BLASTONE SnakeBite XQ Instruction manual

Nozzle and Silencer

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

2

SAFETY WARNINGS

MANUAL CONTENTS

Fill in your model and serial number in the blank

spaces below. These can be used for reference

whenever service or maintenance is required.

Unit Serial Number

______________________________________

Date Of Issue

______________________________________

2 Safety Warnings

6 General Information

7 Installation

11 Operation

14 Service

15 Troubleshooting

WARNING

Do not attempt to operate this equipment

without rst reading and understanding

the manual enclosed with this device.

Suitability for use of this device lies solely

with user.

3

SAFETY WARNINGS

Safety alert symbol.

This symbol means: ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!

This is the “safety alert symbol” used

by this industry. This symbol is used to

warn of possible injury. Be sure to read

all warnings carefully. They are included

for your safety and for the safety of others

working with you.

The primary responsibility for safety with this

equipment falls to the operator. Make sure the

equipment is operated only by trained individuals

that have read and understand this manual. The

operator of this equipment should assess the

risks associated with using this equipment and

implement appropriate risk control measures.

If there is any portion of this manual or function

you do not understand, contact BlastOne

International to obtain further assistance. Keep

this manual available for reference.

TAKE NOTE! THIS SAFETY ALERT SYMBOL

FOUND THROUGHOUT THIS MANUAL IS USED

TO CALL YOUR ATTENTION TO INSTRUCTIONS

INVOLVING YOUR PERSONAL SAFETY OR

OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR

DEATH.

WARNING

4

SAFETY WARNINGS

SIGNAL WORDS: Note the use of signal words

DANGER, WARNING, and CAUTION with the

safety messages. The appropriate signal word

for each has been selected using the following

guidelines:

DANGER: Indicates an imminently hazardous

situation, which if not avoided, will result in

death or serious injury. This signal word is to be

limited to the most extreme situations, typically

for machine components which, for functional

purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous

situation, which if not avoided, could result in

death or serious injury, and includes hazards that

are exposed when guards are removed. It may

also be used to alert against unsafe practices and

indicate potential failure or damage to equipment.

CAUTION: Indicates a potentially hazardous

situation, which if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

Abrasive blasting exposes operators and

bystanders to hazards that can cause injury

or death. The operator of the SnakeBite XQ

Nozzle and Silencer must:

• always comply with local laws,

regulatory requirements and

codes of practice when using the

SnakeBite XQ Nozzle or Silencer.

• follow all blast system manufacturer

operational procedures relating to

blasting.

• carry out a risk assessment specic

to the use of the nozzle and silencer

and implement identied risk

control measures.

DANGER

5

SAFETY WARNINGS

Operator Complacency: the noise and

thrust generated by the SnakeBite XQ

Nozzle and Silencer when operated with

the silencer is signicantly lower than

other typical blasting nozzles. Operators

and bystanders should be aware of these

features and not stop observing the

required safe operation requirements when

this occurs.

Operators must read and understand fully

this operating manual prior to using the

SnakeBite XQ Nozzle and Silencer.

Operator Competence: Operators must

be trained and competent to undertake

abrasive blasting prior to using the

SnakeBite XQ Nozzle and Silencer.

Personal Protective Equipment (PPE):

Operators and bystanders are required

to wear appropriate PPE when blasting

operations are in progress.

WARNING

CAUTION

6

GENERAL INFORMATION

DESCRIPTION

The SnakeBite XQ Nozzle and Silencer

represents a step change in abrasive blasting

nozzle design and functionality. The unique

internal nozzle geometry of the SnakeBite XQ

Nozzle produces a more stable blast stream

than conventional nozzles. This results

in less blast stream turbulence, improved

stability, higher abrasive particle velocity for

an increased distance after the nozzle exit and

delivers increased abrasive particle energy at

the work surface.

The Silencer has been specically designed

to respond to the characteristics of the blast

stream produced by the SnakeBite XQ Nozzle

and is tuned to remove the typical high pitch

screech of the blast stream and reduce the

sound emitted by the blasting process.

