drawing� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Battery Powered � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Loop Powered � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Troubleshooting Guide� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Part Number Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Replacement Parts� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

Mounting Options and Dimensions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Meter Mount � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Remote Mount � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Swivel Mount� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Flow Monitor, B2800 Advanced

Page 4 October 2015DSY-PM-00286-EN-03

Scope of This Manual

SCOPE OF THIS MANUAL

This manual is intended to help you get the B2800 flow monitor up and running quickly�

MPORTANTI

Read this manual carefully before attempting any installation or operation. Keep the manual

accessible for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable

accessories for any physical damage such as scratches, loose or broken parts, or any other

sign of damage that may have occurred during shipment�

OTE:NIf damage is found, request an inspection by the carrier’s agent within 48 hours of

delivery and file a claim with the carrier� A claim for equipment damage in transit

is the sole responsibility of the purchaser�

SAFETY

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, could result in

severe personal injury or death�

Considerations

The installation of the B2800 monitor must comply with all applicable federal, state, and

local rules, regulations, and codes�

EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2.

AVERTISSMENT

RISQUE D’EXPLOSION - LA SUBSTITUTION DE COMPOSANTS PEUT RENDRE

CEMATÉRIEL INACCCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

DO NOT CONNECT OR DISCONNECT EITHER POWER OR OUTPUTS UNLESS THE AREA IS

KNOWN TO BE NON-HAZARDOUS.

AVERTISSMENT

RISQUE D’EXPLOSION. NE PAS DÉBRANCHER TANT QUE LE CIRCUIT EST SOUSTENSION,

À MOINS QU’LL NE S’AGISSE D’UN EMPLACEMENT NON DANGEREUX.

MPORTANTI

Not following instructions properly may impair safety of equipment and/or personnel.

Page 5October 2015 DSY-PM-00286-EN-03

Introduction

INTRODUCTION

The B2800 flow monitor is a state-of-the-art digital signal processing flow monitor designed

to provide exceptional flexibility at a very affordable price� Though designed for use with

Blancett flow meters, this display can be used with almost any flow meter producing a low

amplitude AC output or contact closure signal�

This flow monitor is capable of accepting a low level frequency input for calculating

flow rate and total� These calculations can then be displayed in the specified units of

measurement� All B2800 flow monitors are pre-programmed at the factory, if ordered with

a Blancett flow meter� If required, however, the monitor can easily be reconfigured in

the field�

The monitor’s large 8-digit by 0�75 in� (19 mm) numeric liquid crystal display makes

extended range viewing practical� The second 8-digit by 0�38 in� (9 mm) alphanumeric

display provides for selectable units viewing in RUN mode and prompts for variables in

PROGRAM mode� You can display rate or total, or alternate between rate and total�

