Blancett B3000 User manual

Digital Flow Monitor

B3000

DSY-PM-00022-EN-14 (April 2018) User Manual

C

L

A

S

S

I

F

I

E

D

Digital Flow Monitor, B3000

Page ii April 2018DSY-PM-00022-EN-14

CONTENTS

Scope of This Manual � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Terminology and Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Considerations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Electrical Symbols � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Introduction� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Connecting the B3000 to a Frequency Output Device � � � � � � � � � � � � � � � � � � � � � 7

Power Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Standard� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Solar � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Operating the Monitor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Programming Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Programming Using Frequency Output Turbine Flow Meters � � � � � � � � � � � � � � � 12

Menu Structure� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Liquid� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Advanced I/O Liquid � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Gas � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Advanced I/O Gas � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Liquid (Solar Powered) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Gas (Solar Powered)� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Programming � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Liquid� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Gas � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Return to Run Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Troubleshooting Guide� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Default K-Factor Values � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

User Manual

Page iii

April 2018 DSY-PM-00022-EN-14

Battery Replacement (B30A/B/X/Z only) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

NEMA 4X Enclosure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

Explosion-Proof Enclosure� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

K-Factors Explained � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Calculating K-factors � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Declaration of Conformity � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Explosion-Proof Enclosure� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Modbus Interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 49

Modbus Register / Word Ordering� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 50

Specications� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

Part Number Construction� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

Blancett B3000 Display� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

Blancett B3000 Explosion-proof Display � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

Dimensions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

Meter Mount � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

Remote Mount � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

Explosion-proof � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

Swivel Mount� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

Digital Flow Monitor, B3000

Page iv April 2018DSY-PM-00022-EN-14

Scope of This Manual

Page 5April 2018 DSY-PM-00022-EN-14

SCOPE OF THIS MANUAL

This manual is intended to help you get the B3000 flow monitor up and running quickly�

MPORTANTI

Read this manual carefully before attempting any installation or operation. Keep the manual

accessible for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable

accessories for any physical damage such as scratches, loose or broken parts, or any other

sign of damage that may have occurred during shipment�

OTE:NIf damage is found, request an inspection by the carrier’s agent within 48 hours of

delivery and file a claim with the carrier� A claim for equipment damage in transit

is the sole responsibility of the purchaser�

SAFETY

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, is estimated

to be capable of causing death or serious personal injury�

Indicates a hazardous situation, which, if not avoided, could result in

severe personal injury or death�

Indicates a hazardous situation, which, if not avoided, is estimated

to be capable of causing minor or moderate personal injury or

damage to property�

Considerations

The installation of the B3000 flow monitor must comply with all applicable federal, state,

and local rules, regulations, and codes�

EXPLOSION HAZARD SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2.

AVERTISSMENT

RISQUE D’EXPLOSION LA SUBSTITUTION DE COMPOSANTS PEUT RENDRE

CEMATÉRIEL INACCCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

DO NOT CONNECT OR DISCONNECT EITHER POWER OR OUTPUTS UNLESS THE AREA IS

KNOWN TO BE NONHAZARDOUS.

AVERTISSMENT

RISQUE D’EXPLOSION. NE PAS DÉBRANCHER TANT QUE LE CIRCUIT EST SOUSTENSION,

À MOINS QU’LL NE S’AGISSE D’UN EMPLACEMENT NON DANGEREUX.

Introduction

Page 6 April 2018DSY-PM-00022-EN-14

MPORTANTI

Not following instructions properly may impair safety of equipment and/or personnel.

Electrical Symbols

Function Direct

Current Alternating

Current Earth

(Ground) Protective

Ground Chassis

Ground

Symbol

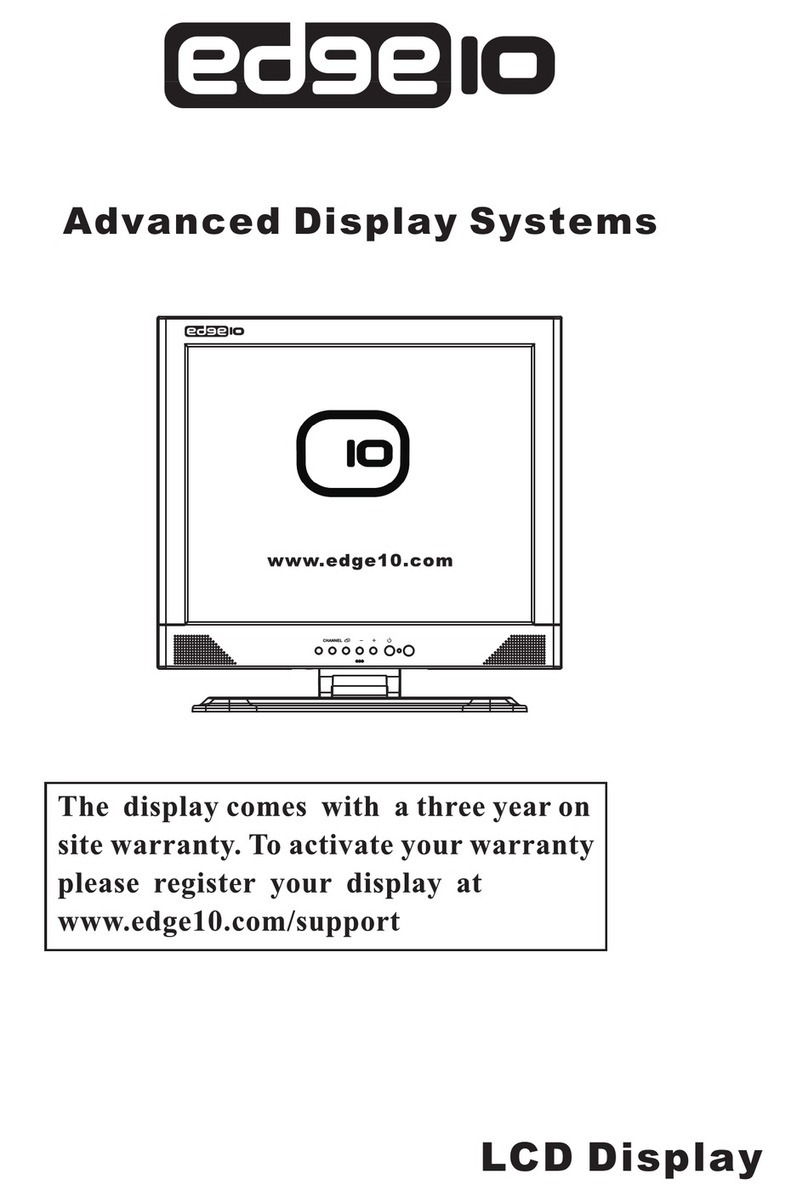

INTRODUCTION

The B3000 flow monitor incorporates state-of-the-art, digital signal processing technology,

designed to provide exceptional flexibility at a very affordable price� Though designed