The Silencer design incorporates a nozzle

thrust reduction feature that reduces the

force produced by the nozzle in the opposite

direction to the blast stream.

FEATURES

• Groundbreaking Nozzle internal geometry

that delivers up to 25% increase in surface

cleaning rates and operator productivity

without increased abrasive usage rates.

• Industry leading nozzle silencer delivering

up to 16dB noise reduction across a wide

range of operating pressures.

• Nozzle thrust reduction of up to 40%,

when operated with the silencer tted,

results in a signicant reduction in

operator fatigue over the shift.

• Silicon Nitride ceramic liner offering

excellent wear characteristics and life.

• Robust anodised aluminium nozzle jacket,

including a nozzle exit bump guard,

7

INSTALLATION

Installing the Nozzle

1. The SnakeBite XQ Nozzle is available in a

range of standard nozzle sizes and includes

a standard contractor inlet thread.

2. Inspect the condition of the nozzle liner and

jacket prior to installing it into the nozzle

holder. Make sure the nozzle liner is not

damaged or cracked or has pieces missing.

Check the nozzle is not excessively worn

by using a nozzle wear gauge – the nozzle

is excessively worn if the throat diameter

has worn to the diameter of the next larger

size nozzle. Inspect the nozzle jacket for

damage. If the nozzle liner is damaged or

excessively worn do not continue to use the

nozzle.

3. Ensure the system pressure is isolated

before installing the nozzle into the nozzle

holder.

4. Clean the threads on the nozzle and the

nozzle holder and make sure they are free

of any grit or debris.

protects the nozzle and liner from the

harsh blasting environment and improved

operator safety.

• Slimline ergonomic nozzle jacket design

providing improved grip and reduced

operator hand fatigue.

• Standard contractor nozzle inlet thread.

Installation - Always isolate the system

pressure prior to installing and removing

the nozzle or silencer and conducting

maintenance. If the Nozzle or Silencer is

damaged, cease using the damaged product.

WARNING

8

INSTALLATION

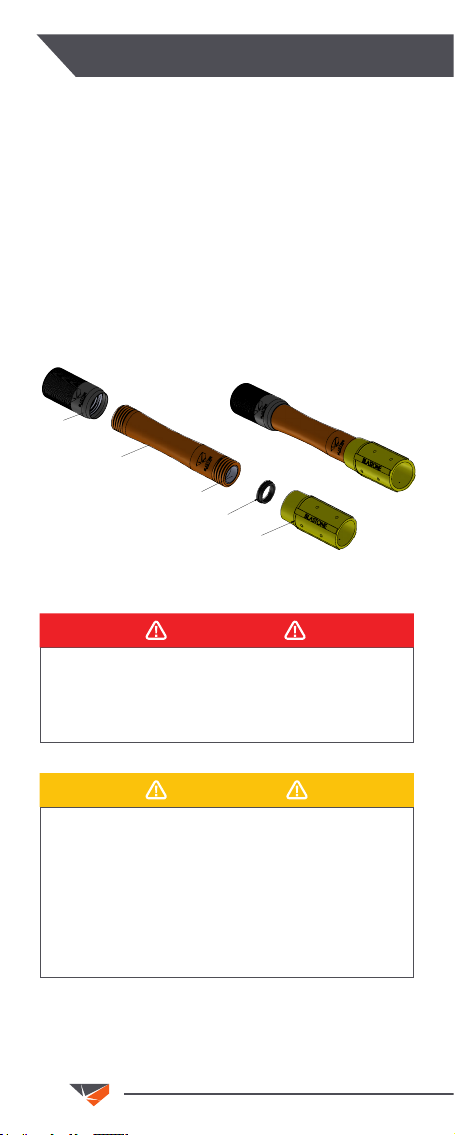

5. The nozzle is installed onto the blast hose

by screwing the bell shaped inlet end of the

of the nozzle into the nozzle holder. Make

sure the nozzle washer is located as shown

below.