Page 6 October 2015DSY-PM-00286-EN-03

Operating the Monitor

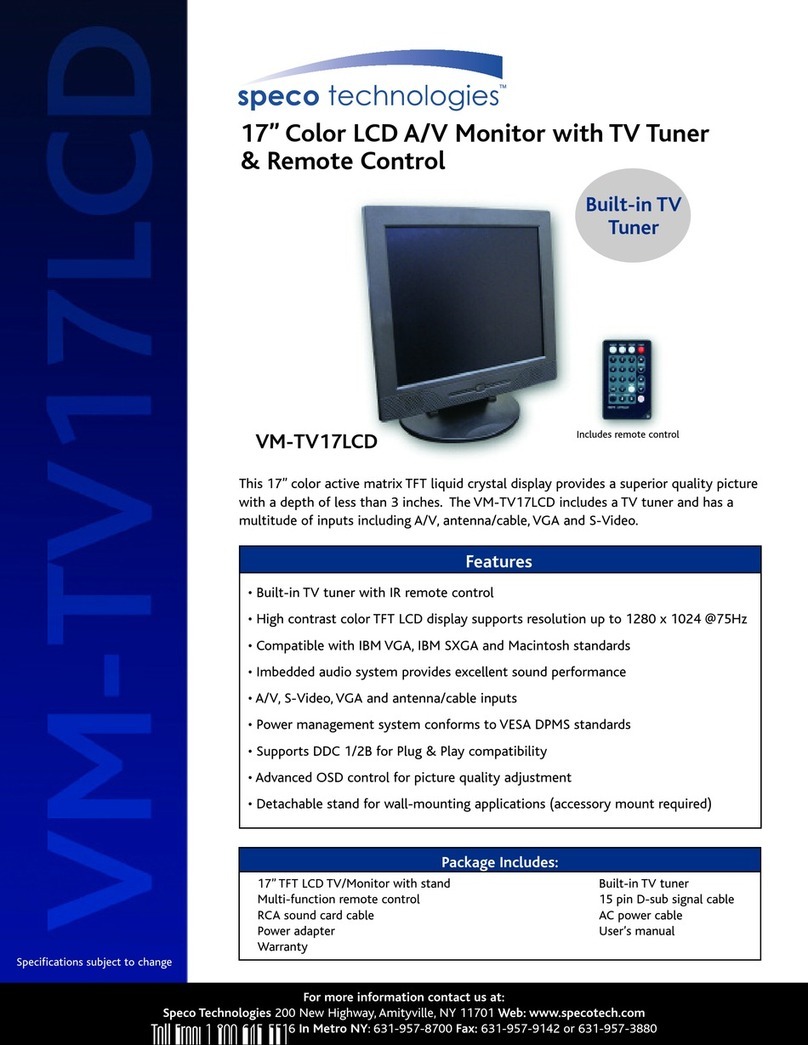

OPERATING THE MONITOR

Programming

Keys

Mode

Indicator

Units Display

And

Programming Choices

Rate / Total Display

And

Programming Choices

RUN PROGRAM

RELAY1 RELAY2

Figure 1: B2800 flow monitor

Buttons

MENU Switches to PROGRAM mode

UP Scrolls forward through the parameter options and increments numeric

variables

RIGHT Scrolls backward through the parameter options and moves the active digit

to the right

ENTER Saves programming information, advances to the next programming

parameter, and used in the reset process

Modes

RUN Normal operating mode

PROGRAM Used to program parameters in the display

If your monitor was ordered with a Blancett flow meter, the two components ship from

the factory calibrated as a set� If the monitor is a replacement, the turbine’s K-factor has

changed or the monitor is being used with some other pulse generating device, the

monitor must be programmed�

Page 7October 2015 DSY-PM-00286-EN-03

Programming

PROGRAMMING

Each turbine flow meter is shipped with either a K-factor value or frequency data� If

frequency data is provided, the data must be converted to a K-factor before programming

the monitor� K-factor information, when supplied, can usually be found on the neck of the

flow meter or stamped on the flow meter body� The K-factor represents the number of

pulses per unit of volume� The K-factor will be needed to program the monitor readout�

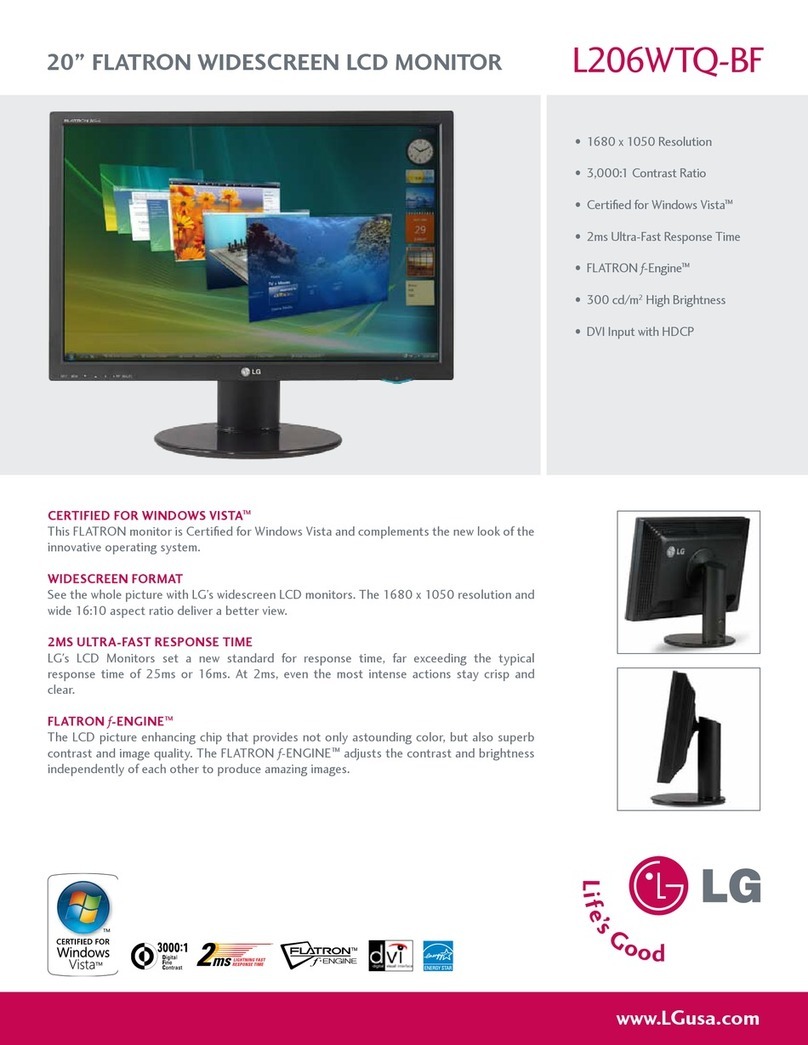

Programming Mode

x

x

See Note

Note: Only available when either

KGS or LBS are Selected

Figure 2: Advanced programming menu

Enter Programming Mode

Press MENU to enter the programming mode� The mode indicator changes from RUN to

PROGRAM�

OTE:NIf any input value exceeds the meter’s capabilities for that particular parameter,

the LIMIT indicator flashes, indicating an invalid entry� Press ENTER to return to

the parameter’s entry screen to reenter the value�

Page 8 October 2015DSY-PM-00286-EN-03

Programming

Select Meter Size

At the METER prompt, press ENTER� The current meter size flashes� If the current setting is

correct, press ENTER to advance to the next parameter� To change the current setting, press