for use with Blancett flow sensors, this monitor can be used with almost any flow sensor

producing a low amplitude AC output or contact closure signal�

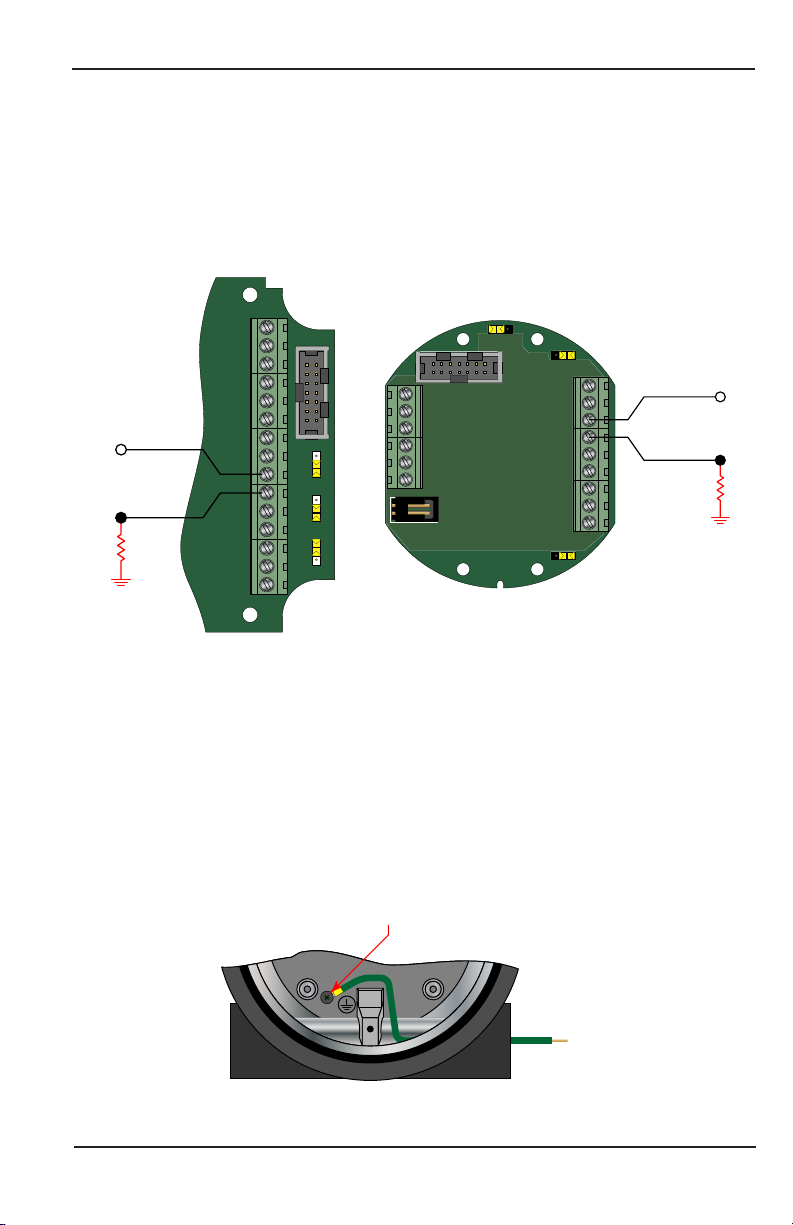

Figure 1: B3000 Flow monitor (NEMA 4X) Figure 2: B3000 Flow monitor (Ex-Proof)

This monitor can accept low-level frequency input signals typically found in turbine flow

sensors� The output signal for these types of sensors is a frequency proportional to the rate

of flow� The B3000 monitor uses the frequency information to calculate flow rate and total

flow� Through the use of the programming buttons, you can select rate units, total units and

unit time intervals among other functions� If required, the monitor can easily be

re-configured in the field� Finally, you can choose between simultaneously showing rate

and total, or alternating between rate and grand total�

The monitor is available in two different levels of functionality and two packaging options�

The base model provides all the functions necessary for the most common flow metering

applications� The advanced version adds communications capabilities over an RS485 bus

using Modbus RTU and control outputs� The B3000 monitor can be powered using loop,

battery or solar power�

Packaging options include a polycarbonate, NEMA 4X version and an aluminum explosion

proof enclosure�

Installation

Page 7April 2018 DSY-PM-00022-EN-14

INSTALLATION

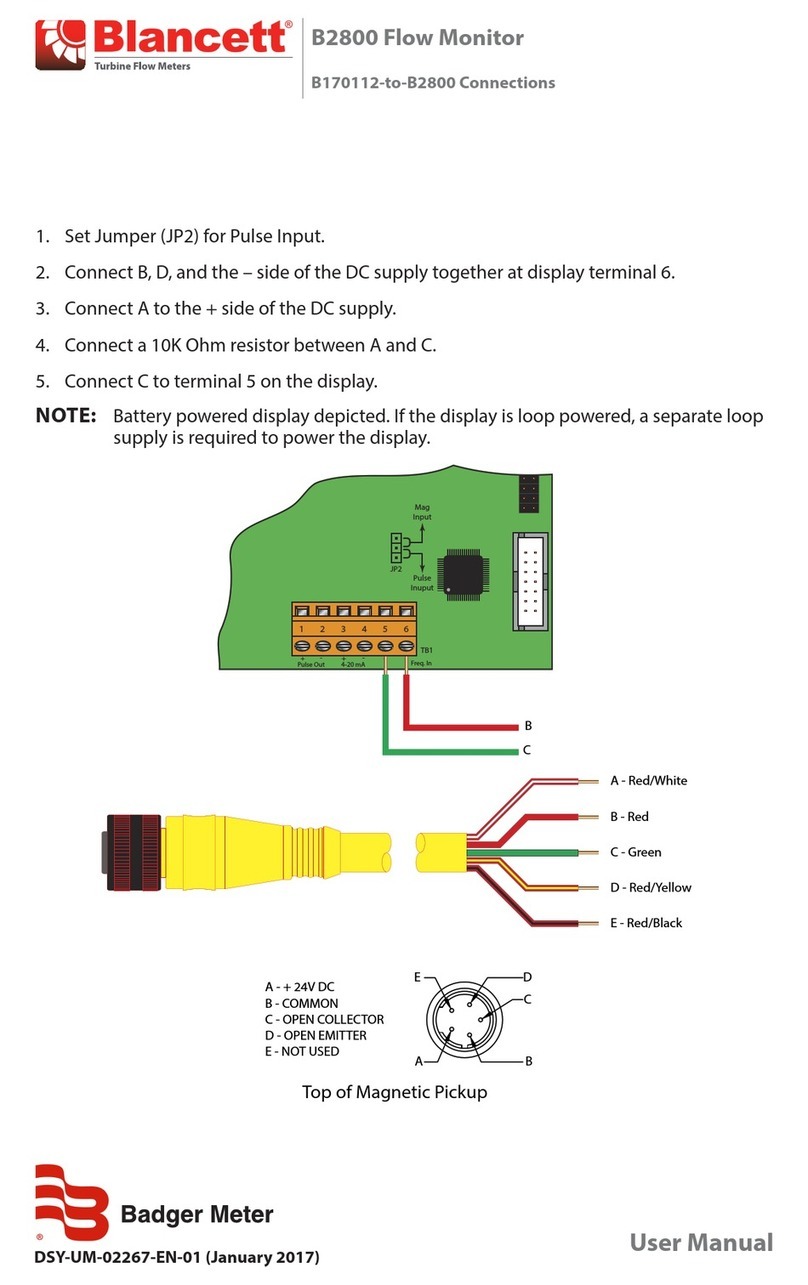

Connecting the B3000 to a Frequency Output Device

Most turbine flow sensors produce a frequency output that is directly proportional to the