6. Continue to screw the nozzle into the nozzle

holder until the nozzle reaches the end of

the nozzle holder thread, then tighten the

nozzle until it is hand tight. Do not over-

tighten the nozzle in the nozzle holder or

use any tools to tighten the nozzle.

7. If the nozzle is to be used without the

silencer, the bump guard must be installed

and securely tted to the outlet end of the

nozzle. Hand tighten the bump guard in the

same way the nozzle is hand tightened.

Note: The bump guard thread is different to

the nozzle inlet thread to ensure the nozzle

cannot be installed backwards.

8. When the nozzle is installed into the nozzle

holder as per the instructions above,

check to make sure the connection is tight

and there is no movement between the

nozzle holder and the nozzle. Check that

the nozzle holder is rmly secured to the

blast hose.

9. The nozzle is removed in the reverse order

to the above sequence.

Note: Ensure the system pressure is

isolated prior to removing the nozzle.

9

INSTALLATION

Installing the Silencer

1. Inspect the condition of the silencer liner

and jacket prior to installing it onto the

nozzle. Make sure the silencer liner is

not damaged or cracked or has pieces

missing. Inspect the silencer liner wall

thickness at the exit of the silencer –

typically the silencing effect will reduce

if the silencer is excessively worn. The

silencer is excessively worn if the exit

diameter has worn per the following table:

Inspect the silencer jacket for damage.

If the silencer is damaged or excessively

worn do not continue to use the silencer.

2. Ensure the system pressure is isolated

before installing the silencer onto the

nozzle.

3. The nozzle has been designed to be used

with or without the silencer. If required,

remove the bump guard, and clean the

threads on the nozzle exit and the silencer

and make sure they are free of any grit or

debris.

4. The silencer is installed onto the nozzle by

screwing it onto the outlet end of the nozzle

as shown below.

Note: there is no silencer washer.

5. Continue to screw the silencer onto the

nozzle until the nozzle reaches the end of

the silencer thread, then tighten the nozzle

until it is hand tight. Do not over-tighten the

nozzle in the nozzle holder or use any tools

to tighten the nozzle.

NOZZLE SIZE EXCESSIVELY WORN DIAMETER

No. 6 27 mm (1.06 in)

No. 7 30 mm (1.18 in)

No. 8 34 mm (1.34 in)

10

INSTALLATION

6. When the silencer is installed onto the

nozzle as per the instructions above, check

to make sure the connection is tight and

there is no movement between the silencer

and the nozzle. Check that the nozzle is

rmly tted into the nozzle holder.

7. The silencer is removed in the reverse

order to the above sequence.

Note: Ensure the system pressure is

isolated prior to removing the silencer.

Never point the nozzle in the direction of

personnel when the system is pressurised

or during blasting operations.

Nozzle Serviceability: Always inspect the

nozzle and silencer for excessive wear or

damage prior to operating the nozzle or

silencer.

Fatigue: Regular operator breaks are

recommended to reduce operator fatigue.

CAUTION

DANGER

NOZZLE AND SILENCER INSTALLATION ARRANGEMENT

SILENCER

NOZZLE

CURVED

NOZZLE

INLET

NOZZLE

WASHER

NOZZLE

HOLDER

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

APPV'D

MFG

Q.A

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:5

SHEET 1 OF 1

A3

WEIGHT:

TREVOR SEEWALD

BLASTONE INTERNATIONAL

#6 Assembly

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

1.6

UNO

TOLERANCES:

LINEAR: ± 0.25mm

ANGULAR: ± 0.1˚

11

OPERATION

Operators must read and understand fully

this operating manual prior to using the

SnakeBite XQ Nozzle and Silencer.

Operator Competence: Operators must

be trained and competent to undertake

abrasive blasting prior to using the

SnakeBite XQ Nozzle and Silencer.