UP or RIGHT to scroll to the bore size of your meter� Press ENTER to save and advance to

the DISPLAY parameter�

OTE:NThe meter connection size and the bore size are different� For example, many of

the one inch NPT turbines have bore sizes that range from 3/8…1 in� (9…25 mm)�

Use the correct bore size so the meter will report correct flows and totals�

Select Display Function

The monitor can display RATE or TOTAL or alternate between BOTH rate and total� At the

DISPLAY prompt, press ENTER� The monitor shows the current display mode� To change to

an alternate display mode, press UP or RIGHT to scroll to the correct display mode� Press

ENTER to save and advance to the RATE UNT parameter�

Select Units of Measure

At the RATE UNT prompt, press ENTER� The monitor shows the current rate unit� If the

current selection is correct, press ENTER to advance to the next parameter� To change to an

alternate unit, press UP or RIGHT to scroll to the correct rate unit� Press ENTER to save and

advance to the RATE INT parameter�

Select Rate (Time) Interval

At the RATE INT prompt, press ENTER� The monitor shows the current time interval� If the

current selection is correct, press ENTER to advance to the next parameter� To change to an

alternate time interval, press UP or RIGHT to scroll to the correct time interval� Press ENTER

to save and advance to the TOTL UNT parameter�

OTE:NIf flow rate is the only measurement of interest, press RIGHT to advance to the

KFAC UNT to complete the programming process�

Select Units of Measure

At the TOTAL UNT prompt, press ENTER� The monitor shows the current total units� If the

current selection is correct, press ENTER to advance to the next parameter� To change to an

alternate unit, press UP or RIGHT to scroll to the correct totalization unit� Press ENTER to

save and advance to the TOTL MUL parameter�

OTE:NThis unit of measure does not have to reflect the rate unit you have previously

chosen�

Example: Rate Units = Gallons, Total Units = Barrels

Page 9October 2015 DSY-PM-00286-EN-03

Programming

Select Total's Display Multiplier

This parameter displays the accumulated flow total in multiples of 10� For example, if the

optimum totalization unit is 1000 gallons, the unit total display increments by one digit

for every 1000 gallons monitored� In RUN mode, at 1000 gallons the total monitor reads 1,

at 3000 gallons, the total display reads 3� This feature eliminates having to look at a total,

count the digits, and mentally insert commas for each 1000 multiple�

At the TOTL MUL prompt, press ENTER� The monitor shows the current total multiplier� If the

current selection is correct, press ENTER to advance to the next parameter� To change to an

alternate multiplier, press UP or RIGHT to scroll to the correct multiplier unit� Press ENTER

to save and advance to the KFAC UNT parameter�

OTE:NIf pounds or kilograms were chosen as the RATE UNT or TOTL UNT, the monitor

advances to the SP GRAV parameter�

Specific Gravity

At the SP GRAV parameter, press ENTER� The first digit of the current specific gravity flashes�

If the current setting is correct, press ENTER to advance to the next parameter� To change

the current setting, press RIGHT to move to the correct digit� Press UP to increment the

digit� Repeat for all digits� Press ENTER to save and advance to the KFAC UNT parameter�

Enter Meter's K-Factor Unit

OTE:NThe K-factor supplied with the meter, or calculated from calibration data, is

needed to complete this step�

At the KFAC UNT prompt, press ENTER� The display shows the current K-factor unit� If the

current selection is correct, press ENTER to advance to the next parameter� To change

the K-factor, press UP or RIGHT to scroll to the correct K-factor� Press ENTER to save and

advance to the SCALE F parameter�

OTE:NFor meters calibrated in gallons, use PUL/GAL; for meters calibrated in cubic

meters, use PUL/M3 or any other unit option�

Scale Factor

The scale factor is used to force a global change to all variables� For example, under

operating conditions the display is reading a consistent three percent below the expected

values at all flow rates� Rather than changing all parameters individually, the scale factor is

used to compensate for the three percent offset� Set the scale factor to 1�03 to correct the

readings� The range of scale factors is 0�5…1�5� The default scale factor is 1�0�

At the SCALE F prompt, press ENTER� The first digit of the current scale factor flashes� If the

current selection is correct, press ENTER to advance to the next parameter� To change to an

alternate scale factor, press UP to increment the display digit until it matches the first digit

of the new scale factor� Press RIGHT to advance to the next digit� Repeat for all digits� Press

ENTER to save and advance to the METERTYP parameter�

Page 10 October 2015DSY-PM-00286-EN-03

Programming

Meter Type

At the METERTYP prompt, press ENTER� The current meter type displays� If the current

selection is correct, press ENTER to advance to the next parameter� To change the type,

press UP or RIGHT� Press ENTER to save and advance to the next parameter� If GAS is

selected, the operating pressure (psig) and operating temperature (° F) must be entered� If