volumetric flow through the sensor� There are, however, different output waveforms that

can be presented to the display device depending on the transducer that converts the

mechanical motion of the turbine into an electrical signal�

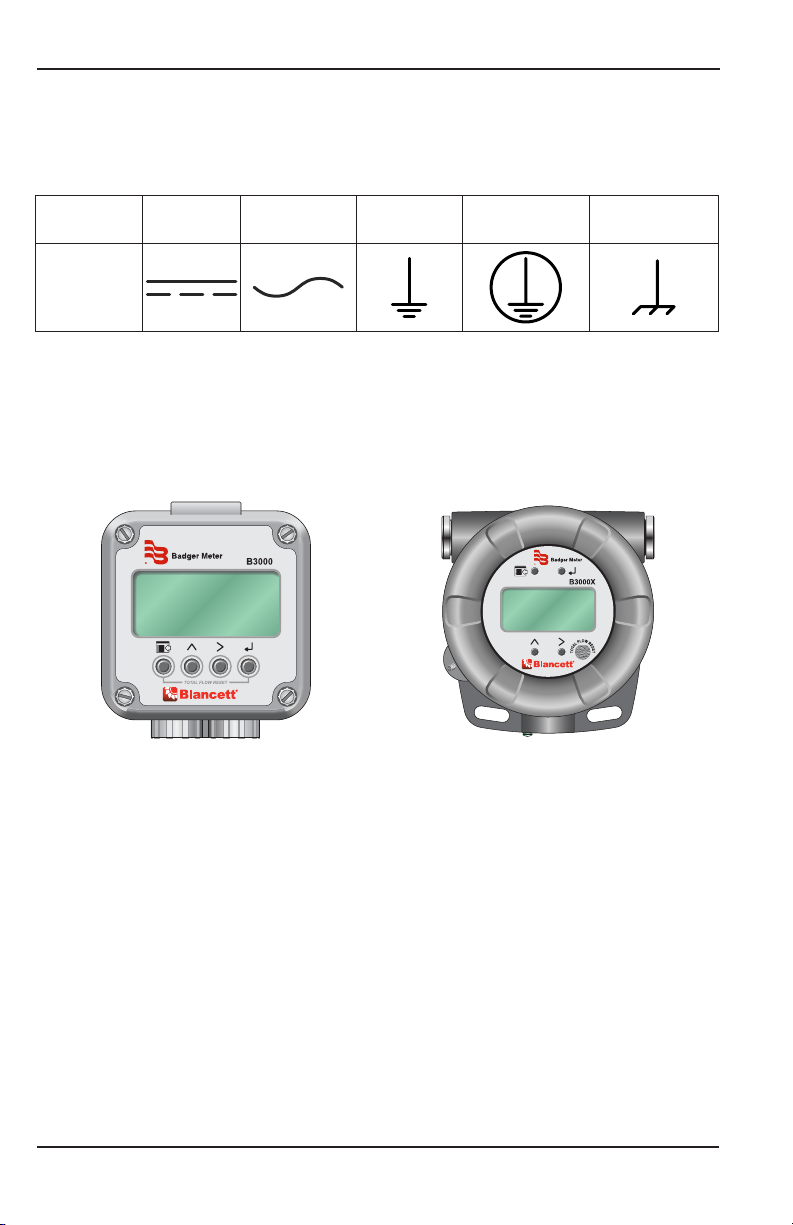

The B3000 monitor has two jumpers for setting the type of signal and the minimum

amplitude of the signal that it accepts� First, establish the type of output provided by the

flow sensor� The outputs almost always fall into one of two types�

• Type 1 is the unaltered frequency signal coming from an un-amplified magnetic

pickup� This signal is normally a sine wave in appearance, and the amplitude of the

waveform varies with the flow� Small turbines have comparatively small rotating

masses so they produce a smaller amplitude waveform and higher frequencies than

larger turbine sensors�

• Type 2 is the frequency signal from the transducer is amplified, wave shaped or both,

to produce a waveform of a specified type and amplitude� Most amplified transducers

output a square wave shape at one of many standard amplitudes� For example a

popular amplified output is a 10V DC square wave�

If the flow sensors output signal is type 1, you must also determine the minimum

amplitude of the frequency output� The B3000 monitor has a high or low signal sensitivity

setting� Use the high signal sensitivity (30 mV) with low amplitude (usually small) turbine

flow sensors� Use the low signal sensitivity setting (60 mV) for larger turbines and amplified

transducers (see Figure 3 and Figure 4)�

OTE:NUse the high signal sensitivity setting where the minimum signal amplitude is

below 60 mV� Setting the sensitivity lower than necessary may allow of noise

interference�

JP1

JP2

JP3

Input Total Pulse Signal

TB1

Mag

Pulse

Iso

OC

Low

High

Input Waveform Selection

(Magnetic Pickup Selection Shown)

Input Signal Level Selection

(Low Signal Sensitivity (60 mV) Selection Shown) Freq. In

+

–

Gnd

JP1

Input

MagPulse

JP2

TB2

TB1

P1

Signal

LowHigh

P1

Input Waveform Selection

(Magnetic Pickup Selection Shown)

Input Signal Level Selection

(Low Signal Sensitivity (60 mV) Selection Shown)

Figure 3: Input jumper settings (NEMA 4X) Figure 4: Input jumper settings (Ex-Proof)