Blasting operations generate noise levels

that can permanently damage hearing:

operators and nearby personnel are to

ensure appropriate personal protective

equipment, including hearing protection is

worn during blasting operations.

Nozzle and Silencer Care: Take care to

place down the SnakeBite XQ nozzle and

silencer rather than dropping from height

and to avoid impact with hard surfaces as

this may damage the nozzle and silencer.

Operators are required to inspect the nozzle

and silencer for damage or excessive wear

before installing onto the blast hose and

before use.

Nozzle control: The Blasting Process

generates thrust through the nozzle in

the opposite direction to the blast stream.

Operators must maintain a secure grip of

the nozzle on start-up and during blasting

to ensure the control of the nozzle is

maintained and the operator hand doesn't

slip off the front of the nozzle.

Remote Shut off: Always use a remote

shut off Deadman system when using the

SnakeBite XQ Nozzle and Silencer.

WARNING

12

OPERATION

The SnakeBite XQ Nozzle and Silencer are

designed to operate effectively across a

wide range of operating pressures, typically

between 80-110psi, with the optimal and

recommended operating pressure being

100psi. Operating the nozzle and silencer

at pressures other than the recommended

pressure will reduce cleaning efciency and

silencing effect.

It is recommended the blast system used is a

BlastOne Schmidt Pressure hold system tted

with a 2” bull hose coupled to an adequately

sized compressor for the nozzle size used – see

BlastOne catalogue for compressor sizing.

The SnakeBite XQ has been designed to optimise

abrasive blasting using GMA Australian Garnet.

Use with alternative abrasive types may result

in reduced performance outcomes compared to

using GMA Australian Garnet.

Preparing to use the nozzle and silencer

1. Setup Blast system in accordance with

manufacturers instructions and connect

nozzle and silencer as per instruction

above.

2. Clear the work area of any debris and

trip hazards and observe all safety

requirements.

3. Pressurise the system and set the nozzle

outlet pressure to 100psi.

Operator standoff

1. The improved blast stream stability

generated by the SnakeBite XQ Nozzle will

allow an increased standoff distance and

faster cleaning rates - around 500-600mm

(20-24 in) for typical situations.

13

OPERATION

Maintenance: Any maintenance on the

Nozzle and Silencer must only be conducted

by trained and qualied personnel.

Ensure the system pressure is isolated

before undertaking maintenance on the

nozzle or silencer.

WARNING

ABRASIVE FLOW RATE AT 100 PSI

Abrasive Type: GMA Garnet Premium Blast

Nozzle Throat Size Kgs/Hr (Lbs/Hr) Abrasive valve turns

6 (3/8”) 180-250 (400-550) 4-5

7 (7/16”) 250-320 (550-700) 4

8 (1/2”) 300-380 (660-840) 3.5-4

2. The optimum nozzle standoff distance

will depend on the type of coating to be

removed and is inuenced by factors such

as coating type and thickness, abrasive

type being used, worksite access and

required surface prole.

3. When safe to do so, start blasting at a

stand-off distance of 500-600mm (20-24 in).

Adjust the standoff distance to nd the

optimum stand off for the job at hand.

Abrasive Flow Rate

Optimum abrasive ow rate varies depending

on nozzle size, air ow and abrasive type. The

table below sets out the recommended typical

abrasive ow rate range when using Australian

GMA Garnet.

14

SERVICE

Use only manufacturer replacement parts.

Substitute parts may not meet the required

standards.

Other than cleaning, there are no operator

maintainable components on the SnakeBite XQ

Nozzle and Silencer.

Regularly measure the wear at the nozzle

throat by using a nozzle wear gauge.

If the Nozzle or Silencer are damaged or

excessively worn do not continue to use the

product.

The Nozzle and Silencer should be cleaned

regularly ensuring there is no build-up of dust

or grit on the threads or around the machined

ns on the silencer.

The SnakeBite XQ Nozzle and Silencer are

available in industry standard nozzle sizes:

SNAKEBITE XQ PART NO.