LIQUID is selected, the monitor advances to the DAMPING parameter�

OTE:NThe 4…20 mA zero and span values are not factory set�

Operating Pressure

At the OP PRES prompt, press ENTER� The first digit of the current setting flashes� If the

current setting is correct, press ENTER to advance to the next paramter� To change the

current setting, press RIGHT to move to the correct digit� Press UP to increment the digit

until it matches the new operating pressure� Repeat for all digits� Press ENTER to save and

advance to the OP TEMP parameter�

Operating Temperature

At the OP TEMP prompt, press ENTER� The first digit of the current setting flashes� If the

current setting is correct, press ENTER to advance to the next paramter� To change the

current setting, press RIGHT to move to the correct digit� Press UP to increment the digit

until it reaches the new operating temperature� Repeat for all digits� Press ENTER to save

and advance to the DAMPING parameter�

Damping Factor

The damping factor is increased to enhance the stability of the flow readings, and

decreased to allow the flow meter to react faster to changing values of flow� This parameter

can be any value 0…99 with 0 being the default�

At the DAMPING prompt, press ENTER� The first digit of the current damping setting flashes�

If the current selection is correct, press ENTER to advance to the next parameter� To change

the damping factor, press UP to increment the digit� Press RIGHT to move to the next digit�

After all digits are entered, press ENTER to save and advance to the PULS OUT parameter�

Totalizer Pulse Output

The pulse output parameter can be either enabled or disabled� When enabled, this output

generates a 20 mS duration pulse for every time the least significant digit of the totalizer

increments� The amplitude of the pulse is dependent on the voltage level of the supply

connected to the pulse output and is limited to a maximum 30V DC�

Page 11October 2015 DSY-PM-00286-EN-03

Programming

Linearization

Linearization enhances the accuracy of the display� The linearization accepts a maximum

of ten points and requires additional calibration data from the meter being used with the

monitor� Typically, calibration information can be obtained in three, five and ten points from

the flow meter’s manufacturer� If linearization is not needed, press RIGHT to advance to the

next parameter� To complete linearization, press ENTER at the LINEAR prompt� The meter

advances to the NUM PTS parameter�

Number of Points

If the number of points is set to 0, linearization is disabled� Press ENTER. The most

significant digit of the number of points entry begins to flash� The first number can be a 1or

a 0only� Press UP to increment the first digit� Press RIGHT to move to the least significant

digit� When both digits have been entered, press ENTER to save and advance to the

FREQ 1 parameter�

Frequency

At the FREQ 1 prompt, press ENTER. The first digit of the first linear point’s frequency input

flashes� If the first frequency is correct, press ENTER to advance to the next parameter� To

change the frequency, press UP to increment the digit� Press RIGHT to move to the next

digit� After all digits are entered, press ENTER to save and advance to the

COEFF 1 parameter�

Coefficient

The coefficient is the value applied to the nominal K-factor to correct it to the exact K-factor

for that point� The coefficient is calculated by dividing the actual K-factor for that point by

the average K-factor for the flow meter�

Coecient = Average K-Factor

Actual K-Factor

At the COEFF prompt, press ENTER. The first digit of the coefficient flashes� If the first

coefficient is correct, press ENTER to advance to the next parameter� To change the

frequency, press UP to increment the digit� Press RIGHT to move to the next digit� Repeat

for all digits� After all digits are entered, press ENTER to save and advance to the next set of

linear points� Continue entering pairs of frequency and coefficient points until all data has

been entered� Press MENU twice at the NUM PTS prompt to exit to the LINEAR prompt� Press

RIGHT to advance to the PASSWORD parameter�

Page 12 October 2015DSY-PM-00286-EN-03

Programming

Password

The password setting restricts access to PROGRAM mode� Initially, the password is set to all

zeros and any user can modify the paramter settings� To change the password, press ENTER

at the PASSWORD prompt� The first digit flashes� Press UP to increment the digit and RIGHT

to advance to the next digit� After entering all digits, press ENTER to store the password

and advance to RST PSWD� The new password is now required to enter PROGRAM mode�

With this password set, any user is able to reset the stored totals on the monitor�

OTE:NThis password will allow the operator to manually reset totals�

Reset Password

The reset password parameter restricts resetting the totals on the monitor� The PASSWORD

must also be set to restrict the total reset� Initially, the password is set to all zeros and any

user can reset the stored totals on the monitor� To change the password, press ENTER at

the RST PSWD prompt� The first digit flashes� Press UP to increment the digit and RIGHT to

advance to the next digit� After entering all digits, press ENTER to store the password and

return to the METER parameter� The reset pasword is now required to reset the totals on

the monitor�

OTE:NEntering a password in the PASSWORD screen and leaving the default password

in the RST PSWD screen allows for total resets (not requiring a password), but

restricts programming modification�

Return to Run Mode

After entering all parameters, press MENU to return to RUN mode�

Run Mode

Reset Total

To reset the monitor’s total display, in RUN mode, press MENU and ENTER simultaneously

until TOTAL RST starts to flash� The display returns to the RUN mode at the conclusion of the

reset procedure�

Store Total

The current total can be manually stored in the monitor’s flash memory� This procedure

may be needed prior to changing the settings or replacing the battery� Press and hold

ENTER for two seconds� The display flashes TOTALSVD and then returns to RUN mode�

Automatic Store Total

The monitor is equipped with a store total feature that works automatically, saving the

current total to flash memory� The frequency of saves depends on the power supply option

chosen�

Battery Powered: Once per hour and just before a low battery condition turns the unit off�

Loop Powered: Once every ten minutes�

Page 13October 2015 DSY-PM-00286-EN-03

Additonal Scaling Parameters

ADDITONAL SCALING PARAMETERS

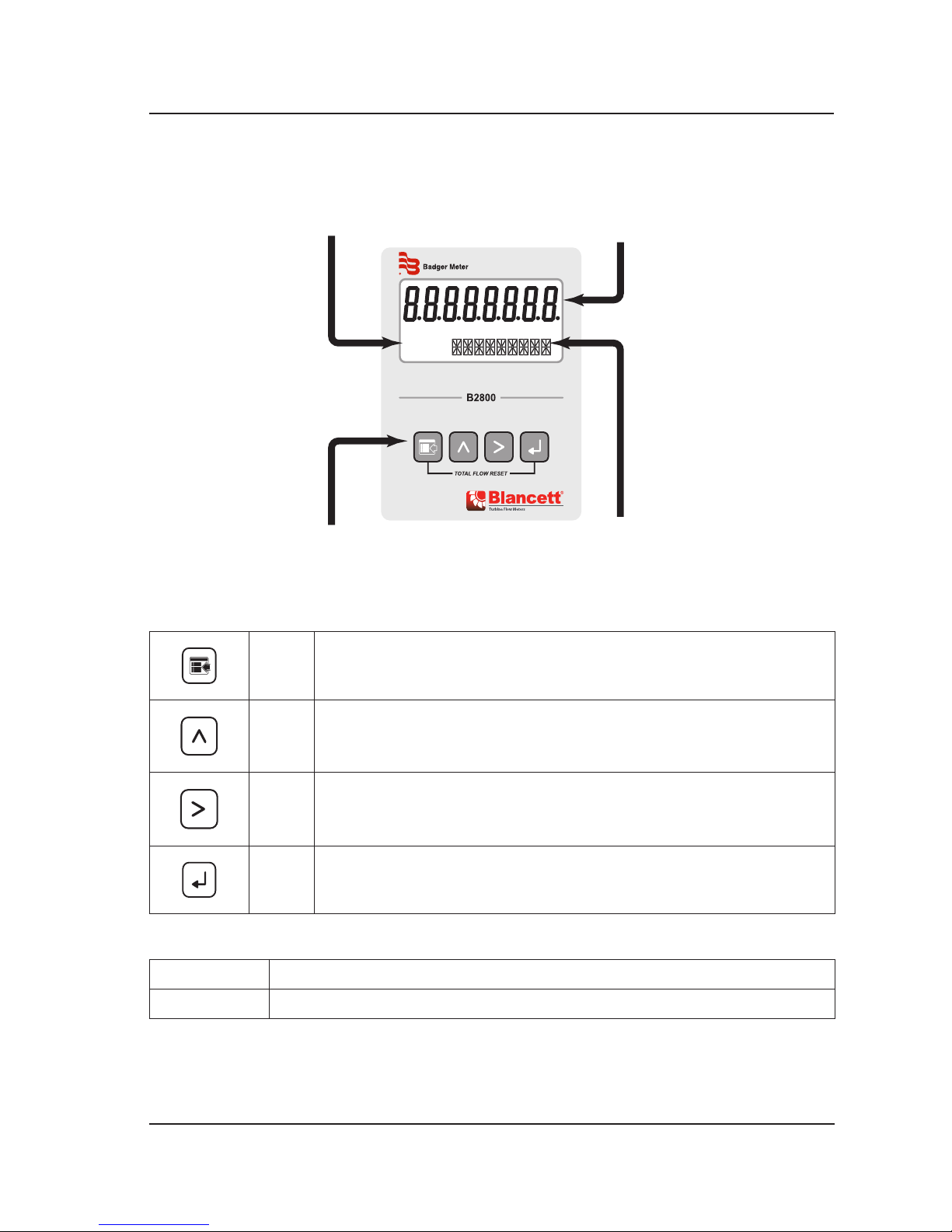

x

x

Figure 3: 4…20 mA programming menu

OTE:NThe programming instructions in this section are only available for loop powered

units� Battery powered units do not include these programming parameters�

Flow 4 mA Setting

Zero is the default flow rate at the 4 mA setting� If the current selection is correct, press

ENTER to advance to the Flow 20 mA parameter� To change the setting, press UP to

increment the flashing digit and press RIGHT to move to the next digit� Press ENTER to

save and advance to the Flow 20 mA parameter�

Flow 20 mA Setting

The turbine meter’s maximum flow rate is the default value for the 20 mA setting� If the

current selection is correct, press ENTER to advance to the 4…20 mA Calibration parameter�

To change the setting, press UP to increment the flashing digit and press RIGHT to move to

the next digit� Press ENTER to save and advance to the 4…20 mA Calibration parameter�

Page 14 October 2015DSY-PM-00286-EN-03

Battery Replacement

4…20 mA Calibration

The 4…20 mA Calibration parameter is the fine adjustment of the 4…20 mA output� The