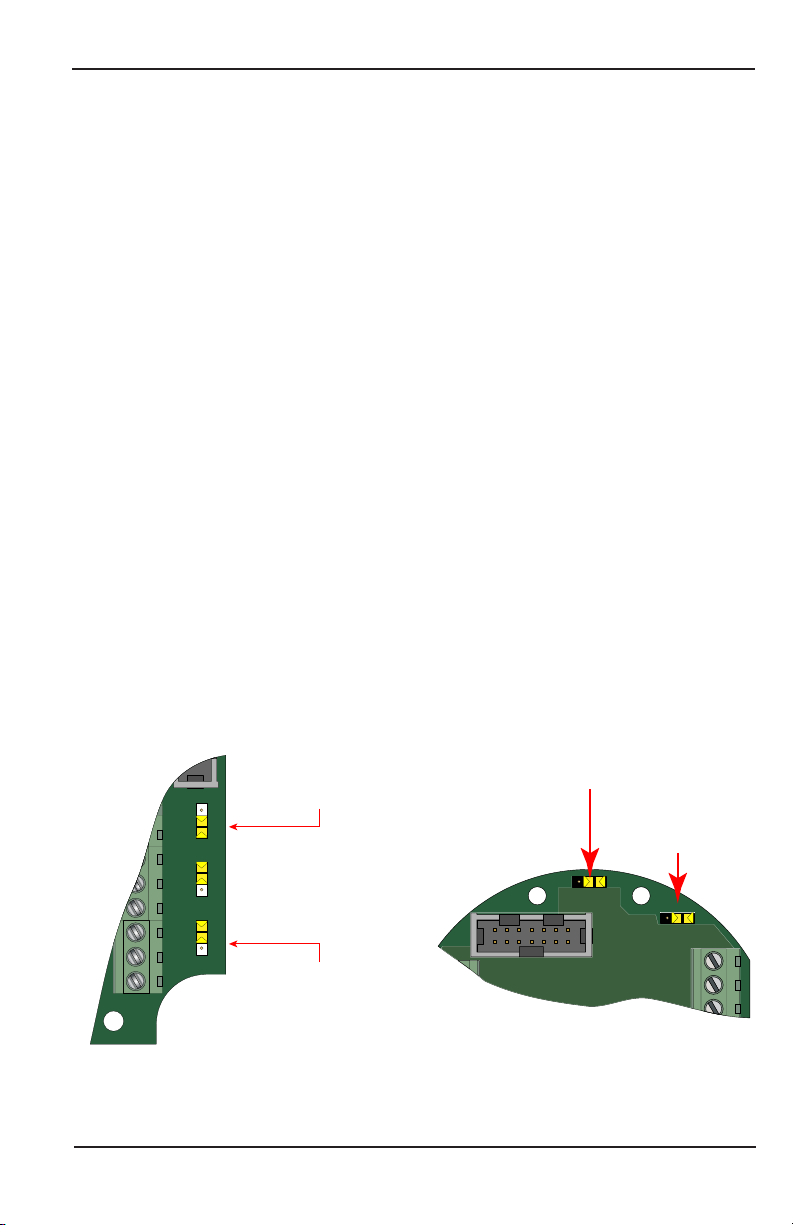

When the type of waveform and input signal level (amplitude) are determined, set the

jumpers on the B3000 monitor circuit board�

Installation

Page 8 April 2018DSY-PM-00022-EN-14

For typical variable reluctance magnetic pickups, set the waveform selection jumper

for Mag� Determine the setting for the input level by looking at the magnetic pickup

specifications� If the minimum amplitude at the minimum rated flow is greater than 60 mV,

use the low signal sensitivity jumper position (see Figure 3 on page 7 and Figure 4 on

page 7)�

If the minimum signal level is below 60 mV, use the high signal sensitivity jumper position�

JP1

JP2

JP3

Input Total Pulse Signal

P1

Freq.In

4-20mA

IsoTotal Pluse

TR_B

TR_A

RS485Gnd

Setpoint 1

Setpoint 2

Gnd

+

–

+

–

+

–

TotalReset

OCTotal Pluse

SignalGnd

TB1

Mag

Pulse

Iso

OC

Low

High

Mag

Pulse

JP1

Input

Freq.I n

4-20mA

IsoTotal Pluse

+

–

+

–

+

–

TotalReset

OCTotal Pluse

Signal Gnd

TR_B

TR_A

RS485 Gnd

Setpoint 1

Setpoint 2

Gnd

+

–

P2 3.6Vdc

Battery

JP3

TotalPulse

ISO OC

JP1

Input

MagPulse

JP2

TB2

TB1

P1

Signal

LowH igh

P1

JP1

Input

MagPulse

Figure 5: Typical magnetic pickup connection

(NEMA 4X)

Figure 6: Typical magnetic pickup connection

(Ex-Proof)

For amplified input signals the input jumper should be set to Pulse and the signal jumper

set to Low (see Figure 7 and Figure 8)�

OTE:NAmplified magnetic pickups require an external power source� The B3000 does

not supply power to an amplified pickup�

JP1

JP2

JP3

Input Total Pulse Signal

P1

Freq.In

4-20mA

IsoTotal Pluse

TR_B

TR_A

RS485Gnd

Setpoint1

Setpoint2

Gnd

+

–

+

–

+

–

TotalReset

OCTotal Pluse

SignalGnd

TB1

Mag

Pulse

Iso

OC

Low

High

POWER

SUPPLY

Mag

Pulse

JP1

Input

Freq.In

4-20mA

IsoTotal Pluse

+

–

+

–

+

–

TotalReset

OCTotal Pluse

Signal Gnd

TR_B

TR_A

RS485 Gnd

Setpoint 1

Setpoint 2

Gnd

+

–

P2 3.6Vdc

Battery

JP3

TotalPulse

ISO OC

JP1

Input

MagPulse

JP2

TB2

TB1

P1

Signal

LowHigh

P1

POWER

SUPPLY

JP1

Input

MagPulse

Figure 7: Typical amplified pickup connection

(NEMA 4X)

Figure 8: Typical amplified pickup connection

(Ex-Proof)

Power Connections

Page 9April 2018 DSY-PM-00022-EN-14

POWER CONNECTIONS

Standard

The power supply used in the B30A/B/X/Z is an internal lithium 3�6V DC D cell that will

power the monitor for about six years when no outputs are used� The monitor can also

get power from a 4…20 mA current loop (see Figure 9 and Figure 10)� If the current loop

is used a sensing circuit within the monitor detects the presence of the current loop and

disconnects the battery from the circuit� The B30S uses solar power only�

JP1

JP2

JP3

Input Total Pulse Signal

P1

Freq. In

4-20mA

Iso Total Pluse

TR_B

TR_A

RS485 Gnd

Setpoint 1

Setpoint 2

Gnd

+

–

+

–

+

–

Total Reset

OC Total Pluse

Signal Gnd

TB1

Mag

Pulse

Iso

OC

Low

High

4…20 mA

Current Loop

(10…28V DC)

Load

10…28V DC

Freq. In

4-20mA

Iso Total Pluse

+

–

+

–

+

–

Total Reset

OC Total Pluse

Signal Gnd

TR_B

TR_A

RS485 Gnd

Setpoint 1

Setpoint 2

Gnd

+

–

P2 3.6Vdc

Battery

JP3

Total Pulse

ISO OC

JP1

Input

MagPulse

JP2

TB2

TB1

P1

Signal

LowHigh

P1

4…20 mA

Current Loop

(10…28V DC)

Load

10…28V DC

Figure 9: Loop power connections (NEMA 4X) Figure 10: Loop power connections (Ex-Proof)

GROUNDING FOR THE EXPLOSION PROOF ENCLOSURE IS NECESSARY. THE EXPLOSION

PROOF ENCLOSURE IS PROVIDED WITH A GROUNDING SCREW ON THE INSIDE OF THE

ENCLOSURE. THE CONDUCTOR USED FOR GROUNDING MUST BE OF A WIRE GAGE

EQUAL TO OR GREATER THAN THE SIGNAL WIRES BEING USED. SEE FIGURE 11.