Throat

Size Nozzle Silencer Bump

Guard

Nozzle &

Silencer

Assembly

6 (3/8”) BNSB6C BNSBXQ6S BNSBBG BNSBXQ6

7 (7/16”) BNSB7C BNSBXQ7S BNSBBG BNSBXQ7

8 (1/2”) BNSB8C BNSBXQ8S BNSBBG BNSBXQ8

15

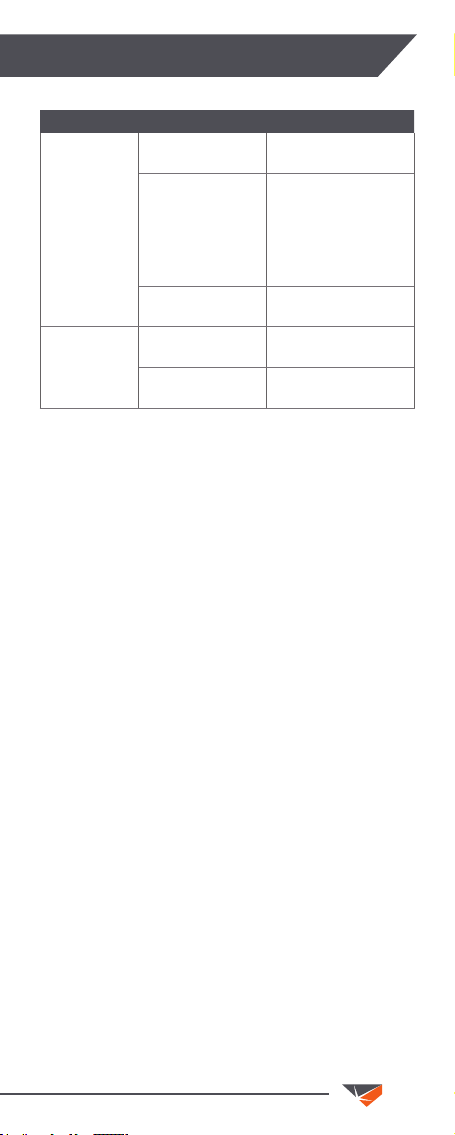

TROUBLESHOOTING

POSSIBLE CAUSE POSSIBLE SOLUTION

Low cleaning

rate.

Low operating

pressure

Adjust nozzle outlet

pressure to 100psi.

In appropriate

abrasive ow rate

Adjust abrasive

ow rate to the

recommended ow

rate for the nozzle

size and abrasive type

combination.

Damaged or worn

nozzle liner

Replace the damaged

or worn component.

Ineffective

silencing

Low operating

pressure

Adjust nozzle outlet

pressure to 100psi.

Worn or damaged

silencer liner.

Replace the damaged

or worn silencer.

AUSTRALIA

57 Alexandra Place Murarrie,

Queensland 4172 Australia

Toll Free 1800 190 190

Email [email protected]om

www.BlastOne.com.au

AUSTRALIAN OFFICES

Brisbane |Mackay |Sydney |Newcastle |Melbourne |

Adelaide |Darwin |Perth |Port Hedland

NORTH AMERICA

4510 Bridgeway Avenue,

Columbus Ohio 43219 USA

Toll Free 800 999 1881

Email [email protected]om

www.BlastOne.com

NORTH AMERICAN OFFICES

Chicago |Columbus |Minneapolis |Los Angeles

MALAYSIA

B-05-07 Neo Damansara, Jalan PJU 8/1,

Bandar Damansara Perdana, 47820 Petaling

Jaya, Selangor, Malaysia

Tel 03 7725 0371

Email [email protected]om

www.BlastOne.my

NEW ZEALAND

15 Fremlin Place, Avondale,

Auckland 1026 New Zealand

Toll Free 0800 190 190

Email [email protected]om

www.BlastOne.co.nz

NEW ZEALAND OFFICES

Christchurch | Auckland

© BlastOne 2021 B3962

Table of contents

Other BLASTONE Shot Blasting Machine manuals