4 mA setting is typically between 35…50� To set the 4 mA value, connect an ammeter

in series with the loop power supply� At the 4MA OUT prompt, press UP to increment

and RIGHT to decrement the 4 mA value to until a steady 4 mA reading is reached on

the ammeter� Press ENTER to lock in this value and advance to 20MA OUT� The 20 mA

adjustment is performed using the same procedure as the 4 mA adjustment�

4…20 mA Test

The monitor contains a diagnostic routine that allows the simulation of mA values between

4…20 to check output tracking� At the 4-20TEST prompt press UP to increment the

simulated mA output or RIGHT to decrement the value in increments of

1 mA� The ammeter should track the simulated mA output� If a 4…20 mA test in not

necessary, press ENTER once to escape the testing at any time�

OTE:NIf you ordered the B2800 flow monitor with a Blancett turbine flow meter, the

4…20 mA was programmed and factory calibrated�

Pulse Out Freq. In4-20 mA

10…30V DC

1…5V DC

123456

+ -+ -+ -

JP2

Mag

Input

TB1

12345

J2

Keypad

Connector

DC

Pulse

Input

Figure 4: Typical ammeter connection

BATTERY REPLACEMENT

Battery powered monitors use a single 1�5V, D size alkaline battery� When replacement

is necessary, use a clean fresh battery to ensure continued trouble-free operation� It is

recommended that the total be saved to memory before the battery is removed�

1� Unscrew the two captive screws on the front panel to gain access to the battery�

2� Replace the battery, being sure to observe the proper polarity�

3� Refasten the front panel�

Page 15October 2015 DSY-PM-00286-EN-03

Additional Input Options

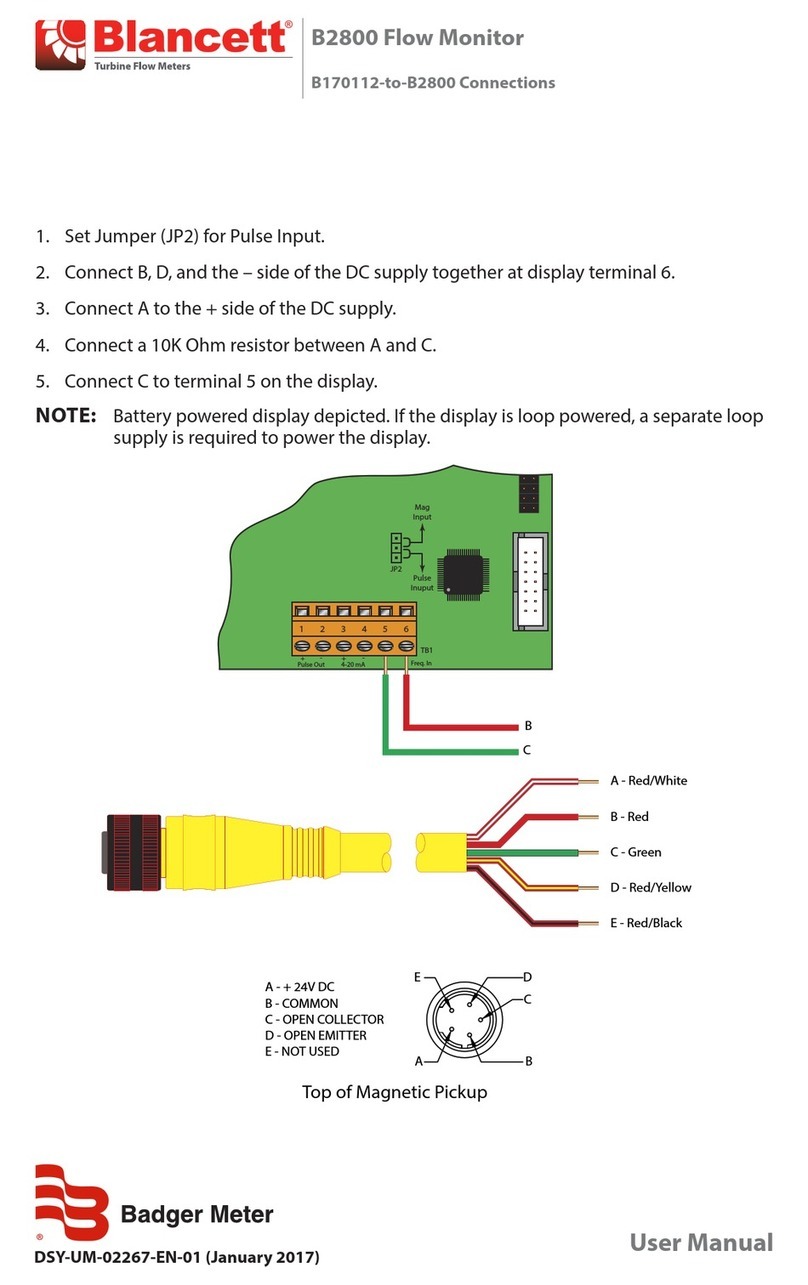

ADDITIONAL INPUT OPTIONS

The B2800 flow monitor is capable of receiving magnetic pickup input (small signal sine

wave) or a contact closure input (pulse)� Since most Blancett turbine flow meters use a

magnetic pickup, the B2800 flow monitor is shipped configured for magnetic pickup input�

To change to a contact closure input, remove JP2 from the top two pins and jumper them

to the bottom two pins� See Figure 6�

+ Pulse In

Magnetic Pickup

10K

30V DC (Max)

20 mS Pulse

RMAX =

(Loop Supply Voltage - 5)

0.02

123456

+ -+ -+ -

- Pulse In

10…30V DC

- Common

Pulse Input Card

Analog Input Card - 4-20 mA

Figure 5: Wiring diagram

Pulse Out Freq. In4-20 mA

Magnetic Pickup

10K

30V DC (Max)

10…30V DC

1…5V DC

20 mS Pulse

250 Typ

RMAX = (Loop Supply Voltage - 5)

0.02

123456

+ -+ -+ -

JP2

Mag

Input

Pulse

Inuput

TB1

12345

J2

Keypad

Connector

Loop Powered

Pulse Out Freq. In4-20 mA

Magnetic Pickup

10K

30V DC (Max)

20 mS Pulse

123456

+ -+ -+ -

JP2

Mag

Input

Pulse

Inuput

TB1

12345

J2

Keypad

Connector

N/C N/C

Battery Powered

Figure 6: Circuit board layouts

Page 16 October 2015DSY-PM-00286-EN-03

Additional Scaling Information

ADDITIONAL SCALING INFORMATION

This information is supplied as a general introduction to the basic concepts used to scale

rate displays� The applicability of the information is dependent on the type and capabilities

of the specific display/monitor used�

Flow meters producing an electronic signal are normally supplied in one of two output

formats� The pulse format generates some form of alternating signal that can be raw, that

is no amplification or wave shaping can be done prior to transmission to the readout�

The output pulse rate is related proportionally to flow rate� Pulses can also be modified to

produce higher output amplitudes or specific wave shapes�

The other output format is an analog signal� This is a continuous, variable voltage or current

signal that is normally scaled to the dynamic range of the meter� Typical analog signals are

0…5V DC, 0…10V DC, and 4…20 mA� The analog signals may or may not be derived from a

raw pulse signal produced by the flow meter�

Scaling for any of these input signals always requires at least two scaling points for a linear

process – zero or minimum flow point and the maximum flow point� Additionally, each

scaling point has two components, the actual input signal value and the desired display

value at that input signal for that scaling point�

For example, a pulse output flow meter has a flow of 50 gpm at a pulse rate of 100 Hz�

The actual input signal is the 100 Hz figure, but allowing the display to read 100 would be

meaningless to the operator� The solution to this problem is to scale the display to read 50

(gpm) when the input is 100 Hz�

Pulse Output Signals for Linear Processes

Pulse output signals are related to flow rate by a constant, usually referred to as the K-factor�

The K-factor is reported as the number of accumulated pulses that represents a particular

volume, such as gallon or liter� K-factors are indicated in pulses per unit volume or counts

per unit volume� An example of a K-factor, normally supplied by the manufacturer, might

be 2000 counts per gallon� The K-factor is correlated to flow through a simple mathematical

relationship:

Frequency = K-factor × Volume per unit of time

60

Using the previous example of 2000 counts per gallon and further assuming this meter

has a maximum flow rate of 25 gpm, the formula can be arranged to calculate the input

frequency required for a scaling point as follows:

Frequency = 60

2000 × 1 (gal) = 33.333 Hz at 1 gpm

Page 17October 2015 DSY-PM-00286-EN-03

Additional Scaling Information

Given that the meter has a maximum flow rate of 25 gpm, the maximum frequency would

then be:

Frequency = 60

2000 × 25 (gal) = 833.333 Hz at 25 gpm

A programmable display requires at least two points� The first point is the zero or minimum

flow and the second is normally the maximum flow rate� For the imaginary flow meter used

in the example above, the scaling would be as follows:

Input Value for Scaling Point 1 = 0

Display Value for Scaling Point 1 = 0

Input Value for Scaling Point 1 = 833�33

Display Value for Scaling Point 2 = 25

Pulse Output Signals for Non-linear Processes

Few flow meters actually behave in a linear way� There is always some uncertainty about

the exact flow at a given reported input value� For many common flow measurement

applications, the assumption of linear flow is adequate for the process being measured�

When higher accuracy is required, a technique called linearization is often employed�

When the flow meter is being calibrated, multiple data points are obtained for the

particular meter being tested� A typical five point calibration run is displayed below�

GPM (LPM) Average Frequency **UUT Hz Counts/GAL UUT K (Hz × 60)/NK

gpm

Error

(% FS)

15�00 (59�78) 769�7 3078�59 14�90 –0�65

9�06 (34�3) 466�1 3086�75 9�03 –0�38

5�49 (20�78) 285�2 3118�64 5�52 0�65

3�32 (12�57) 171�7 3103�95 3�32 0�17

2�00 (7�57) 103�6 3101�80 2�01 0�10

**UUT = Unit Under Test

If this meter produced an actual linear output, the K-factor calculation for the Unit Under