The explosion proof enclosure is provided with a grounding screw on the inside of the

enclosure� The conductor used for grounding must be of a wire gage equal to or greater

than the signal wires being used�

To Earth Ground

Grounding Screw

Figure 11: Required grounding for Ex-proof enclosure

Power Connections

Page 10 April 2018DSY-PM-00022-EN-14

Solar

A solar cell mounted on the top of the monitor in the B30S charges an internal 3�6V DC

nickel-cadmium battery that powers the monitor� A fully charged battery powers the

monitor for approximately 30 days� The solar powered B3000 has a single totalizing pulse

output and cannot be powered by a 4…20 mA loop�

Solar Cell

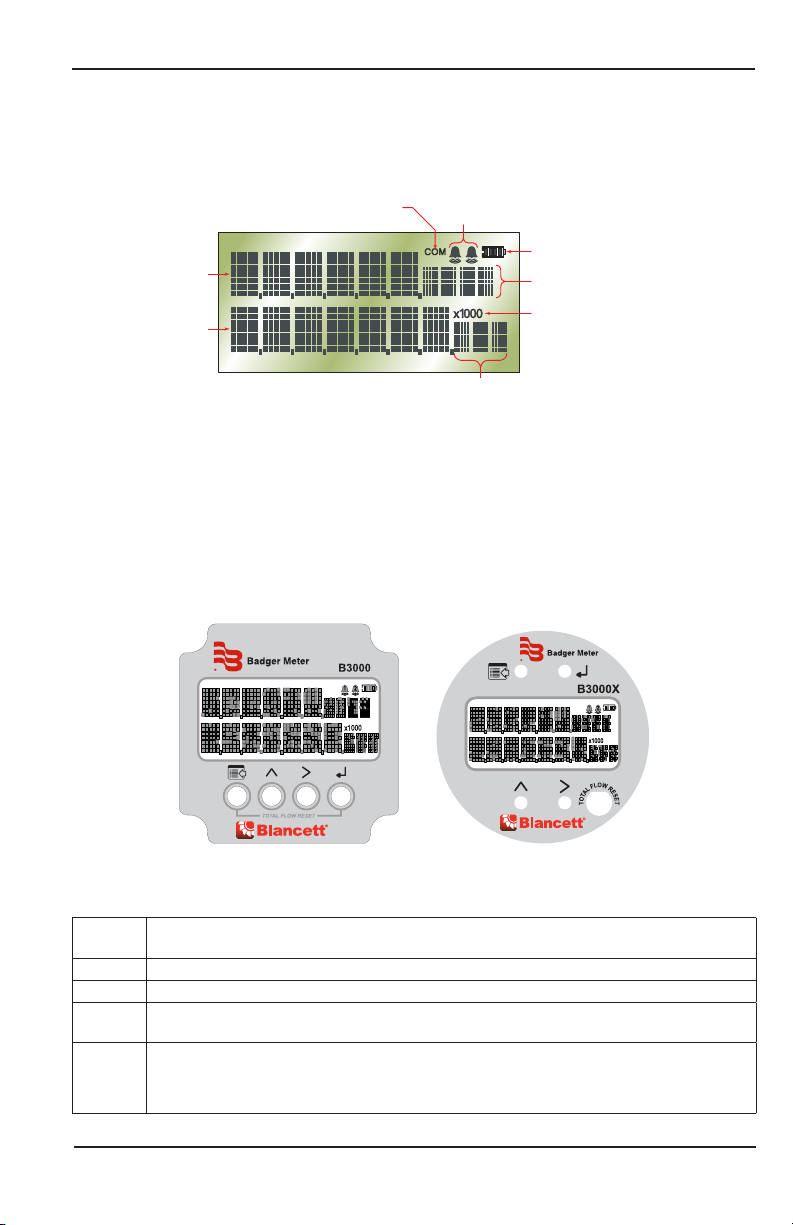

Figure 12: Solar powered B3000

Operating the Monitor

Page 11April 2018 DSY-PM-00022-EN-14

OPERATING THE MONITOR

The monitor has three modes of operation referred to as the Run, Programming, and

Extended Programming modes�

2

1Battery

Indicator

Alarm

Activation

Rate

Units

Totalizer

Units

Totalizer

Multiplier

Total

Rate

Communications

Indicator

Figure 13: Display annunciators

To access the Programming mode, momentarily press and then release MENU until the first

programming screen displays� The Extended Programming mode is entered by pressing and

holding MENU until the first programming option appears� After programming the display

with the necessary information, a lock out feature is available to prevent unauthorized

access or changing of the meter’s setup parameters�

Programming Mode

COM 12

COM 12

Figure 14: Keypad detail

Buttons

MENU Switches to Program mode, press and hold for three seconds to enter Extended

Programming mode, and is used in reset process

UP Scrolls forward through the parameter options and increments numeric variables

RIGHT Scrolls backward through the parameter options and moves the active digit to the right

ENTER Saves programming information, advances to the next programming parameter, and is

used in the reset process

TOTAL

FLOW

RESET

Explosion-proof only—allows the total to be reset without opening up the case

NOTE: The functionality can be enabled or disabled through the Extended Programming

menu item RST Key� The factory default is Disabled�

Operating the Monitor

Page 12 April 2018DSY-PM-00022-EN-14

Special Functions

MENU + ENTER – Simultaneously press and hold to reset the current totalizer�

MENU - Press and hold menu for three seconds to enter extended programming

mode�

UP + Right – Simultaneously press and hold to show the firmware version

number, then the grand total�

UP – In run mode increases display contrast�

RIGHT – In run mode decreases display contrast�

Explosion-Proof Models Only

Explosion-proof models are equipped with a through-the-glass total reset function� This

function allows the user to reset the monitor without removing the front cover� To

enable this function, see “Enable Reset Through the Glass (Explosion-Proof Models Only)” on

page32�

To use this function, press and hold your finger to the glass of the monitor over the area

marked Total Flow Reset for two seconds� When the monitor recognizes your finger is on

the glass, the outline of the battery icon in the upper right corner of the screen disappears�

When the monitor displays Press to Reset, remove your finger from the glass for one second,

then place it back on the same area of glass for two seconds� The monitor flashes Tot Rst�

The monitor displays 0 for the totals when the operation is complete� The timing of placing

and removing your finger from the glass is an important part of this process� If the reset

does not work the first time, try the operation again making sure that the timing is correct�

Modes

RUN – Normal operating mode�

PROGRAM – Used to program variables into the display�

EXTENDED PROGRAM –Used to program advanced variables into the display�

TEST –Used as a diagnostic tool to show input frequency and totalizer counts�

Programming Using Frequency Output Turbine Flow Meters

Each Blancett turbine flow meter is shipped with either a K-factor value or frequency data� If

frequency data is provided, the data must be converted to a K-factor before programming

the monitor� K-factor information, when supplied, can usually be found on the neck of the

flow meter or stamped on the flow meter body� The K-factor represents the number of

pulses per unit of volume (see “K-Factors Explained” on page43)� The K-factor is required

to program the monitor�

Operating the Monitor

Page 13April 2018 DSY-PM-00022-EN-14

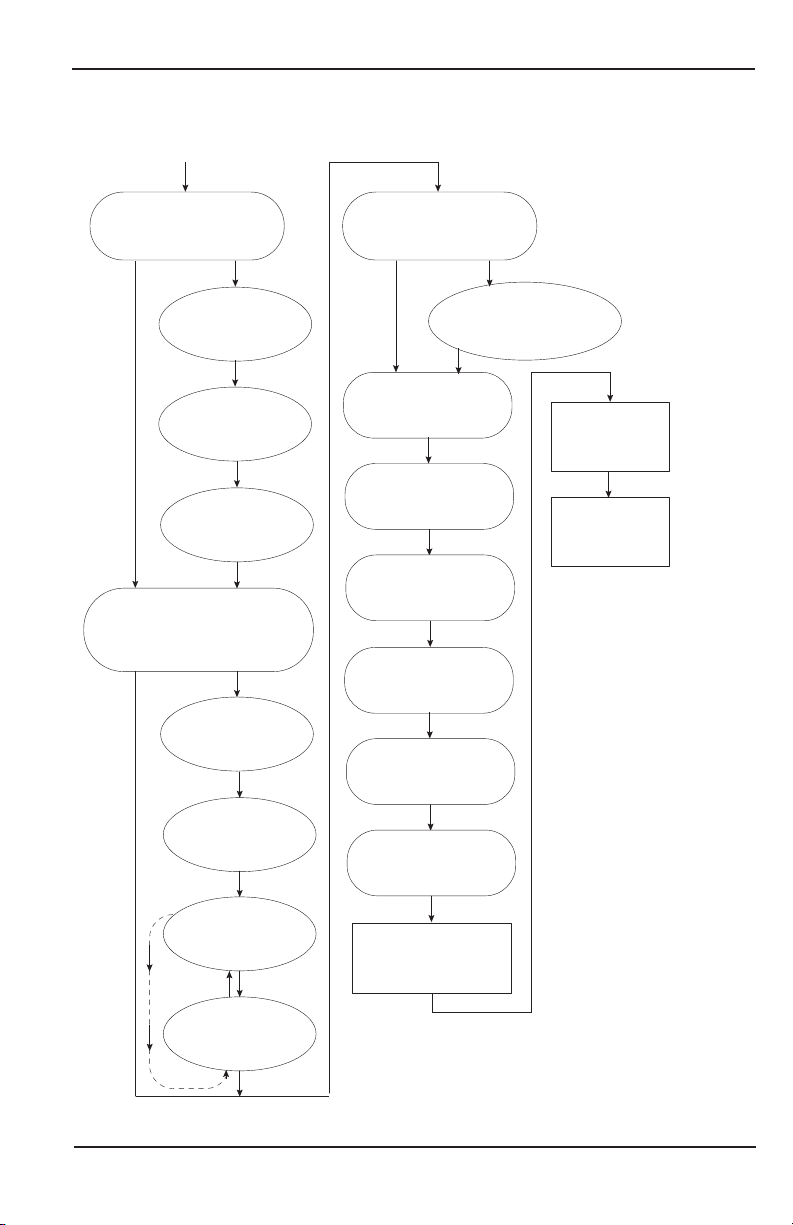

Essentials

The B3000 monitor is engineered to provide several levels of programming tailored to the

needs of the user� The first, or Programming level, provides access to the most commonly

used setup parameters bypassing the more advanced settings� The first level programming

is entered by pressing MENU for about one second�

The second level, or Extended Programming level, is accessed by pressing and holding

MENU until the extended programming menu starts�

With the standard and solar models there is a third level� For the most basic unit setup

choices the B3000 monitor employes a Simple and Advanced setup option accessed

through the Rate SU parameter� If Simple is selected the rate and total choices are reduced

to the five most common combinations avoiding the need to make unit and interval

choices�

Liquid Meters Standard Solar Advanced I/O

Basic Functions Press MENU for about one second and then release�

Extended Functions Press and hold MENU until the extended programming menu starts�

Simple Setup Select Rate SU in the extended functions and choose

Simple�Not Applicable

Advanced Setup Select Rate SU in the extended functions and choose

Advanced�

Table 1: Display mode selection information

Enter Programming Mode

The programming modes are accessed by pressing MENU for basic functions� Extended