Test would be exactly the same for each measurement point� Inspection of the UUT K in

the example provided shows that this is not the case and indicates that this meter is not a

perfectly linear device�

Many programmable displays allow for linearization and can provide a better match of

the displayed flow values with the actual flow values by incorporating more measurement

points� In the example, the unit would be programmed for six points, the five data points

and a zero point, and use pairs of input values to accomplish the linearization�

Page 18 October 2015DSY-PM-00286-EN-03

Default K-factor Values

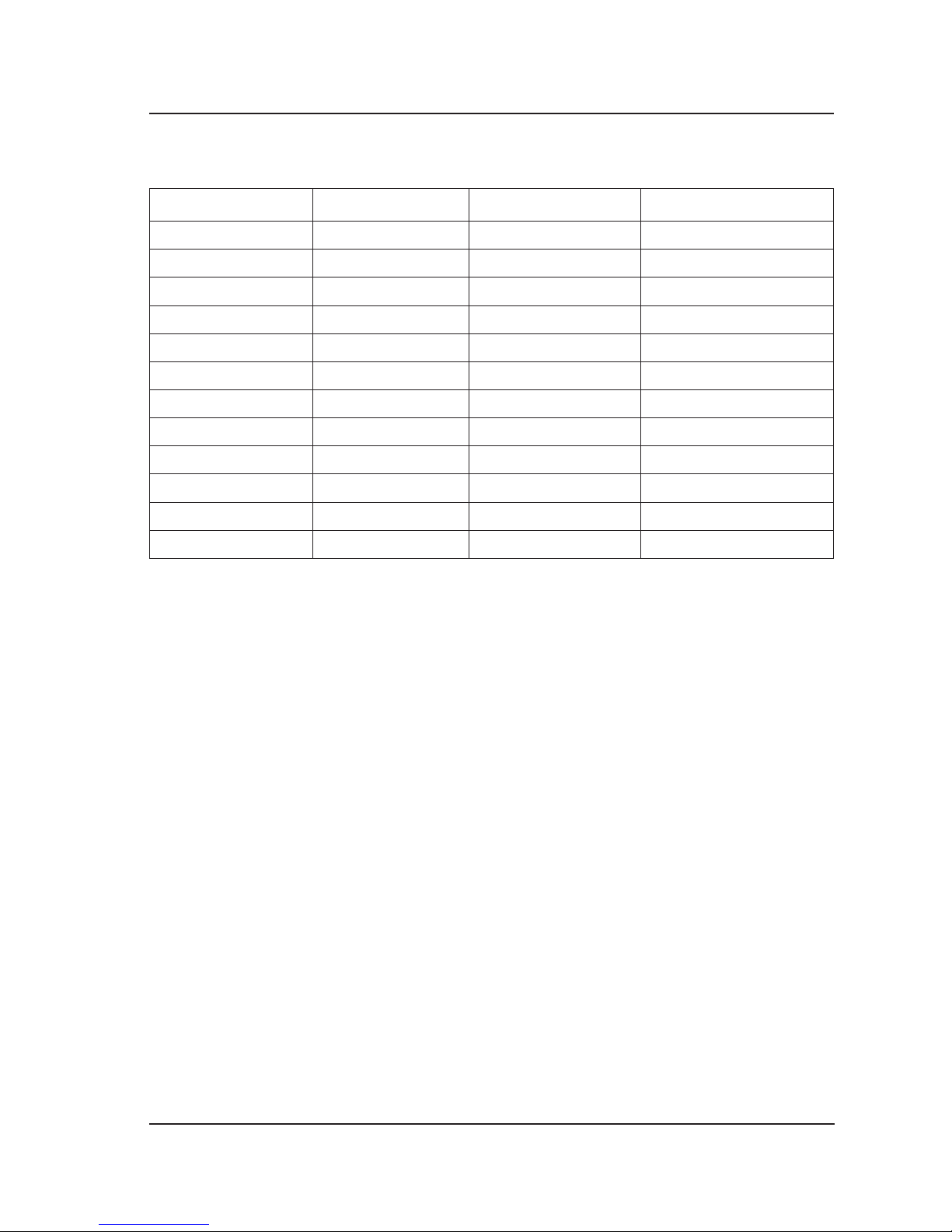

DEFAULT KFACTOR VALUES

Meter Size Default K-factor Lower Limit Upper Limit

3/8 in� (9�53 mm) 20,000 16,000 24,000

1/2 in� (12�7 mm) 13,000 10,400 15,600

3/4 in� (19�05 mm) 2750 2200 3300

7/8 in� (22�23 mm) 2686 2148 3223

1 in� (25�4 mm) 870�0 696�0 1044

1-1/2 in� (38�1 mm) 330�0 264�0 396�0

2 in� (50�8 mm) 52�0 41�6 62�0

3 in� (76�2 mm) 57�0 45�6 68�0

4 in� (101�6 mm) 29�0 23�2 35�0

6 in� (152�4 mm) 7�0 5�6 8�0

8 in� (203�2 mm) 3�0 2�4 4�0

10 in� (254 mm) 1�6 1�3 2�0

Page 19October 2015 DSY-PM-00286-EN-03

Installation Drawing

INSTALLATION DRAWING

Battery Powered

Page 20 October 2015DSY-PM-00286-EN-03

Other manuals for B2800 Standard

5

Table of contents

Other Blancett Monitor manuals