functions are accessed by pressing and holding MENU until the first programming

parameter appears�

2

1Battery

Indicator

Units

Indicator

Totalizer

Units

Totalizer

Multiplier

Numeric

Values

Function

Figure 15: Programming mode display

Menu Structure

Page 14 April 2018DSY-PM-00022-EN-14

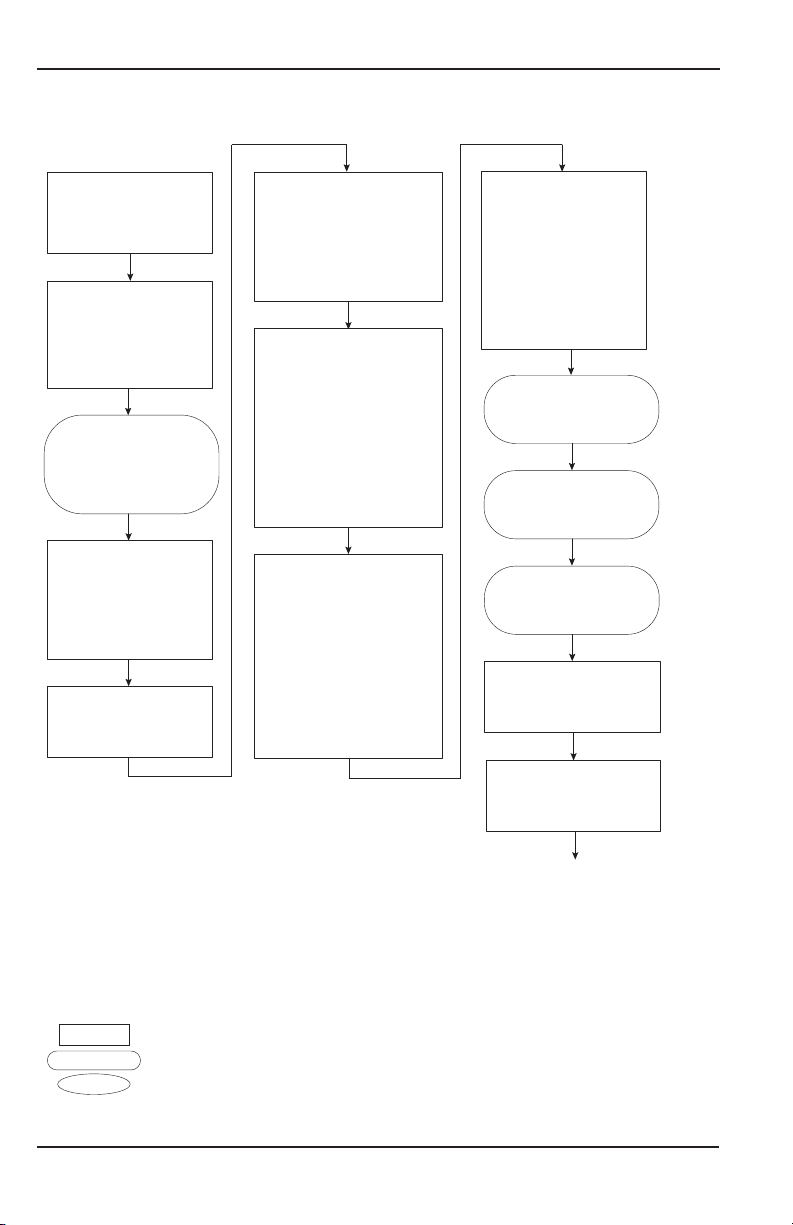

MENU STRUCTURE

Liquid

Fluid

Meter (Size)

Numeric Entry

KFactor

(K-Factor Value)

KFacUnt

(K-Factor Unit)

MASS

Display (Options)

START

Basic Menu

Extended Menu

Sub Menu

Liquid

Gas

0.250

0.375

0.500

0.625

0.750

0.875

1.0

1.25

1.5

Flow

Flow GT = Grand Total

Test

2.0

3.0

4.0

6.0

8.0

10.0

1225

1250

1275

Pul/Gal

Pul/m³

Pul/Ltr

Pul/Ft³

=

=

=

=

Pulses/Gallon

Pulses/meter³

Pulses/Liter

Pulses/Ft³

=

=

=

=

Sec

Min

Hour

Day

Second

Minute

Hour

Day

RateInt

(Rate time interval)

RateUnt

(Unit/interval=T)

GPT

LB/T

OB/T

AF/T

ML/T

LPT

m³/T

Ft³/T

MG/T

Kg/T

Lb/T

=

=

=

=

=

=

=

=

=

=

=

Gallons/T

Liquid Barrel/T

Oil Barrel/T

Acre Feet/T

Million Liters/T

Liters/T

Meters³/T

Feet³/T

Million

Gallons/T

Kilograms/T

Pounds/T

MASS

TotalUnt

(Totalizer Unit)

Gal

LBL

OBL

AFt

MLt

LPT

m³

Ft³

MGa

Kgs

Lbs

=

=

=

=

=

=

=

=

=

=

=

Gallons

Liquid Barrel

Oil Barrel

Acre Feet

Million Liters

Liters

Meters³

Feet³

Million

Gallons

Kilograms

Pounds

Menu item appears

only when MASS

units are selected.

Continued at B

on next page.

Shape Key

Rate SU

(Rate Unit Setup)

Simple Advanced

RateUnt

(Rate/Total Units)

GPM

Gal

OB/D

m³/D

m³

m³/H

m³

LPM

Ltr

=

=

=

=

=

=

=

=

=

Gallons/Min

Gallons

Oil Barrel/Day

Meters³/Day

Meters³

Meters³/Hour

Meters³

Liters/Min

Liters

Continued at A

on next page.

Menu Structure

Page 15April 2018 DSY-PM-00022-EN-14

Liquid (continued)

4-20Cal

(Calibrate 4-20)

Lin Pts = Linear Points (2 to10)

Linear

(Linearization)

Freq#1

(Frequency 1)

Clr G-T

(Clear Grand Total)

NO YES

4mA Out

(4 mA Output)

Numeric Entry

20mA Out

(20 mA Output)

Numeric Entry

4-20Tst

(4-20 mA Output)

Numeric Entry

Numeric Entry

Numeric Entry

Coef#1

(Coecient 1)

Numeric Entry

Freq#(x)

(Frequency 2-10)

Numeric Entry

Coef#(x)

(Coecent 2-10)

Numeric Entry

NO YES

Passwd

(Password)

Numeric Entry

RstPswd

(Reset Password)

Numeric Entry

Spec Gr

(Specic Gravity)

TotlMult

(Totalizer Multiplier)

× 1000

× 100

× 10

× 1

× 0.1

× 0.01

=

=

=

=

=

=

×1000

×100

×10

1

0.1

0.01

Numeric Entry

Scale F

(Scale Factor)

Numeric Entry

SetTotal

(Set Total Value)

Numeric Entry

Cuto

(Low Flow Cuto)

Numeric Entry

Damping

(Display Damping)

Numeric Entry

PulsOut

(Pulse Output)

Disable

Enable

Numeric Entry

Fl=20mA

(Flow at 20 mA)

Continued from B

on previous page.

Continued from A

on previous page.

Menu Structure

Page 16 April 2018DSY-PM-00022-EN-14

Advanced I/O Liquid

Fluid

Meter (Size)

Numeric Entry

KFactor

(K-Factor Value)

KFacUnt

(K-Factor Unit)

Spec Gr

(Specic Gravity)

MASS

Display (Options)

START

Basic Menu

Extended Menu

Sub Menu

Liquid

Gas

0.250

0.375

0.500

0.625

0.750

0.875

1.0

1.25

1.5

Flow

Flow GT = Grand Total

Test

2.0

3.0

4.0

6.0

8.0

10.0

1225

1250

1275

Pul/Gal

Pul/m³

Pul/Ltr

Pul/Ft³

=

=

=

=

Pulses/Gallon

Pulses/meter³

Pulses/Liter

Pulses/Ft³

=

=

=

=

Sec

Min

Hour

Day

Second

Minute

Hour

Day

RateInt

(Rate time interval)

RateUnt

(Unit/interval=T)

GPT

LB/T

OB/T

AF/T

ML/T

LPT

m³/T

Ft³/T

MG/T

Kg/T

Lb/T

=

=

=

=

=

=

=

=

=

=

=

Gallons/T

Liquor Barrel/T

Oil Barrel/T

Acre Feet/T

Million Liters/T

Liters/T

Meters³/T

Feet³/T

Million

Gallons/T

Kilograms/T

Pounds/T

MASS

TotalUnt

(Totalizer Unit)

Gal

LBL

OBL

AFt

MLt

LPT

m³

Ft³

MGa

Kgs

Lbs

=

=

=

=

=

=

=

=

=

=

=

Gallons

Liquor Barrel

Oil Barrel

Acre Feet

Million Liters

Liters

Meters³

Feet³

Million

Gallons

Kilograms

Pounds

TotlMult

(Totalizer Multiplier)

× 1000

× 100

× 10

× 1

× 0.1

× 0.01

=

=

=

=

=

=

×1000

×100

×10

1

0.1

0.01

Numeric Entry

Scale F

(Scale Factor)

Numeric Entry

SetTotal

(Set Total Value)

Numeric Entry

Cuto

(Low Flow Cuto)

Numeric Entry

Damping

(Display Damping)

Numeric Entry

PulsOut

(Pulse Output)

Disable

Enable

Numeric Entry

Fl=20mA

(Flow at 20 mA)

Menu item appears

only when MASS

units are selected. Continued on

next page.

Shape Key

Menu Structure

Page 17April 2018 DSY-PM-00022-EN-14

Advanced I/O Liquid (continued)

4-20Cal

(Calibrate 4-20)

Lin Pts = Linear Points (2 to10)

Linear

(Linearization)

Freq#1

(Frequency 1)

Modbus Address (1 to127)

BusAddr

Clr G-T

(Clear Grand Total)

Passwd

Password

NO YES

4mA Out

(4 mA Output)

Numeric Entry

20mA Out

(20 mA Output)

Numeric Entry

4-20Tst

(4-20 mA Output)

Numeric Entry

Numeric Entry

Numeric Entry

Coef#1

(Coecient 1)

Numeric Entry

Freq#(x)

(Frequency 2-10)

Numeric Entry

Coef#(x)

(Coecent 2-10)

Numeric Entry

Modbus

Disable Enable

Numeric Entry

SetPT1

(Setpoint 1)

Numeric Entry

Passwd

Password

HystSP1

(Hysteresis1)

Numeric Entry

Passwd

Password

TripSP1

(Trip On 1)

High Low

Passwd

Password

SetPT2

(Setpoint 2)

Numeric Entry

Passwd

Password

HystSP2

(Hysteresis2)

Numeric Entry

Passwd

Password

TripSP2

(Trip On 2)

High Low

NO YES

Passwd

(Password)

Numeric Entry

RstPswd

(Reset Password)

Numeric Entry

Continued from previous page.

Menu Structure

Page 18 April 2018DSY-PM-00022-EN-14

Gas

Fluid

Meter (Size)

Numeric Entry

KFactor

(K-Factor Value)

KFacUnt

(K-Factor Unit)

Display (Options)

START

Basic Menu

Extended Menu

Sub Menu

Liquid

Gas

Flow

Flow GT = Grand Total

Test

2.0 in. Low

2.0 in. Med

2.0 in. High

Pul/m³

Pul/Ltr

Pul/Ft³

=

=

=

Pulses/meter³

Pulses/Liter

Pulses/Ft³

=

=

=

=

Sec

Min

Hour

Day

Second

Minute

Hour

Day

RateInt

(Rate time interval)

RateUnt

(Unit/interval=T)

SCF/T

ACF/T

Nm³/T

Am³/T

Lt/T

mmF³/T

mF³/T

=

=

=

=

=

=

=

Standard Ft³/T

Actual Ft³/T

Normal M³/T

Actual M³/T

Liters/T

Million Ft³/T

Thousand Ft³/T

Shape Key

Continued on next page.

TotlUnt

(Totalizer Unit)

SCF

ACF

Nm³

Am³

Lt

mmF³

mF³

=

=

=

=

=

=

=

Standard Ft³

Actual Ft³

Normal M³

Actual M³

Liters

Million Ft³

Thousand Ft³

TotlMult

(Totalizer Multiplier)

× 1000

× 100

× 10

× 1

× 0.1

× 0.01

=

=

=

=

=

=

×1000

×100

×10

1

0.1

0.01

Scale F

(Scale Factor)

Numeric Entry

SetTotal

(Set Total Value)

Numeric Entry

Cuto

(Low Flow Cuto)

Numeric Entry

Numeric Entry

Op Pres

(Operating Pressure psi)

Numeric Entry

Op Temp

(Operating Temp °F)

Menu Structure

Page 19April 2018 DSY-PM-00022-EN-14

Gas (continued)

4-20Cal

(Calibrate 4-20)

Lin Pts = Linear Points (2 to10)

Linear

(Linearization)

Freq#1

(Frequency 1)

Clr G-T

(Clear Grand Total)

NO YES

4mA Out

(4 mA Output)

Numeric Entry

20mA Out

(20 mA Output)

Numeric Entry

4-20Tst

(4-20 mA Output)

Numeric Entry

Numeric Entry

Numeric Entry

Coef#1

(Coecient 1)

Numeric Entry

Freq#(x)

(Frequency 2-10)

Numeric Entry

Coef#(x)

(Coecent 2-10)

Numeric Entry

NO YES

Passwd

(Password)

Numeric Entry

RstPswd

(Reset Password)

Numeric Entry

Continued from

previous page.

Damping

(Display Damping)

Numeric Entry

PulsOut

(Pulse Output)

Disable

Enable

Numeric Entry

Fl=20mA

(Flow at 20 mA)

Menu Structure

Page 20 April 2018DSY-PM-00022-EN-14

Advanced I/O Gas

Fluid

Meter (Size)

Numeric Entry

KFactor

(K-Factor Value)

KFacUnt

(K-Factor Unit)

Display (Options)

START

Basic Menu

Extended Menu

Sub Menu

Liquid

Gas

Flow

Flow GT = Grand Total

Test

2.0 in. Low

2.0 in. Med

2.0 in. High

Pul/m³

Pul/Ltr

Pul/Ft³

=

=

=

Pulses/meter³

Pulses/Liter

Pulses/Ft³

=

=

=

=

Sec

Min

Hour

Day

Second

Minute

Hour

Day

RateInt

(Rate time interval)

RateUnt

(Unit/interval=T)

SCF/T

ACF/T

Nm³/T

Am³/T

Lt/T

mmF³/T

mF³/T

=

=

=

=

=

=

=

Standard Ft³/T

Actual Ft³/T

Normal M³/T

Actual M³/T

Liters/T

Million Ft³/T

Thousand Ft³/T

Shape Key

Continued on next page.

TotlUnt

(Totalizer Unit)

SCF

ACF

Nm³

Am³

Lt

mmF³

mF³

=

=

=

=

=

=

=

Standard Ft³

Actual Ft³

Normal M³

Actual M³

Liters

Million Ft³

Thousand Ft³

TotlMult

(Totalizer Multiplier)

× 1000

× 100

× 10

× 1

× 0.1

× 0.01

=

=

=

=

=

=

×1000

×100

×10

1

0.1

0.01

Scale F

(Scale Factor)

Numeric Entry

SetTotal

(Set Total Value)

Numeric Entry

Cuto

(Low Flow Cuto)

Numeric Entry

Numeric Entry

Op Pres

(Operating Pressure psi)

Numeric Entry

Op Temp

(Operating Temp °F)

Other manuals for B3000

1

Table of contents

Other Blancett Monitor manuals